Method for preparing double-layer wave-permeable heat proofing and insulating composite structural part

A composite material and double-layer structure technology, which is applied in the field of preparation of double-layer anti-heat-insulation and wave-transmitting composite material structural parts to achieve the effects of excellent wave-transmitting performance, saving space and reducing wave-transmitting loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

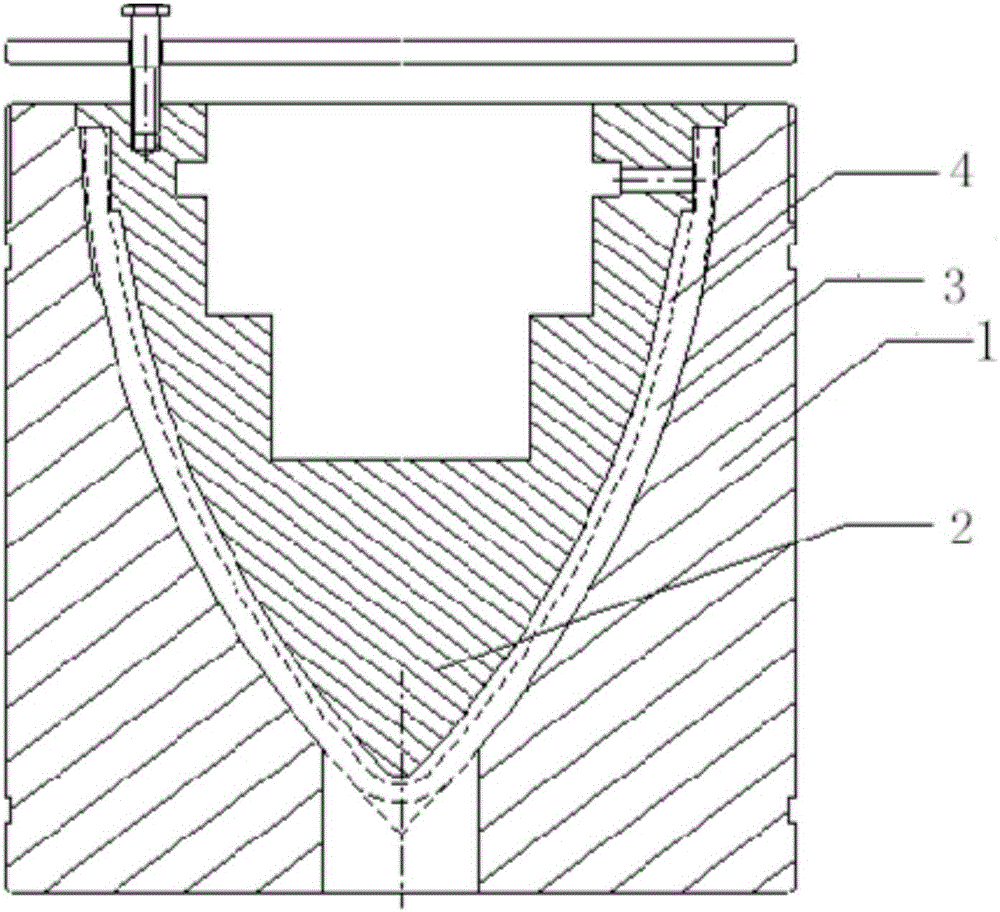

[0028] Such as figure 1 Shown: The preparation of a double-layer anti-heat insulation wave-transparent radome for a short-range missile:

[0029] (1) Make quartz fiber profiling fabric according to the size requirements, then impregnate silica sol for multiple rounds, and obtain a density of 1.75g / cm after high temperature sintering and mechanical processing 3 The outer layer of quartz composite ceramic heat-proof material 4, that is, the outer layer of quartz composite ceramic cover body 4;

[0030] (2) Mix ethyl orthosilicate and n-octylamine at a molar ratio of 1:1.4, then stir electromagnetically at room temperature at 600rpm for 5 minutes, and then deionized water and ethyl orthosilicate at a molar ratio of 1:110. Ionized water was added to the above mixture, and the stirring was continued for 5 minutes, and a white precipitate would appear. The precipitate was then filtered off and dried at room temperature. Then place the dried solid precipitate in a muffle furnace w...

Embodiment 2

[0036] Preparation of double-layer anti-heat-insulation wave-transparent radome for a medium-range missile:

[0037] (1) Make hollow quartz fiber profiling fabric according to the size requirements, then impregnate silica sol for several rounds, and obtain a density of 1.70g / cm after high temperature sintering and mechanical processing 3 The outer layer of quartz composite ceramic cover.

[0038] (2) Mix tetraethyl orthosilicate and n-octylamine at a molar ratio of 1:1.2, then electromagnetically stir at room temperature at 500 rpm for 3 minutes, and then deionized water and tetraethyl orthosilicate at a molar ratio of 1:100. Ionized water was added to the above mixture, and the stirring was continued for 5 minutes, and a white precipitate would appear. The precipitate was then filtered off and dried at room temperature. Then place the dried solid precipitate in a muffle furnace with a heating rate of 1°C / min, keep it at 700°C for 4 hours, and cool down with the furnace to o...

Embodiment 3

[0044] Preparation of double-layer anti-heat insulation and wave-transparent antenna window for a medium-range missile:

[0045] (1) Make quartz fiber profiling fabric according to the size requirements, then impregnate silica sol for several rounds, and obtain a density of 1.78g / cm after high-temperature sintering and mechanical processing 3 The outer layer of quartz composite ceramic windows.

[0046] (2) Mix tetraethyl orthosilicate and n-octylamine at a molar ratio of 1:1.3, then electromagnetically stir at room temperature at 700 rpm for 3 minutes, and then deionized water and tetraethyl orthosilicate at a molar ratio of 1:120 Ionized water was added to the above mixture, and the stirring was continued for 5 minutes, and a white precipitate would appear. The precipitate was then filtered off and dried at room temperature. Then place the dried solid precipitate in a muffle furnace with a heating rate of 1°C / min, keep it at 600°C for 5 hours, and cool down with the furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com