Method for utilizing glass fibers for preparing flame-retardant cloth

A technology of glass fiber and flame retardant cloth, which is applied in the manufacture of fire-retardant and flame-retardant filaments, chemical post-treatment of synthetic polymer rayon filaments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

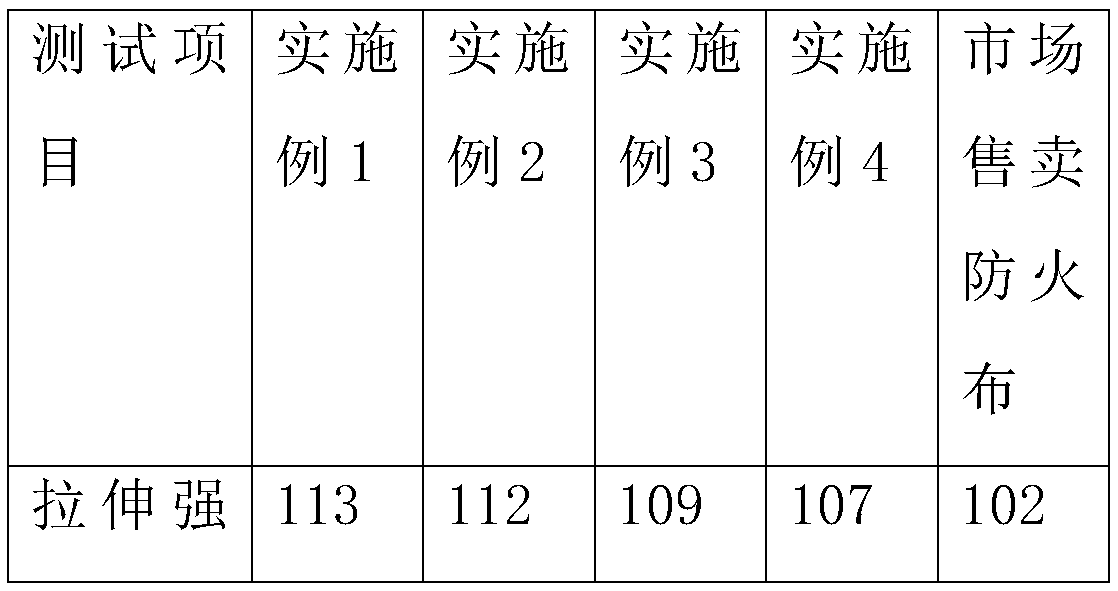

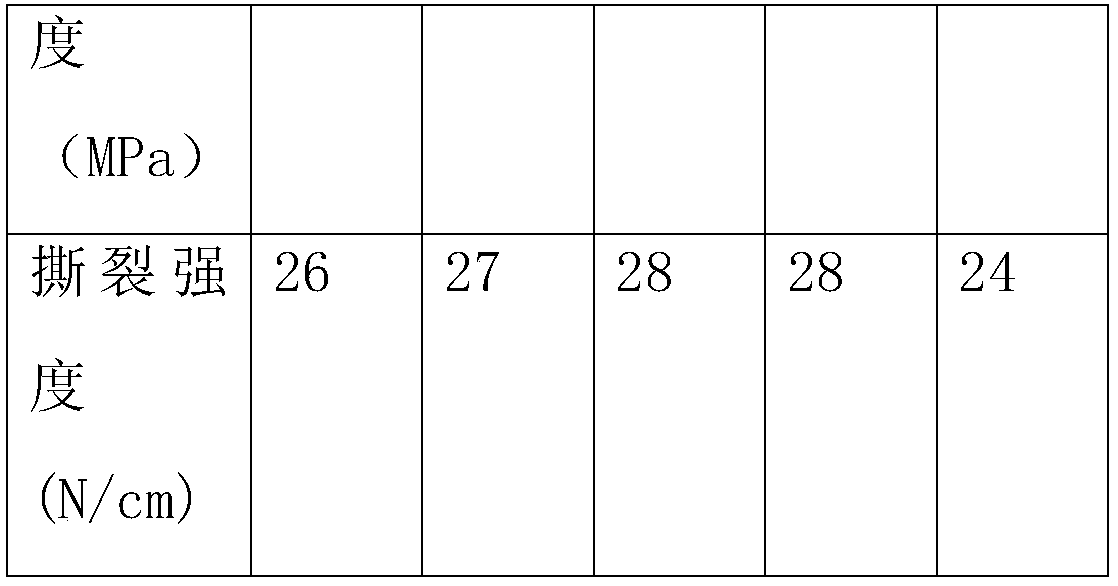

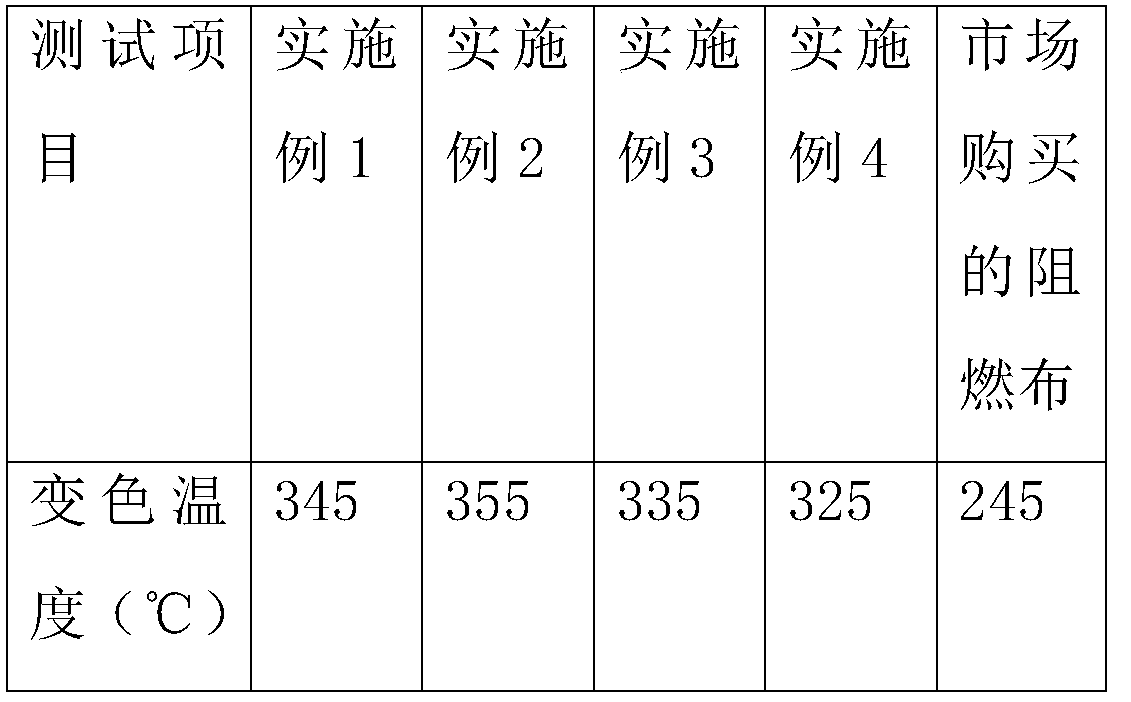

Examples

Embodiment 1

[0020] A method for preparing flame-retardant cloth using glass fiber includes the following steps:

[0021] (1) Add 35 parts of polyacryl cyanide, 12 parts of polyimide, 8 parts of polyarylene ether, 1.5 parts of dispersant to the reaction kettle and react at 60°C for 2 hours. High temperature plasticizer.

[0022] (2) Add 40 parts of glass fiber, 55 parts of cyclohexane, 6 parts of polytriols, 3 parts of p-phenylene diisocyanate, 1.5 parts of organophosphorus catalyst in the reaction kettle at 50℃ The reaction is carried out for 3 hours, wherein the speed of the stirrer is controlled at 450 rpm, and the modified glass fiber is obtained.

[0023] (3) 15 parts of epoxy resin, 25 parts of polyethylene, 8 parts of nylon, and 1.5 parts of dispersant are added to a single-screw granulator for granulation and extrusion, and the particles obtained after extrusion are combined agents.

[0024] (4) 15 parts of calcium stearate, 9 parts of potassium dodecyl sulfonate, and 6 parts of PE wax ar...

Embodiment 2

[0029] A method for preparing flame-retardant cloth using glass fiber includes the following steps:

[0030] (1) Add 32 parts of polyacryl cyanide, 14 parts of polyimide, 7 parts of polyaryl ether, 1 part of dispersant to the reaction kettle and react at 55°C for 2 hours. High temperature plasticizer.

[0031] (2) Add 35 parts of glass fiber, 55 parts of cyclohexane, 7 parts of polytriols, 2 parts of p-phenylene diisocyanate, 1 part of organophosphorus catalyst to the reactor at 45℃ The reaction is carried out for 3 hours, wherein the speed of the stirrer is controlled at 400 rpm, and the modified glass fiber is obtained.

[0032] (3) Add 12 parts of epoxy resin, 22 parts of polyethylene, 8 parts of nylon, and 1 part of dispersant into a single-screw granulator for granulation and extrusion. The particles obtained after extrusion are used as a joint agent.

[0033] (4) 16 parts of calcium stearate, 8 parts of potassium dodecyl sulfonate, and 8 parts of PE wax are mixed uniformly at 6...

Embodiment 3

[0038] A method for preparing flame-retardant cloth using glass fiber includes the following steps:

[0039] (1) Add 38 parts of polyacrylic cyanide, 13 parts of polyimide, 8 parts of polyarylene ether, 1.5 parts of dispersant to the reaction kettle, and react at 50°C for 3 hours. High temperature plasticizer.

[0040] (2) Add 45 parts of glass fiber, 56 parts of cyclohexane, 5 parts of polytriols, 4 parts of p-phenylene diisocyanate, 1 part of organophosphorus catalyst to the reaction kettle at 55℃ The reaction is carried out for 3 hours, wherein the speed of the stirrer is controlled at 450 rpm, and the modified glass fiber is obtained.

[0041] (3) Add 16 parts of epoxy resin, 22 parts of polyethylene, 8 parts of nylon, and 1 part of dispersant into a single-screw granulator for granulation and extrusion, and the particles obtained after extrusion are combined agents.

[0042] (4) After mixing 16 parts of calcium stearate, 8 parts of potassium dodecyl sulfonate, and 8 parts of PE ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com