Device and method for mounting high noise resistance quartz window under high temperature environment

A high-temperature environment and installation device technology, applied in the installation of window glass, measuring devices, instruments, etc., can solve the problem of not having a good quartz window installation device, and achieve the effect of buffering thermal deformation, maintaining integrity, and ensuring integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

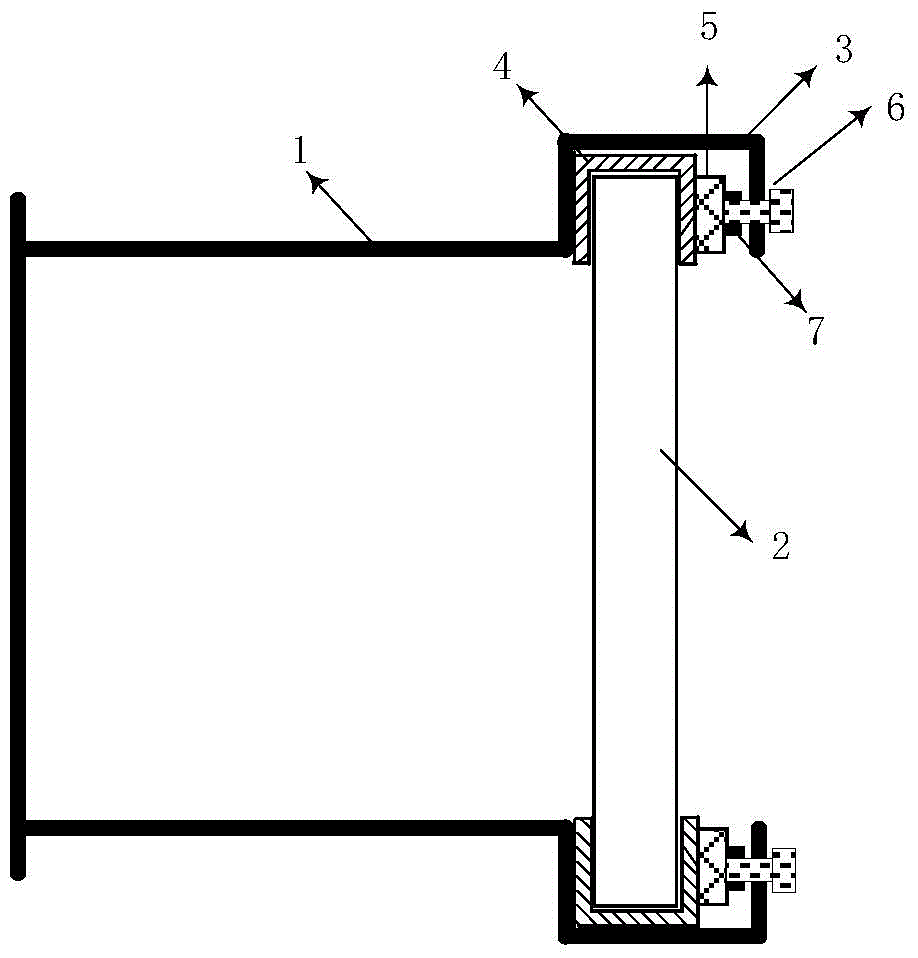

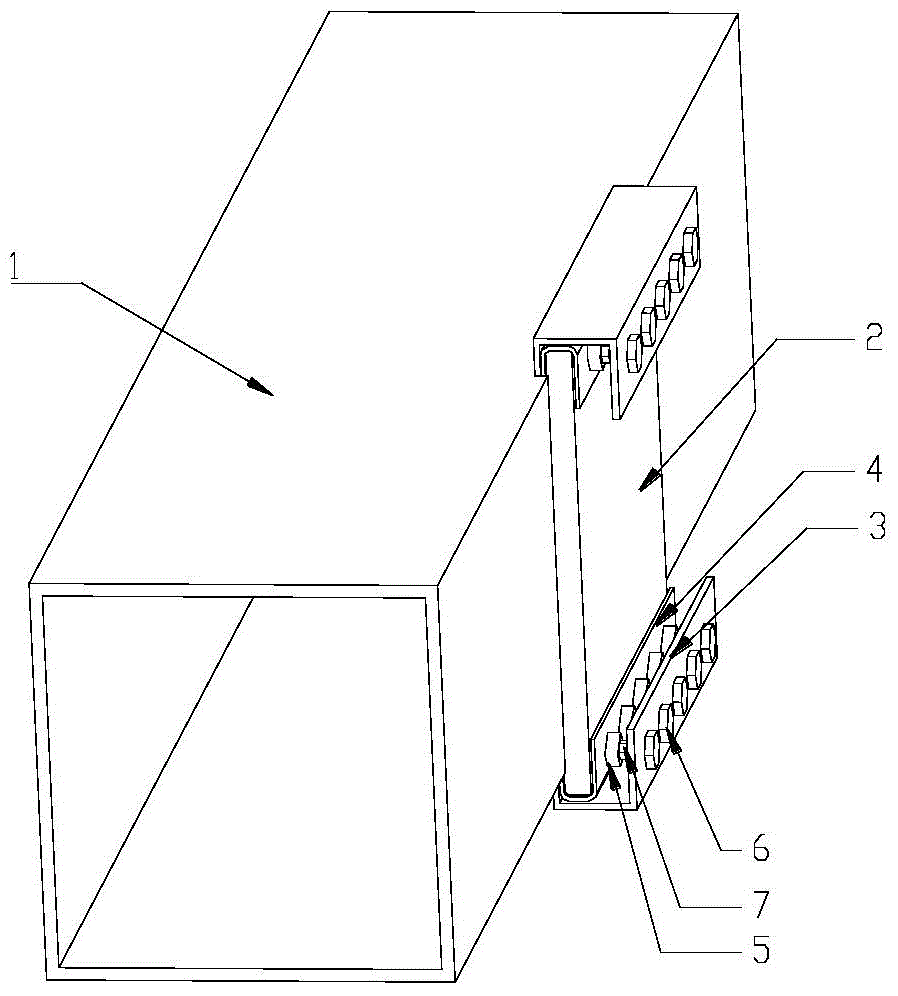

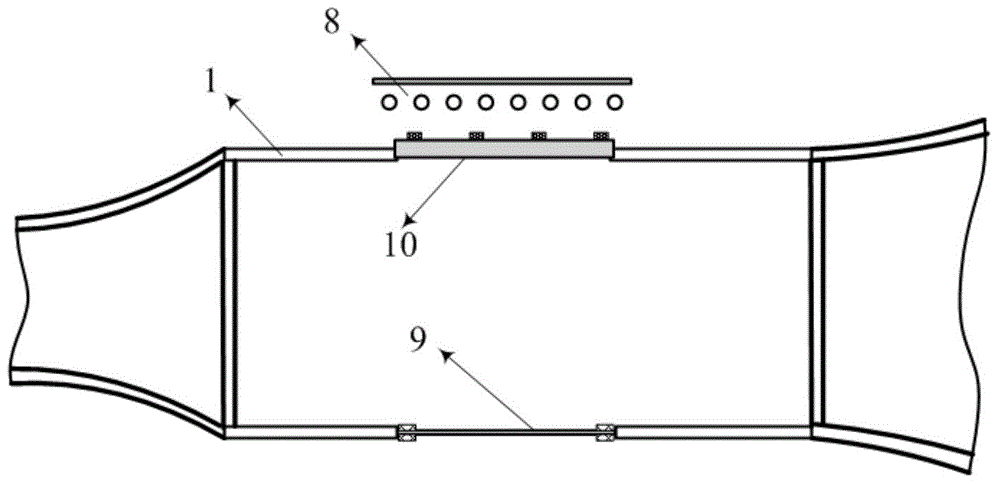

[0022] The invention provides a quartz window installation device for a structure thermal noise test system, the installation device is as figure 1 As shown, it is used to install the quartz window 2 on the traveling wave tube 1, mainly including: a bracket 3, a thermal insulation blanket 4, a metal shock absorber 5, a fastening bolt 6 and a compression nut 7. The traveling wave tube 1 is a commonly used noise generating device. A window is opened at the installation part of the quartz window for the installation of the quartz window. The quartz window 2 is a rectangular glass made of quartz. Same size. Bracket 3 is two identical U-shaped grooves with a width of about 60 mm, and the material is the same as that of a traveling wave tube. Each bracket has five equally spaced threaded holes.

[0023] The insulation blanket 4 is a flexible pad processed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com