Distributed dust removal device based on workshop for flour processing

A dust removal device and decentralized technology, which is applied in the direction of dust removal, cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of flour factory explosion, no dehumidification function, dust dissipation and dispersion, etc., to improve the dispersion and absorption performance, Excellent dispersing and absorbing performance, and the effect of improving the regulating function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

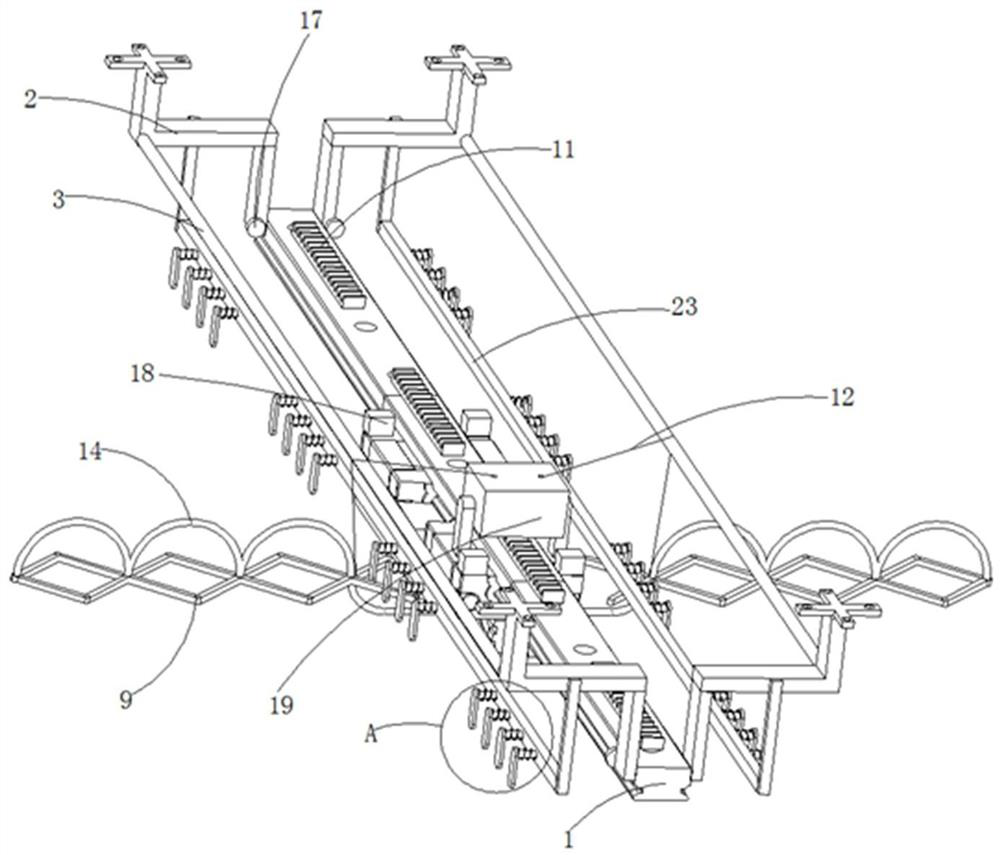

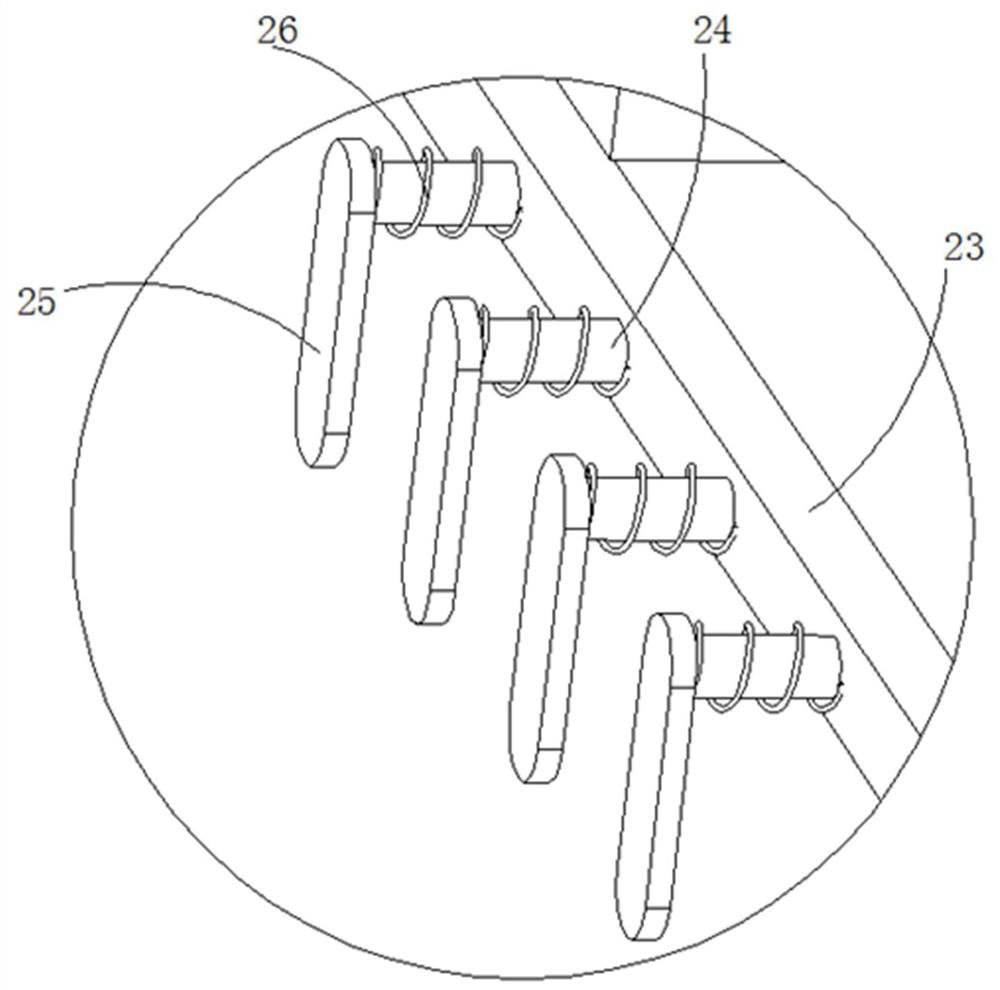

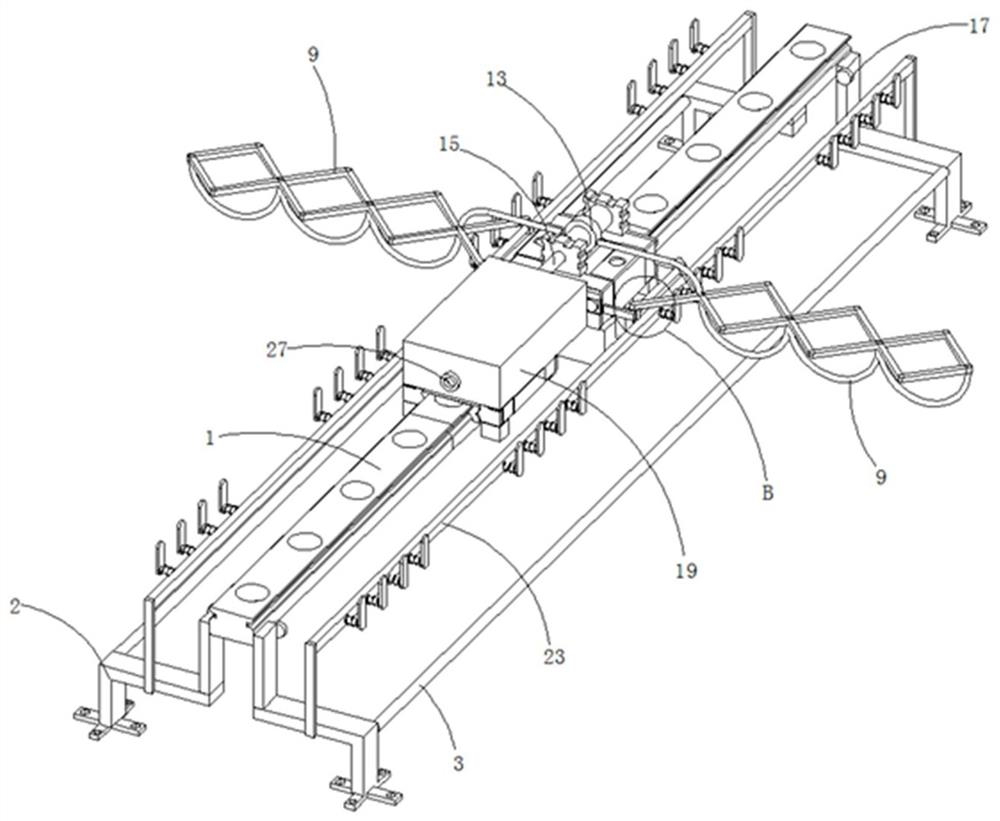

[0036] refer to Figure 1-6, a decentralized dust removal device based on a factory building for flour processing, including a hoisting guide rail 1, the two ends of the hoisting guide rail 1 are connected with a mounting frame 2, a limit rod 3 is fixed between the mounting frames 2, and the bottom of the hoisting rail 1 is sequentially connected There is a driving rail seat 4 and a driven connection 5, a connecting rod 6 is connected between the driving rail seat 4 and the driven connecting seat 5, the bottom of the driving rail seat 4 is fixedly connected with an air extraction assembly, and the side wall of the driving rail seat 4 is fixed. A U-shaped frame 7 is connected, and the horizontal section of the U-shaped frame 7 is slidably connected with a symmetrically distributed sliding seat 8. The bottom of the sliding seat 8 is connected with a scissor-type connecting rod group 9. At the hinge point of the rod group 9, the mounting frame 2, the driving rail seat 4 and the d...

Embodiment 2

[0045] refer to Figure 1-6 , a decentralized dust removal device based on a factory building for flour processing, including a hoisting guide rail 1, the two ends of the hoisting guide rail 1 are connected with a mounting frame 2, a limit rod 3 is fixed between the mounting frames 2, and the bottom of the hoisting rail 1 is sequentially connected There is a driving rail seat 4 and a driven connection 5, a connecting rod 6 is connected between the driving rail seat 4 and the driven connecting seat 5, the bottom of the driving rail seat 4 is fixedly connected with an air extraction assembly, and the side wall of the driving rail seat 4 is fixed. A U-shaped frame 7 is connected, and the horizontal section of the U-shaped frame 7 is slidably connected with a symmetrically distributed sliding seat 8. The bottom of the sliding seat 8 is connected with a scissor-type connecting rod group 9. At the hinge point of the rod group 9, the mounting frame 2, the driving rail seat 4 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com