Patents

Literature

88results about How to "Achieve high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A kind of metal surface modification method

InactiveCN102268626AWide range of applicationsSave resourcesMolten spray coatingCoated surfaceState of art

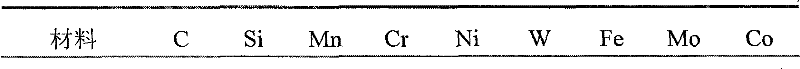

The invention relates to a metal surface modification method. The invention first obtains a textured surface with a certain surface roughness value on the surface of a material by an electron beam texturing method, forms uniform tiny pits, and increases the bonding strength of the interface; then uses plasma The spraying process uses Co-based alloy or Ni-based alloy powder as the material to form a coating; finally, laser remelting technology is used to remelt the coating surface to improve the surface structure of the coating and improve the surface performance. Compared with the existing technology, this process can realize high temperature resistance, corrosion resistance, oxidation resistance, and fatigue resistance, and has high bonding strength, and the coating structure is uniform and compact, thereby greatly broadening the application range.

Owner:SHANGHAI UNIV OF ENG SCI

Irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and preparation method of irradiation crosslinking halogen-free flame retardant polyolefin material

InactiveCN105315541AAchieve oil resistanceAchieve high temperature resistancePlastic/resin/waxes insulatorsElastomerPolymer science

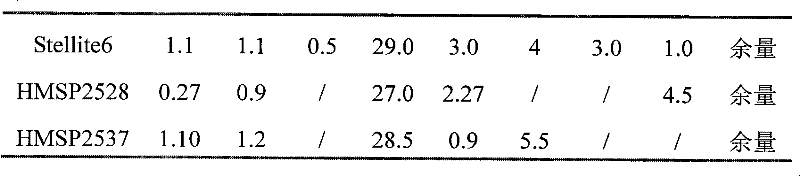

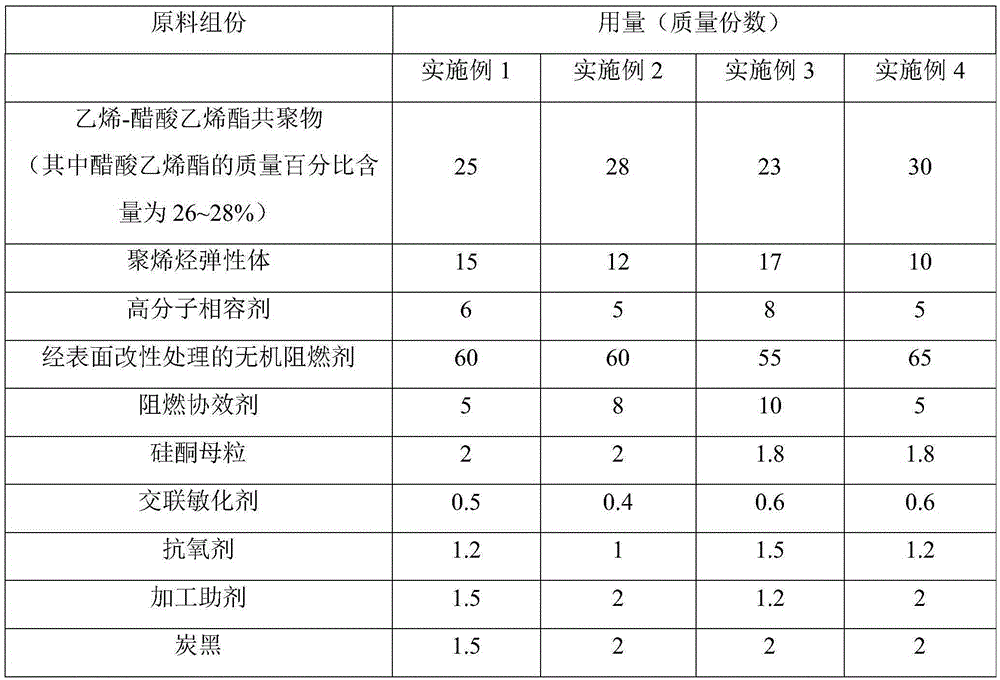

The invention belongs to the field of low-smoke halogen-free flame retardant materials, and particularly relates to an irradiation crosslinking halogen-free flame retardant polyolefin material for locomotive wires and a preparation method of the irradiation crosslinking halogen-free flame retardant polyolefin material. The polyolefin material comprises the following components in parts by mass: 20-30 parts of ethylene-vinyl acetate copolymer, 10-20 parts of polyolefin elastomer, 5-10 parts of a macromolecular compatilizer, 45-65 parts of an inorganic flame retardant subjected to surface modification treatment, 5-10 parts of a flame retardant synergist, 0.8-1.5 parts of an antioxidant, 1.5-2.5 parts of silicone masterbatches, 0.3-0.6 part of a crosslinking sensitizer, 1.5-2 parts of carbon black and 1-2 parts of a processing aid. The preparation method comprises the technological steps of surface treatment of the inorganic flame retardant, proportioning, mixing, melting, extrusion for pelletization, and the like. Compared with the prior art, the polyolefin material has the characteristics of excellent flame retardation (capable of passing the D type group burning test), oil resistance (mineral oil and fuel oil resistant), high temperature resistance (the grade is 150 DEG C), ultraviolet resistance, scratch resistance, low corrosion, low toxicity, environment friendliness, excellent processing performance, extrusion speed capable of reaching 100-150 m / min, and bright surface.

Owner:SHANDONG UNIV OF TECH +1

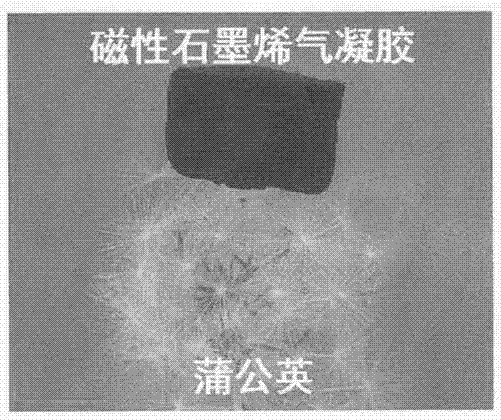

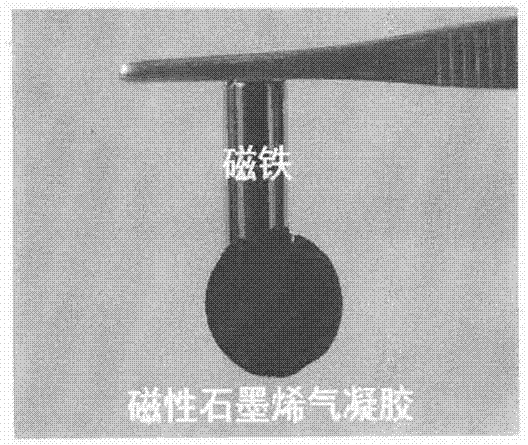

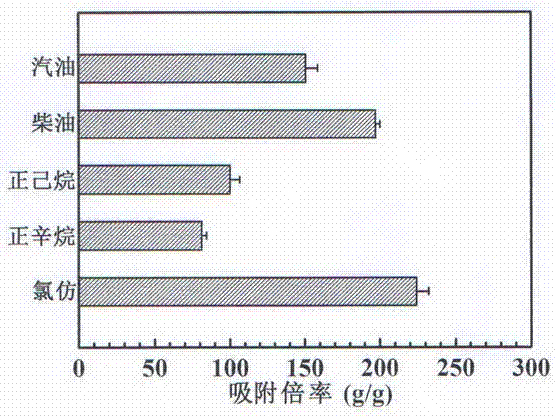

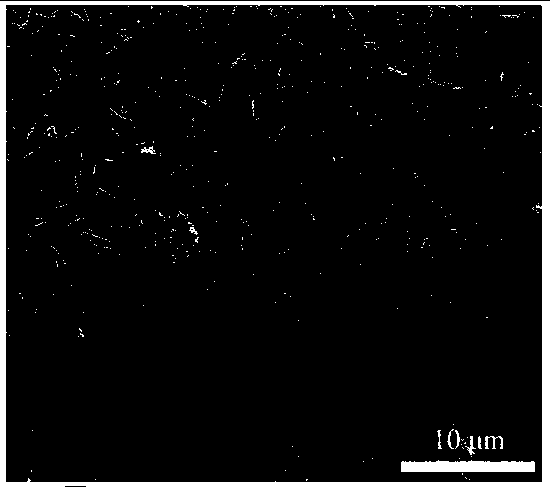

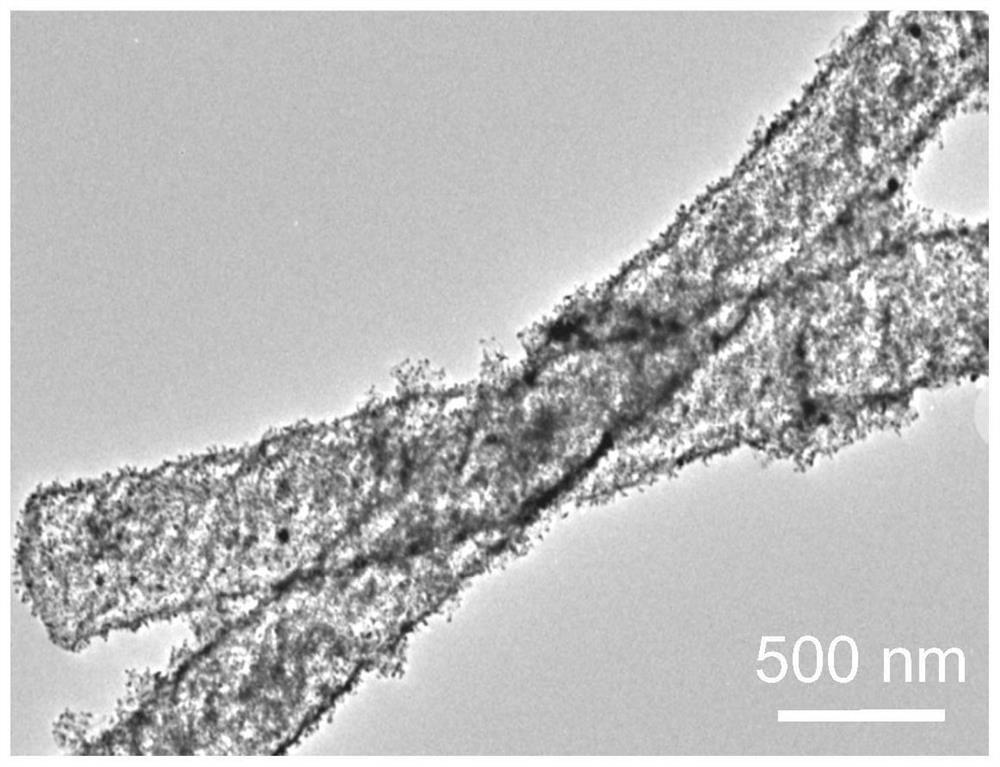

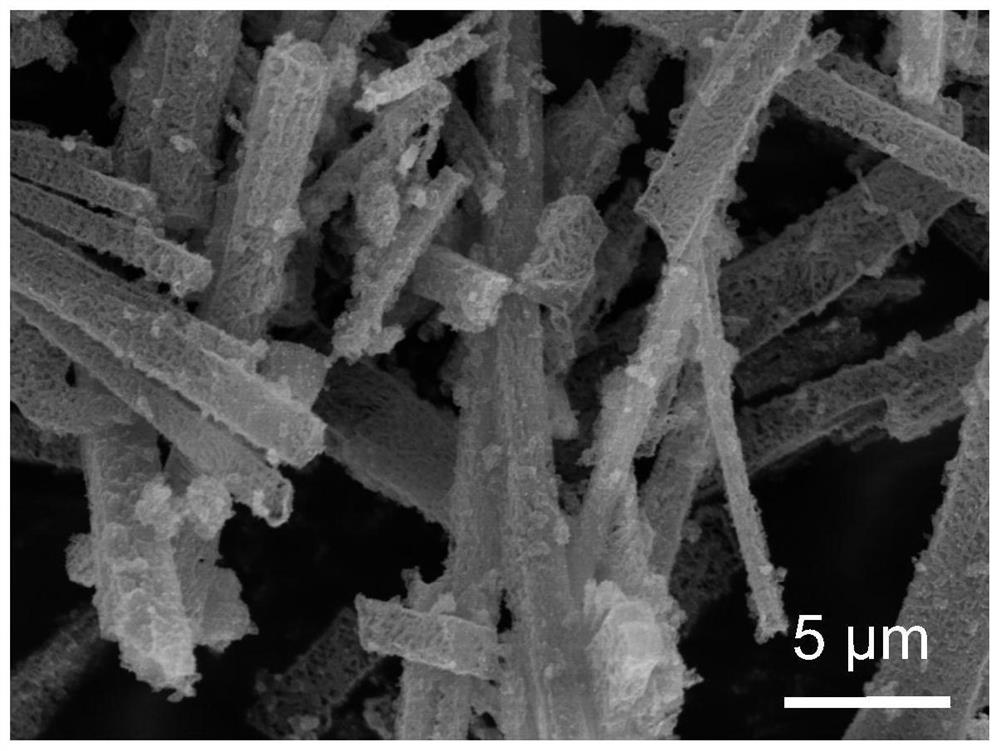

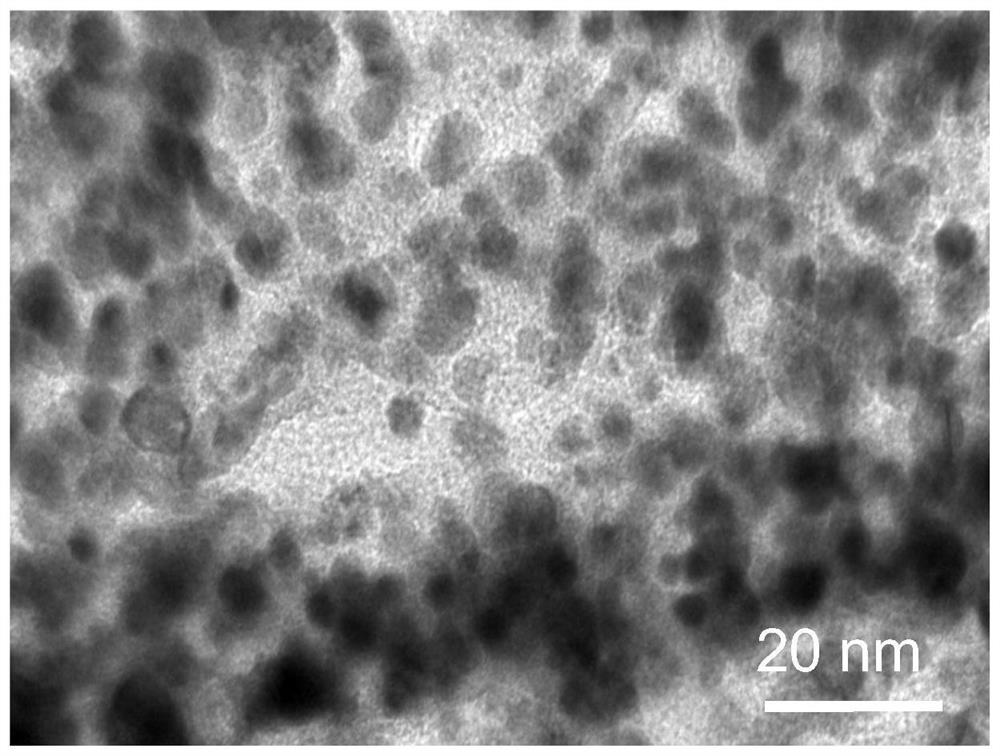

Preparation method of magnetic graphene aerogel

ActiveCN107140620ASimple and efficient operationLow costOther chemical processesGrapheneIonTemperature resistance

The invention relates to a preparation method of magnetic graphene aerogel. The preparation method comprises the steps of crosslinking dopamine modified graphene oxide with iron ions, carrying out heating reduction and self-assembling to form a three-dimensional graphene aerogel structure, and carrying out freeze drying and thermal treatment, so as to obtain a magnetic graphene aerogel material in situ. The preparation method which is simple in operation and preparation process and low in cost is utilized for preparing the magnetic graphene aerogel material with stable structure and good uniformity in situ and is a new technique for massively preparing the magnetic graphene aerogel material. The prepared material has good magnetic property, low density, good mechanical property, high temperature resistance, large specific surface area, super-strong adsorptive property, conductive property and wave absorbing property, is hopeful to be used as a novel functional magnetic material in the fields of water treatment, photoelectric materials, wave absorbing materials and the like and further has certain application values and market prospects.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI +2

Method for preparing double-layer wave-permeable heat proofing and insulating composite structural part

The invention discloses a method for preparing a double-layer wave-permeable heat proofing and insulating composite structural part. The structural part comprises an inner heat insulation material and an outer heat-proof +material. The method includes steps of preparation of the outer heat-proof material, preparation of silicon oxide hollow microspheres, preparation of chopped fiber reinforced silicon oxide hollow microsphere slurry, casting of the chopped fiber reinforced silicon oxide hollow microsphere slurry and thermal treatment of a structural part blank material. Quartz fiber reinforced quartz composite ceramic serves as the outer heat-proof material, chopped fiber reinforced silicon oxide hollow microsphere ceramic serves as the inner heat insulation material, compact combination of the inner and outer materials is realized by means of slurry casting and high-temperature sintering moulding, and integration of advantageous performances of high temperature resistance, heat proofing, heat insulation, wave permeability and the like is realized.

Owner:湖北三江航天江北机械工程有限公司

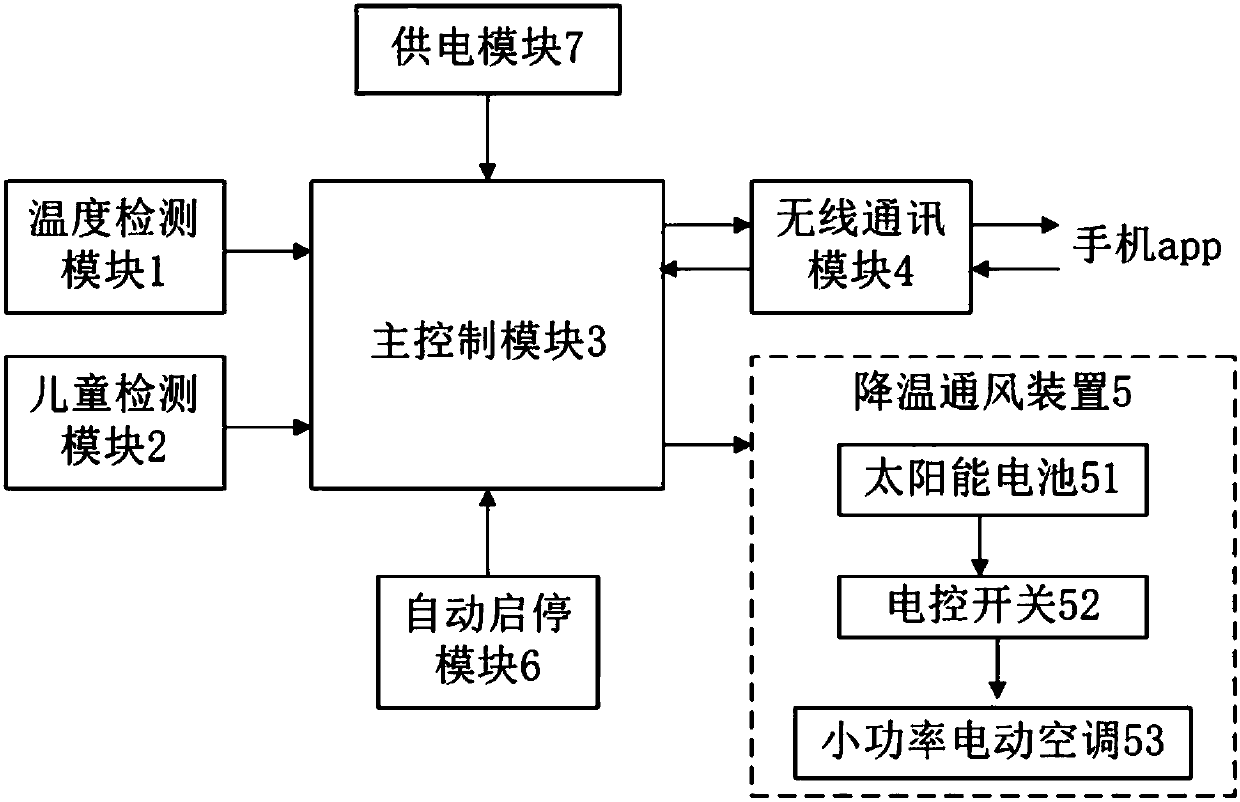

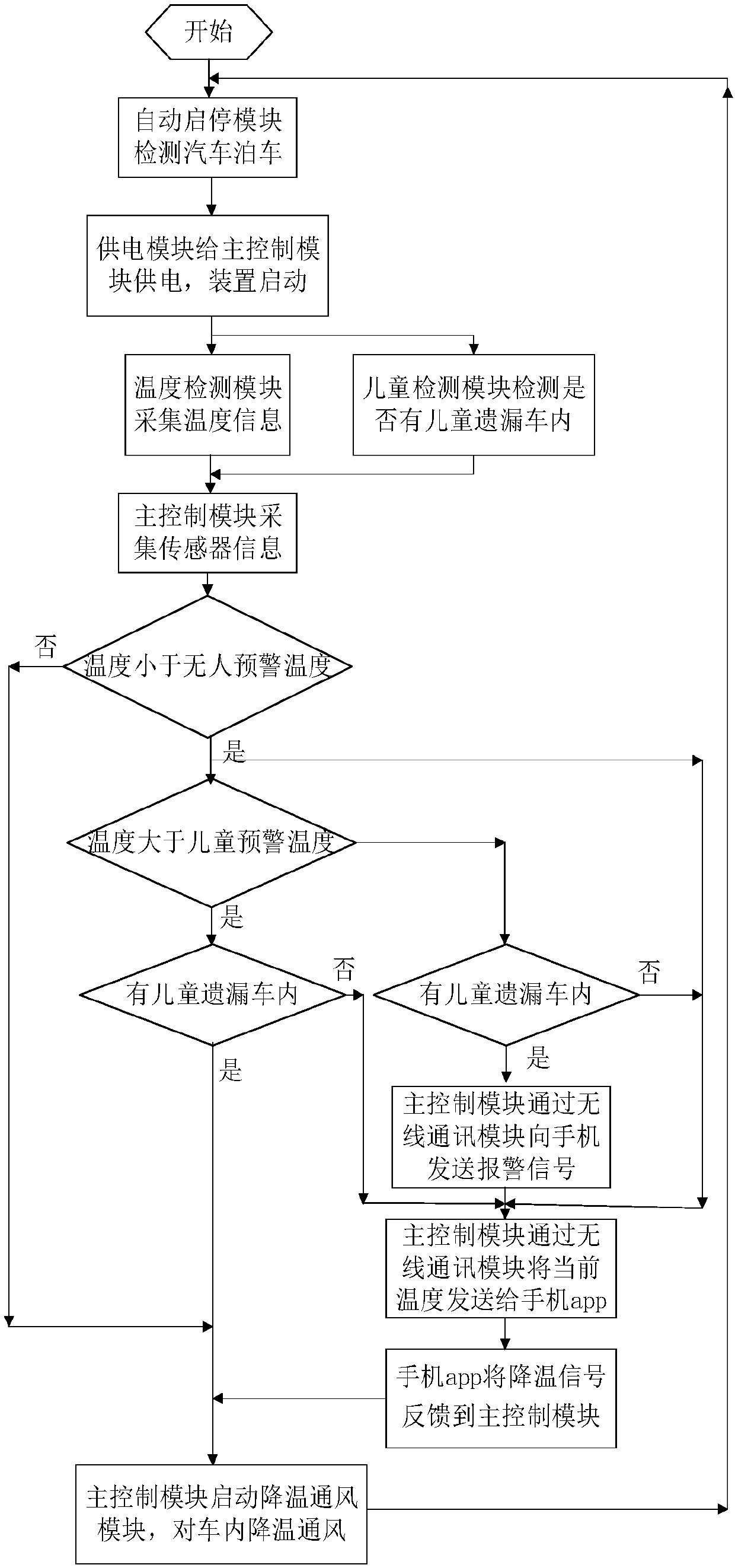

Parked state in-car high-temperature preventing device and control method thereof

PendingCN107933245AEnsure safetyVersatileAir-treating devicesPedestrian/occupant safety arrangementSpontaneous combustionStart stop

The invention discloses a parked state in-car high-temperature preventing device and a control method thereof. The parked state in-car high-temperature preventing device comprises a temperature detecting module, a children detecting module, a master control module, a wireless communication module, a power supply module, a cooling and ventilating device and an automatic start-stop module, wherein the master control module comprises temperature identification, children omission identification and early warning, and cooling control; the children detecting module comprises pressure sensors distributed on non-driver seats and a camera arranged inside a car; the automatic start-stop module comprises pressure sensors distributed on a driver seat and a rotating speed sensor on an engine; the cooling and ventilating device comprises a solar battery, an electric control switch and a low-power electric air conditioner to achieve parked state cooling and ventilation. The parked state in-car high-temperature preventing device can prompt a car owner with parked state in-car real-time temperature for implementing remote control, and meanwhile can high-temperature spontaneous combustion as well assuffocation of omitted children in car during a parked state, thereby ensuring safety and the car and in-car personnel.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Multifunctional phosphating solution, and preparation method and application thereof

InactiveCN103397324AHigh hardnessStrong impact resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention relates to a multifunctional phosphating solution and a preparation method and application thereof. The multifunctional phosphating solution comprises liquid A and liquid B and is characterized in that a ratio of the liquid A to the liquid B in the multifunctional phosphating solution is 1: 0.1-1. The liquid A comprises the following substances, by mass, 26 to 48 parts of diammonium phosphate, 0.9 to 12 parts of phosphoric acid with a concentration of 85%, 0.8 to 1.8 parts of metal powder, 0.6 to 1.4 parts of animal glue, 0.4 to 10 parts of calcined gypsum powder and 0.3 to 0.8 part of alum, with the balance being water. The liquid B comprises the following substances, by mass, 20 to 46 parts of zinc dihydrogen phosphate, 38 to 55 parts of zinc nitrate, 2 to 3.8 parts of sodium fluoride, 2 to 4 parts of zinc oxide and 2 to 6 parts of phosphoric acid with a concentration of 85%, with the balance being water. The multifunctional phosphating solution provided by the invention is composed of the liquid A and the liquid B, can realize removal of oil and rust at the same time and has the efficacy of rust protection, heat insulation, high temperature resistance, heat preservation, flame retardation, noise abatement, shock prevention, isolation, pollution cleaning and resistance to fire. The multifunctional phosphating solution has the following beneficial effects: a fast rust removal speed, great thickness of a formed film, long antirust time, etc.

Owner:李春清

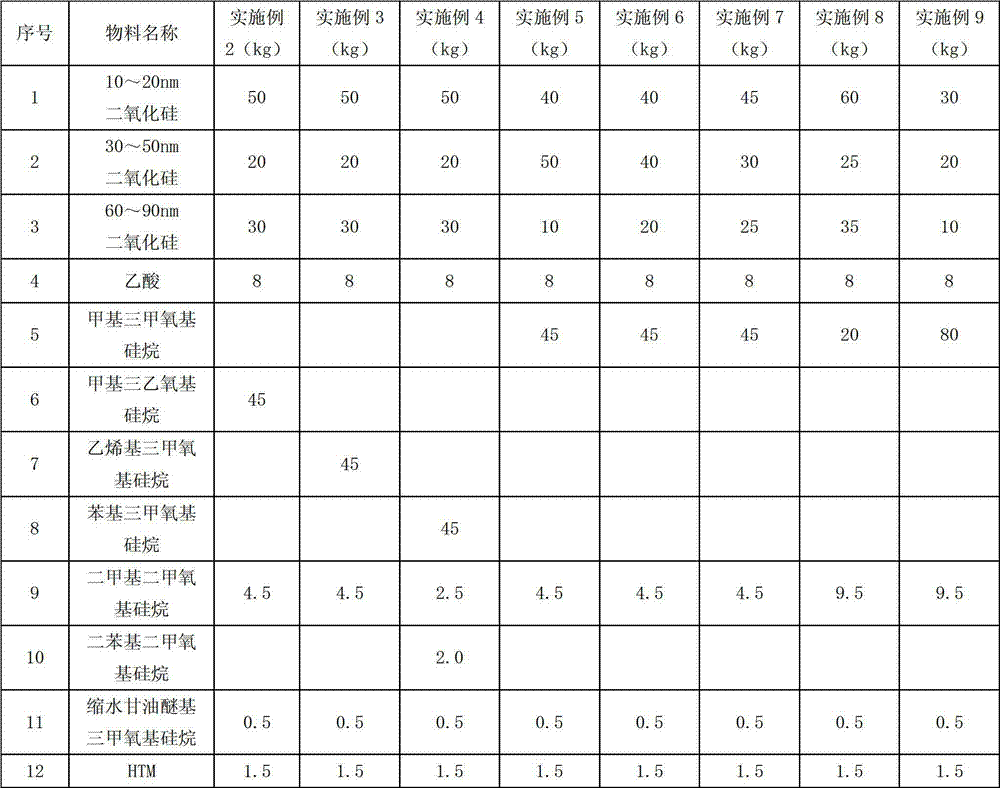

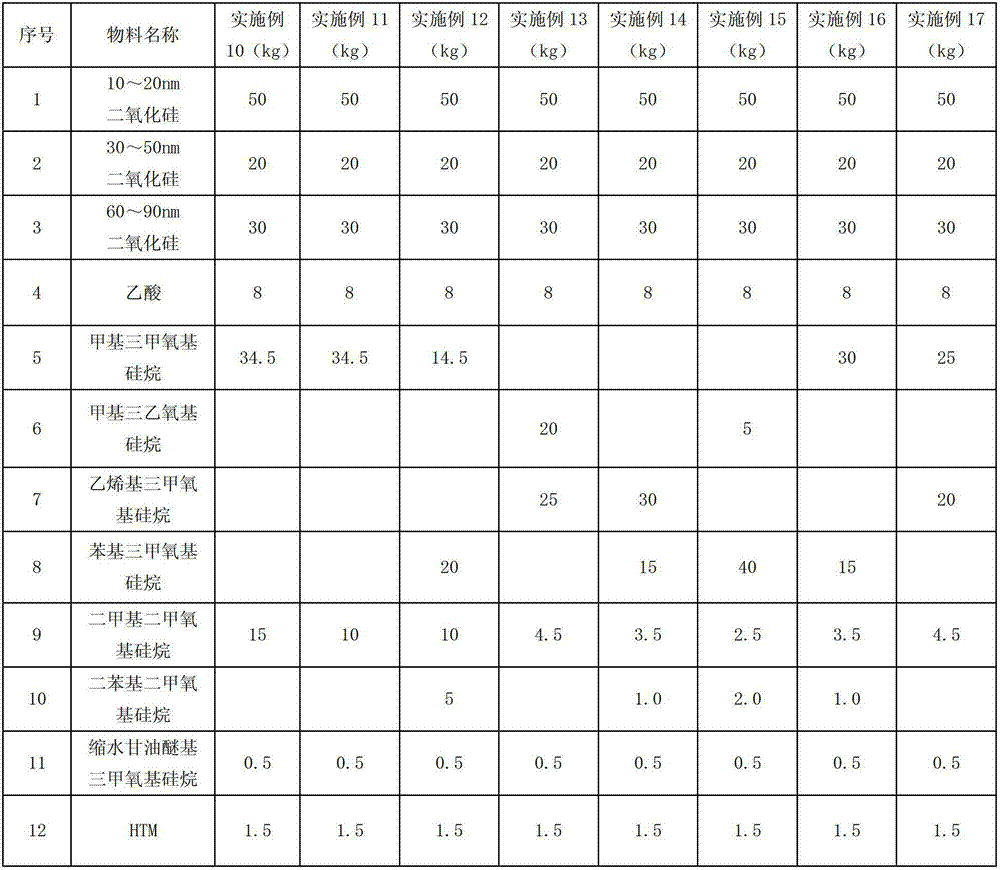

Smokeless smellless inorganic nano high-temperature-resistant corrosion-resistant wear-resistant paint and preparation method thereof

The invention discloses a smokeless smellless inorganic nano high-temperature-resistant corrosion-resistant wear-resistant paint and a preparation method thereof. The wear-resistant paint comprises an inorganic nano resin and a mixed solvent, wherein the inorganic nano resin is prepared from the following components in percentage by weight: 30-90% of silicon dioxide, 10-70% of silane, 0.1-10% of pH value regulator and 0.01-1% of accelerator HMT (hexamethylenetetramine); and the mixed solvent is prepared from high-temperature-resistant environment-friendly pigment, filler, ethanol and water. The preparation method comprises the following steps: mixing the nano silicon dioxide dispersion with different particle sizes, adding the pH regulator and mixed silanes, carrying out thermostatic reaction, adding the metered accelerator HMT, and keeping the temperature to react, thereby obtaining the inorganic nano resin; and mixing the prepared inorganic nano resin and the mixed solvent, dispersing with a high-speed dispersion machine at high speed, and grinding to obtain the smokeless smellless inorganic nano high-temperature-resistant corrosion-resistant wear-resistant paint. The smokeless smellless inorganic nano high-temperature-resistant corrosion-resistant wear-resistant paint is smokeless, smellless and environment-friendly, does not discolor, has high wear resistance, and has favorable functions of corrosion resistance and rust prevention.

Owner:CHANGSHA HUANGMEI PAINT

Laser cladding repair method for breast roll

InactiveCN109722662AAchieving wear resistanceMeet wear resistanceMetallic material coating processesOptoelectronicsHigh pressure water

The invention discloses a laser cladding repair method for a breast roll. The laser cladding repair method comprises the following steps of removing a fatigue layer, performing overlaying to restore the size, performing annealing, performing outer diameter turning, performing low carbon overlaying, performing preheating, performing laser cladding, performing slow cooling and performing argon arc welding repair. For re-repairing, it is presented that re-repairing is performed when a laser cladding layer is worn away by 0.8-1.2 mm; and according to the laser cladding repair method, the repair ofthe breast roll is realized, meanwhile, the requirements for impact resistance, wear resistance, oxidation corrosion resistance, high temperature resistance and high-pressure water erosion resistanceof the breast roll are met, and the service life reaches 2 years or more.

Owner:鞍山大陆激光技术有限公司

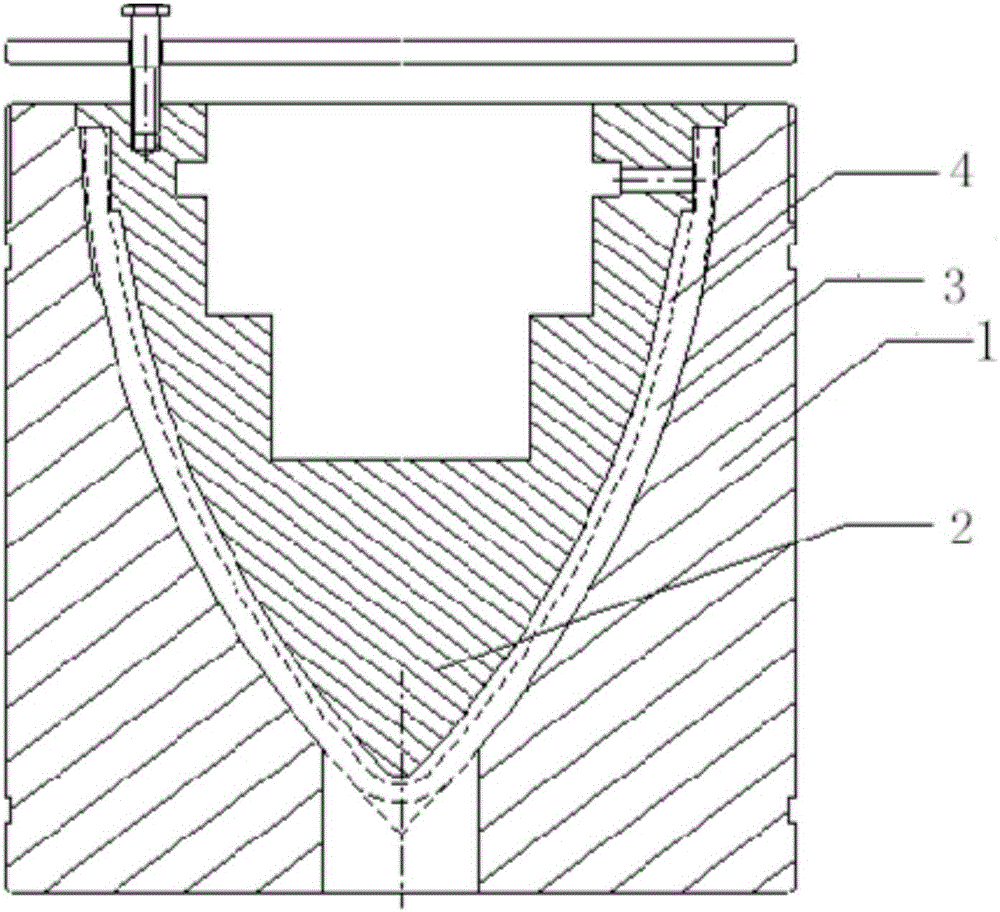

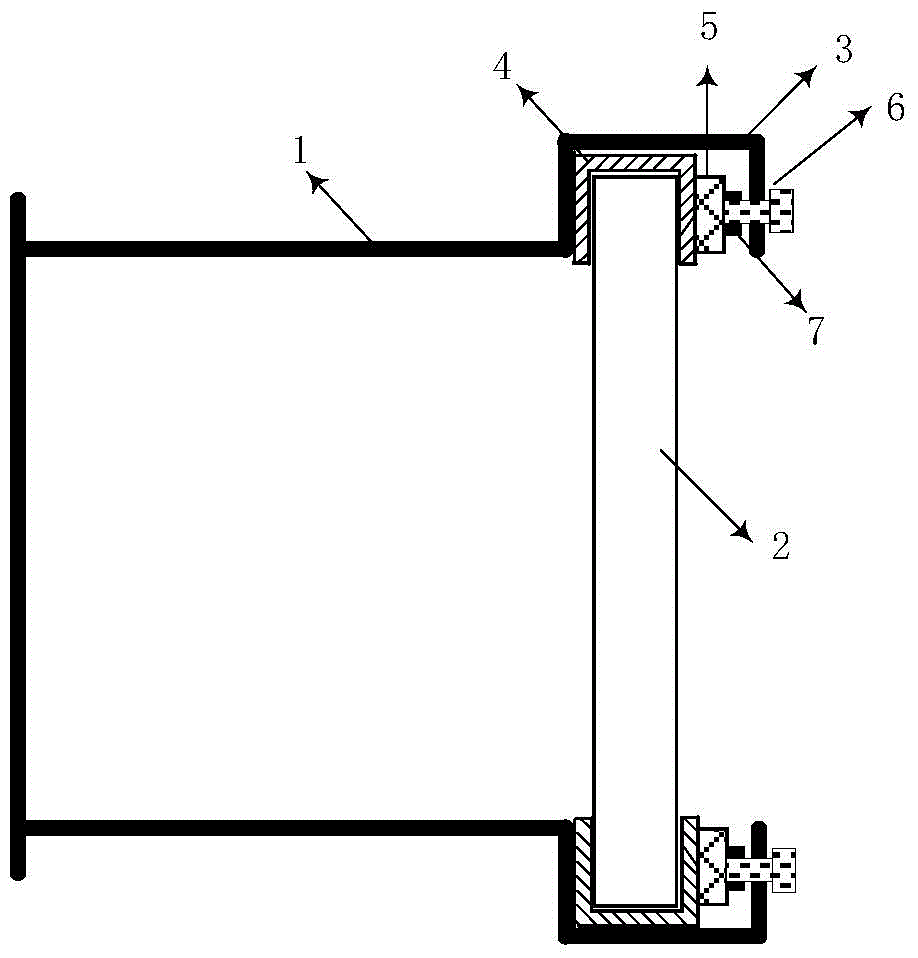

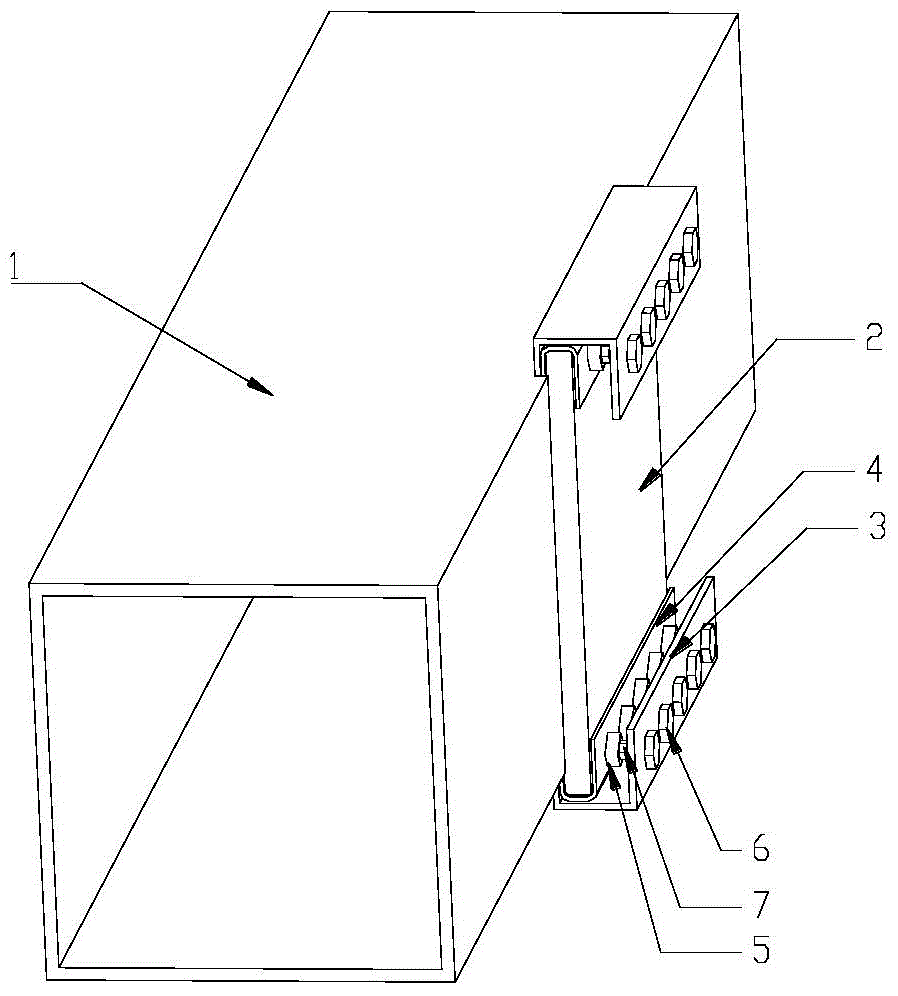

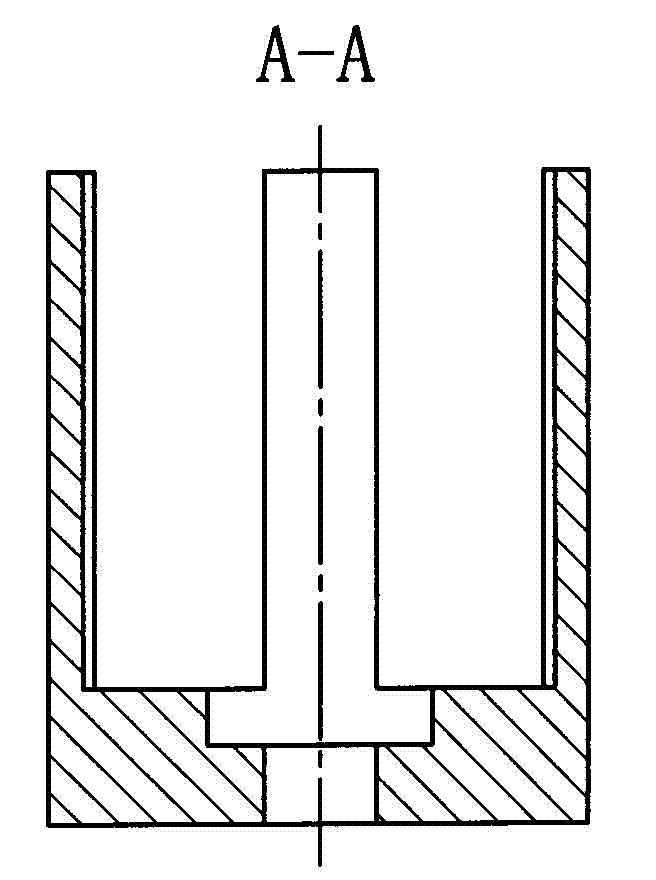

Device and method for mounting high noise resistance quartz window under high temperature environment

ActiveCN104594769AIntegrity guaranteedRelieve installation stressMaterial thermal analysisGlass pane fixingThermal insulationThermal deformation

The invention relates to the technical field of structural thermal noise composite environment tests, in particular to a device and method for mounting a high noise resistance quartz window under a high temperature environment. The mounting device comprises brackets (3), thermal insulation felt (4), metal shock pads (5), fastening bolts (6) and gland nuts (7). The brackets (3) are U-shaped groove components and are arranged on the upper side and the lower side of the window of a mounted object (1), and the two brackets (3) with opposite openings are mounted to be used for constraining the quartz window (2). The thermal insulation felt (4) is arranged between the quartz window (2) and the brackets (3) in a cushioned mode. In the horizontal direction, the metal shock pads (5), the fastening bolts (6) and the gland nuts (7) are used for fixing the quartz window (2). By the adoption of the device and method, the mounting stress caused by thermal deformation of a traveling-wave tube can be relieved, meanwhile, stable pretightening force can be provided under the high temperature environment, and the integrity of the thermal noise test system is guaranteed.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

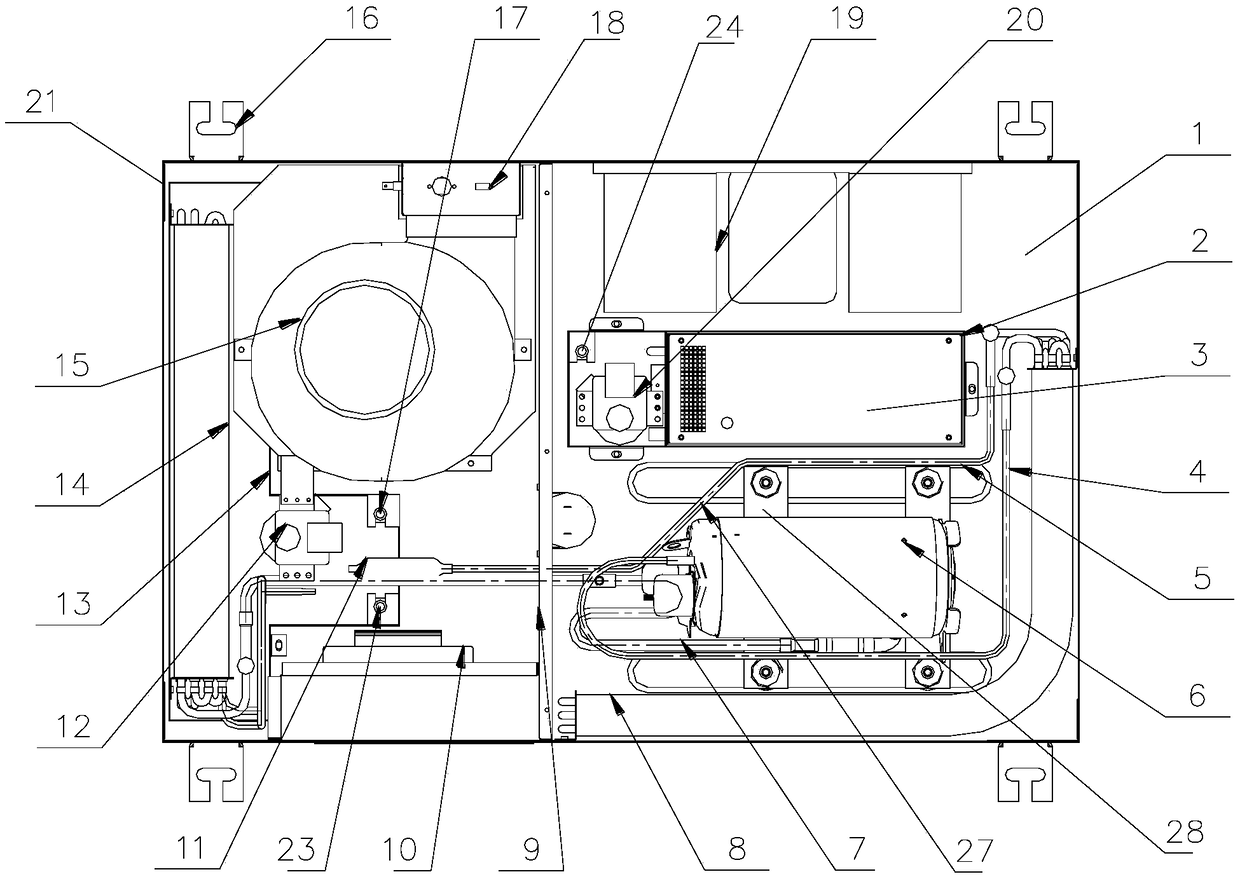

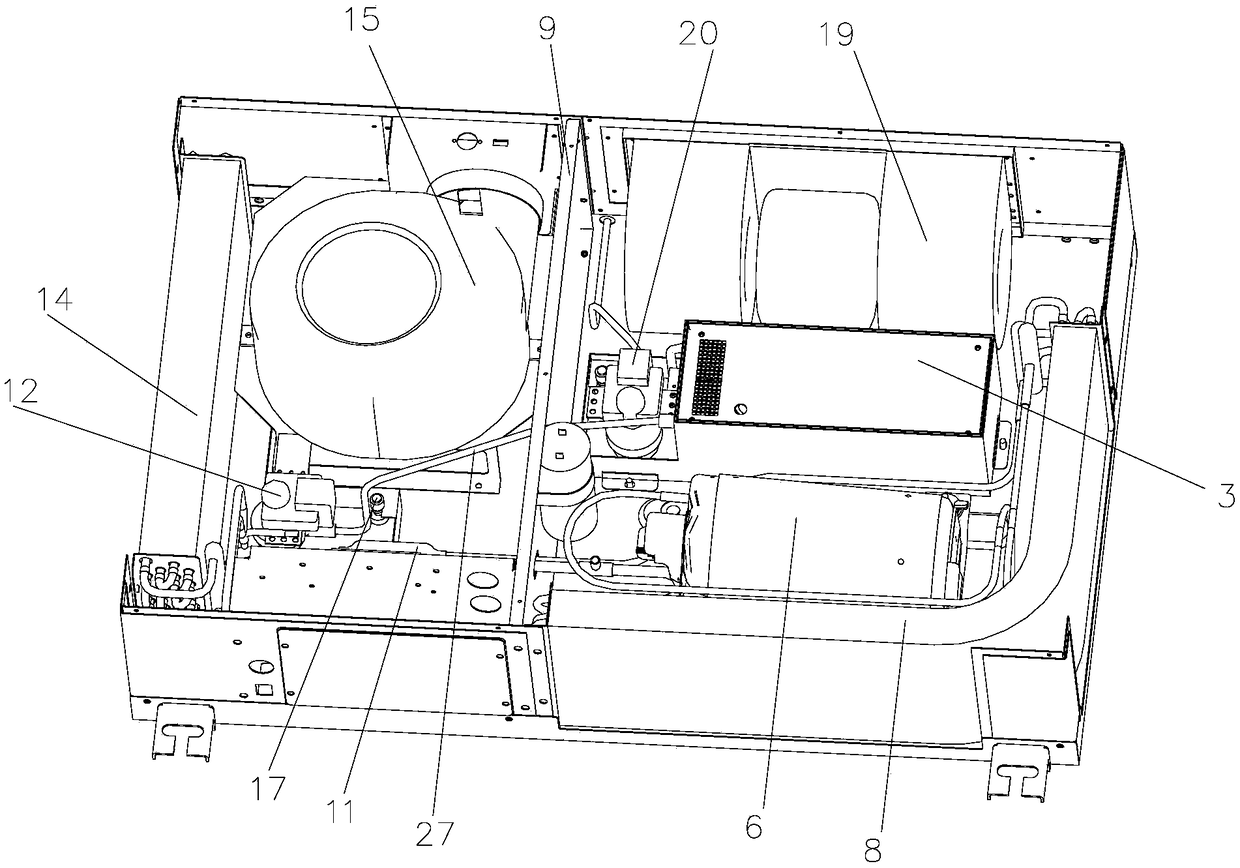

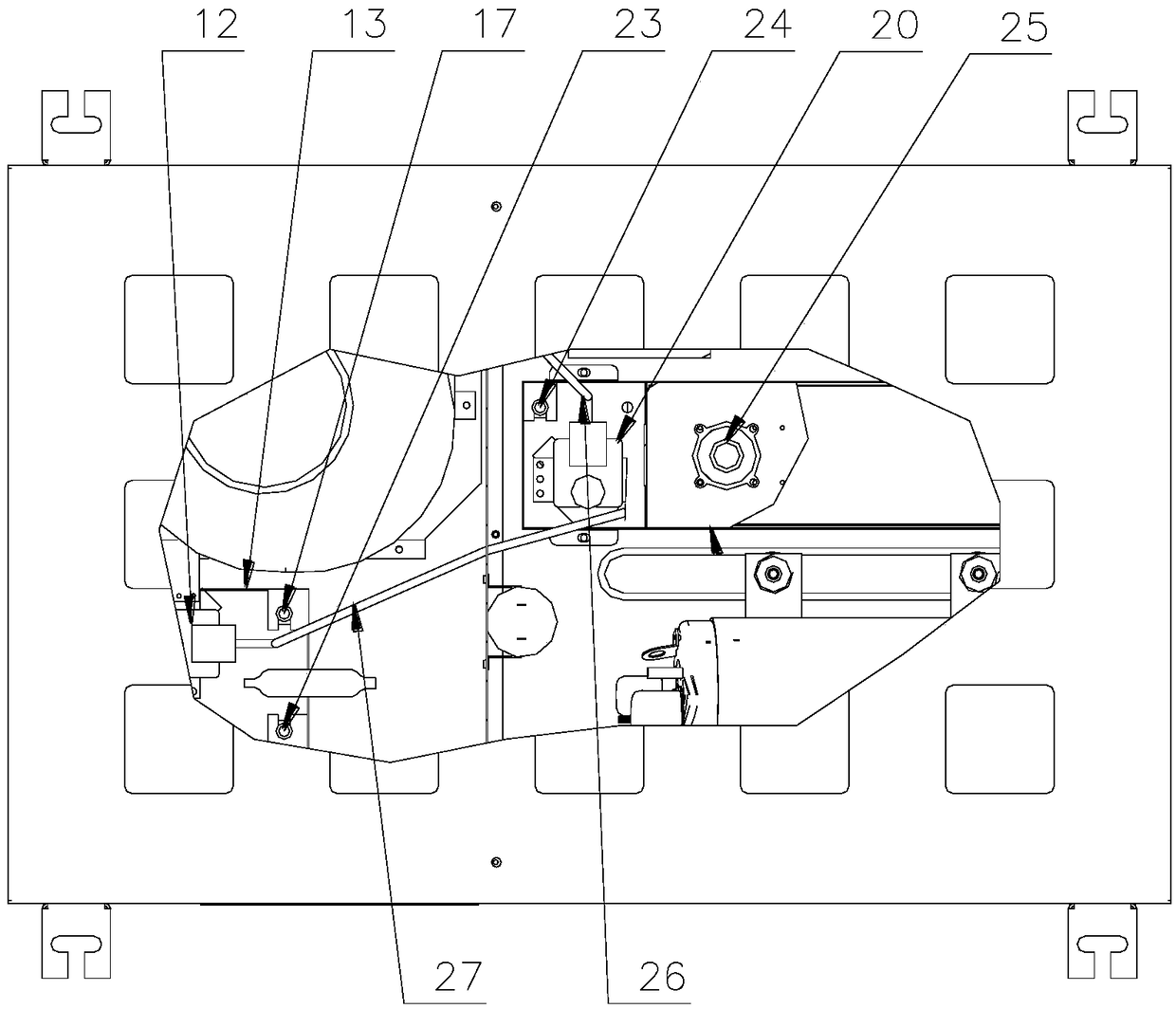

Ultrathin overall kitchen air conditioner

PendingCN108662679AReduce thicknessBeautiful integrationDucting arrangementsCondensate preventionWater storageWater leakage

The invention provides an ultrathin overall kitchen air conditioner. The ultrathin overall kitchen air conditioner comprises a shell; the internal of the shell is divided into an evaporation side anda condensation side; a horizontal compressor, a condenser and a direct-current condensation centrifugal fan are mounted on the condensation side; an evaporator, an alternating-current evaporation centrifugal fan and a direct-current power supply are mounted on the evaporation side; the evaporator is connected with the horizontal compressor through an air return pipe; the alternating-current evaporation centrifugal fan is connected with the evaporator; the direct-current power supply is connected with a direct-current condensation centrifugal fan; a water storage box is mounted at the lower part of the evaporator; a drainage pump is arranged in the water storage box; first and second triggers are arranged in the water storage box; the first trigger is lower than a liquid level of the secondtrigger; when a water level of the water storage box exceeds the first trigger, the drainage pump is started for drainage; and when the water level exceeds the second trigger, the compressor is stopped operating, and an alarm prompt is displayed on a controller. The overall kitchen air conditioner is compact in internal structure, can reach the total thickness of below 200 mm, and meanwhile, caneffectively prevent the internal water leakage condition.

Owner:SHANGHAI HIGHLY AUTOMATIC ELECTRIC +1

Silicon carbide coating and preparation method of sagger with silicon carbide coating

InactiveCN110451984AAchieve high temperature resistanceRealized coating with high temperature resistanceCharge supportsTemperature resistanceWear resistance

The invention discloses a silicon carbide coating which comprises 15-30% of silicon carbide, 15-30% of aluminum oxide, 15-30% of zirconium oxide, 20-40% of an organic silicon resin, 10-20% of an organic metal salt, 1-15% of organic silicon flame retardant, 0.1-5% of isopropanol and 1-10% of deionized water. The invention discloses a preparation method of a sagger with the silicon carbide coating.The preparation method comprises the following steps: weighing the raw materials, putting the raw materials into a stirring machine, and performing stirring so as to obtain the silicon carbide coating; smearing the silicon carbide coating to the inner surface of a sagger blank, or uniformly smearing the silicon carbide coating to the inner surface of the sagger blank; naturally drying the sagger blank coated by the silicon carbide coating, and transferring the sagger into a drying chamber for drying; and putting the dried sagger blank coated by the silicon carbide coating into a high-temperature kiln, and performing sintering, so as to obtain the sagger. The silicon carbide coating and the sagger disclosed by the invention are high in stability, low in cost and good in wearing resistance,corrosion resistance, high temperature resistance and flame retardancy effect.

Owner:湖南太子新材料科技有限公司

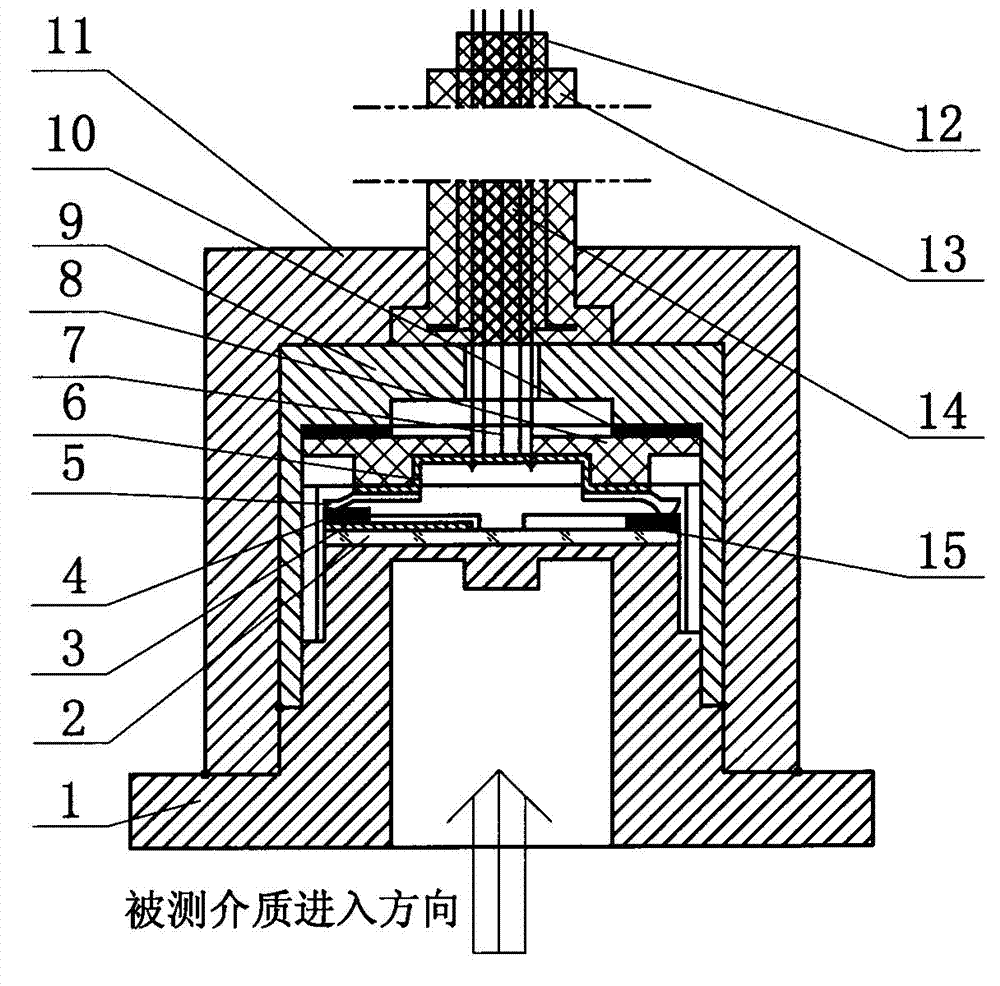

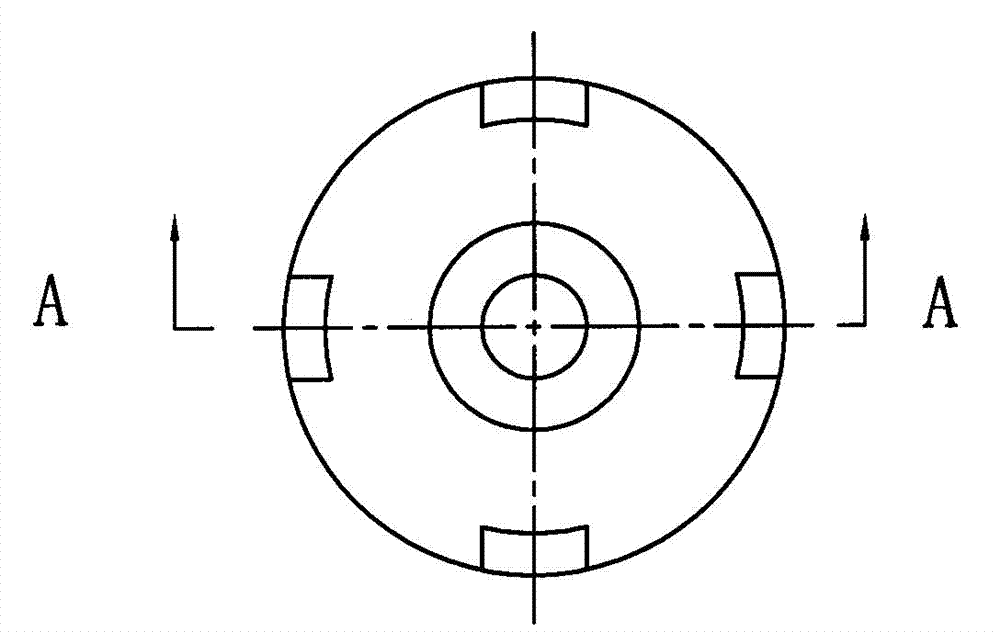

High-temperature pressure and temperature compounded sensor and preparation method thereof

ActiveCN102221429BAdd new featuresImprove reliabilityThermometers using electric/magnetic elementsUsing electrical meansManufacturing technologyMetal foil

The invention provides a high-temperature pressure and temperature compounded sensor and a preparation method thereof. The invention improves the structure of the previous patent of the inventor: silicon sapphire force sensor and the preparation method thereof. The manufacturing method comprises the following steps of manufacturing a platinum thermal resistor having same materials with a strain resistance leading-through platinum welding disc and a platinum welding disc of an internal leading-through at one corner of a non-stress area on a same sapphire wafer with a silicon strain resistor; adopting a welding metal foil strip to replace the original elastic metal contact or the internal leading-through in other forms, thus preparing the high-temperature pressure and temperature compoundedsensor with strong vibration resistance and large acceleration resistance. The method solves the problem that the high reliability can not be met when the pressure and the temperature are measured ata same point in the prior art. The high-temperature pressure and temperature compounded sensor remains the advantages of the existing silicon sapphire force sensor; furthermore, compared with the similar product, the high-temperature pressure and temperature compounded sensor has the advantages of more reasonable manufacturing technology, quick operation, low relative cost, high production efficiency and the like, and obviously improves the high reliability of the measurement under the severe conditions.

Owner:SHENYANG SENSOR TECH INST

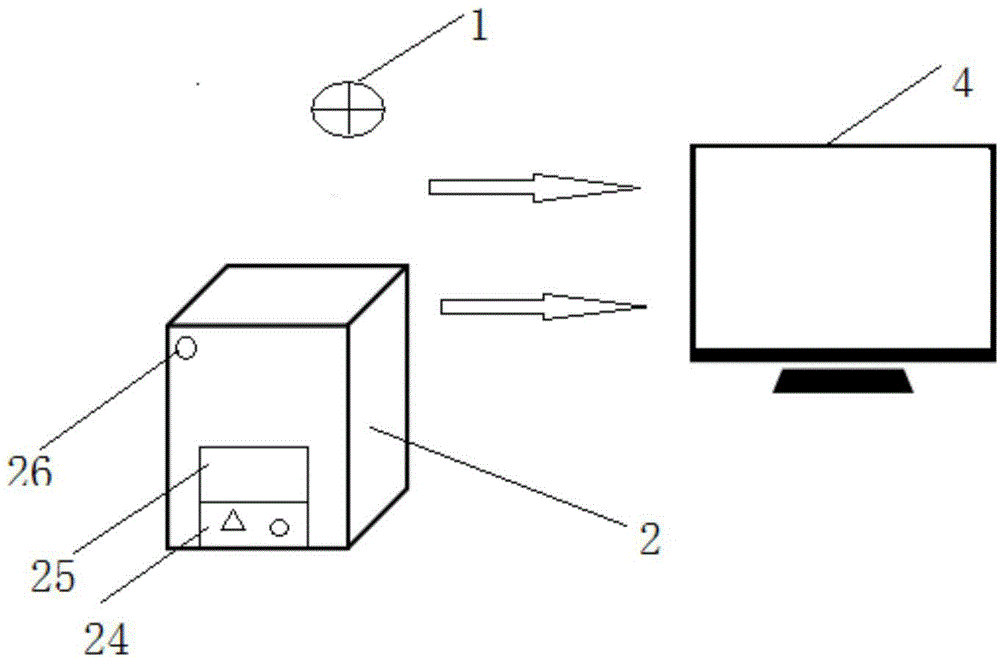

Electric heating device and electric-heating heat supply system based on communication platform

InactiveCN104807063ARealize constant temperature heatingRealize anti-leakageLighting and heating apparatusElectric heating systemElectricityAutomatic control

The invention relates to an electric heating device based on a communication platform. The electric heating device comprises an indoor temperature detecting device, a box body, a heater and a remote controller, wherein the heater is connected with the box body by a pipeline; the box body and the temperature detecting device are in remote communication connection with the remote controller by a network. The electric heating device provided by the invention can realize intelligent control on electric heating, can realize constant-temperature heating and is high in heating speed, high in efficiency, long in service life and capable of automatically controlling the temperature so as to realize automatic protection such as electric leakage prevention, high temperature prevention, burning prevention and freezing prevention; moreover, the heating time can be set as needed, so the aim of saving electricity and energy is realized.

Owner:STATE GRID JIBEI ENERGY SAVING SERVICE +1

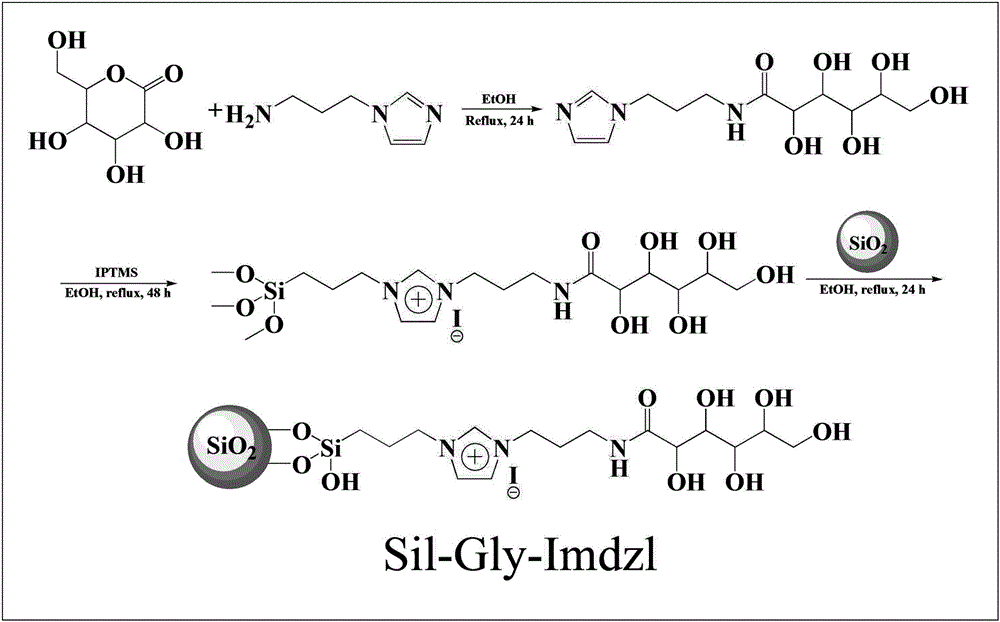

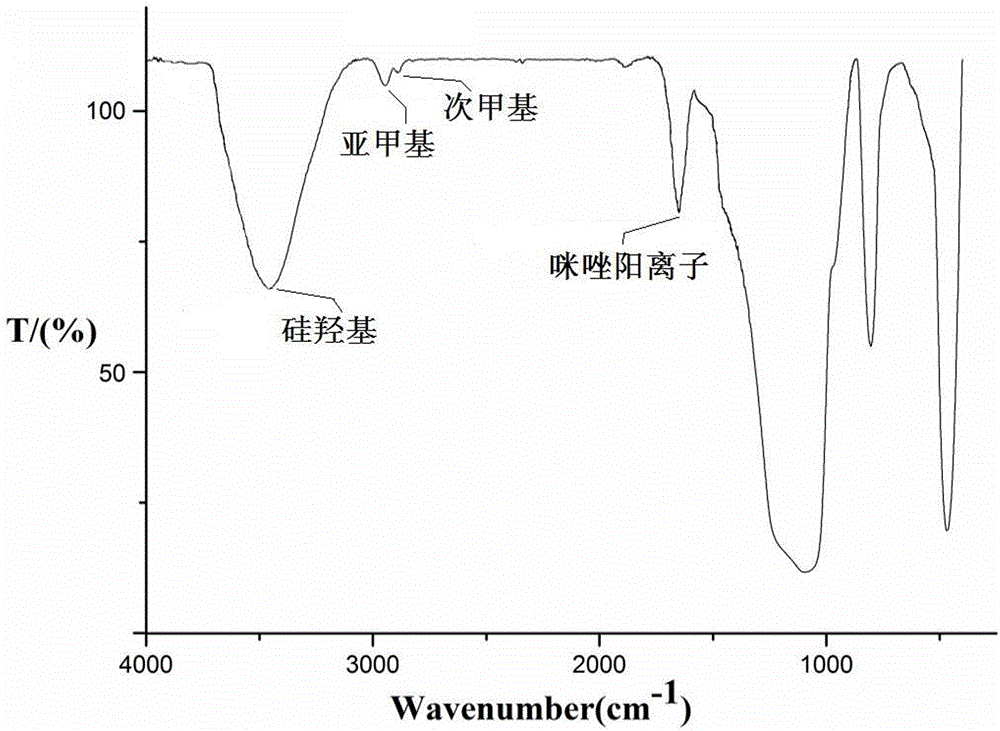

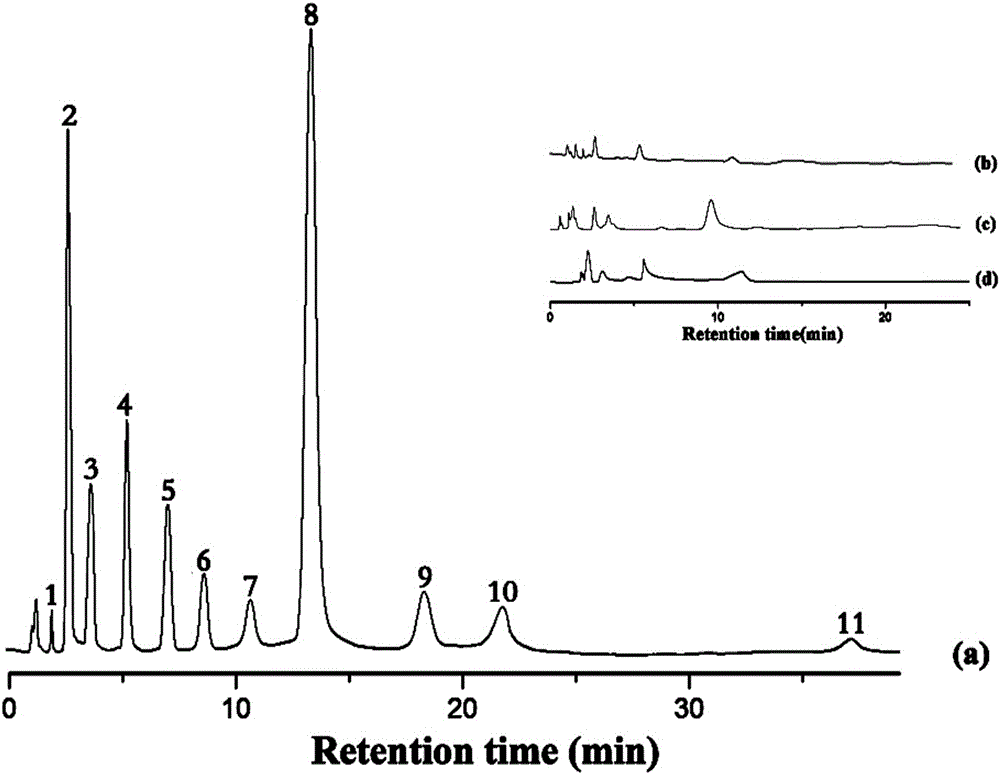

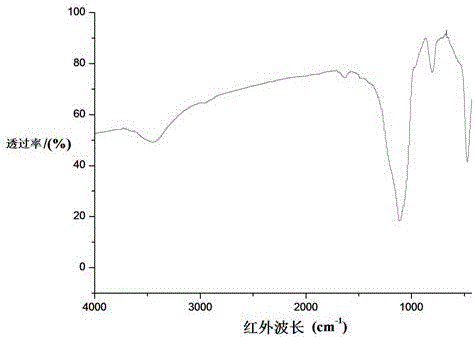

Preparation method of glycosyl-functionalized imidazole ionic liquid stationary phase

ActiveCN105664888AImprove physical structureHydrophilicCation exchanger materialsOrganic anion exchangersSilanesSilica matrix

The invention provides a preparation method of a glycosyl-functionalized imidazole ionic liquid stationary phase. The method comprises the steps of: firstly preparing activated silica methanol homogenate for standby use; dissolving D-glucolactone and N-(3-amino propyl) imidazole in ethyl alcohol to obtain N-imidazole propyl glucosamide; mixing the N-imidazole propyl glucosamide with 3-isocyanate propyl trimethoxy silane, and dissolving the mixture in ethyl alcohol to obtain N-trimethylsilyl propyl-N'-glucosamide propylimidazole+ iodide ion solution; and then adding the silica homogenate in the solution and heating to obtain an N, N'-trimethoxy propyl glucosamide imidazole ionic liquid bonded silica gel chromatographic stationary phase. The glycosyl-functionalized imidazole ionic liquid stationary phase chromatographic packing material has excellent physical structure of the silica matrix and special chromatographic performance of the functionalized glycosyl, has relatively strong separation performance for biological molecular compounds, and has a stable separation effect; and the chromatographic packing material has the characteristics of organic solvent resistance, acid resistance, high temperature resistance and high separation efficiency.

Owner:ZHENGZHOU UNIV

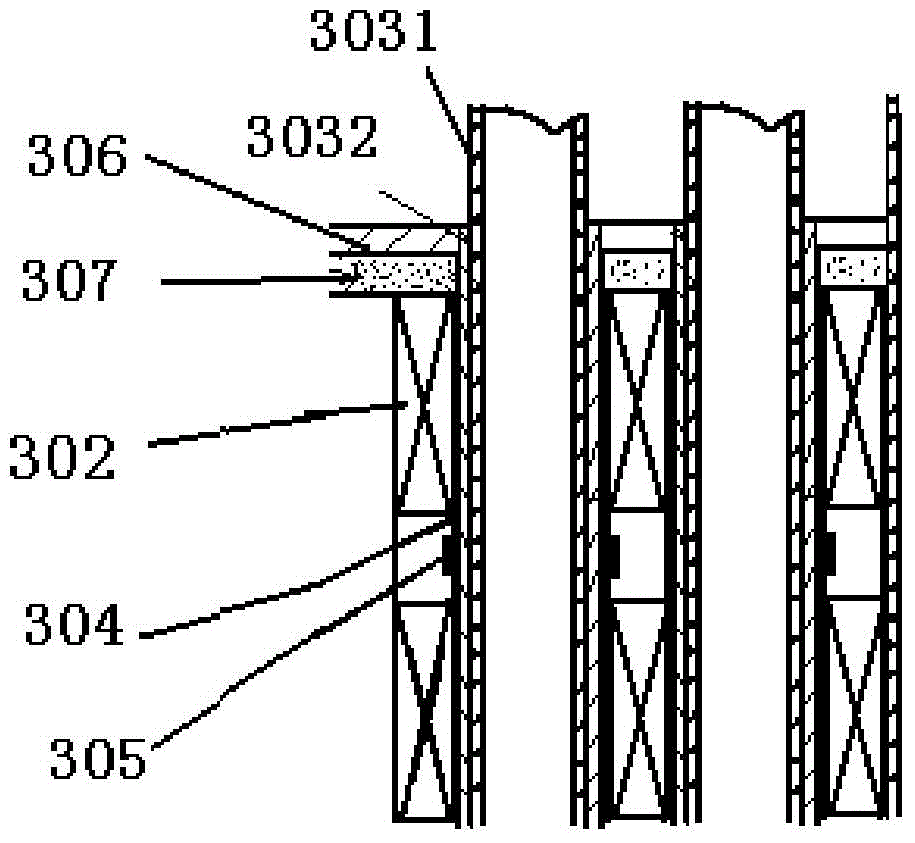

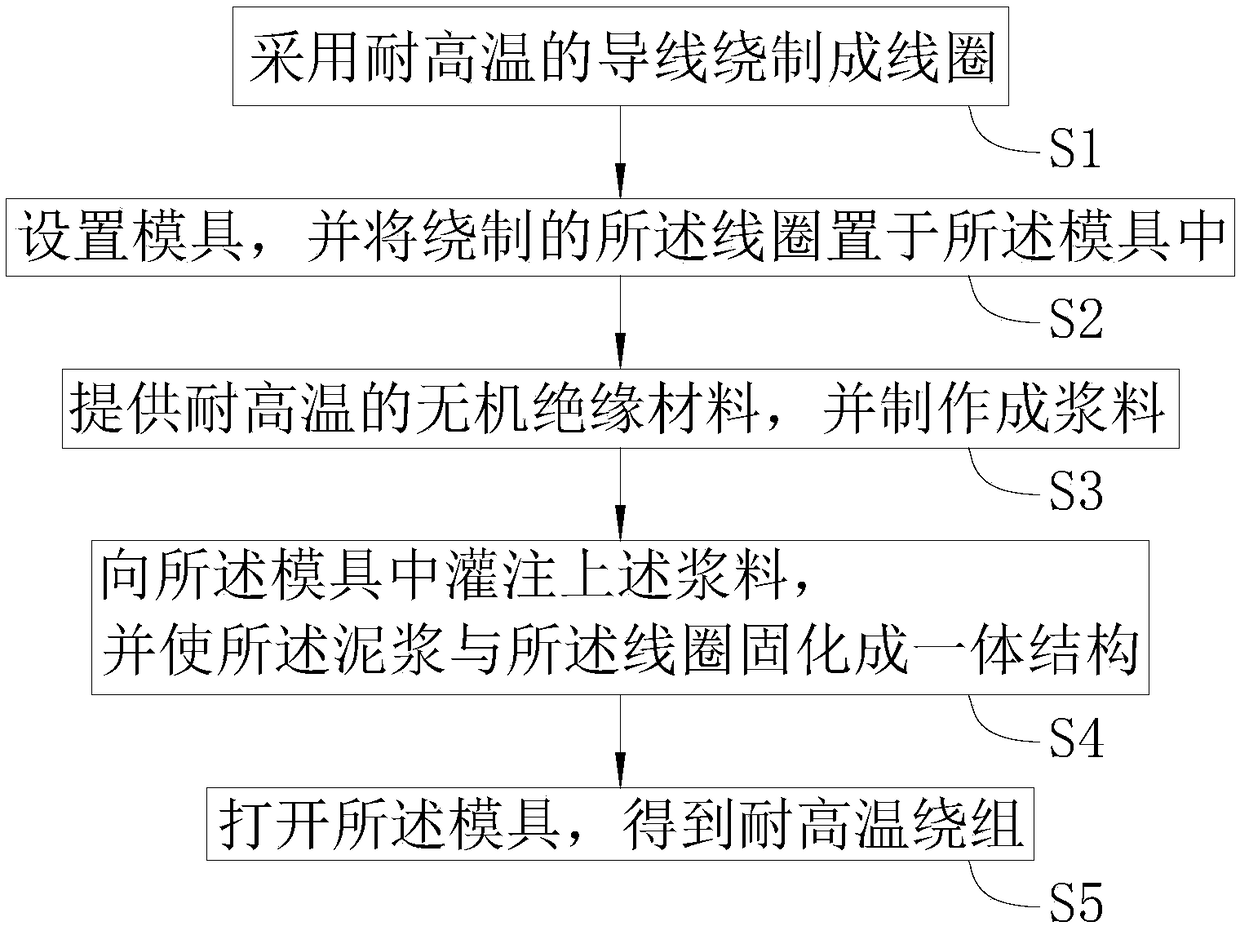

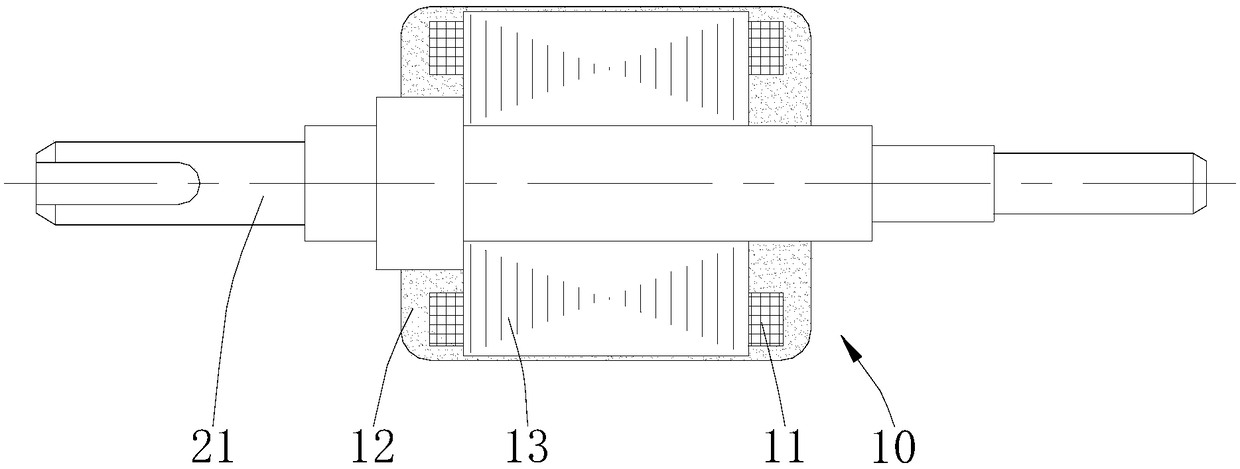

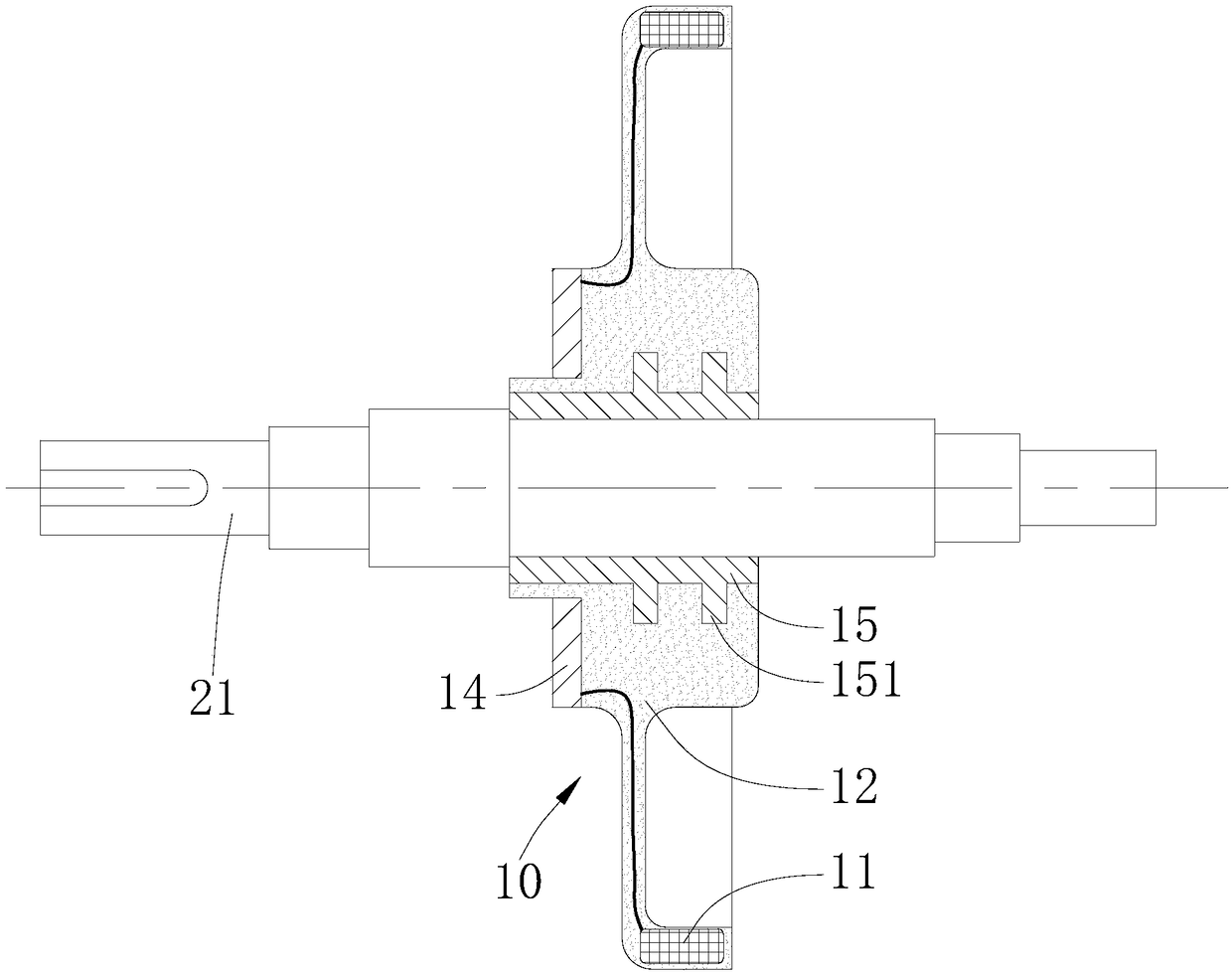

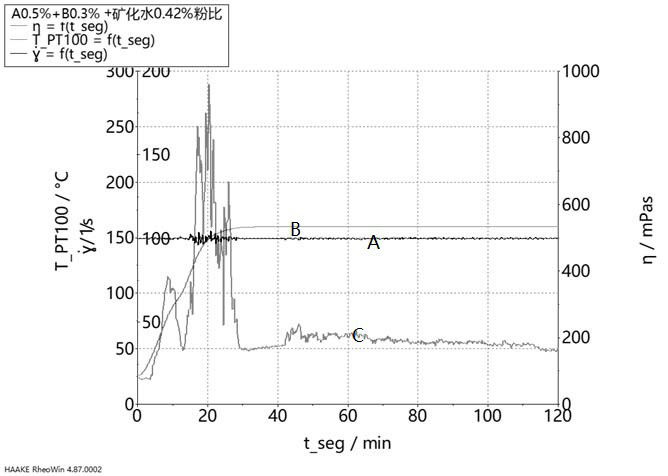

High-temperature-resistant winding and manufacturing method thereof, motor and electric appliance

InactiveCN109038901APlay a cooling roleAchieve high temperature resistanceManufacturing dynamo-electric machinesWindings conductor shape/form/constructionSurface layerSlurry

The invention provides a high-temperature-resistant winding, a manufacturing method thereof and a motor. The manufacturing method of the high-temperature-resistant winding comprises the following steps: a high-temperature-resistant conductor is wound into a coil; the conductor comprises a conductor and an insulating surface layer made of an inorganic insulating material; Placing the wound coil ina mold; Pouring slurry made of high-temperature-resistant inorganic insulating material into the mould, and solidifying the slurry and the coil into an integral structure; Opening the mold to obtain ahigh temperature resistant winding. As the high-temperature-resistant wire is wound into a coil, the insulate surface layer of the wire is made of an inorganic insulate material, so that the coil canwithstand a high-temperature environment of more than 300 DEG C; The inorganic insulating material is used for potting and solidifying the coil, which plays the role of fixing and protecting the coil, and enhances the effect of bearing current and force of the winding manufactured in the high temperature environment above 300 DEG C. The limit that existing motors and electrical appliances using polymer organic materials fpr insulation and temperature resistance are difficult to be above 300 DEG C is broken through.

Owner:刘容彰

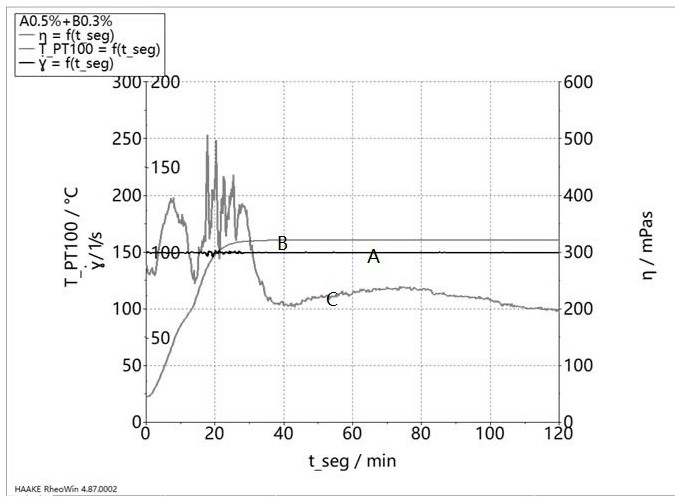

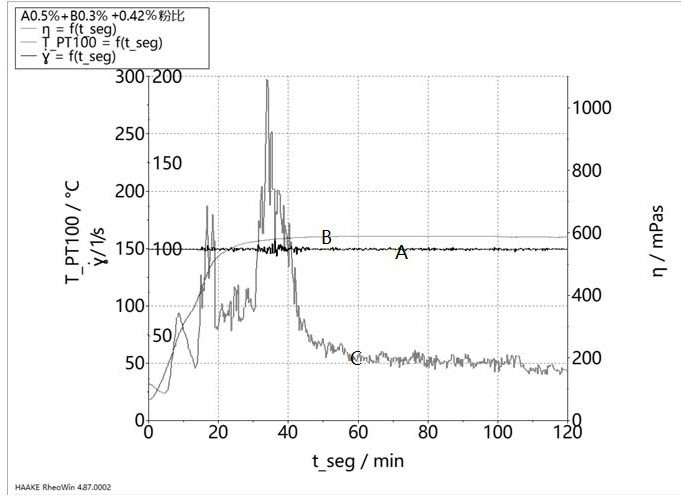

Novel high-temperature-resistant nano-composite zirconium cross-linking agent as well as preparation method and application thereof

PendingCN113755151ALarge specific surface areaIncrease the number ofDrilling compositionOrganic acidGlycol synthesis

The invention relates to a novel high-temperature-resistant nano-composite zirconium cross-linking agent as well as a preparation method and application thereof, and belongs to the technical field of oilfield chemistry. The cross-linking agent is prepared from the following raw materials in parts by weight: 45-50 parts of ethylene glycol, 7-10 parts of inorganic zirconium salt, 15-18 parts of polyhydric alcohol, 23-26 parts of organic acid, 0.1-0.2 part of a nano-particle material and 10-20 parts of a dispersing agent. The preparation method comprises the following two steps: firstly, an organic zirconium cross-linking agent is synthesized, and then the molecular surface of the organic zirconium cross-linking agent is modified by adopting a nano-particle material to prepare the nano-composite zirconium cross-linking agent. When the nano-composite zirconium cross-linking agent is applied to the acidic cross-linking fracturing fluid, good gel can be formed under high-temperature and acidic conditions, even gel can be formed under the condition that the concentration of the acidic cross-linking fracturing fluid is relatively low, the nano-composite zirconium cross-linking agent is high in shear resistance, good in temperature resistance and high in sand carrying capacity, the preparation method is simple, convenient to popularize and apply and suitable for industrial production, and good application prospects are realized.

Owner:郑州市新郑梅久实业有限公司

Preparation method of mutually staggered crescent bismuth vanadate composite material

InactiveCN109395736AIncrease surface areaEnhanced light absorptionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIndiumBismuth vanadate

The invention discloses a preparation method of mutually staggered crescent nickel: iron hydroxide / bismuth vanadate composite material deposited on tin indium oxide (ITO) conducting glass, and belongsto the field of material preparation. The method includes the steps: substrate cleaning; precursor solution preparation; bismuth oxyiodide electro-deposition; bismuth vanadate generation; nickel: iron hydroxide / bismuth vanadate composite material synthesis. The preparation method has the advantages that a large-area crescent composite material structure is formed, technological process is simple,the tin indium oxide conducting glass with high light transmittance and good conductivity is selected as a substrate, environmental pollution is avoided, the operation process is simple, the cost islow, and reaction conditions are easily implemented. The nickel: iron hydroxide / bismuth vanadate composite material can be formed only by a two-step method, visible light absorption can be enhanced, photoelectric conversion efficiency can be improved, and the composite material has a wide application prospect in the fields of photocatalysis, solar batteries and the like.

Owner:UNIV OF JINAN

Insulating paint for changing current distribution of cathode

InactiveCN102653642AReduce the effect of horizontal currentImprove stabilityPolyamide coatingsEpoxy resin coatingsThermal conductivitySpray coating

The invention relates to an insulating paint for changing current distribution of a cathode, relating to an insulating paint, in particular to an insulating paint for painting an aluminum electrolysis cathode. The insulating paint is characterized in that components of a raw material comprise resin for a film forming matter, a color filler and an auxiliary. The insulating paint is painted on an appointed position of the aluminum electrolysis cathode, thereby effectively changing a cathode current distribution situation, reducing the damage of horizontal current and realizing energy saving and consumption reduction. The invention has the characteristics of quick solidification, good insulativity, good thermal conductivity, high temperature resistance, strong adhesive force with a base body, convenience to construct and the like. Through a spray coating or brush coating method, a coating material with the thickness of 0.5-2mm is coated on the certain position of a cathode steel bar and is solidified for 4-5h at normal temperature, and a construction process is simple and convenient in an application process.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Base tube prepared from modified polyimide film and its preparation method

InactiveCN101145017AImprove mechanical propertiesAchieve high temperature resistanceElectrographic process apparatusCoatingsPolymer scienceRoom temperature

A parent tube is made of a modified polyimide film; the raw material which is aggregated by mixing the main material acid polyamide resin the solid content of the raw material is 10-25 percent and the nano-modified polymer together, as well as stirring the mixture under normal temperature, is made into a parent tube, the thickness of the parent tube is arranged between 10 microns and 200 microns, while the length of the parent tube is arranged between 10mm and 1000 mm, and the diameter of the parent tube is arranged between 1mm and 100mm; the present invention has the advantages that as follows: 1, The present invention adopts polyimide modified by nanometer powder material, thereby meet the special requirements of fixing structures of office equipment and achieving high temperature-resistance, high mechanics property, good thermal conductivity and long life cycle; the preparation of the present invention is simple, and does not need huge equipment as well as big tooling and plant investment, and thereby reducing the cost and suitable for mass production.

Owner:庞力

Wear-resisting plastic of producing timer cam

The invention relates to a wear-resisting plastic for producing a timer cam. The wear-resisting plastic is composed of the following raw materials by weight percentage: 65%-85% of foundation plastic nylon 66 and 10%-35% of the wear-resisting plastic. According to the technical scheme, the wear-resisting plastic is added in the nylon 66, so that the cam has high temperature resistance property, high mechanical strength property and the wear-resisting property.

Owner:宁波东龙电子科技有限公司

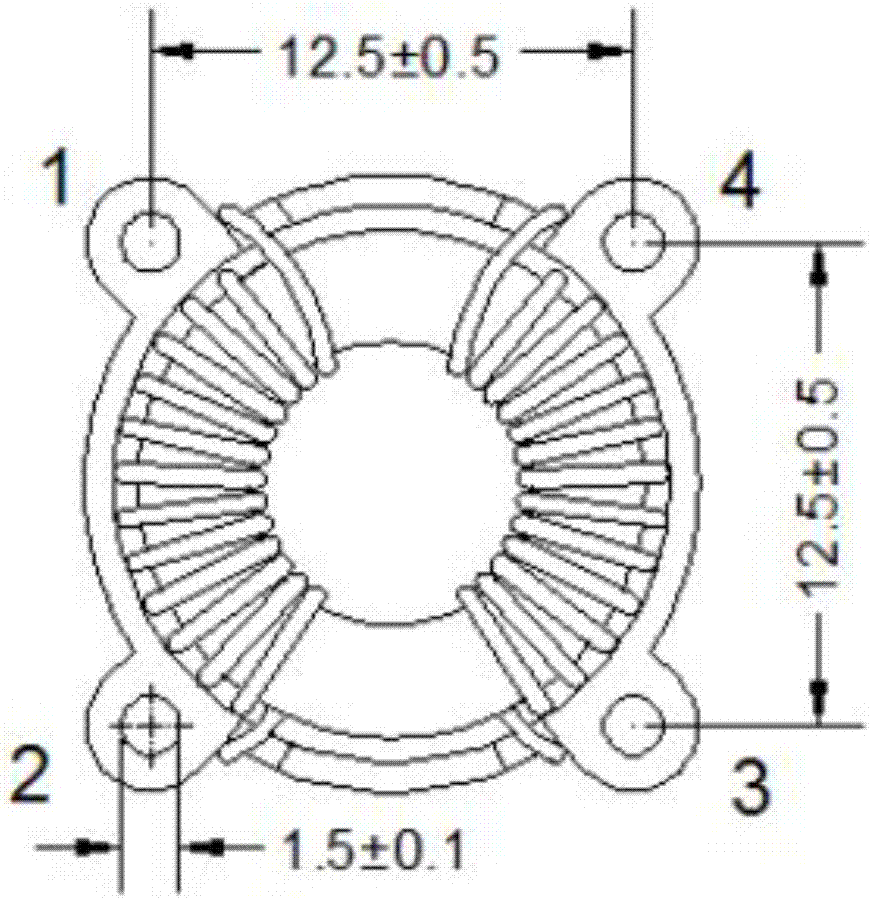

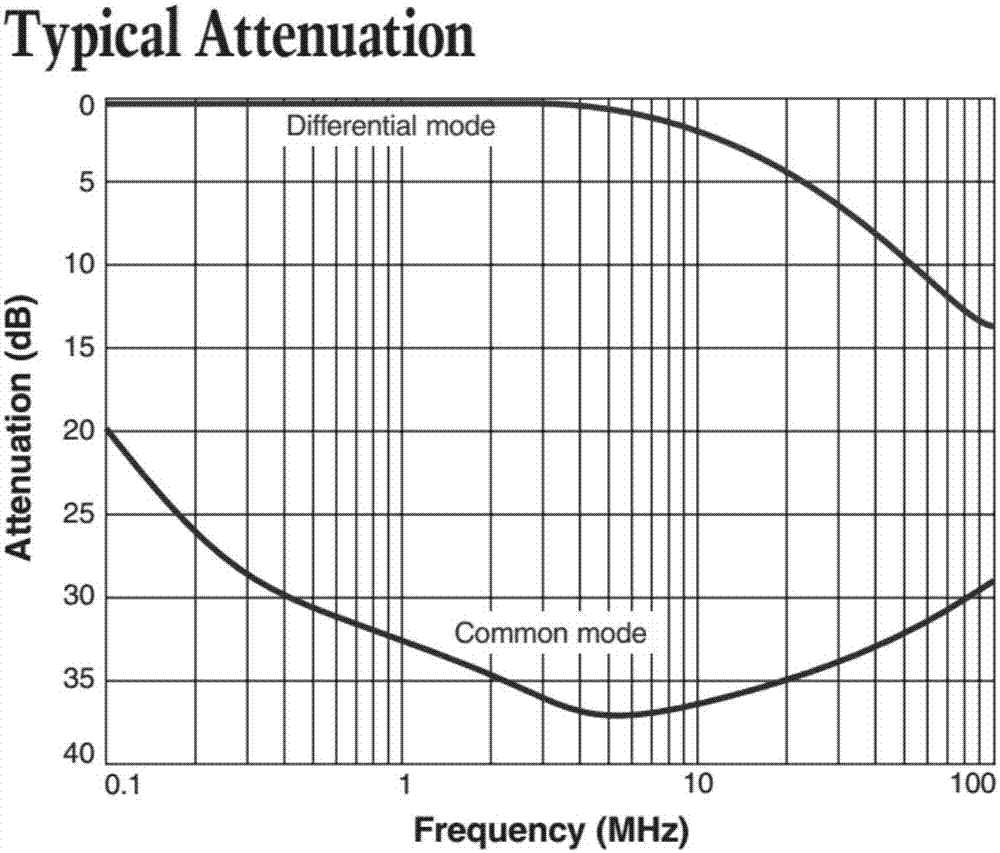

High temperature resistant common mode inductor having shielding layers and magnetic core embedded in PCB

ActiveCN107256757ASolve the problem of poor high-frequency filtering characteristicsReduce production processTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionEngineeringInductor

The invention relates to a high temperature resistant common mode inductor having shielding layers and a magnetic core embedded in a PCB. The high temperature resistant common mode inductor having the PCB, and the magnetic core vertically embedded in the PCB; the PCB includes n insulating layers forming n+1 board layers, n+1 shielding layers forming in each board layer, and a coil; the coil adopts a multi-wire duplex winding structure including a plurality of parallel wires; the coil includes k winding parts, and k-1 connection parts for connecting two adjacent winding parts; the first winding part, the second winding part, ..., and the k winding part are positioned in the m-th board layer, the m+2 board layer, ..., and the m+2(k-1) board layer respectively, and each winding part is formed by allowing wires to travel a distance around a central column of the magnetic core; the connection parts are of through hole structures; and in the board layers where the winding parts are located, the shielding layers surround the winding parts of the coil. The problem that high frequency filter characteristics of the general common mode inductors are poor, the production cost is reduced, a high temperature resistant characteristic can be achieved by adoption of a suitable material, and the demand of a severe environment can be satisfied.

Owner:SUZHOU HUAQI INTELLIGENT TECH

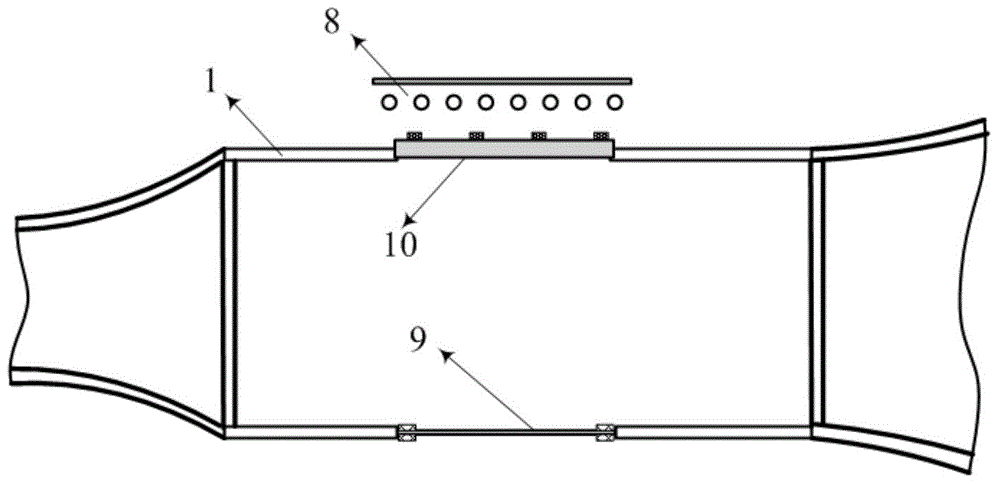

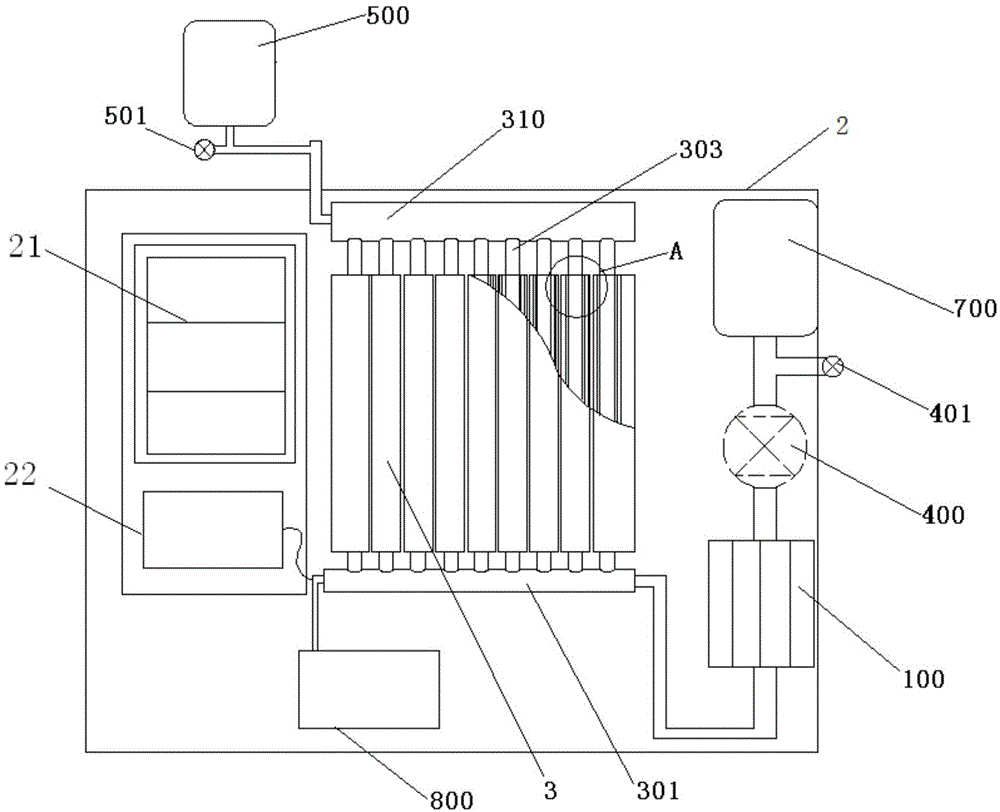

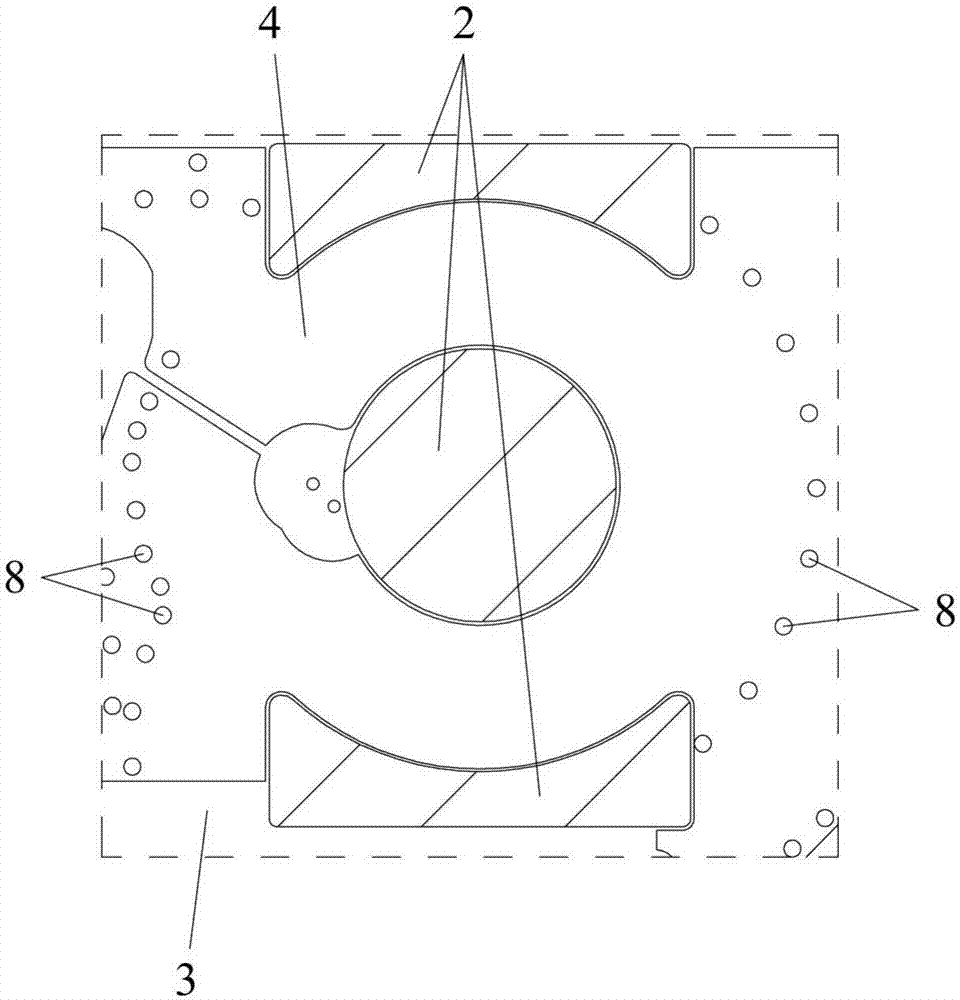

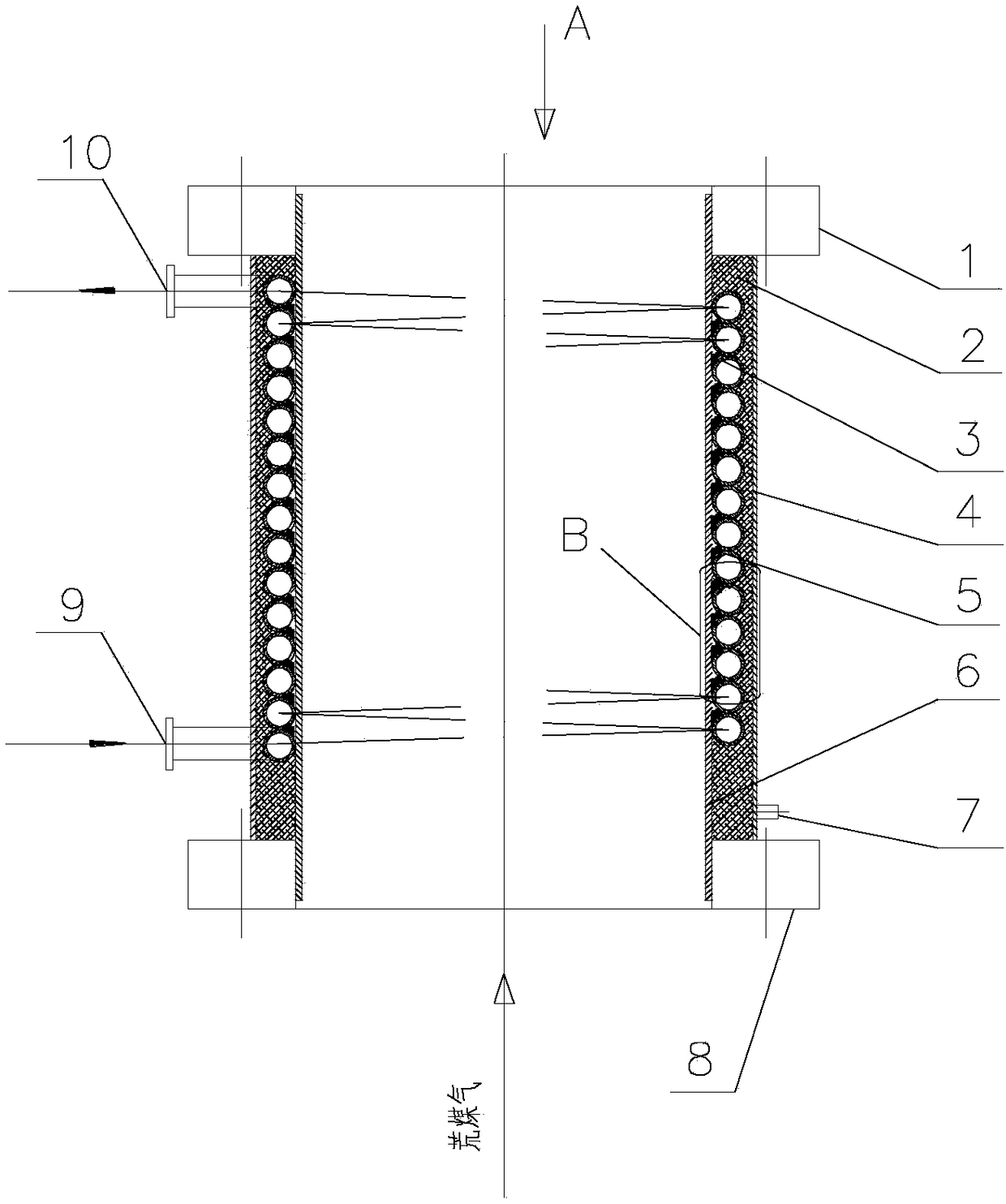

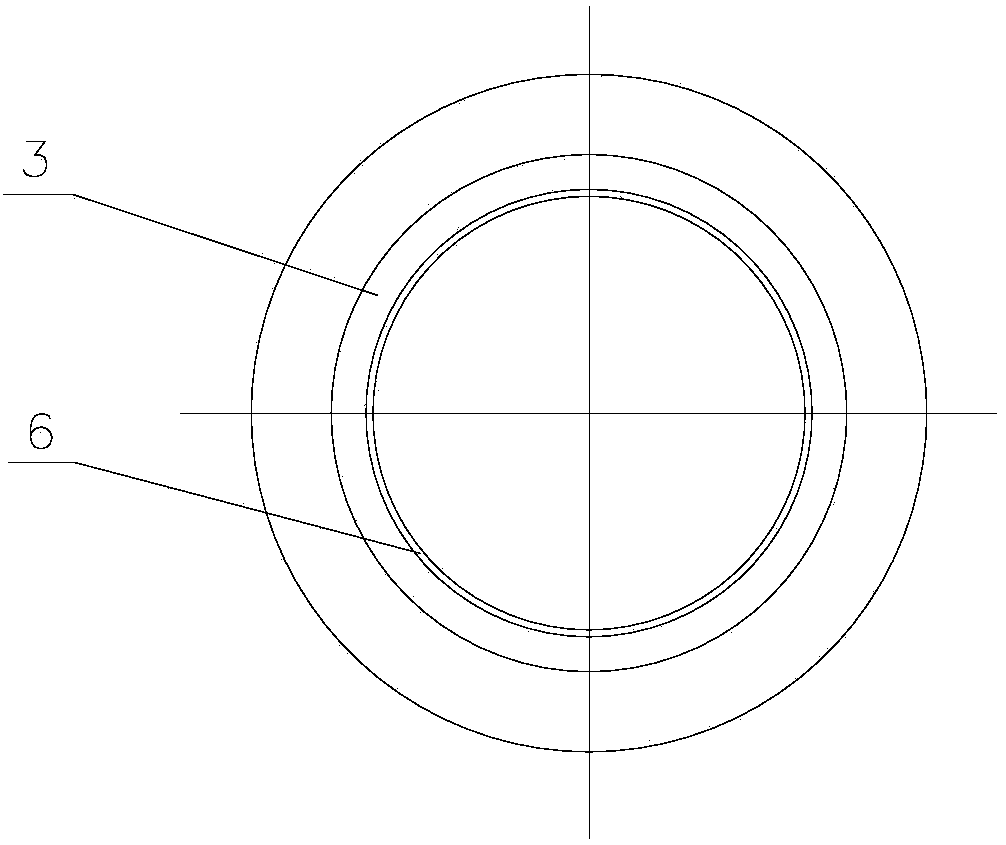

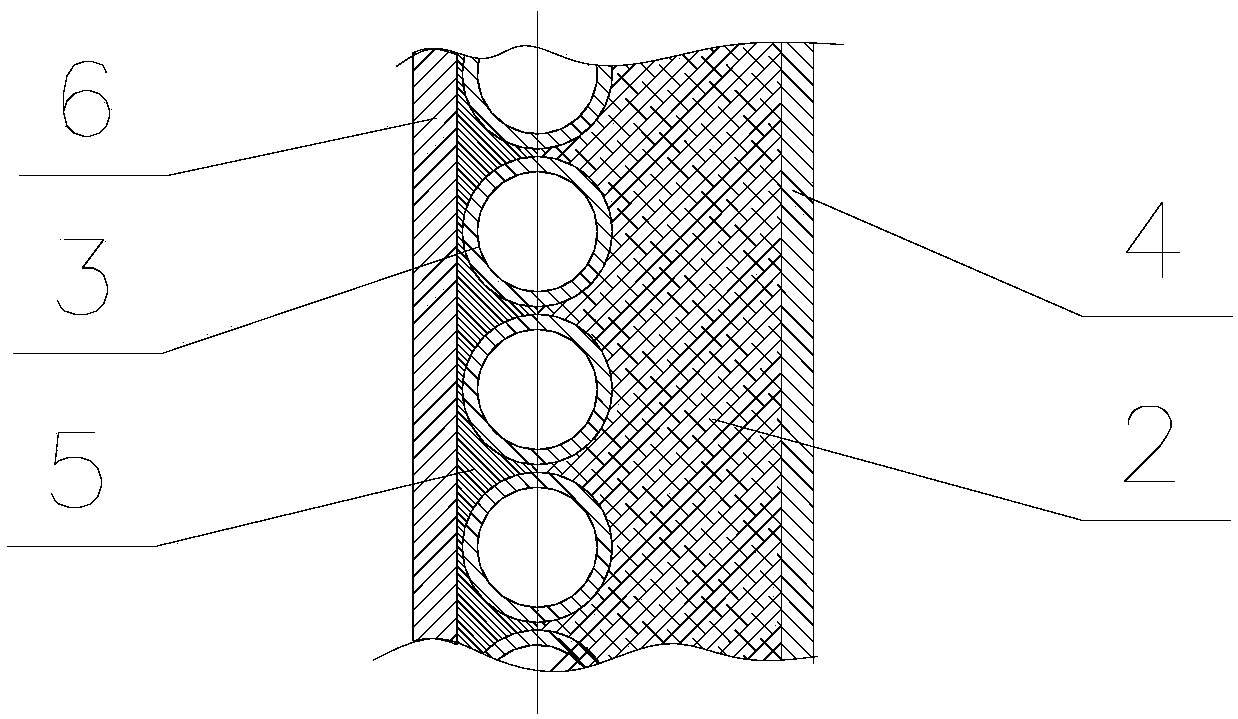

Spiral coil conduction type raw coke oven gas waste heat recovery equipment

PendingCN108467737AImprove securityFacilitate production operation managementEnergy inputIndirect heat exchangersWaste heat recovery unitTar

The invention discloses spiral coil conduction type raw coke oven gas waste heat recovery equipment. The spiral pipe conduction type raw coke oven gas waste heat recovery equipment comprises an ascending pipe inner barrel, an ascending pipe outer barrel and a heat transfer coil, wherein connecting flanges are arranged at the upper end and the lower end of the ascending pipe inner barrel and the ascending pipe outer barrel, the heat transfer coil is spirally wound on the outer side of the ascending pipe inner barrel, a heat transfer base plate is arranged between the heat transfer coil and theascending pipe inner barrel, the inner wall of the heat transfer base plate is tightly fitted with the outer wall of the ascending pipe inner barrel, the shape of the outer wall of the heat transfer base plate is matched with that of the heat transfer coil spirally wound on the heat transfer base plate, an insulating layer fills between the heat transfer coil and the ascending pipe outer barrel, and a vent nozzle is arranged at the bottom of the ascending pipe outer barrel. Compared with the prior art, the spiral coil conduction type raw coke oven gas waste heat recovery equipment has the beneficial effects that the heat transfer condition between the heat transfer coil and the ascending pipe inner barrel is improved, and the recovery rate of the heat of the raw coke oven gas is increased;the phenomenon that the tar in the raw coke oven gas is condensed on the cold wall is avoided; and the manufacturing cost of the waste heat recovery equipment is reduced.

Owner:樊晓光

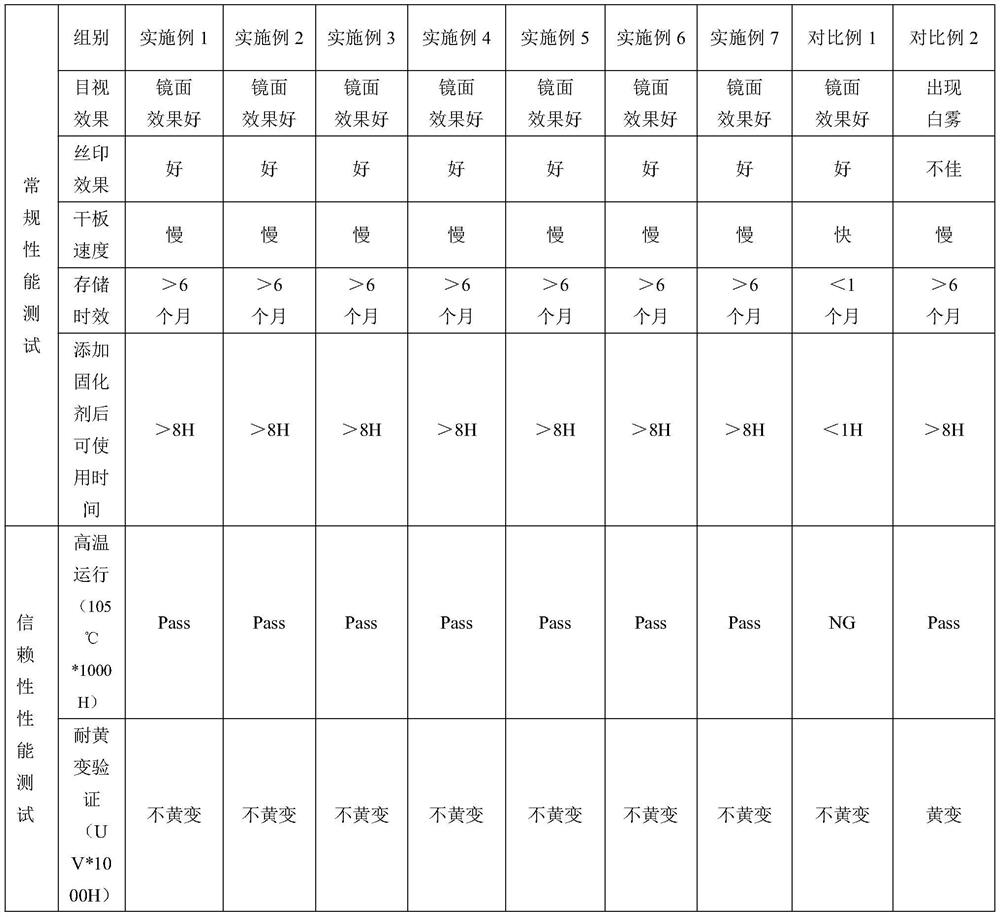

High-temperature-resistant mirror ink and preparation method thereof

The invention relates to the technical field of mirror ink, and discloses high-temperature-resistant mirror ink. The high-temperature-resistant mirror ink is prepared from the following components: 10-20 parts by weight of epoxy resin, 1-2 parts by weight of a toughening agent, 20-50 parts by weight of nano-metal of which the particle size D100 is less than or equal to 200 nm, 30-50 parts by volume of a solvent, 0.1-0.3 part by volume of a leveling agent, 1-3 parts by volume of a defoaming agent, 0.25-1.5 parts by volume of a coupling agent, 0.1-0.5 part by volume of a wetting agent, 0.05-0.2 part by volume of an anti-settling agent, 2-10 parts by volume of a dispersant, 1-5 parts by volume of a curing agent, and 0.1-0.2 part by volume of an ultraviolet light absorber. The mirror ink prepared by using the formula can be matched with different mesh numbers of gauzes for silk-screen printing, the particle size of the used nano metal powder can reach the nano level, and the nano metal powder is uniformly dispersed into the epoxy resin through the dispersant, so that the surface problem that a 'rime fog' defect is formed due to diffuse reflection on the surface can be avoided.

Owner:江苏德恒新材料科技有限公司

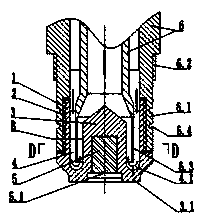

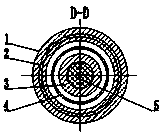

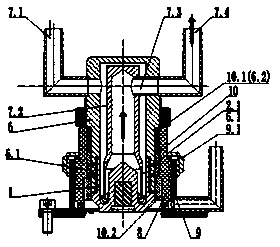

Water-cooled cathode head of plasma generator

PendingCN109862682AImprove cooling effectAchieve high temperature resistancePlasma techniqueSurface coolingPlasma generator

Disclosed is a water-cooled cathode head of a plasma generator. Outer cooling walls are arranged at intervals on the outer periphery of a central seat with an internal emission body, and the bottom ends of the outer cooling walls and the central seat are connected into an integrated heating body by a sealing ring bottom, and a water returning groove is formed in an inner cavity of the sealing ringbottom, so that the heat of a cathode emitting end is dispersed, and the heat, which is originally concentrated in the central seat, is dispersed in the central seat, the sealing ring bottom and theouter cooling walls. Water is introduced from an annular barrel at the outer layer of a cathode water cooling jacket, firstly flows through the external cold wall thread section for primary cooling, then falls into the water returning groove, and then turns upwards to cool the central seat along the surface of the central seat, so that the two-time cooling of the heat source of the emitting end iscompleted. High temperature resistance and low probability of damage are achieved; and the continuous emission time is prolonged to 700 hours from the original 400 hours. Due to the fact that external threads of the outer cold wall are in threaded connection with the lower threaded section of the water cooling sleeve of the cathode, when a discharging surface is burnt out, the threads are rotated, so that the cathode head can be replaced conveniently. The water-cooled cathode head of plasma generator can be used for a non-transfer and transfer arc plasma generator, in particular to a high-power 200-500 KW generator.

Owner:CHENGDU JINCHUANGLI SCI & TECH

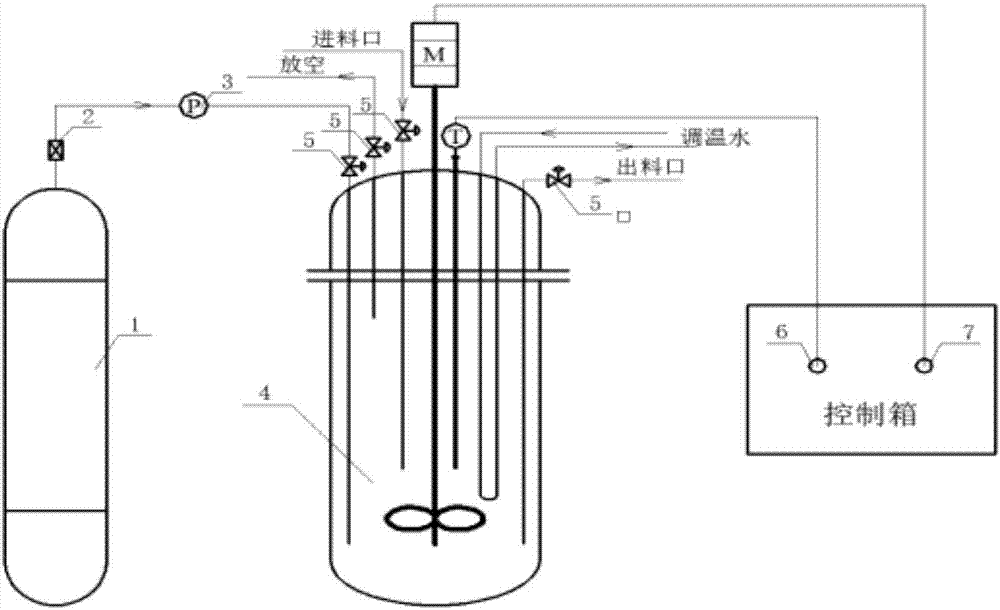

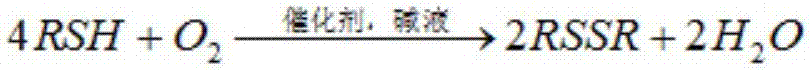

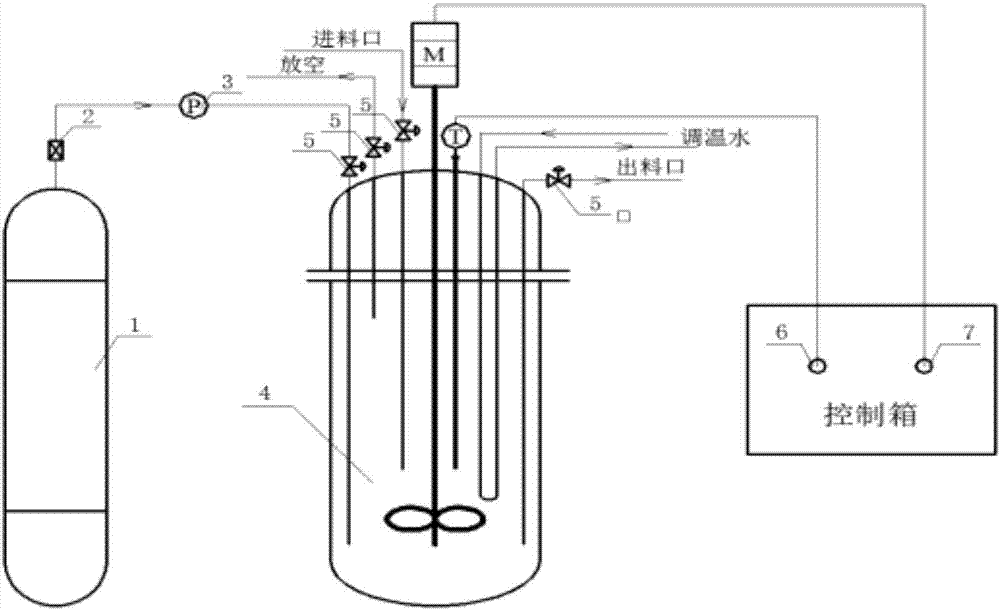

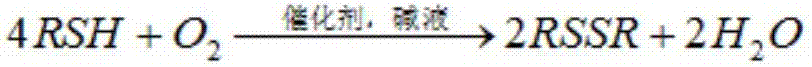

Activated carbon-loaded tetrasulfo cobalt phthalocyanine and application thereof in preparing dimethyl disulfide as catalyst

InactiveCN106984362AStable structureEfficient manufacturingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonCatalytic oxidation

The invention belongs to the field of chemical engineering and in particular to activated carbon-loaded tetrasulfo cobalt phthalocyanine and an application thereof in preparing dimethyl disulfide as a catalyst. The preparation method of the activated carbon-loaded tetrasulfo cobalt phthalocyanine comprises the following step: loading tetrasulfo cobalt phthalocyanine to modified activated carbon by means of a chemical grafting method to obtain activated carbon-loaded tetrasulfo cobalt phthalocyanine (AC-CoPcS), wherein the modified activated carbon is ethidene diamine modified activated carbon. The catalyst is stable in structure, can be repeatedly used, and can realize effective catalytic oxidation of thiomethoxide to prepare dimethyl disulfide in a reaction system in an alkali-resistant, pressure-resistant and high-temperature-resistant manner. By taking AC-CoPcS as the catalyst, the catalyst can be better separated from a product in a process of preparing the dimethyl disulfide, and the product yield and DMDS purity are higher than those obtained by catalysis of free state CoPcS. The DMDS yield of the obtained product can reach 86.8%, and the product purity can reach 100%.

Owner:CHONGQING UNISPLENDOUR CHEM

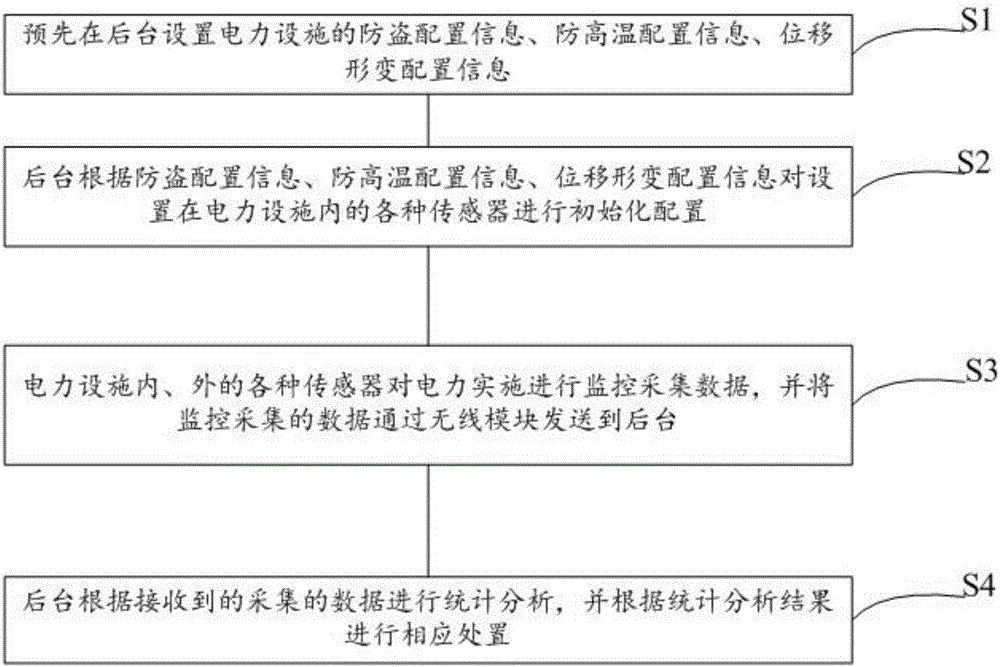

Electric-power-facility remote monitoring system and method thereof

InactiveCN106483917ARealize anti-theftAchieve high temperature resistanceProgramme controlComputer controlStatistical analysisMonitoring system

The invention provides an electric-power-facility remote monitoring method. The method comprises the following steps that S1, antitheft configuration information, high temperature prevention configuration information and displacement deformation configuration information of an electric power facility are arranged on a background in advance; S2, the background carries out initialization configuration on various kinds of sensors arranged in the electric power facility according to the antitheft configuration information, the high temperature prevention configuration information and the displacement deformation configuration information; S3, the various kinds of sensors arranged in and outside the electric power facility monitor electric power implementation so as to collect data and send the monitored and collected data to the background through a wireless module; and S4, the background carries out statistics analysis according to the received collected data and carries out corresponding disposal according to a statistics analysis result. The invention also provides an electric-power-facility remote monitoring system.

Owner:宁波精丰测控技术有限公司

Activated carbon-loaded tetraamino cobalt phthalocyanine and application thereof in preparing dimethyl disulfide as catalyst

ActiveCN106984361AStable structureEfficient manufacturingOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonCobalt phthalocyanine

The invention belongs to the field of chemical engineering and in particular to activated carbon-loaded tetraamino cobalt phthalocyanine and an application thereof in preparing dimethyl disulfide as a catalyst. The preparation method of the activated carbon-loaded tetraamino cobalt phthalocyanine comprises the following step: loading tetraamino cobalt phthalocyanine to modified activated carbon by means of a chemical grafting method to obtain activated carbon-loaded tetraamino cobalt phthalocyanine, wherein the modified activated carbon is 1,5-dibromopentane modified activated carbon. The catalyst is stable in structure, can be repeatedly used, and can realize effective catalytic oxidation of thiomethoxide to prepare dimethyl disulfide in a reaction system in an alkali-resistant, pressure-resistant and high-temperature-resistant manner. By taking AC-CoTAPc as the catalyst, the catalyst can be better separated from a product in a process of preparing the dimethyl disulfide, and the product yield and DMDS purity are higher than those obtained by catalysis of free state CoTAPc. The DMDS yield of the obtained product can reach 87.4%, and the product purity can reach 100%.

Owner:CHONGQING UNISPLENDOUR CHEM

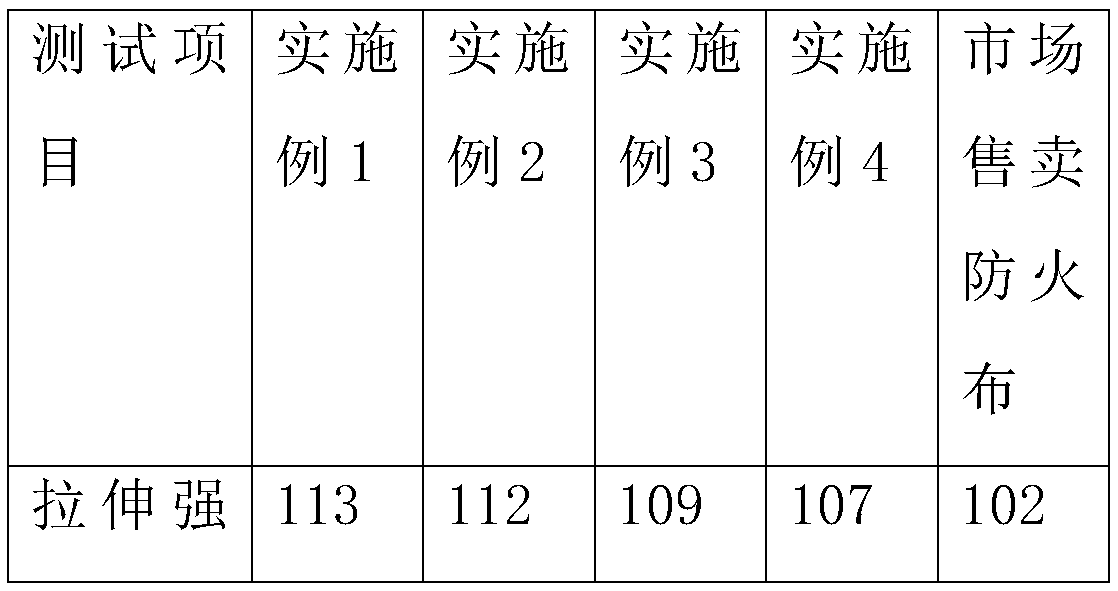

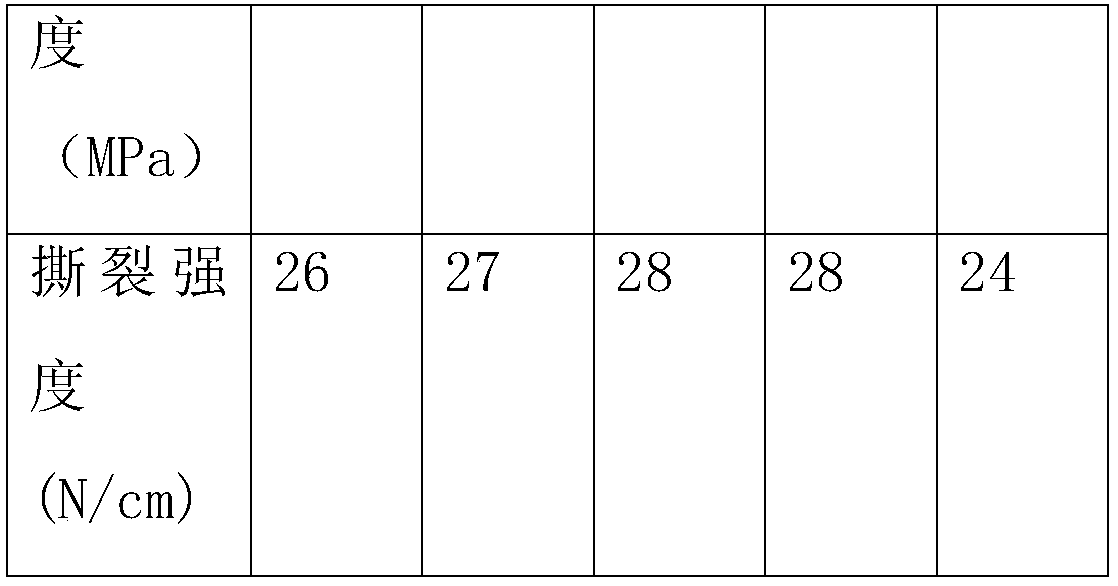

Method for utilizing glass fibers for preparing flame-retardant cloth

InactiveCN109097871AImprove high temperature resistance and flame retardancyImprove high temperature resistanceFlame-proof filament manufactureSynthetic polymer filament chemical after-treatmentPlasticizerYarn

The invention belongs to the technical field of high-polymer materials, and particularly relates to a method for utilizing glass fibers for preparing flame-retardant cloth. The flame-retardant cloth is prepared from, by mass, 30-40 parts of high-temperature-resistant plasticizer, 50-60 parts of modified glass fibers, 10-20 parts of polyurethane, 10-15 parts of polytetrafluoroethylene, 40-50 partsof bonding agent, 2-3 parts of dispersing agent, 1-2 parts of dyed color master batch and 6-20 parts of flexibilizer. According to the method for utilizing the glass fibers for preparing the flame-retardant cloth, by adjusting the proportion of the modified glass fibers, the high-temperature-resistant plasticizer, polyurethane and polytetrafluoroethylene, optimizing silk yarn manufactured under the processing condition and spraying a layer of compact nanometer-type aluminum trioxide to the surface of the yarn, the yarn achieves the flame-retardant and fireproof effect.

Owner:北京点域科技有限公司

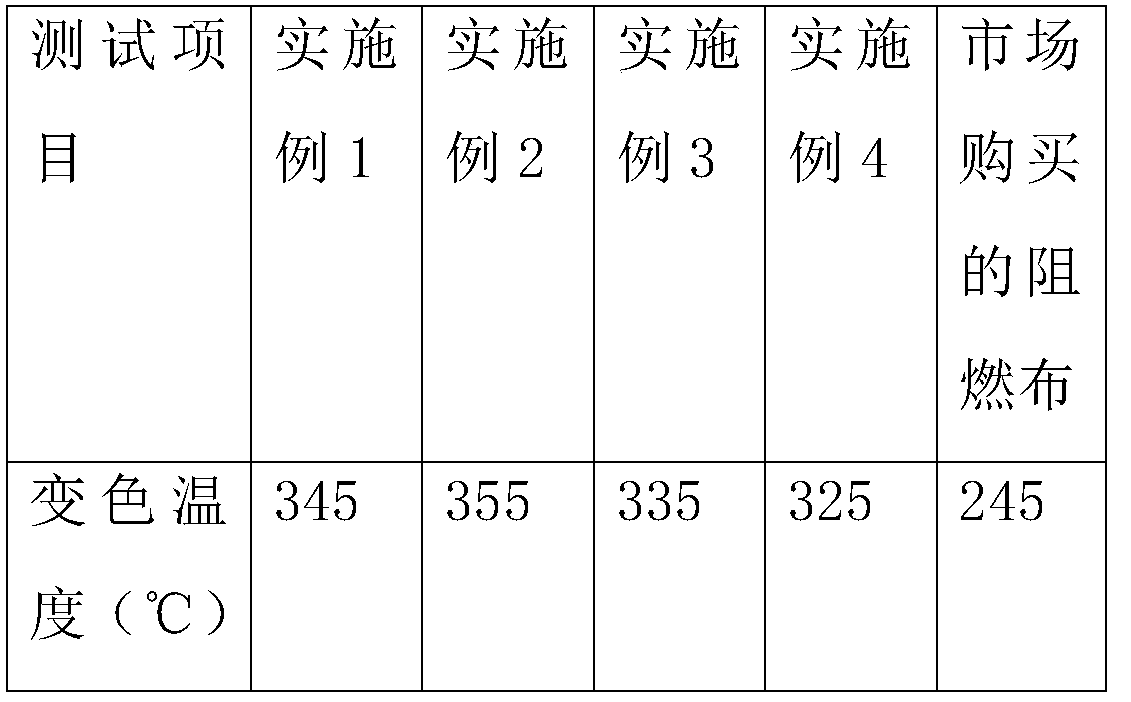

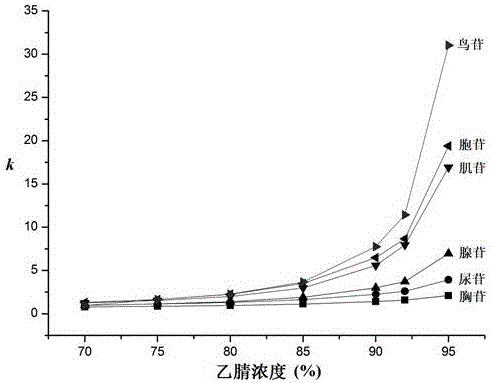

Novel glucosyl group ionic liquid stationary phase and application thereof

InactiveCN105903455AImprove physical structureWith glucoseSugar derivativesOther chemical processesEpoxyStationary phase

The invention discloses a novel glucosyl group ionic liquid stationary phase. The stationary phase is prepared through the method comprising the steps that firstly, acid treatment is performed on the surface of porous spherical silica gel for chromatography, washing is performed till to neutral, silica gel surface excitation is achieved, then, then, an epoxy loop opening reaction is utilized for enabling meglumine to react with gamma-(2,3-epoxy propyl) propyl trimethoxy silane, methyl iodide is added, the synthesized glucosyl group ionic liquid is modified on the surface of a silica gel carrier, and high efficiency and high selectivity of the stationary phase are achieved. The invention further discloses application of the novel glucosyl group ionic liquid stationary phase on the aspect of nucleoside separation.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Preparation method of embedded porous Fe-Nx@Pd-NC nanorod, nanorod prepared by preparation method, and application of nanorod

ActiveCN112736257AIncrease the active siteMany active sitesMaterial nanotechnologyCell electrodesPtru catalystAqueous ethanol

The invention discloses a preparation method of an embedded porous Fe-NX@Pd-NC nanorod, the prepared nanorod and application of the nanorod. The preparation method comprises the following steps: adding PdCl2 and naphthylamine into an ethanol aqueous solution, uniformly mixing, standing to generate a complex, dispersing the complex and FePc powder into a THF solvent, stirring, centrifugally drying, collecting solid powder, calcining at high temperature, and cooling to obtain the embedded porous Fe-NX@Pd-NC nanorod. The method is simple and easy to implement and low in raw material cost, large-scale production can be achieved, and the prepared Fe-NX@Pd-NC nanorod has the structural advantages of being large in specific surface area, good in electrical conductivity, high in permeability, resistant to high temperature and the like; and two high-activity metal sites, namely Fe-Nx and Pd, are simultaneously provided for driving the alkaline oxygen reduction reaction. Therefore, the Fe-NX@Pd-NC shows excellent catalytic activity and stability as an oxygen reduction cathode catalyst.

Owner:NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com