Patents

Literature

80results about How to "Influence structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

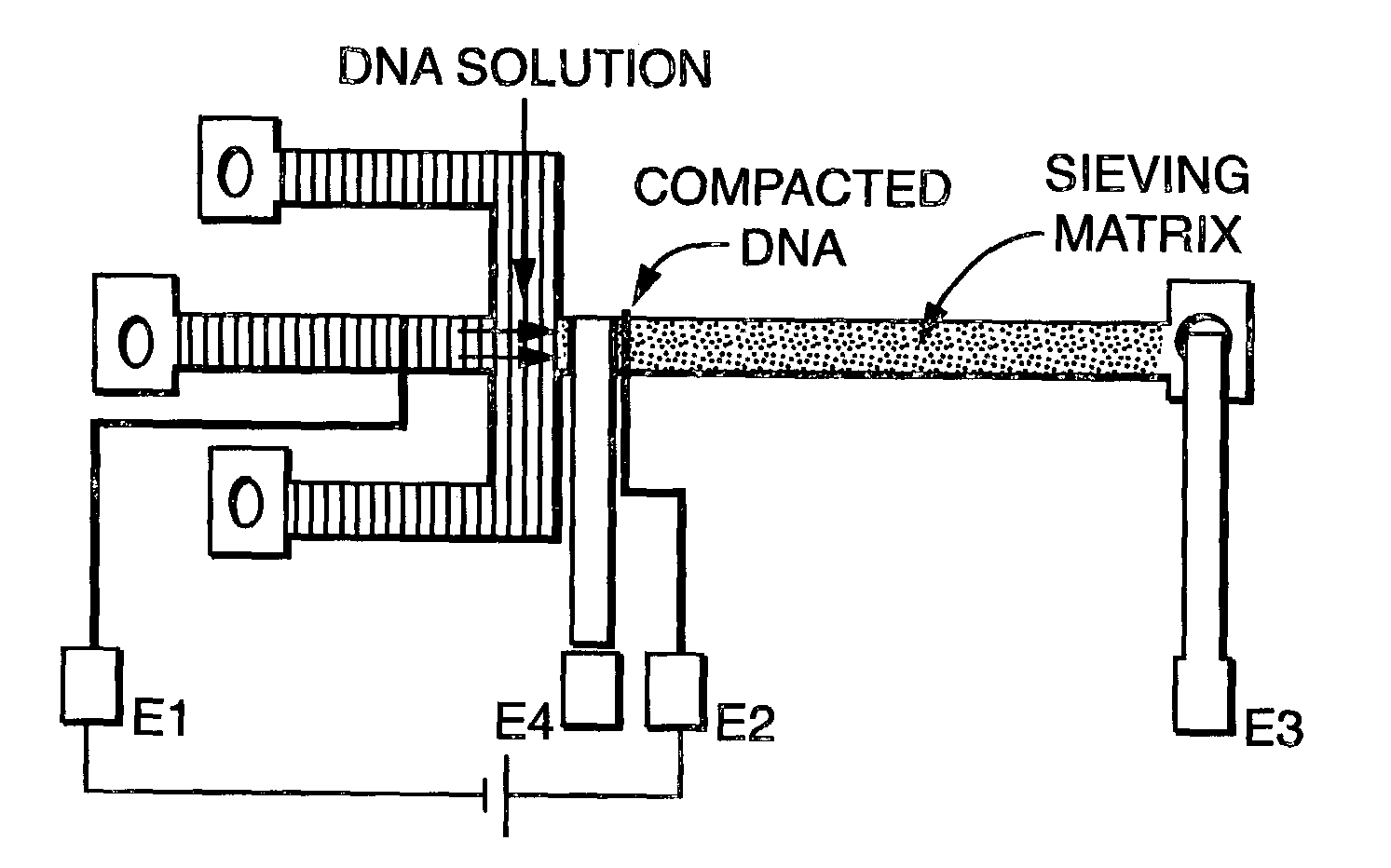

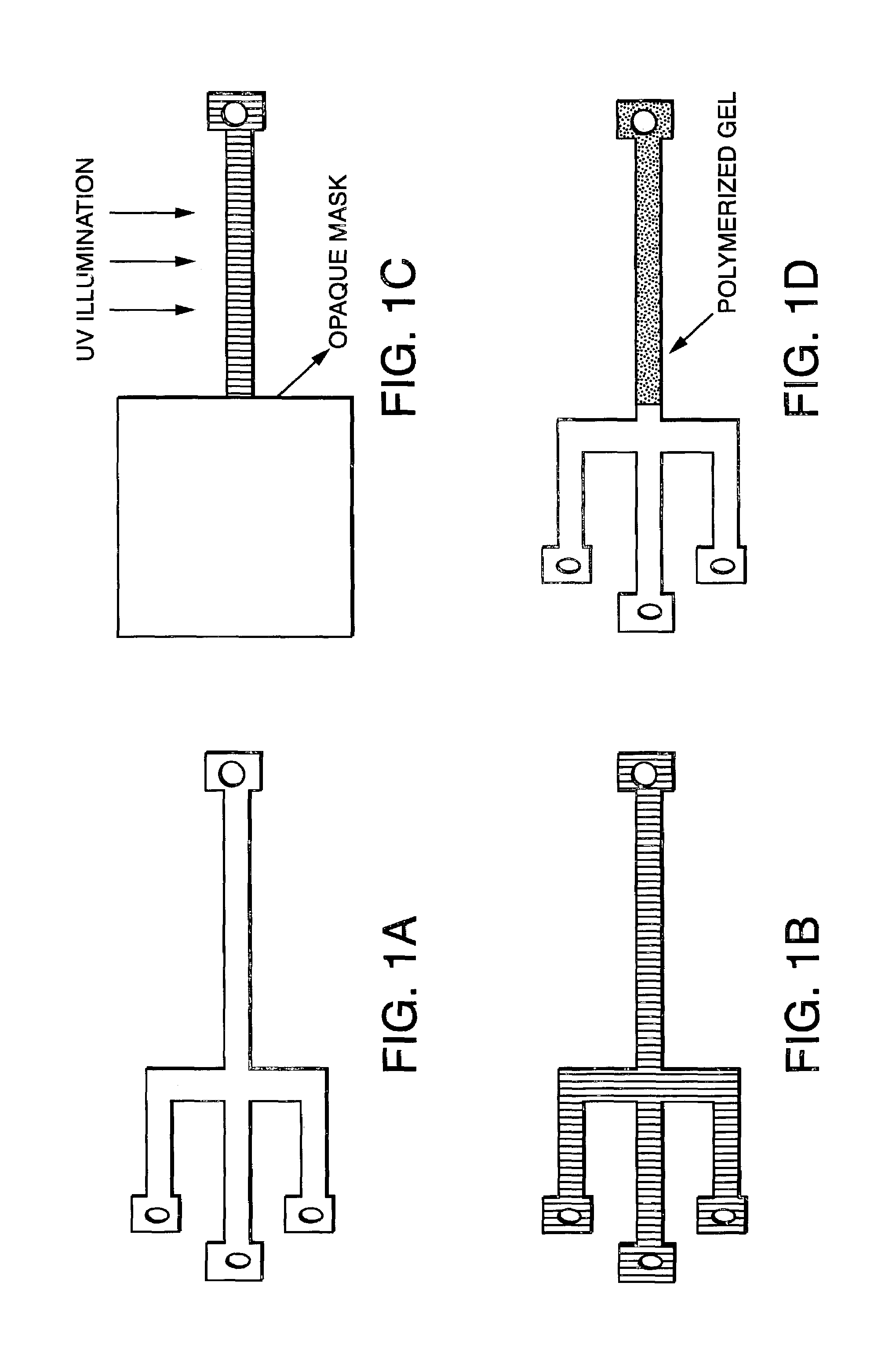

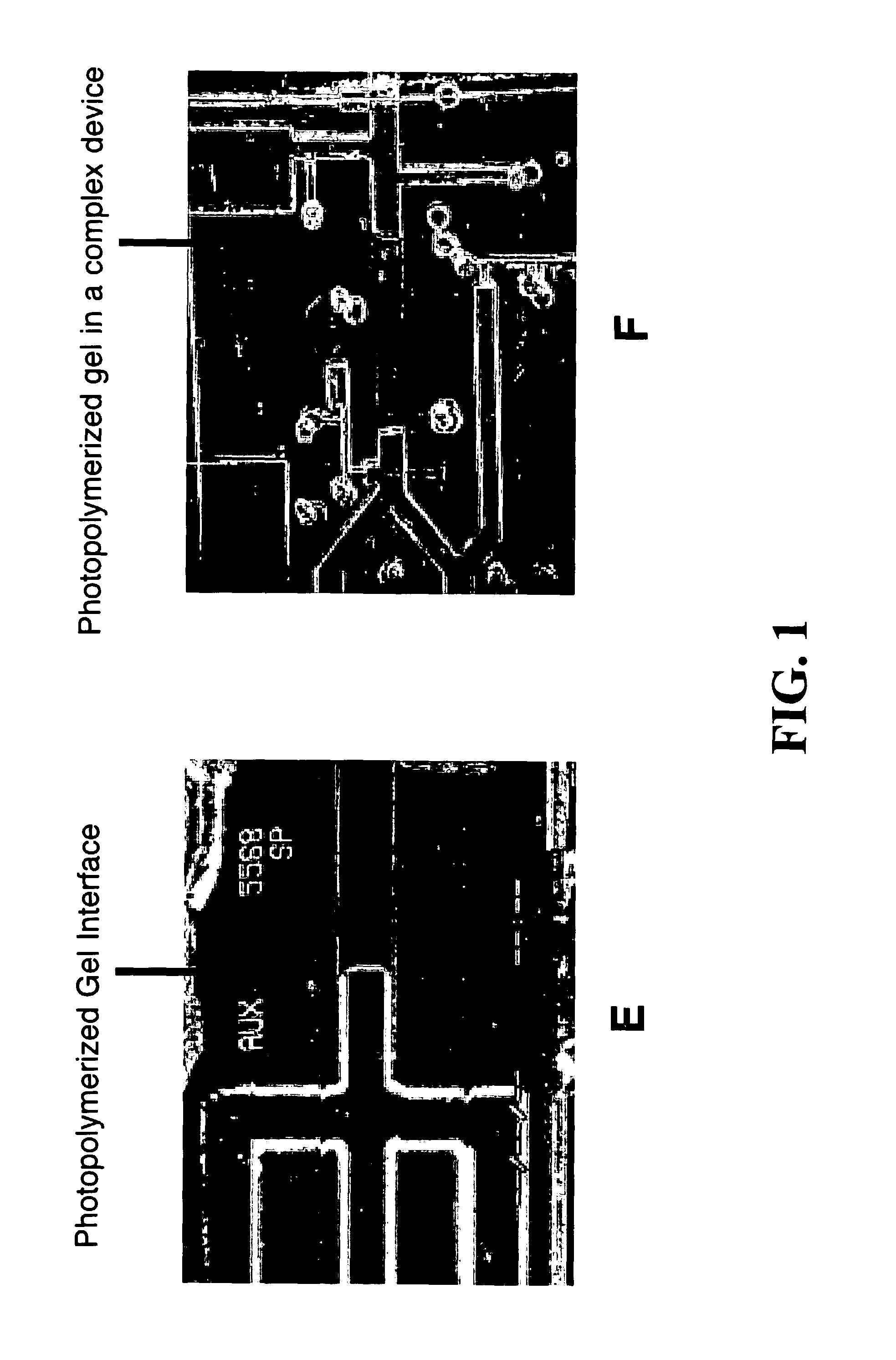

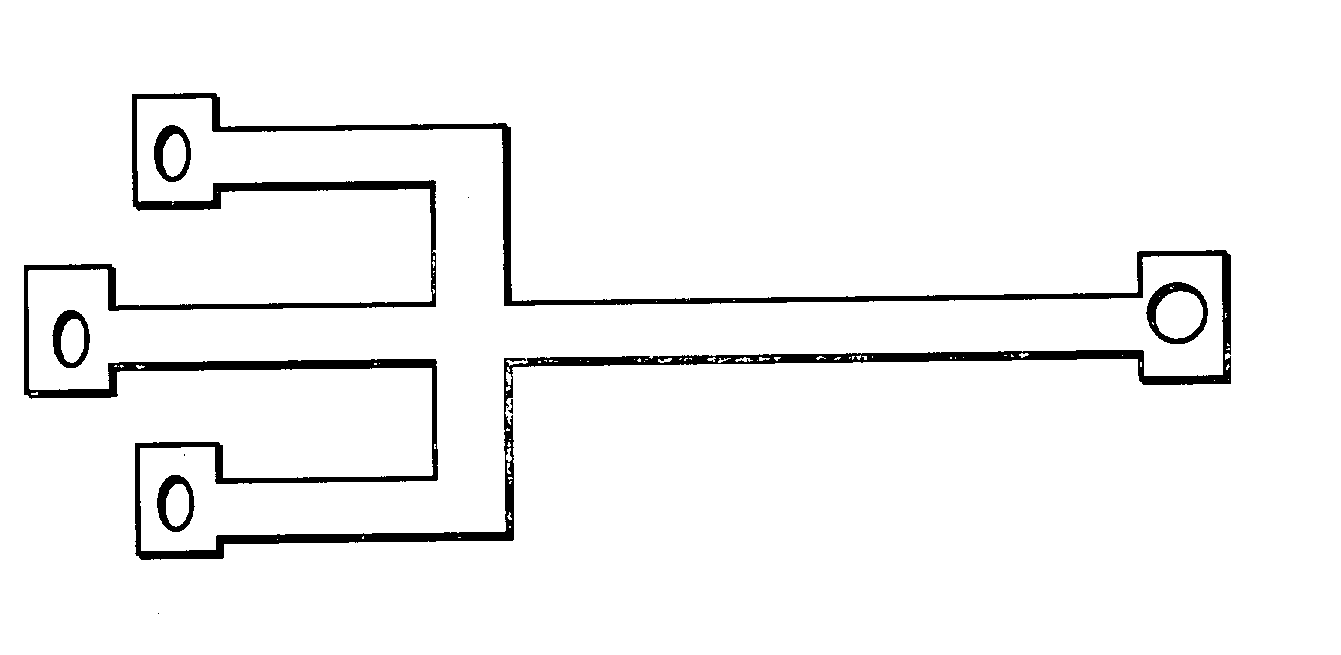

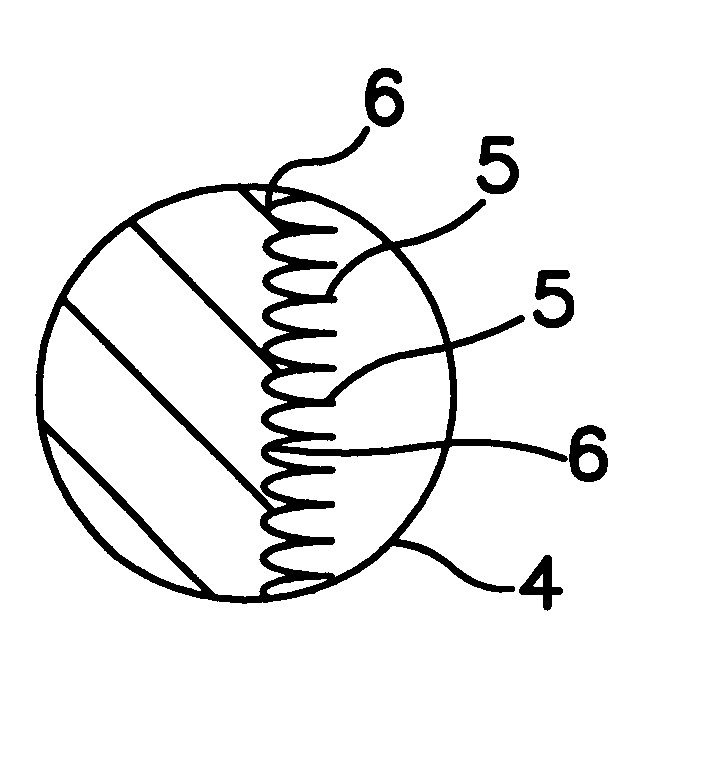

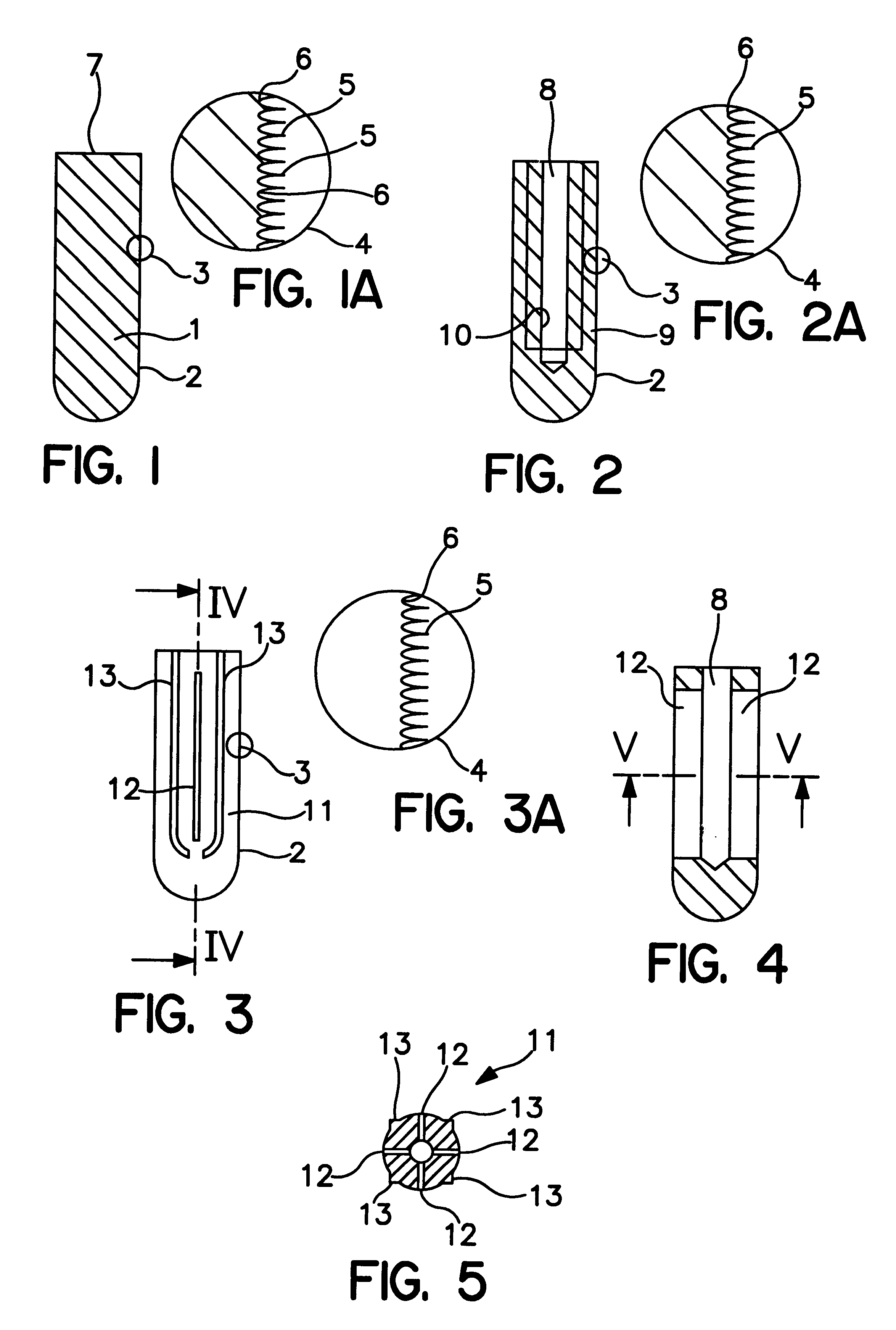

Electrophoresis in microfabricated devices using photopolymerized polyacrylamide gels and electrode-defined sample injection

InactiveUS7005050B2High resolutionLow costSludge treatmentVolume/mass flow measurementDiffusionElectrophoresis

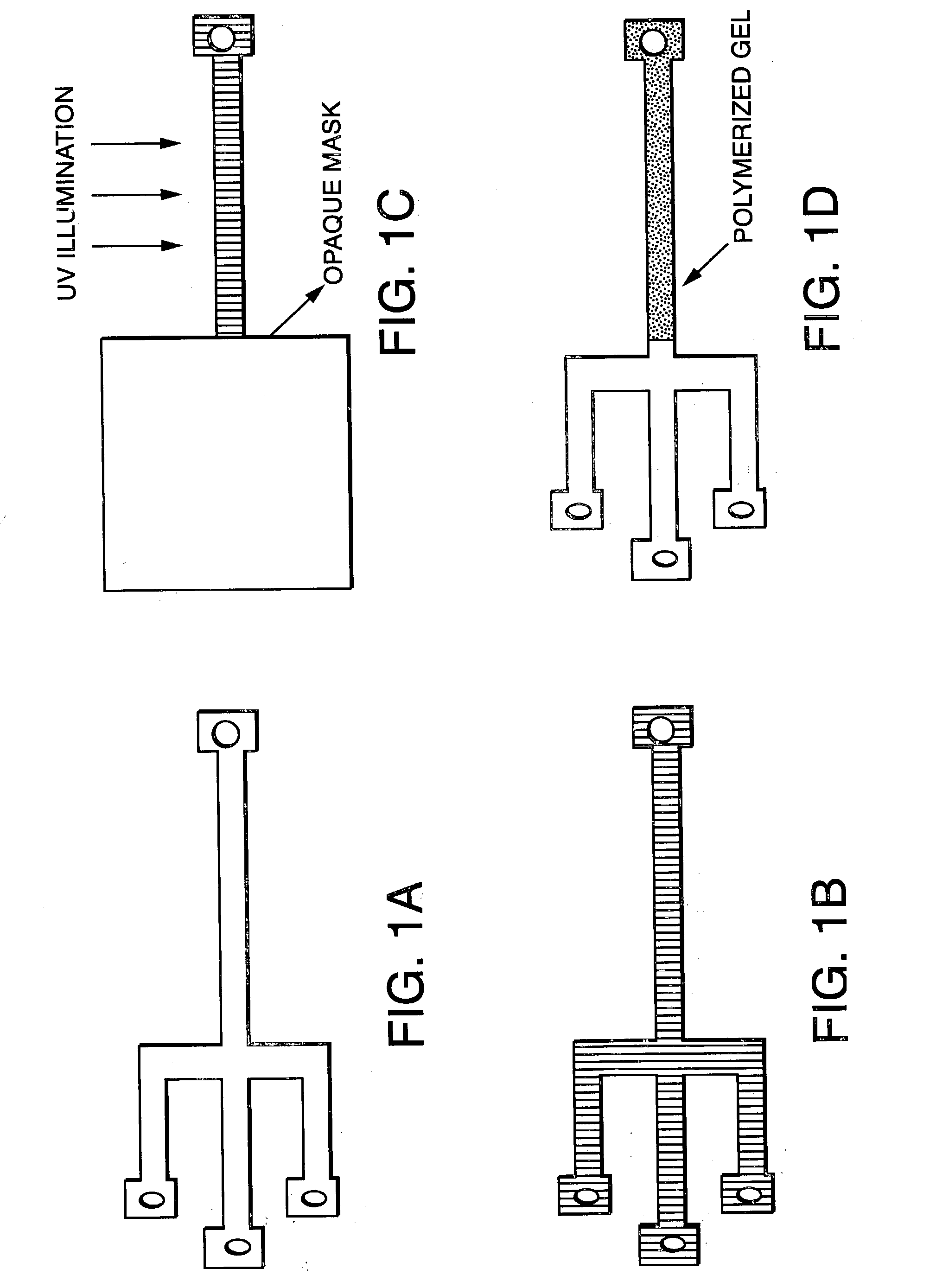

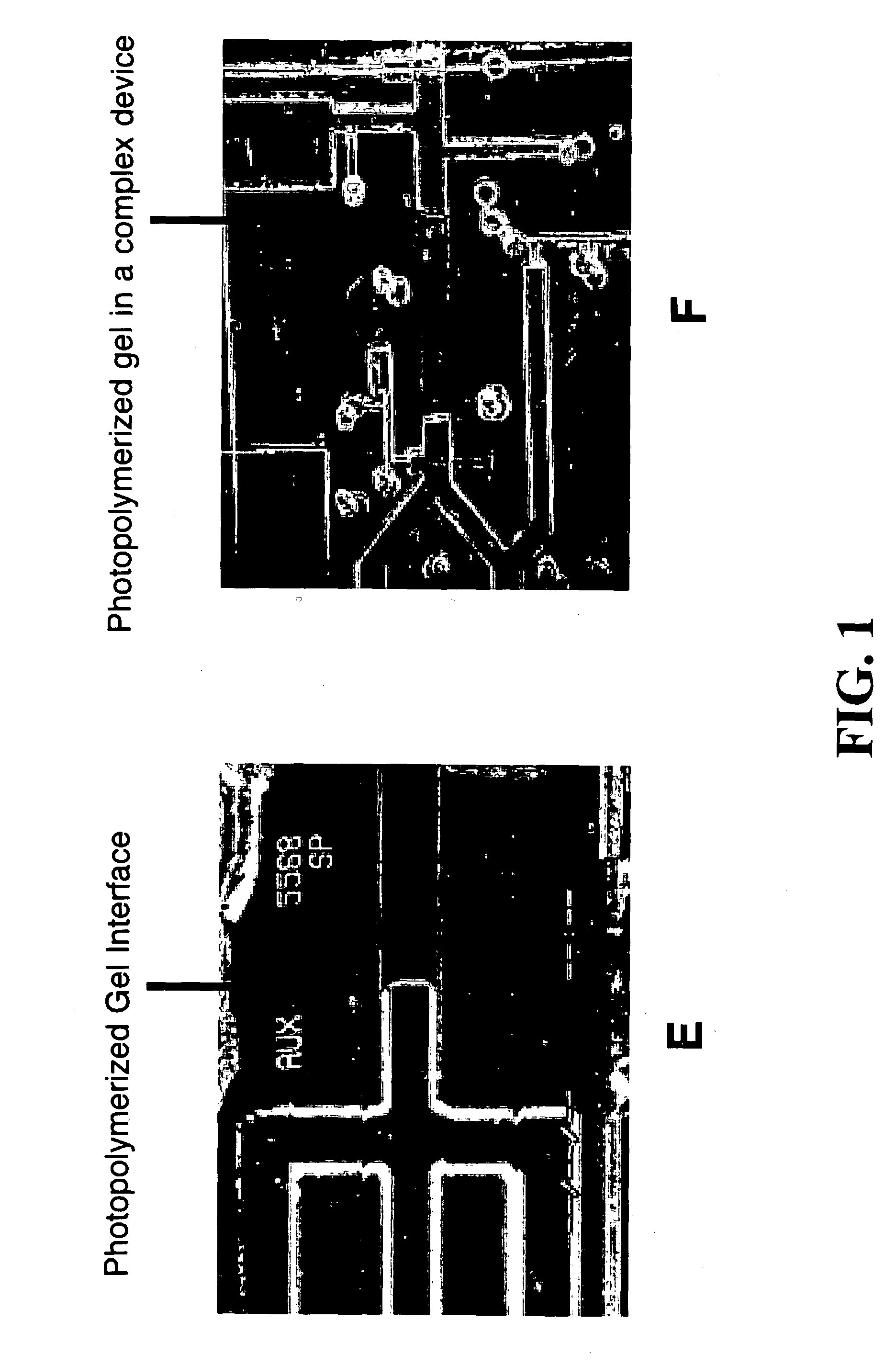

The present invention relates to a novel, small-scale, electrophoretic separation system based on photodefined polymers and electrode-defined sample injection. Diffusion and displacement coefficients may be modified by varying the gel concentration, the intensity of the incident UV radiation and the temperature at which the gel is run. The device is an major advance over current technology since it provides for a significant reduction in size of the micro-electrophoresis apparatus and a significant cost savings.

Owner:RGT UNIV OF MICHIGAN

Preparation method of starch and fatty acid compound

The invention belongs to the technical field of natural polymer modification and discloses a preparation method of a starch and fatty acid compound. The method comprises the following steps: adding de-ionized water into starch and balancing moisture in a closed container; carrying out heat treatment to obtain the starch subjected to wet and hot treatment; then adding a buffering solution to prepare a starch solution; after pre-heating, adding 2 to 5u / g pullulanase liquid to react for 4 to 5 hours; after carrying out enzyme deactivation, centrifuging and separating to obtain enzyme treatment modified starch; then stirring and gelatinizing the starch in a boiled water bath for 25 to 45 minutes and cooling to 60 to 90 DEG C to obtain gelatinized starch; then transferring the gelatinized starch into a homogenizing machine and adding fatty acid to carry out homogenization and mixing; and keeping the heat of the water bath to synthesize for 30 to 40 minutes to obtain the starch and fatty acid compound. According to the preparation method, a greener and more environment-friendly new way is provided for synthesizing the starch and fatty acid compound through wet and hot treatment and controlled enzymolysis treatment by adopting a gelatinizing method.

Owner:SOUTH CHINA UNIV OF TECH

Electrophoresis in microfabricated devices using photopolymerized polyacrylamide gels and electrode-defined sample injection

InactiveUS20030116437A1Superior resolutionCost reductionSludge treatmentVolume/mass flow measurementPhysicsCost savings

The present invention relates to a novel, small-scale, electrophoretic separation system based on photodefined polymers and electrode-defined sample injection. Diffusion and displacement coefficients may be modified by varying the gel concentration, the intensity of the incident UV radiation and the temperature at which the gel is run. The device is an major advance over current technology since it provides for a significant reduction in size of the micro-electrophoresis apparatus and a significant cost savings.

Owner:THE RGT OF THE UNIV OF MICHIGAN

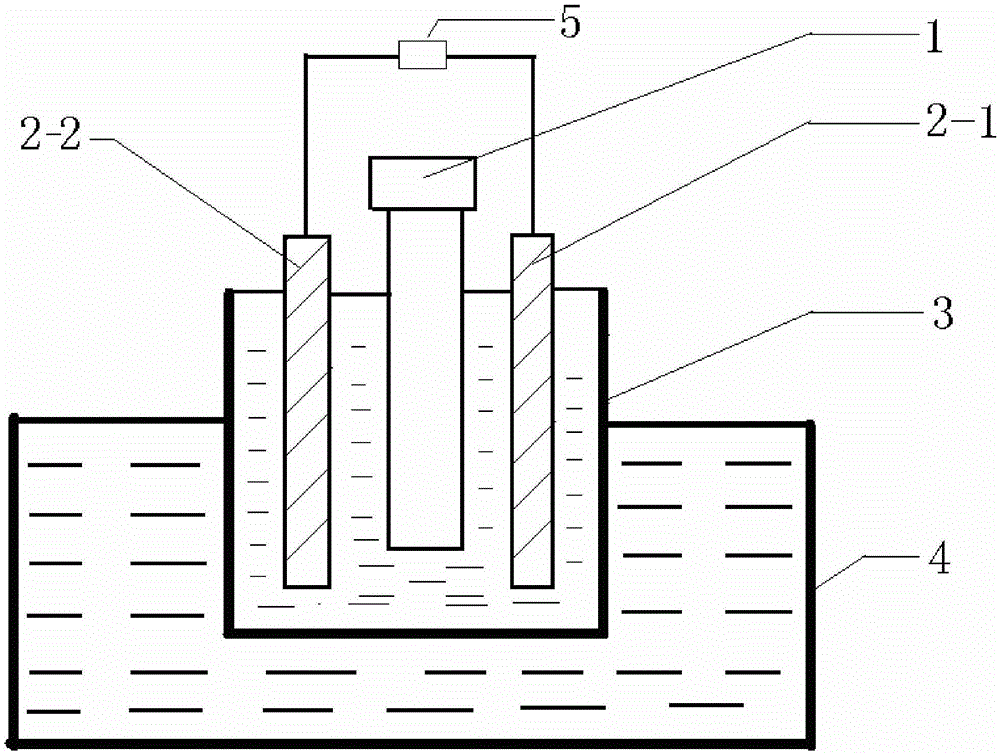

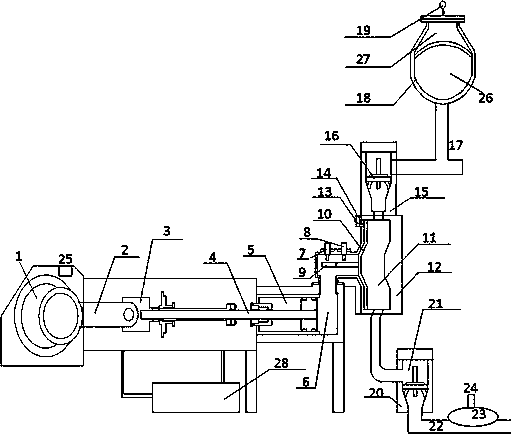

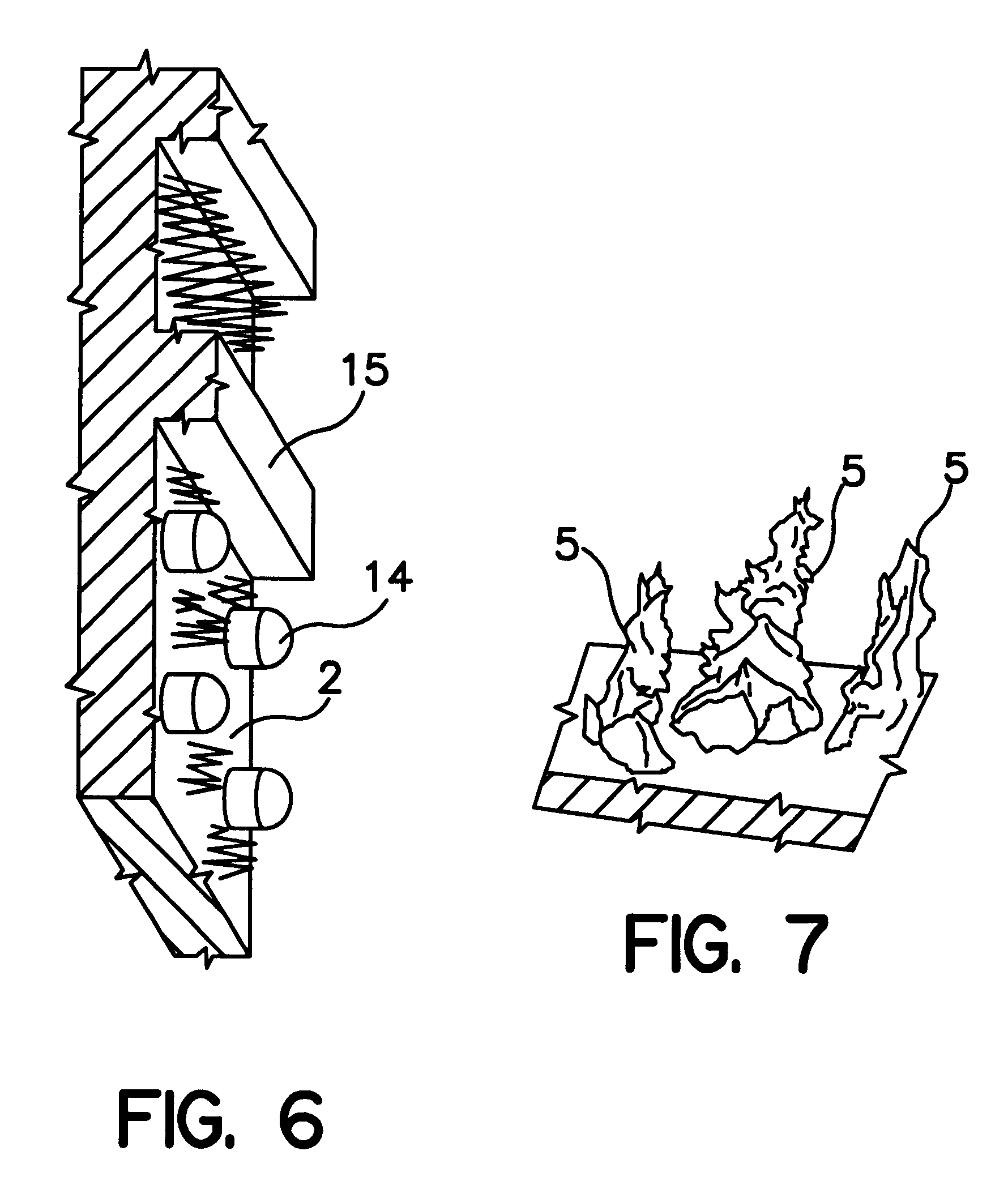

Device and method for preparing porous foam metal by metal melt inflation process

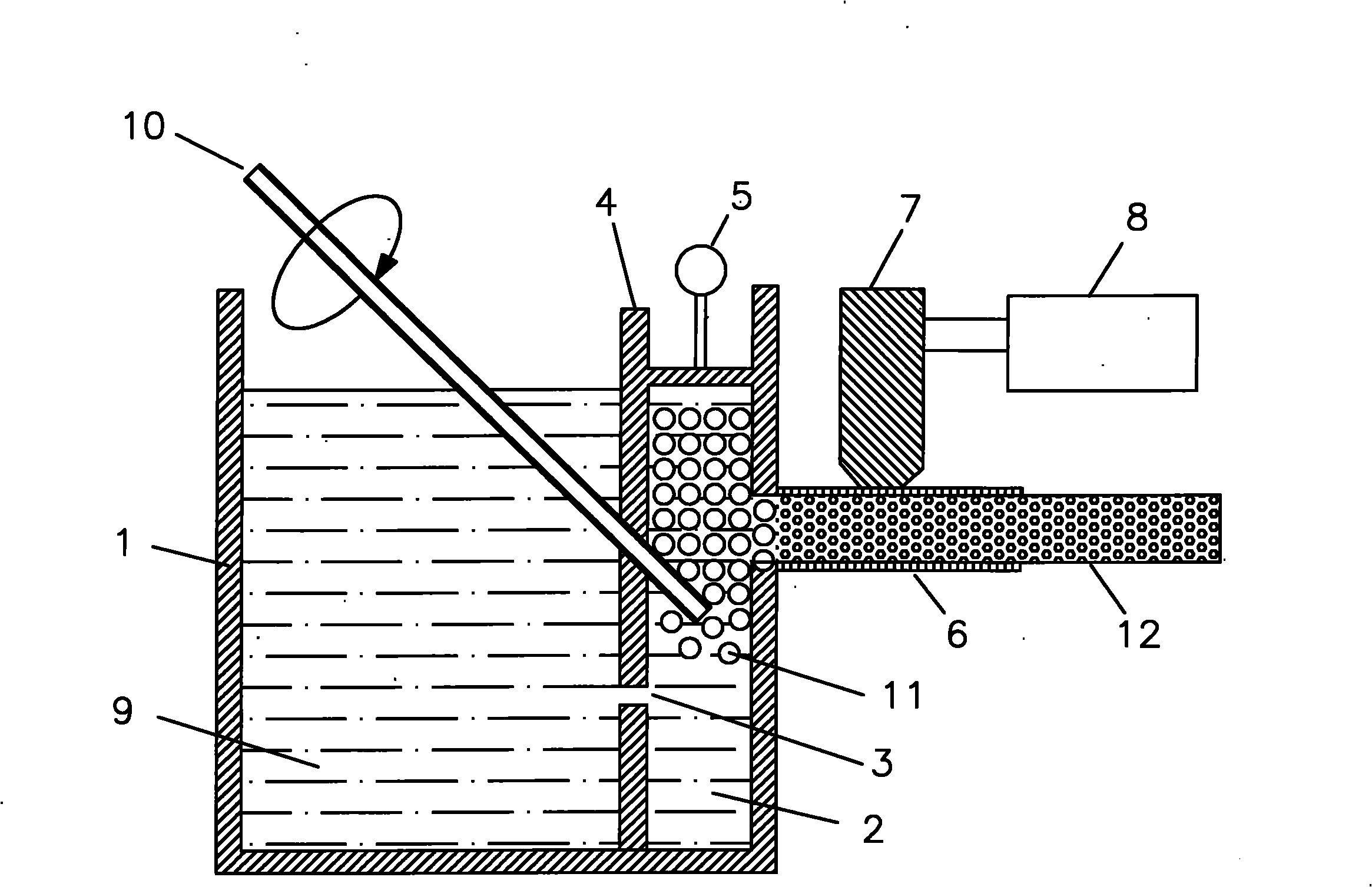

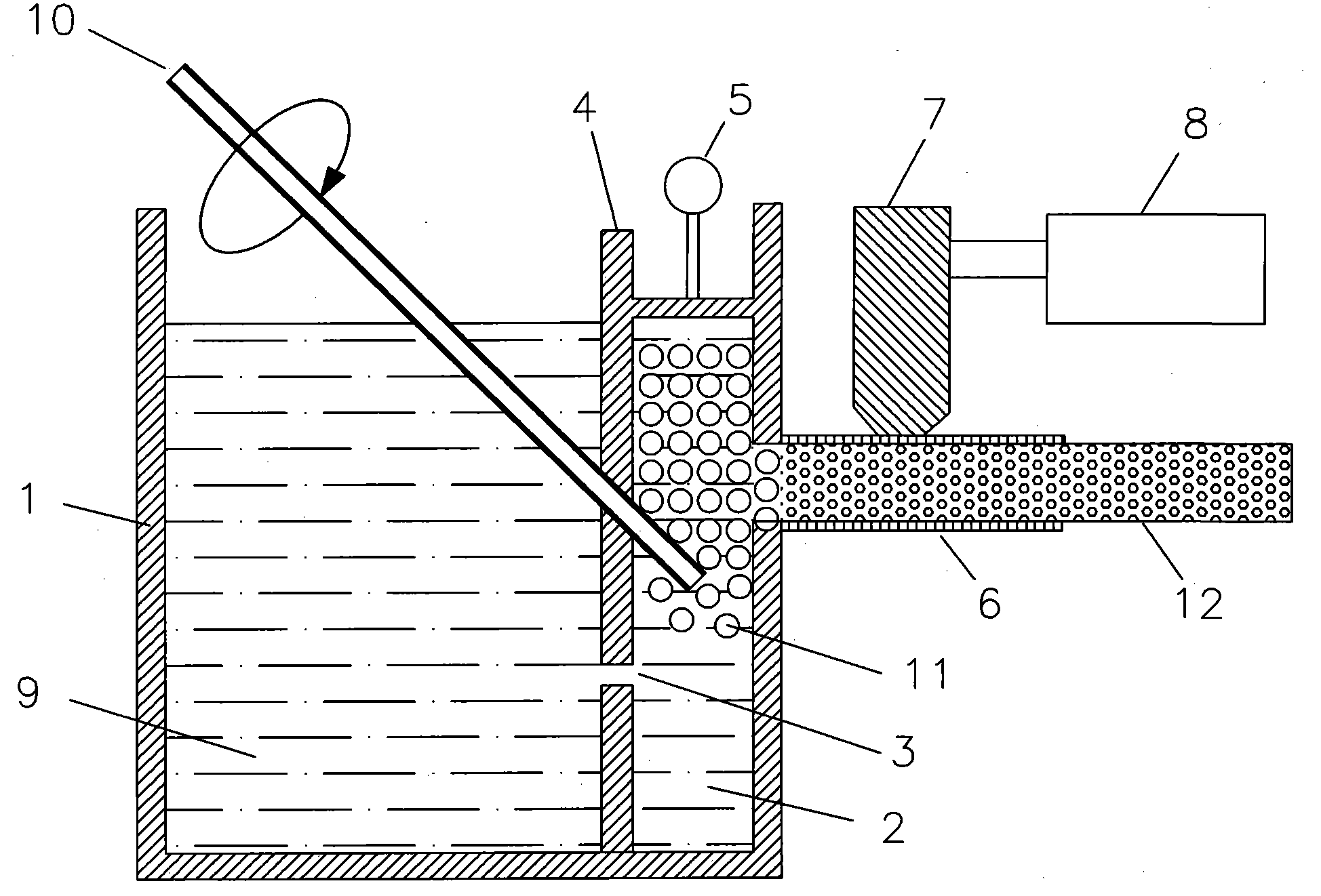

The invention discloses a device and a method for preparing porous foam metal by a metal melt inflation process. The device comprises a metal melt groove, a foaming chamber, a fluid hole, a release valve and a metal crystallizer. The middle of the metal crystallizer is provided with a high-frequency ultrasonic oscillator; and the high-frequency ultrasonic oscillator is connected with a high-frequency ultrasonic power source used for adjusting the oscillation frequency, amplitude and power of the high-frequency ultrasonic oscillator. The high-frequency ultrasonic oscillator is started, when the bubble-containing metal melt passes through the metal crystallizer, bubbles are subjected to ultrasonic oscillation for fragmentation under the action of the high-frequency ultrasonic oscillation, and a bubble is fragmented into several smaller bubbles; and the oscillation frequency and the amplitude of the high-frequency ultrasonic oscillator are adjusted, so that the fragmentation degree and the size of the bubbles meet the requirements. The bubbles formed by high-frequency ultrasonic oscillation have uniform size and distribution; and the device and the method have the advantages of simple process and low cost, and are suitable for large-scale production, promotion and application.

Owner:DALIAN MARITIME UNIVERSITY

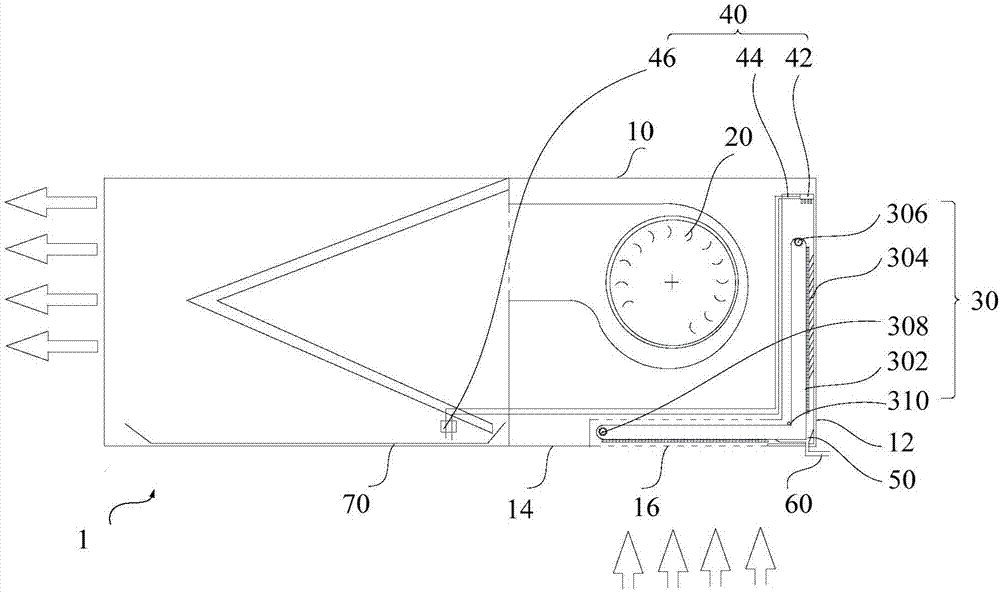

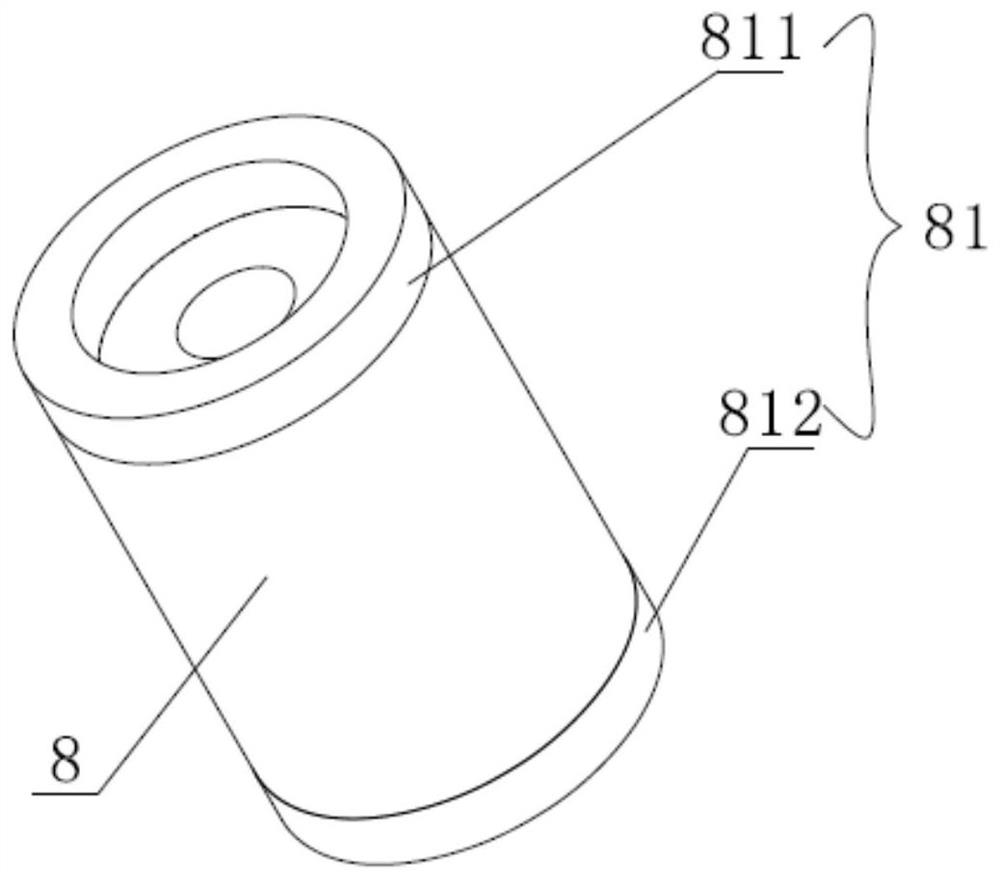

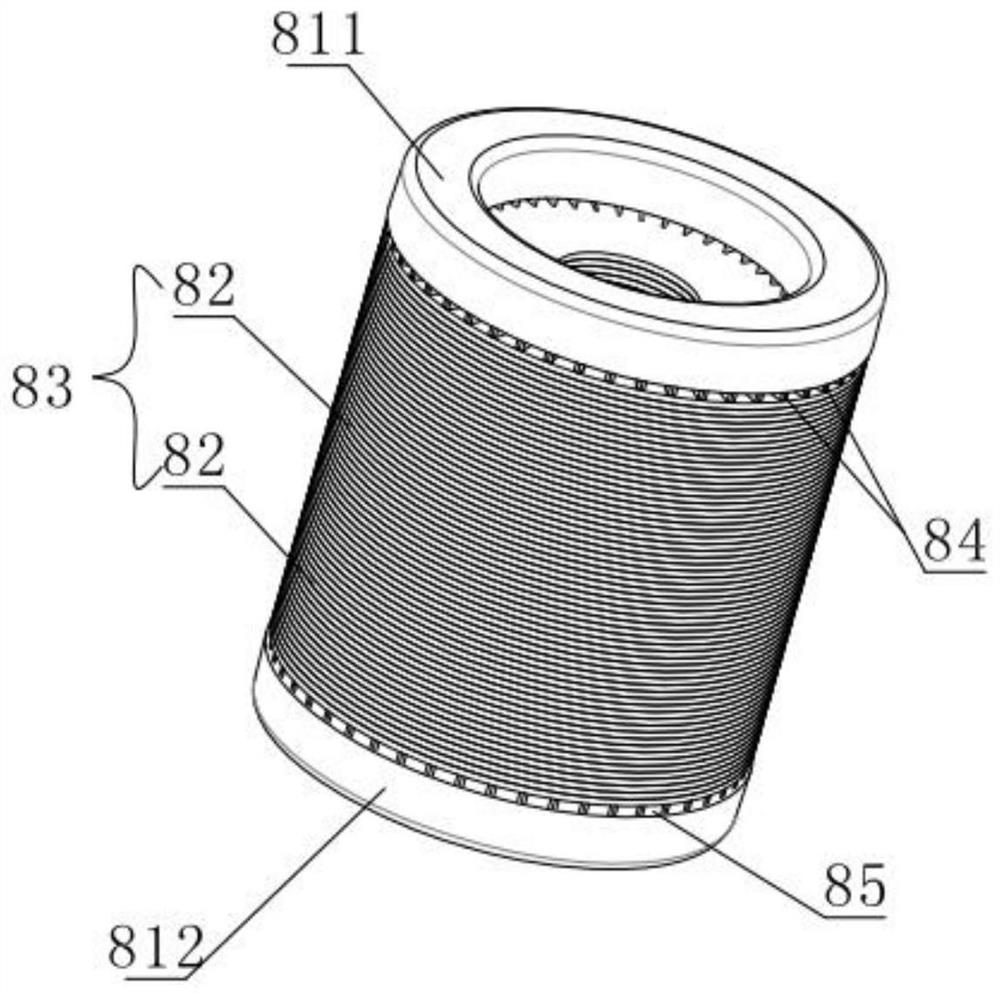

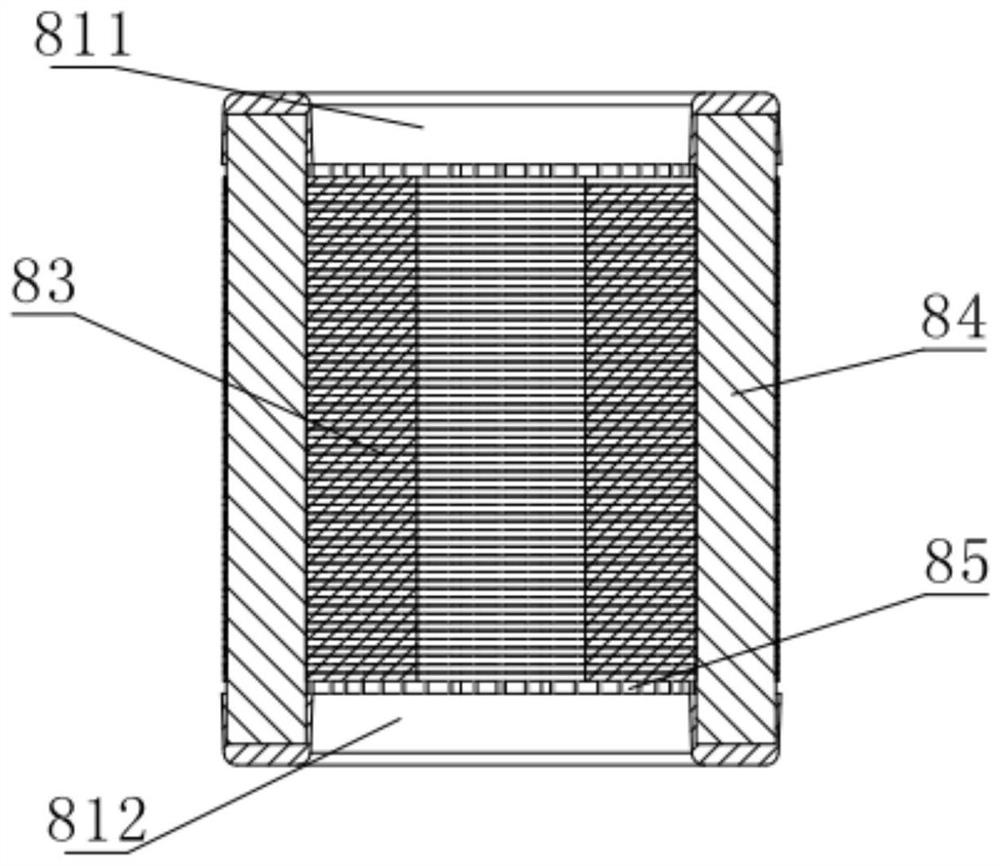

Indoor unit and air-conditioner

InactiveCN107192015AAffecting workInfluence structureCondensate preventionLighting and heating apparatusAir conditioningReturn channel

The invention provides an indoor unit and an air-conditioner. The indoor unit is used in the air-conditioner and comprises a shell, a fan and a filter screen assembly. The filter screen assembly comprises a filter screen, a hairbrush, a first transmission device, a second transmission device and a first drive device. The two ring-shaped ends of the filter screen are arranged on the first transmission device and the second transmission device in a sleeving manner correspondingly. The first drive device drives the first transmission device or the second transmission device to rotate around the self axis to drive the filter screen to rotate around the first transmission device and the second transmission device, and the filter screen covers a wind return opening in the rotating process and / or makes interference contact with the hairbrush. In the working process, the filter screen can cover the wind return opening and has a function of filtering impurities and dust, it is ensured that air entering an air-conditioning room is clean, the hairbrush can clean the dust on the filter screen automatically, and the filter screen does not need to be manually disassembled to be cleaned. An interval is reserved between the hairbrush and the wind return opening, it is effectively ensured that the filter screen assembly does not occupy a wind return channel, and the wind return efficiency is ensured.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

Double-resistant polytetrafluoroethylene microporous membrane and preparation method thereof

InactiveCN103432917AInfluence structureAffects air permeabilitySemi-permeable membranesEmulsionOil soluble

The invention discloses a double-resistant polytetrafluoroethylene microporous membrane and a preparation method thereof. The double-resistant polytetrafluoroethylene microporous membrane is prepared through the following steps of: proportionally mixing a polytetrafluoroethylene dispersion resin, double-resistant powder and an extrusion auxiliary together to form an oil-containing base band, degreasing the oil-containing base band and longitudinally stretching the oil-containing base band for the first time; treating the stretched band by using a double-resistant oil soluble emulsion; stretching the band bidirectionally to form the double-resistant polytetrafluoroethylene microporous membrane. The double-resistant polytetrafluoroethylene microporous membrane provided by the invention has the advantages of high filter efficiency, antibiosis and anti-staticelectricity, low running resistance, easy ash removal, resistance to high and low temperatures, resistance to acids and bases, and corrosion resistance.

Owner:SHANGHAI LINFLON FILM TECH

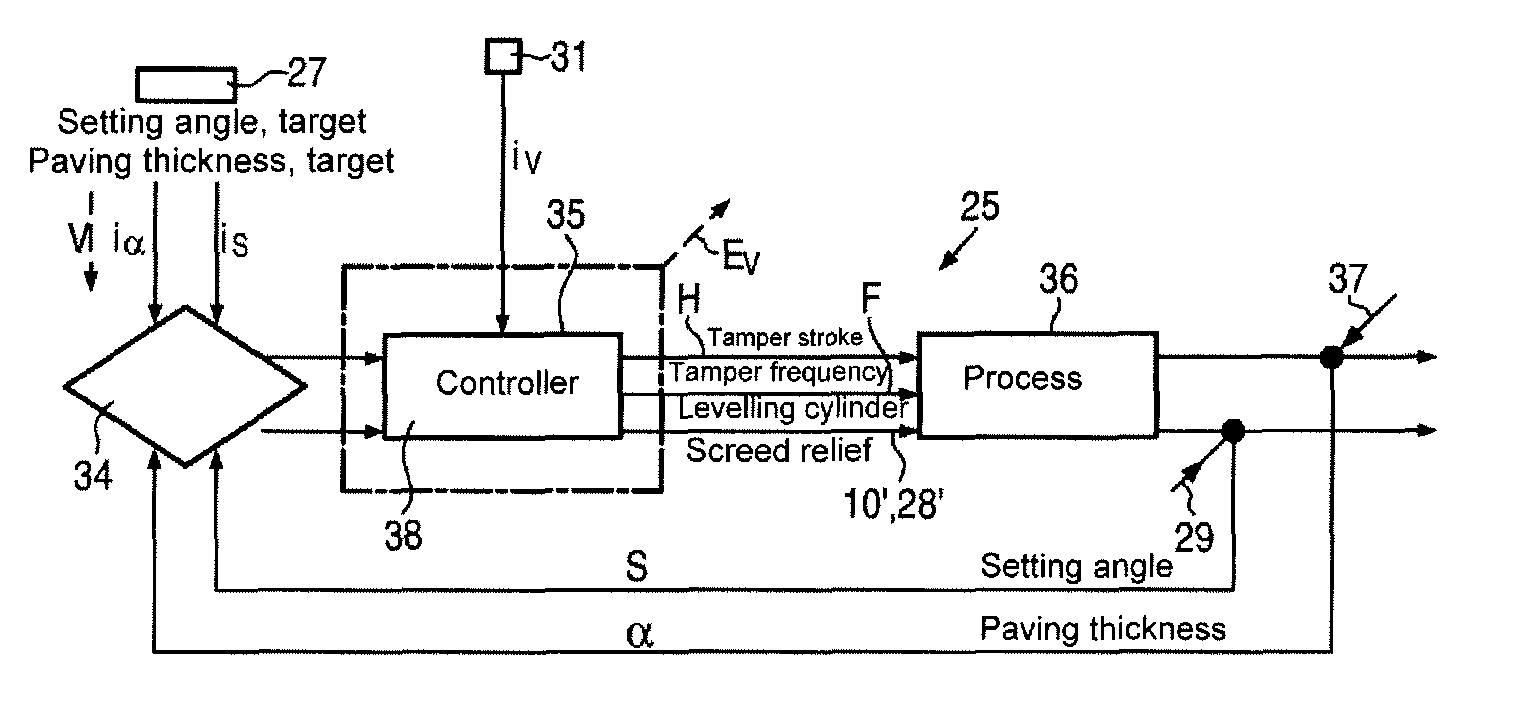

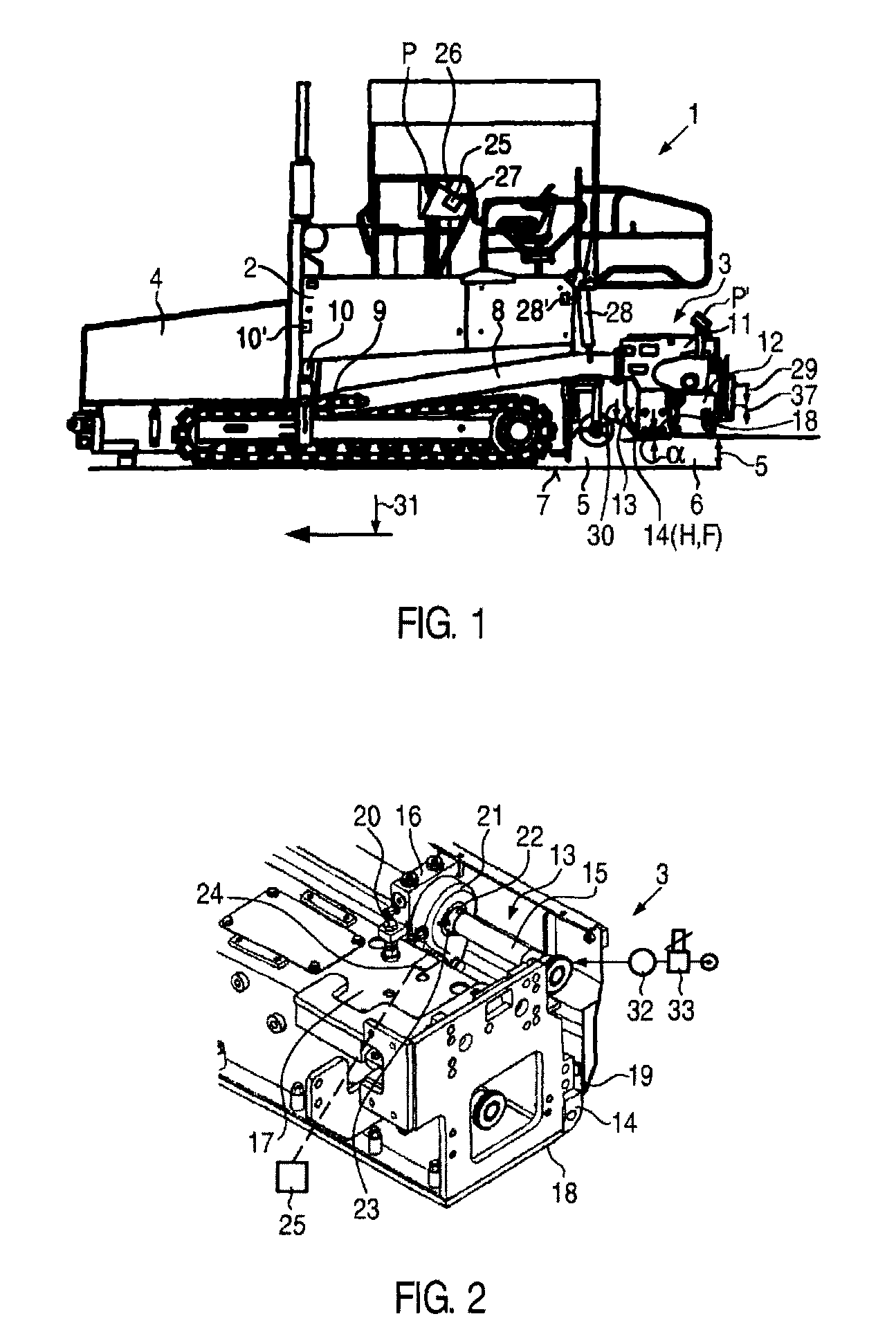

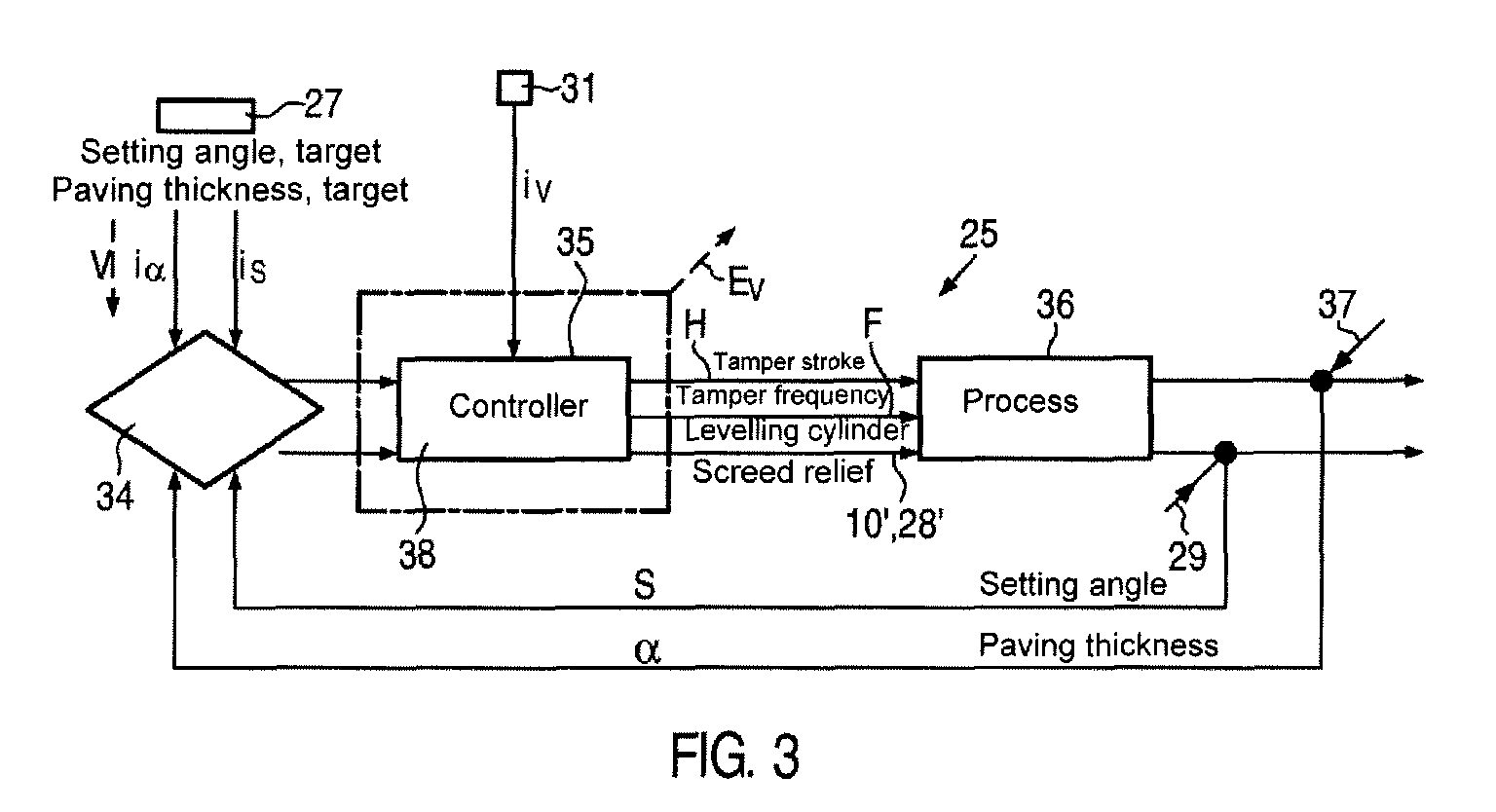

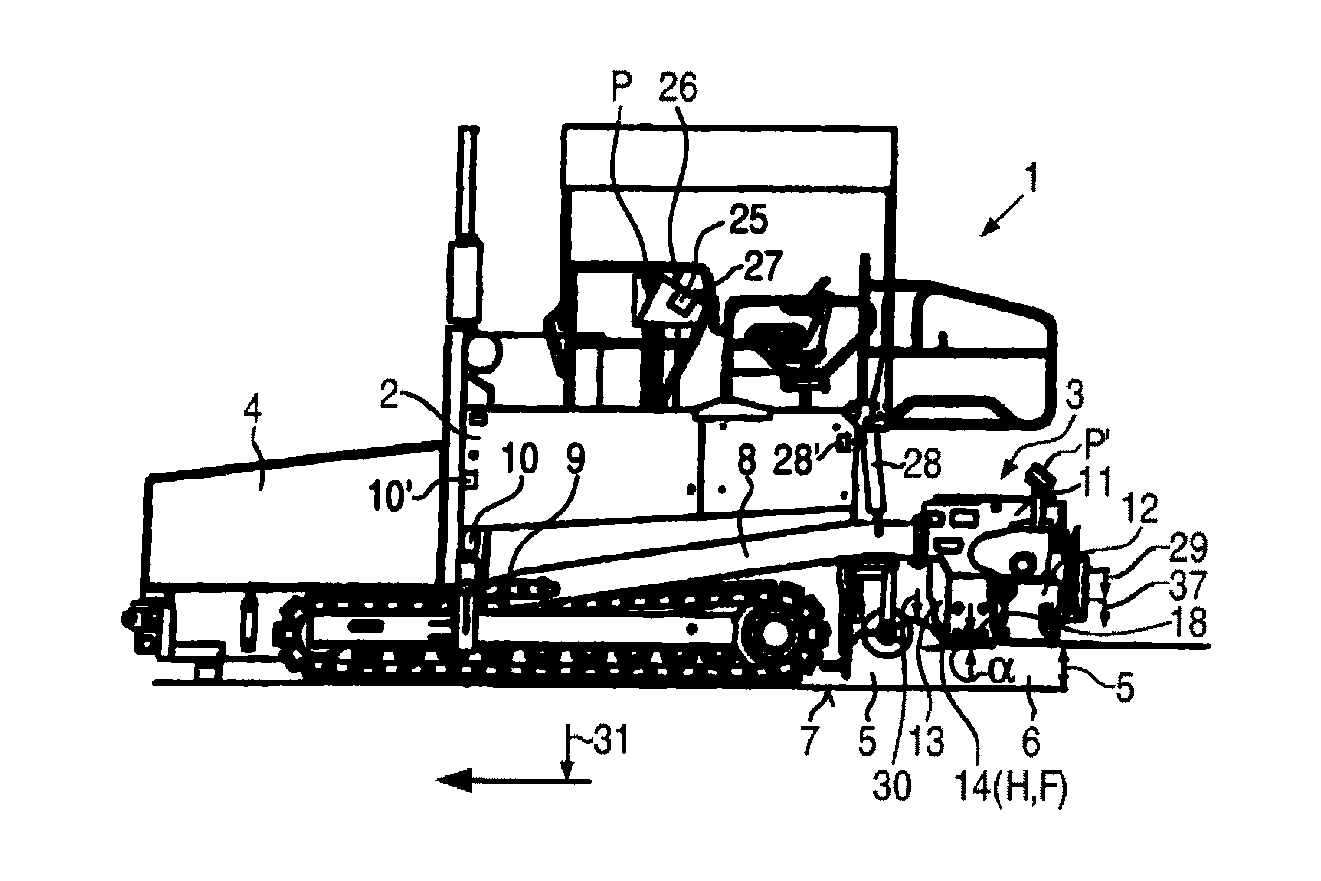

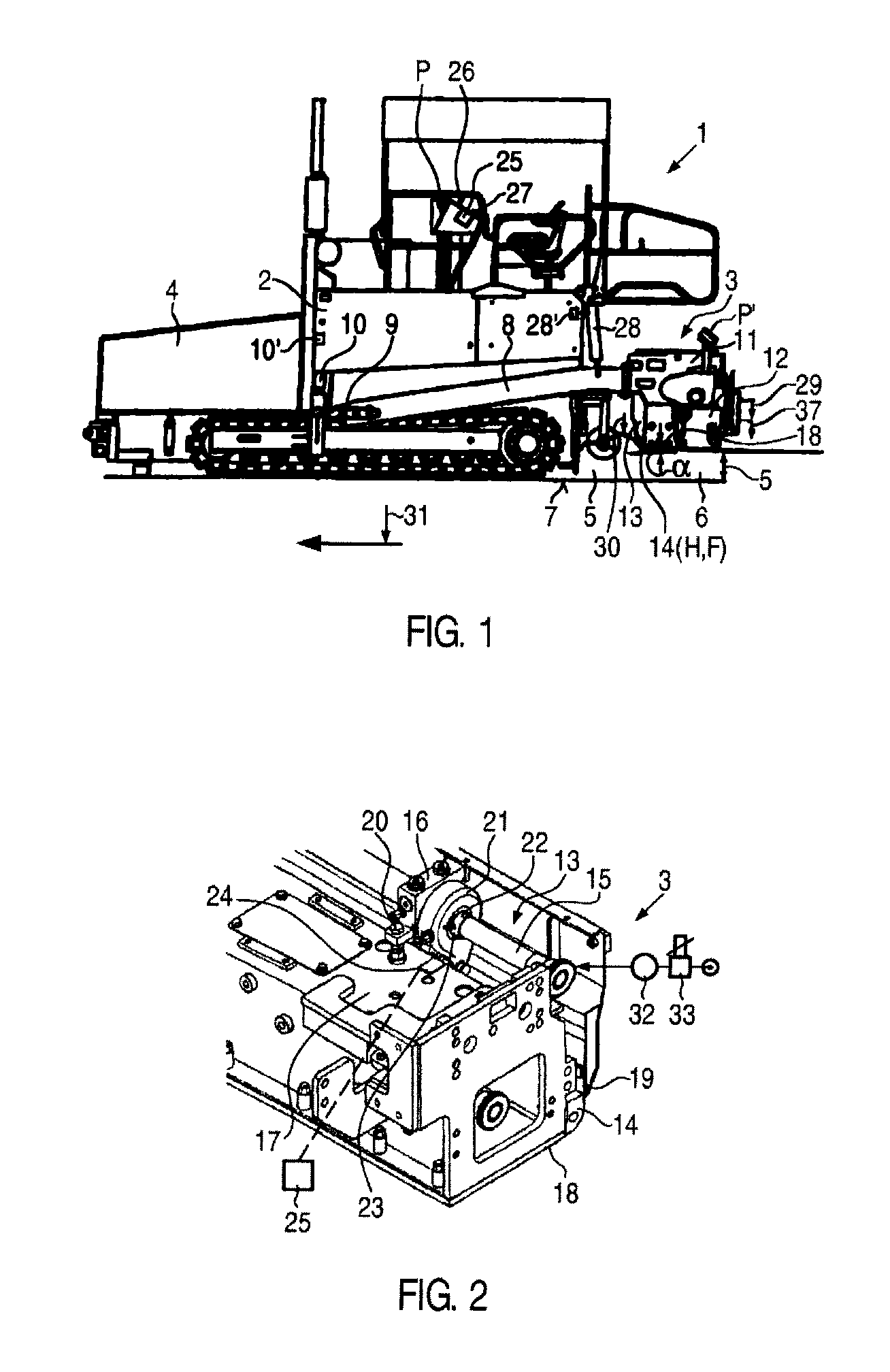

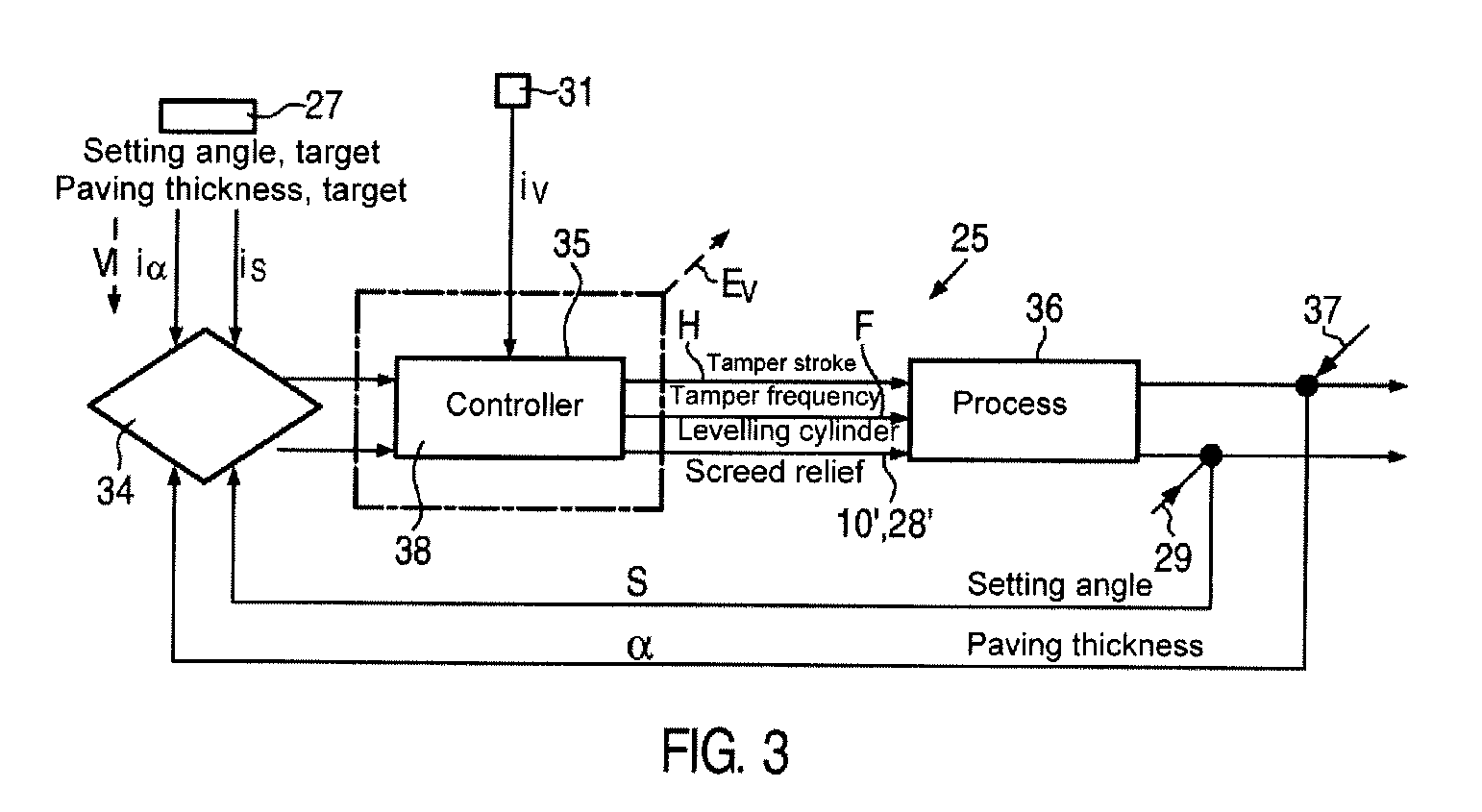

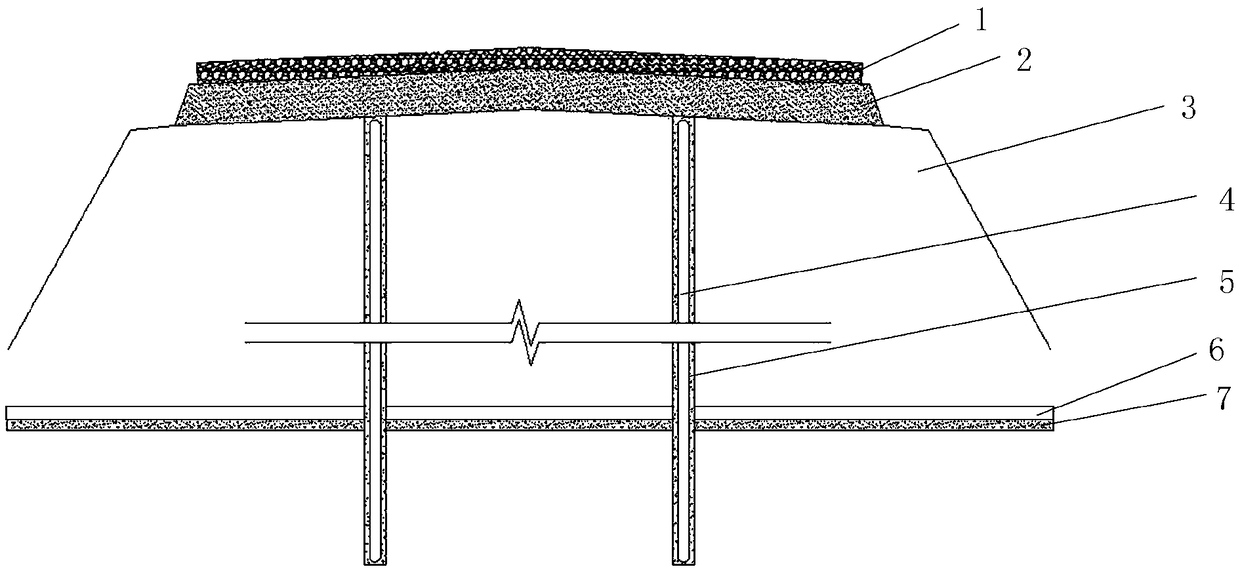

Method for controlling the process when producing a paving mat and road finisher

ActiveUS8454266B2Direct controlImprove the sense of responsibilityPaving detailsRoads maintainenceScreedOperating point

A method for controlling the process laying a layer in a selectable paving thickness with a road finisher in which the laying process is automatically controlled in that a target value for the paving thickness is entered into an automatic closed-loop control system and communicates the actuating signals to such members and the signals. A road finisher has a computerized, either fully automatic or operator aided closed-loop control system for the direct control of the laying process with control of the paving thickness to a predetermined target value and for the optimization of the operating point of the pre-compaction system, which is connected to sensors at least for the acquisition of the setting angle of the screed, of the paving thickness and of the laying rate.

Owner:JOSEPH VOEGELE AG

Device for quickly peeling graphene under ultrasonic and electric field synergistic effect and method for quickly peeling graphene by using same

The invention relates to a device for quickly peeling graphene under an ultrasonic and electric field synergistic effect and a method for quickly peeling the graphene by using the device, and belongs to the technical field of materials. The problem that various defects exist in an existing method for preparing the graphene is solved. The device comprises an ultrasonic device, a graphite positive electrode, a graphite negative electrode and a container. The method comprises the following steps: firstly, preparing the device; secondly, applying ultrasonic wave to control the forward and reverse voltages of graphite electrodes; thirdly, after the reaction is finished, filtering, collecting sediments, washing and carrying out freeze drying to obtain the graphene. High-purity graphite is taken as the positive and negative electrodes, an intercalation agent in electrolyte enters into the graphite electrodes under the ultrasonic and electric field synergistic effect, so that the graphene is quickly peeled from the surface of a graphite block body and is further crashed, and the obtained graphene is good in uniformity and dispersibility. The device is simple, simple in technology and low in cost, cannot cause influence on the structure and performance of the graphene, is green and environment-friendly, and is convenient for industrial production.

Owner:焦云 +1

Method for controlling the process when producing a paving mat and road finisher

ActiveUS20110229263A1Direct controlImprove the sense of responsibilityPaving detailsRoads maintainenceScreedOperating point

A method for controlling the process laying a layer in a selectable paving thickness with a road finisher in which the laying process is automatically controlled in that a target value for the paving thickness is entered into an automatic closed-loop control system and communicates the actuating signals to such members and the signals. A road finisher has a computerized, either fully automatic or operator aided closed-loop control system for the direct control of the laying process with control of the paving thickness to a predetermined target value and for the optimization of the operating point of the pre-compaction system, which is connected to sensors at least for the acquisition of the setting angle of the screed, of the paving thickness and of the laying rate.

Owner:JOSEPH VOEGELE AG

Solvent modifying method for polyamide composite film

InactiveCN1569317AEasy to separateDoes not affect chemical stabilitySemi-permeable membranesSeparation factorComposite film

The invention is a solvent modification method for film. The polyamide compound film is immersed in the polyamide solvent, bleached in deioned water, dried in room temperature, and the modified polyamide penetration vaporous compound film can be acquired. The pressure of the modified film to water compound containing 87wt% of isopropyl alcohol under 25deg.C is less than 1000 Pa, the water flux is 174g / m2h-405g / m2h, the separation factor is 174-276, the percent swell rate to water and isopropyl alcohol are 31.7-40.89 and 10.24-15.73, after modified, the water flux is decreased about 51%, the upgrading rate of separation factor reaches to 144%, the percent swell rate to water is upgraded about 10%-42%, the percent swell rate to is decreased to 4%-39%. The invention is simple.

Owner:HANGZHOU WATER TREATMENT TECH RES & DEV CENT NAT BUREAU OF OCEANGRAPHY

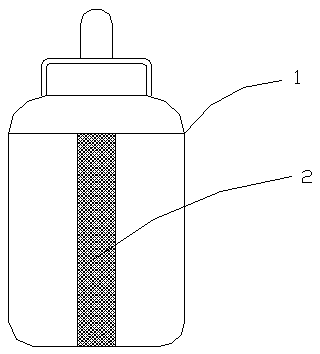

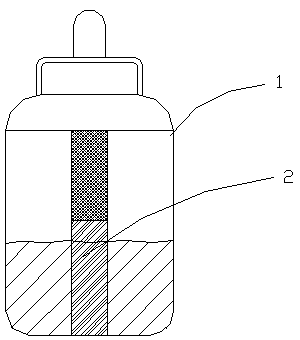

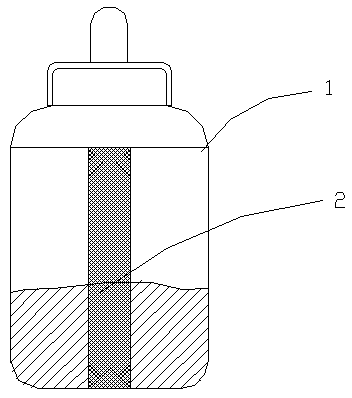

Temperature sensing milk bottle

The invention relates to a temperature sensing milk bottle, which is made of plastic or silica gel suitable for the milk bottle; a temperature sensing and color developing area is arranged on the side surface of a bottle body; the single lamellar bottle body is formed by integrating the temperature sensing and color developing area with the peripheral area; and the temperature sensing and color developing area is modulated in a manner of presenting a first color when the temperature is in a first temperature range and presenting a second color when the temperature rises to a second temperature range. The temperature sensing milk bottle has the advantages that on the basis that the structure, a material and the process of the existing milk bottle are maintained as much as possible, the function of sensing temperature changes in the specific area on the bottle body through color changes is provided.

Owner:广州永盈橡胶制品有限公司

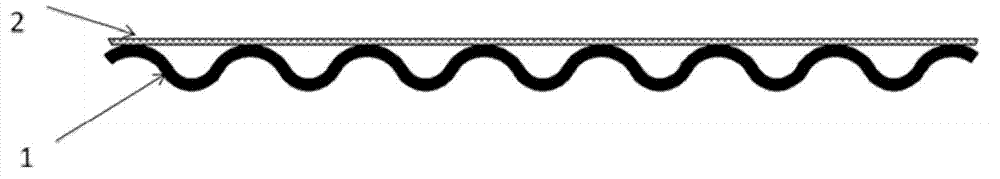

High-integration-level fuel cell bipolar plate for optimizing distribution of reaction gas

InactiveCN103618091ARaise the concentration of the reactant gasIncrease output powerFinal product manufactureCell electrodesEngineeringFluid field

The invention provides a high-integration-level fuel cell bipolar plate for optimizing the distribution of reaction gas. According to the high-integration-level fuel cell bipolar plate, the bipolar plate is in a two-layer structure; a lower layer is a metal plate punched with a runner and an upper layer is a net-shaped porous flow field plate; the net-shaped porous flow field plate is a flat plate; the net-shaped porous flow field plate is arranged on the metal plate punched with the runner to form an anode plate or a cathode plate. The high-integration-level fuel cell bipolar plate for optimizing the distribution of the reaction gas has the beneficial effects that the concentration of the reaction gas of a membrane electrode opposite to a convex part of the flow field under a galvanic pile assembling condition can be improved obviously; the effective area of an electrode in a galvanic pile operation process is improved greatly; the output power and the specific power density of a galvanic pile are improved greatly; transition is formed between a microcosmic size pore of electrode carbon paper and the macroscopic size runner of the metal plate by the porous flow field plat, so that the discharging of liquid-state water generated by a reaction is facilitated and the water management of a fuel cell is simplified; materials are simple and novel materials do not need to be explored; the structure is simple and only a conventional structure of an existing fuel cell needs to be improved simply; great influences on the assembling and the structure of the galvanic pile are avoided.

Owner:SUNRISE POWER CO LTD

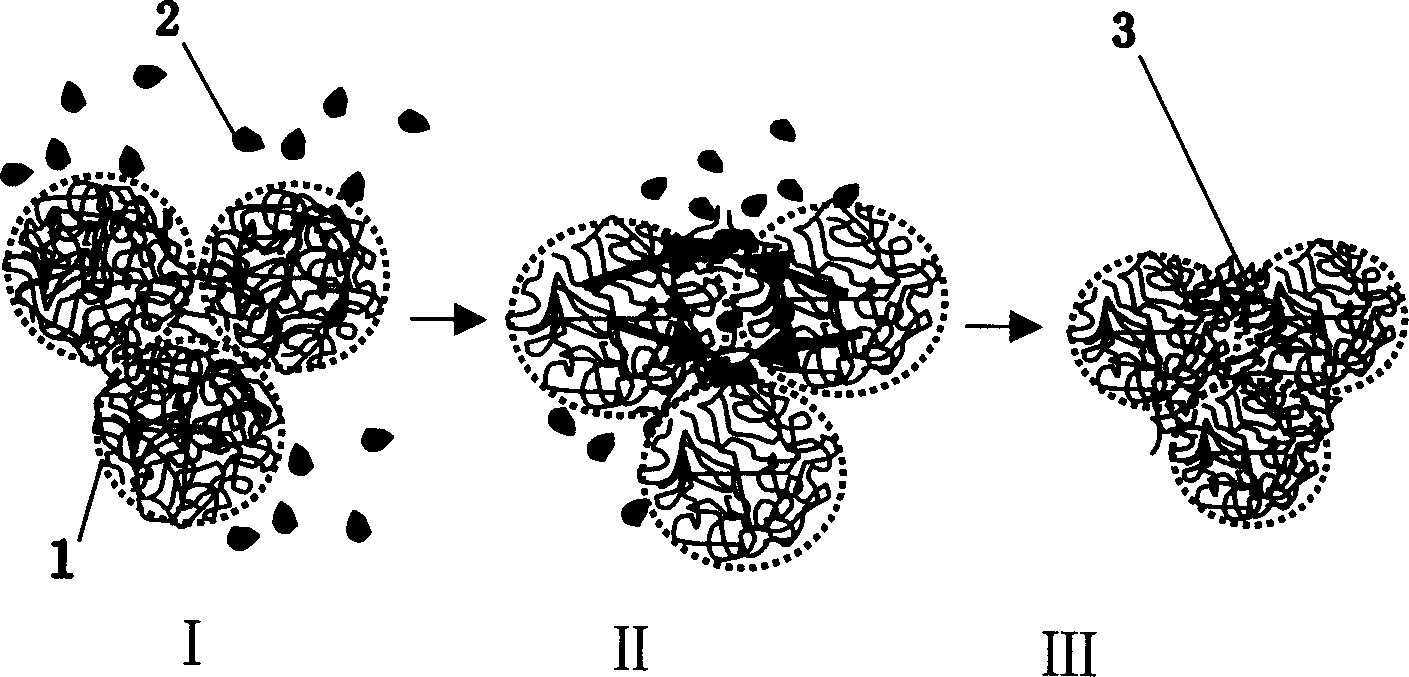

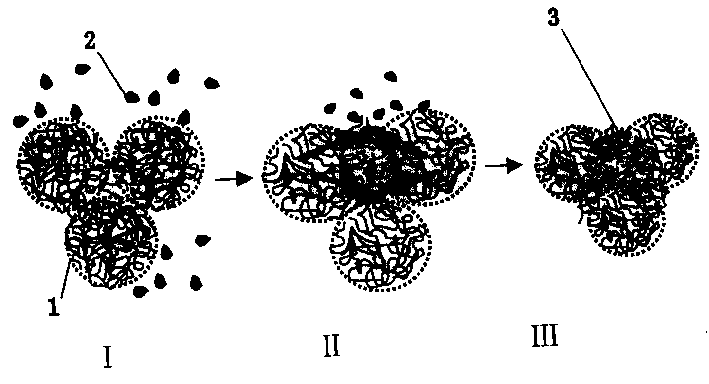

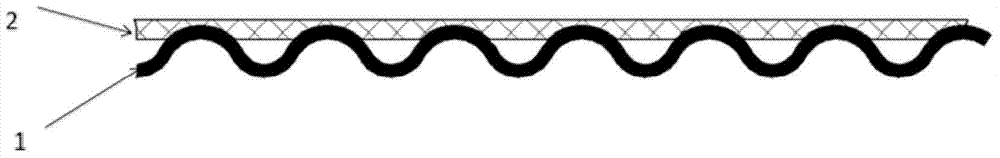

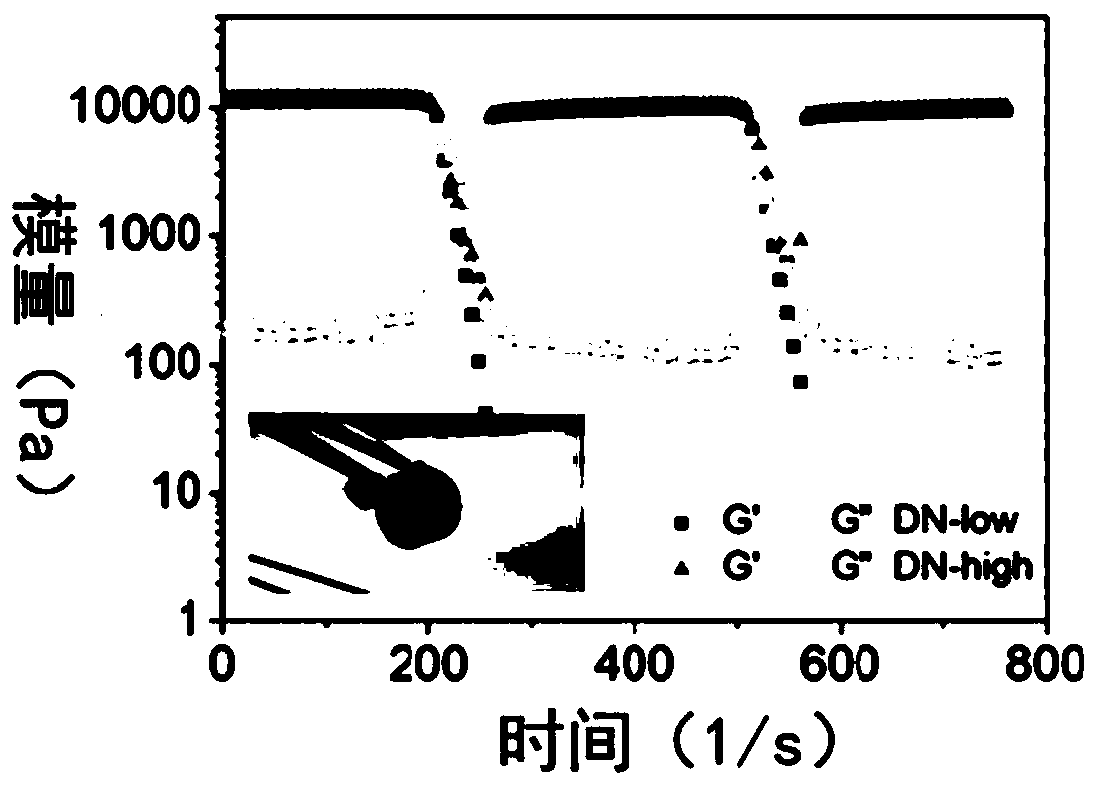

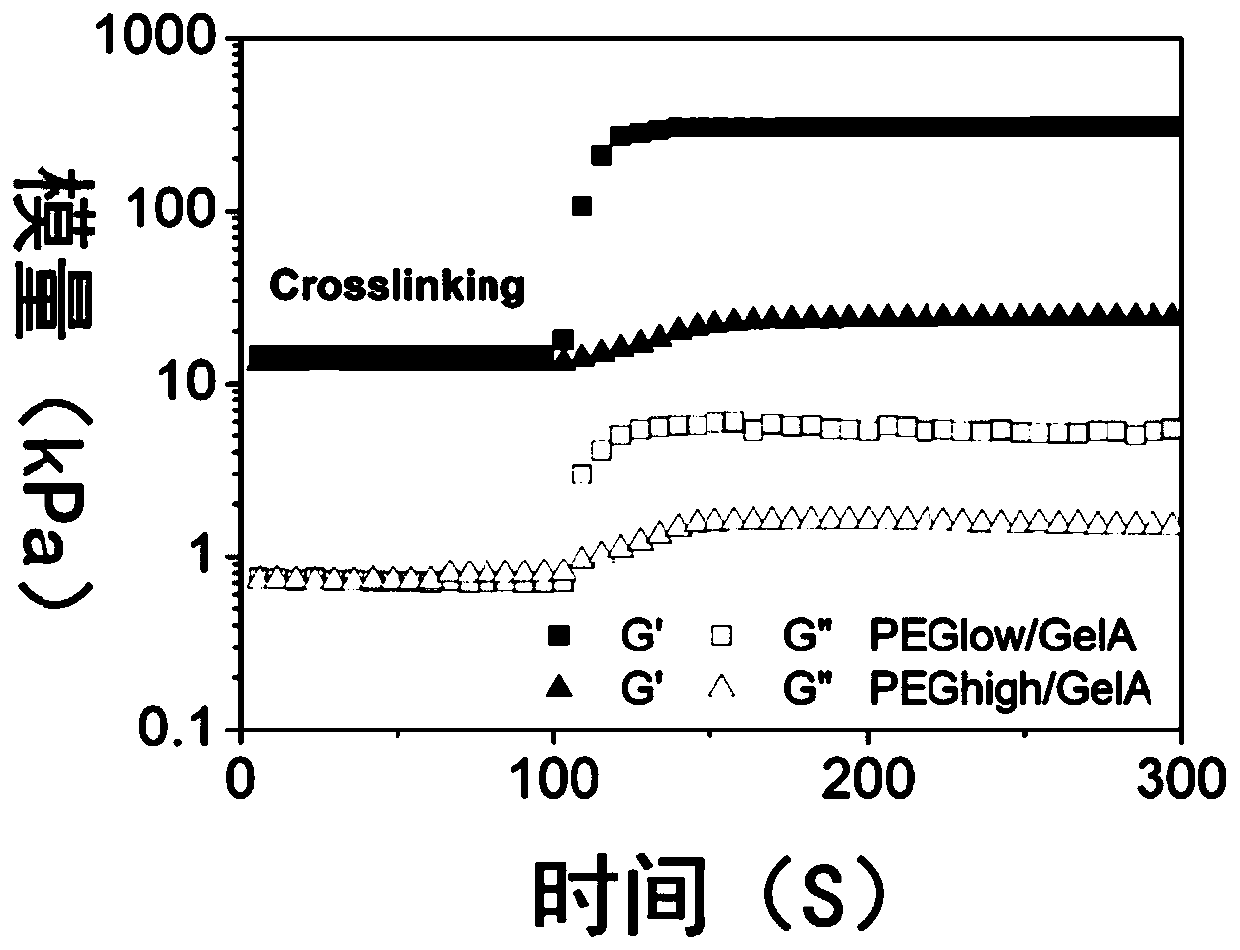

Double-network hydrogel based on polyethylene glycol/gelatin particles and preparation method and application thereof

InactiveCN111040205AGood biocompatibilityInfluence structureAerosol deliveryOintment deliveryPolymer sciencePolyethylene glycol

The invention discloses polyethylene glycol / gelatin particle dual-network hydrogel based on dual-network design and a preparation method thereof. Gelatin particles capable of dissipating energy of a network and polyethylene glycol macromolecules capable of keeping the structural integrity of the hydrogel are used, and the hydrogel material with high mechanical properties is formed on the basis ofa double-network design, when the polymer network is not formed, the reversible physical interaction between the colloidal gel materials endows the hydrogel with excellent shear thinning and self-repairing properties, and after the polymer network is formed, the mechanical properties of the hydrogel are obviously enhanced, and the hydrogel has printability and biocompatibility and has huge application potential in tissue engineering and regenerative medicine.

Owner:DALIAN UNIV OF TECH

Diaphragm pump with automatic protection function and automatic protection method of diaphragm pump

ActiveCN104214078AWith self-protection functionReduce maintenance rateFlexible member pumpsPump controlDiaphragm pumpEngineering

The invention provides a diaphragm pump with an automatic protection function and an automatic protection method of the diaphragm pump. Parameters of the diaphragm pump such as diaphragm oil pressure, slurry pressure, piston strokes and the like can be monitored in real time by arranging a first pressure sensor for monitoring oil pressure in a diaphragm oil cavity in the diaphragm pump, a second pressure sensor for monitoring the slurry pressure in a pumping outlet pipeline in the diaphragm pump, a third pressure sensor for monitoring the slurry pressure in a pumping inlet pipeline in the diaphragm pump and a strokes detection sensor for monitoring piston strokes in the diaphragm pump, whether wearable parts such as a valve chamber, the diaphragm, a check valve, a piston cylinder and the like of the diaphragm pump is abnormal or not is automatically judged according to the variation of parameters, so that the automatic protection function of the diaphragm pump can be realized, the maximum service life of each wearable part of the diaphragm pump can be prolonged, the repairing cost of the diaphragm pump can be reduced, and the working efficiency of the diaphragm pump can be effectively improved.

Owner:YUNNAN DAHONGSHAN PIPELINE

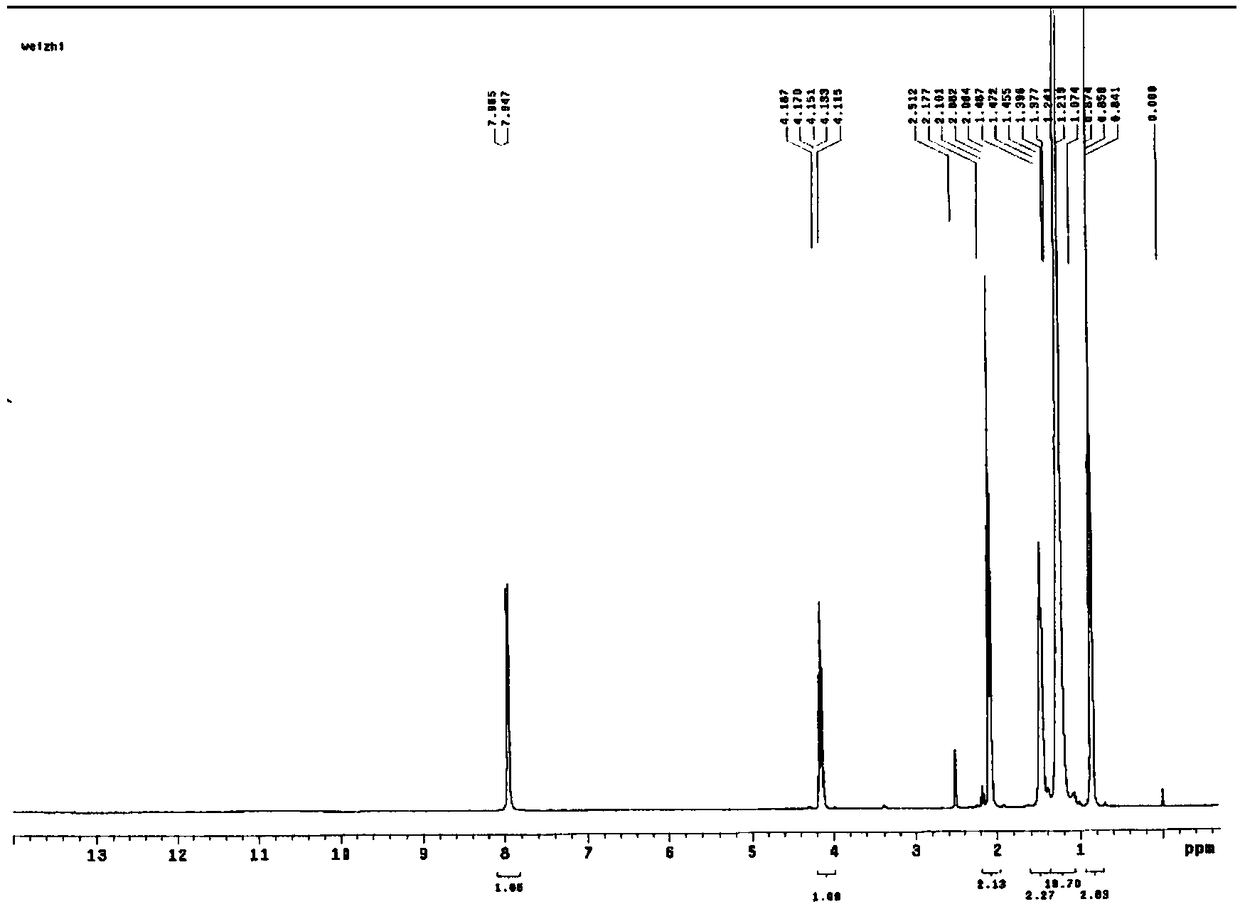

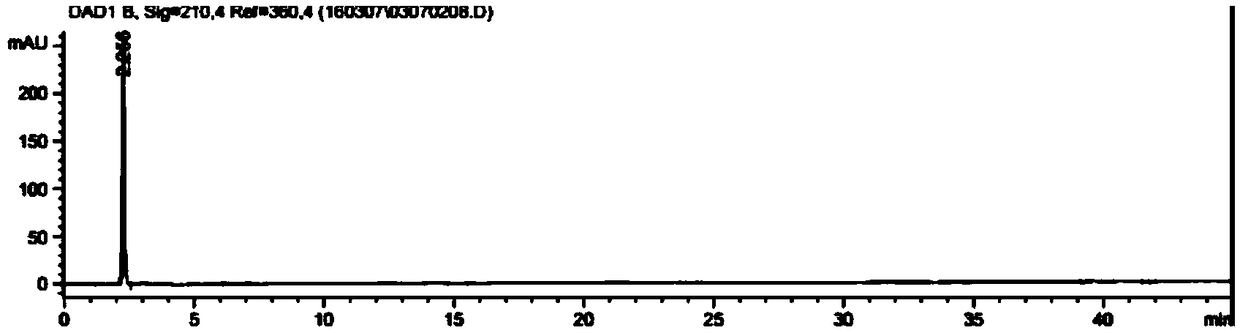

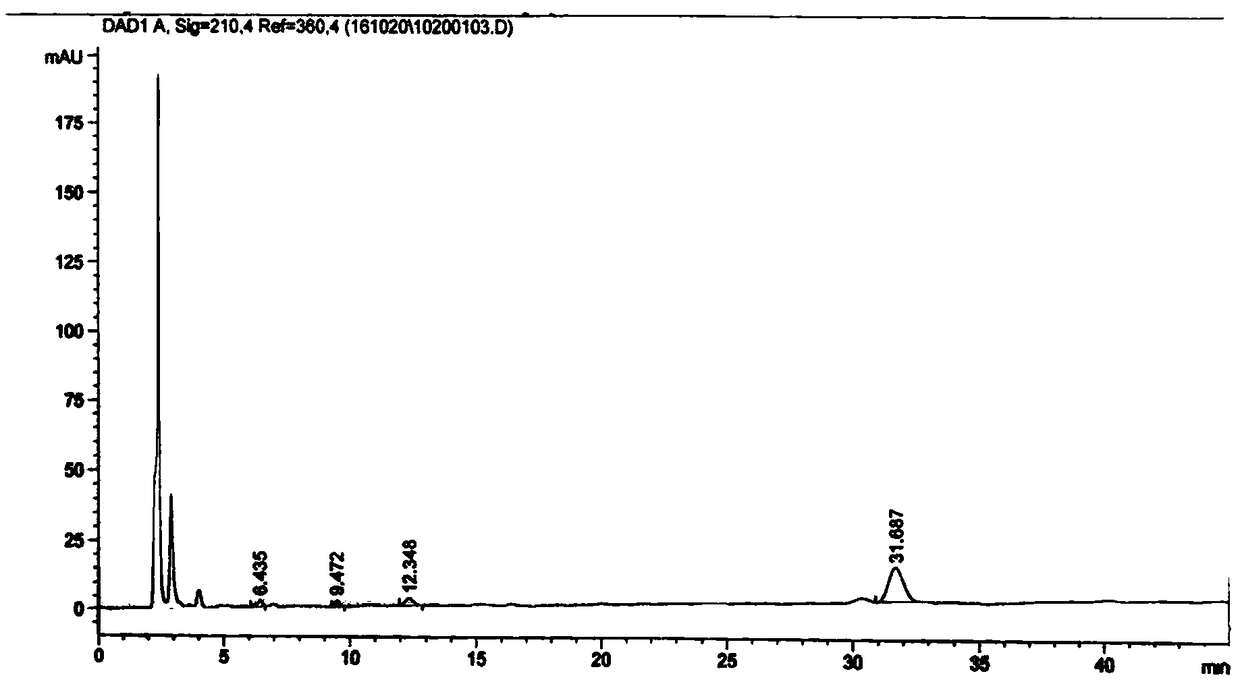

Preparation method and application of N-lauroyl-L-alanine

ActiveCN108752228ABeneficial technical effectThe process steps are simpleOrganic compound preparationTransportation and packagingL-alanosineN-lauroyl-L-alanine

The invention discloses a preparation method of N-lauroyl-L-alanine. The preparation method comprises the following steps: preparing L-alanine salt, preparing pasty N-lauroyl-L-alanine salt, and preparing an N-lauroyl-L-alanine crude product and the like. The invention further provides application of amino acid in the daily chemical field and industries such as agriculture and medicines. The aminoacid provided by the invention has high performance, and has an obvious effect in the aspects of bacterium inhibition, pesticide removal, peculiar smell elimination and the like.

Owner:SUZHOU OULIT BIOPHARM CO LTD

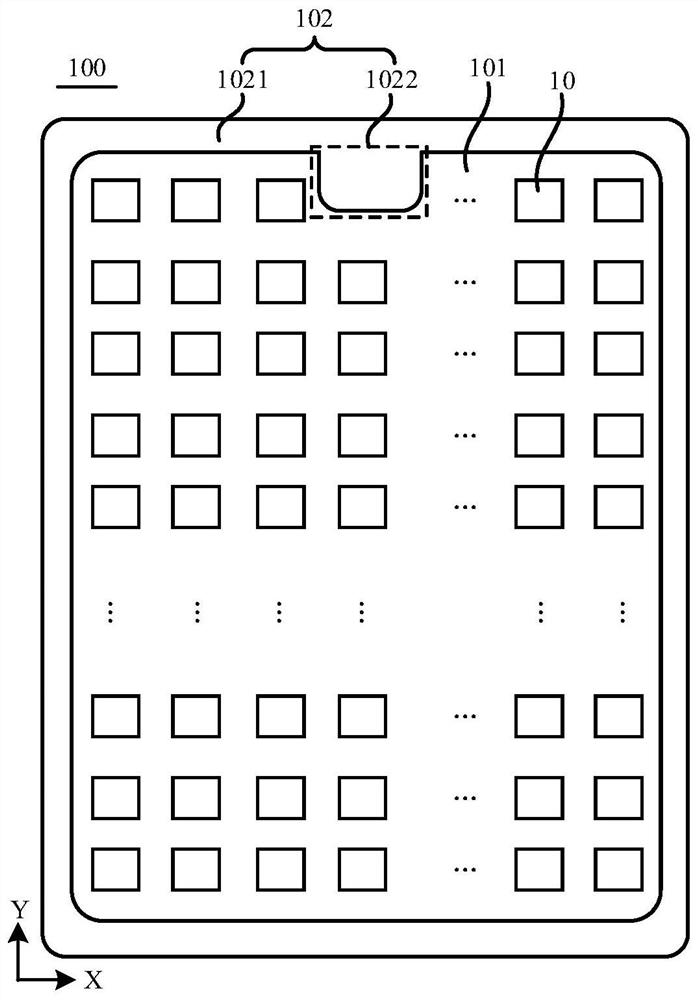

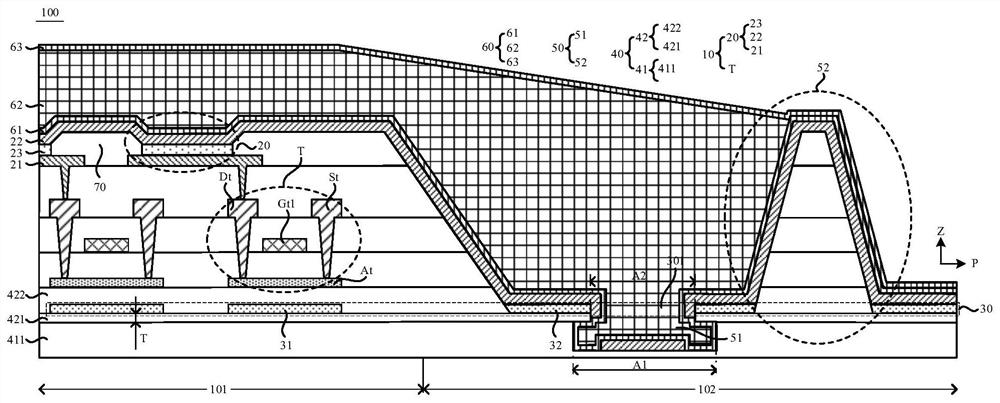

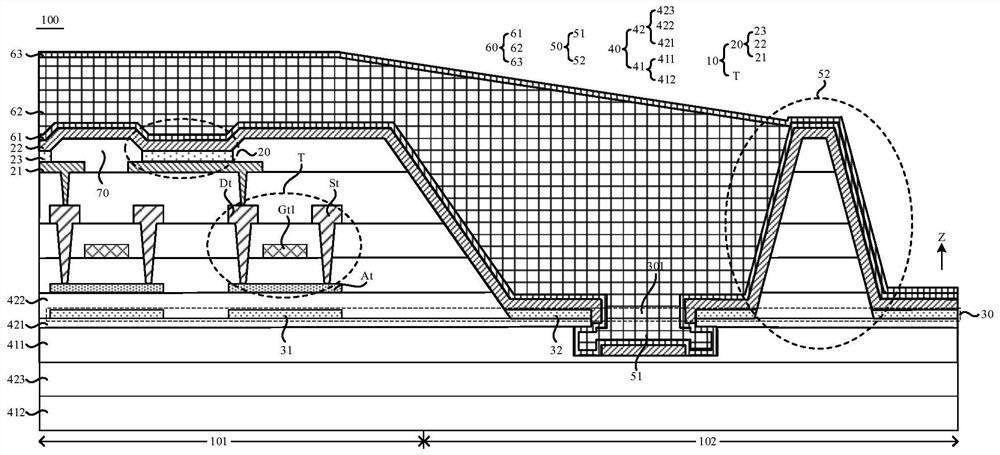

Display panel and display device

ActiveCN113066839ASimple structureImprove the display effectSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceHemt circuits

The embodiment of the invention discloses a display panel and a display device. The display panel comprises a display area and a non-display area; a substrate which comprises at least one organic layer and at least one inorganic layer, wherein the organic layer and the inorganic layer are arranged in a stacked mode; a plurality of pixel circuits, wherein each pixel circuit comprises a driving transistor; a driving transistor which comprises a first active layer; a semiconductor layer which comprises a shielding structure and an etching blocking structure, wherein the shielding structure is located in the display area, the vertical projection of the shielding structure on the film layer where the first active layers are located is overlapped with the first active layers, the etching blocking structure is located in the non-display area, and the etching blocking structure comprises at least one opening; and a blocking unit located in the non-display area, wherein the blocking unit comprises at least one groove structure and the groove structure penetrates through the first inorganic layer from the opening in the direction perpendicular to the plane where the first organic layer is located and extends into the first organic layer. According to the embodiment of the invention, the process cost of the display panel can be reduced, and the display effect of the display panel is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Motor rotor and end ring casting equipment and method thereof

PendingCN111799961AAvoid it happening againImprove product qualityStatorsAsynchronous induction motorsMolten stateElectric machine

The invention belongs to the technical field of motors, and particularly relates to motor rotor end ring casting equipment which comprises a positioning device used for fixing a rotor core, a formingdie used for casting an end ring, a heating device and a lifting device. The heating device is used for heating the metal raw material into a molten state in the forming mold. The lifting device is used for adjusting the distance between the positioning device and the forming mold, so that the lower end of the rotor core is immersed into the molten raw material in the forming mold. By the adoptionof the technical scheme, the metal raw materials are heated to be in the molten state in the forming die under vacuum or in the environment filled with inert gas, the lower end of the rotor is immersed in the molten metal raw materials, and the end ring is directly formed at the lower end of the rotor. The equipment is simple in structure, low in production cost and good in anti-oxidation effect.

Owner:CHONGQING JINKANG POWER NEW ENERGY CO LTD

Forming method of semiconductor device and grid electrode

ActiveCN104681417AReduce surface roughnessSimple structureSemiconductor/solid-state device manufacturingSemiconductor devicesSurface roughnessPhotoresist

The invention provides a forming method of a semiconductor device and a grid electrode. In the forming method of the semiconductor device, a photoresist layer arranged above a hard mask layer is subjected to patterning, and after photoresist patterns are formed, the photoresist patterns are subjected to softening processing process, so that the surface roughness degree of the photoresist patterns is effectively reduced, then, the photoresist patterns are used as marks for etching the partial hard mask layer, the remained photoresist at the bottom of the side wall of the photoresist patterns is removed, then, the photoresist patterns are subjected to tightening processing process, the photoresist patterns are cured, meanwhile, a decoration layer is formed on the surfaces of the photoresist patterns, the smoothness of the side wall surface of the photoresist patterns is improved, the quality of the hard mask patterns subsequently obtained by using the photoresist patterns as the marks for etching the hard mask layer can be improved, and further, the structure precision of the semiconductor device obtained after the hard mask patterns are used as the masks for etching the materials to be etched in the subsequent steps can be improved, so that the performance of the semiconductor device is optimized.

Owner:SEMICON MFG INT (SHANGHAI) CORP

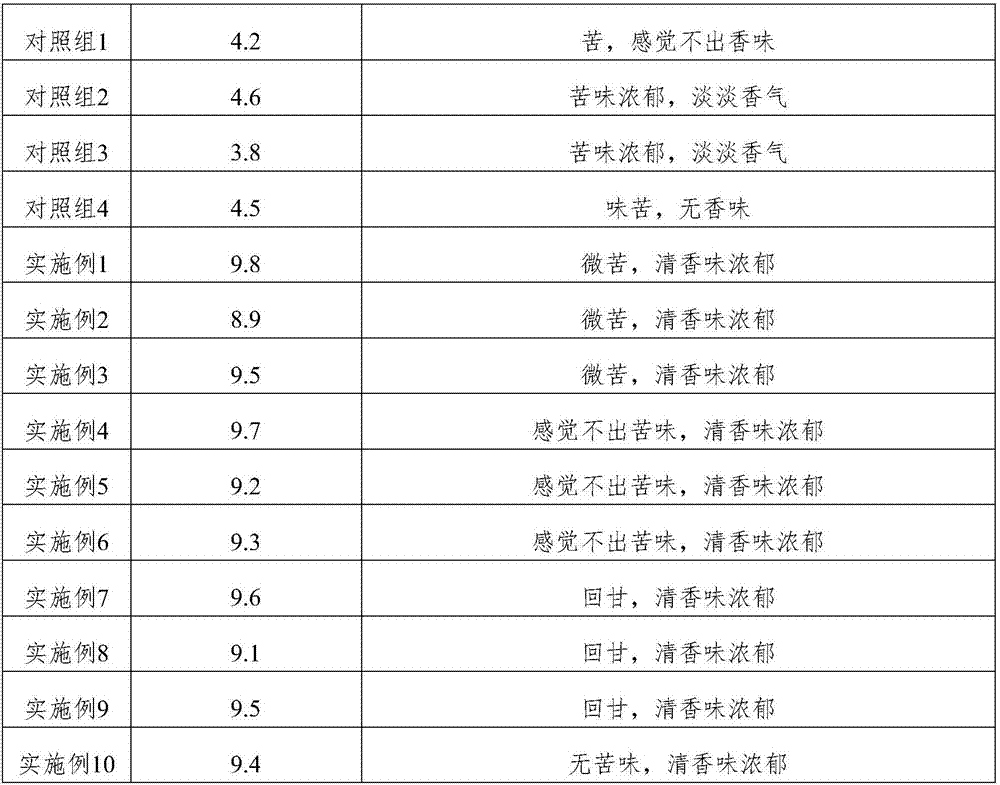

Sabia parviflora Wall.ex Roxb green tea preparation method

InactiveCN107279392AImprove qualityKeep the fragranceTea substituesEpigallo-catechin gallateNutrient content

The invention relates to the technical field of green tea preparation, particularly to a Sabia parviflora Wall.ex Roxb green tea preparation method. According to the present invention, Sabia parviflora Wall.ex Roxb leaves are selected, and the green tea is prepared by using the semi-lignified leaves as the raw material, such that the prepared green tea has the excellent taste; in the preparation process, by combining air drying, withering, enzyme deactivating, rolling molding and drying, the bitter taste of the Sabia parviflora Wall.ex Roxb leaves is removed, such that the change is generated under the physical and chemical parameter conditions while various nutrients of the Sabia parviflora Wall.ex Roxb leaves are retained; and the green tea is prepared by mixing the flower and the leaves of Sabia parviflora Wall.ex Roxb, such that the taste of the green tea can be effectively improved, the quality of the green tea can be improved, and particularly the prepared green tea can have the sweet aftertaste after the being drunk.

Owner:望谟县麻岭生态科技发展有限责任公司

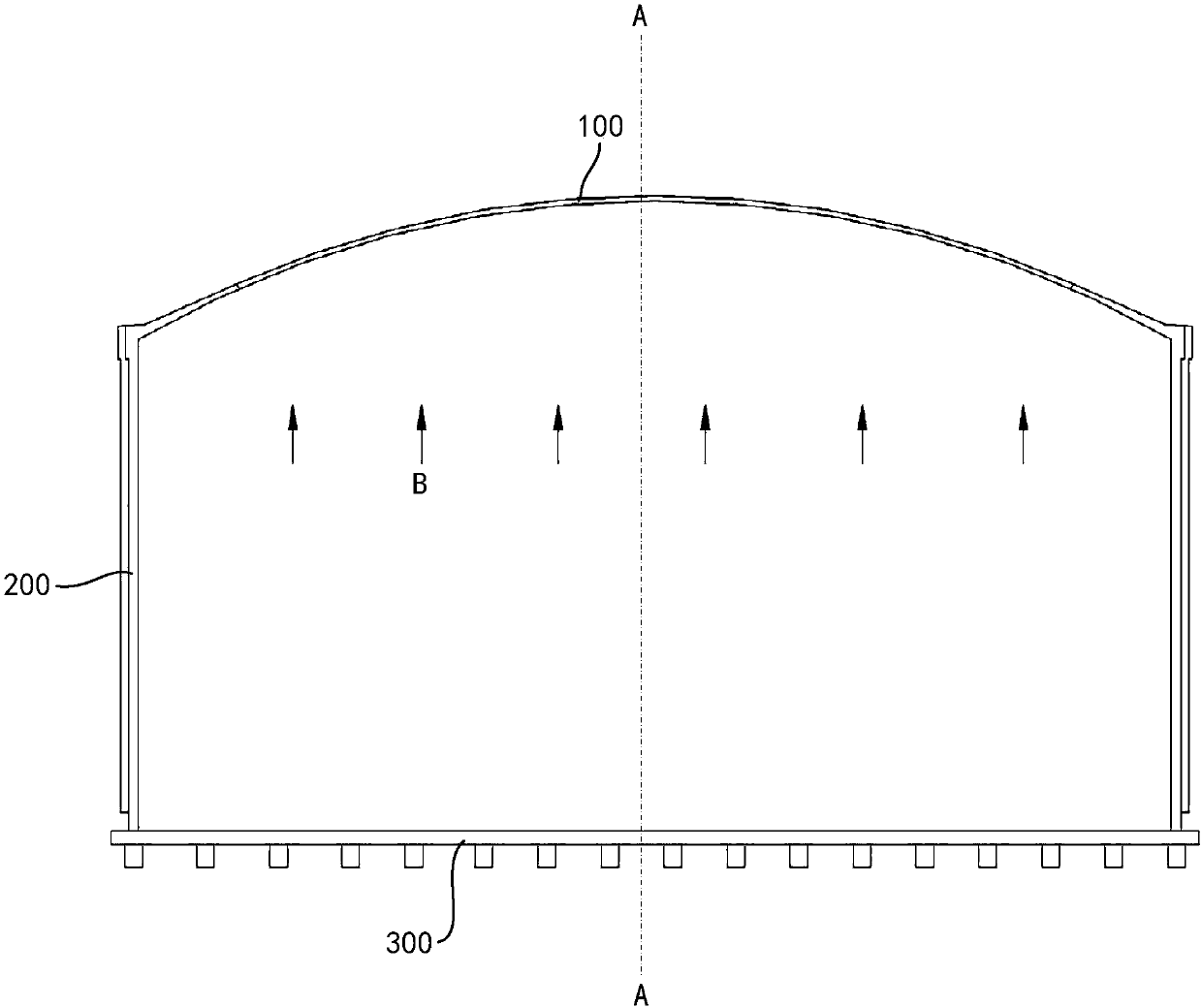

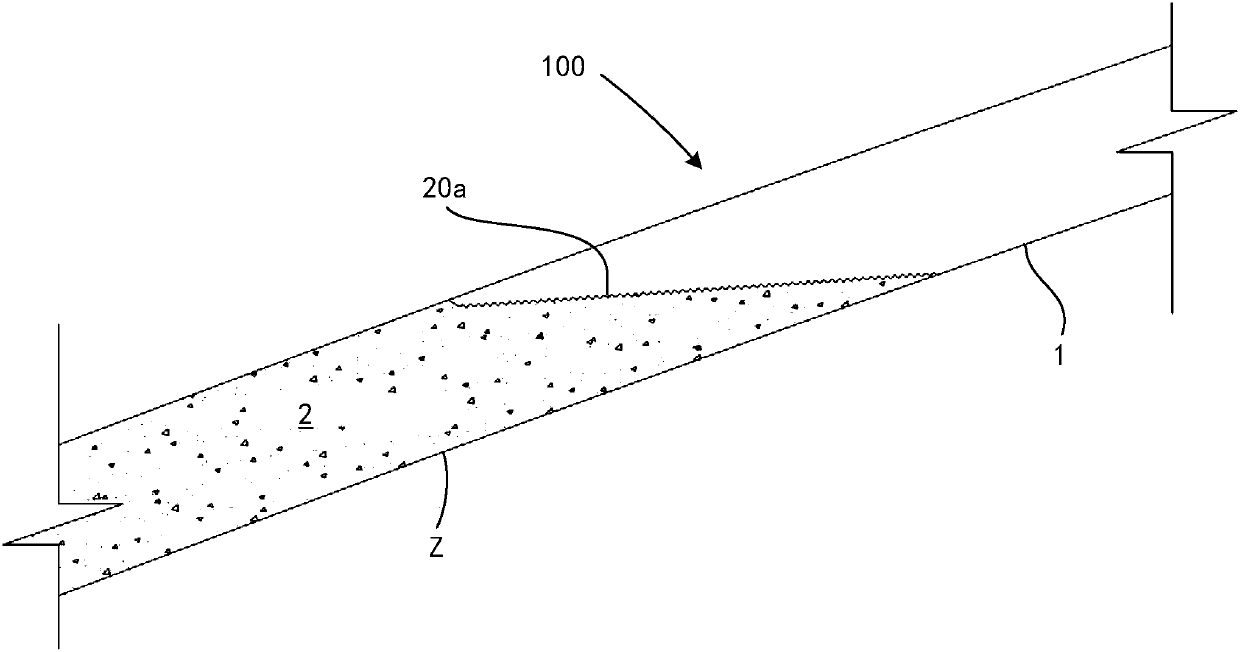

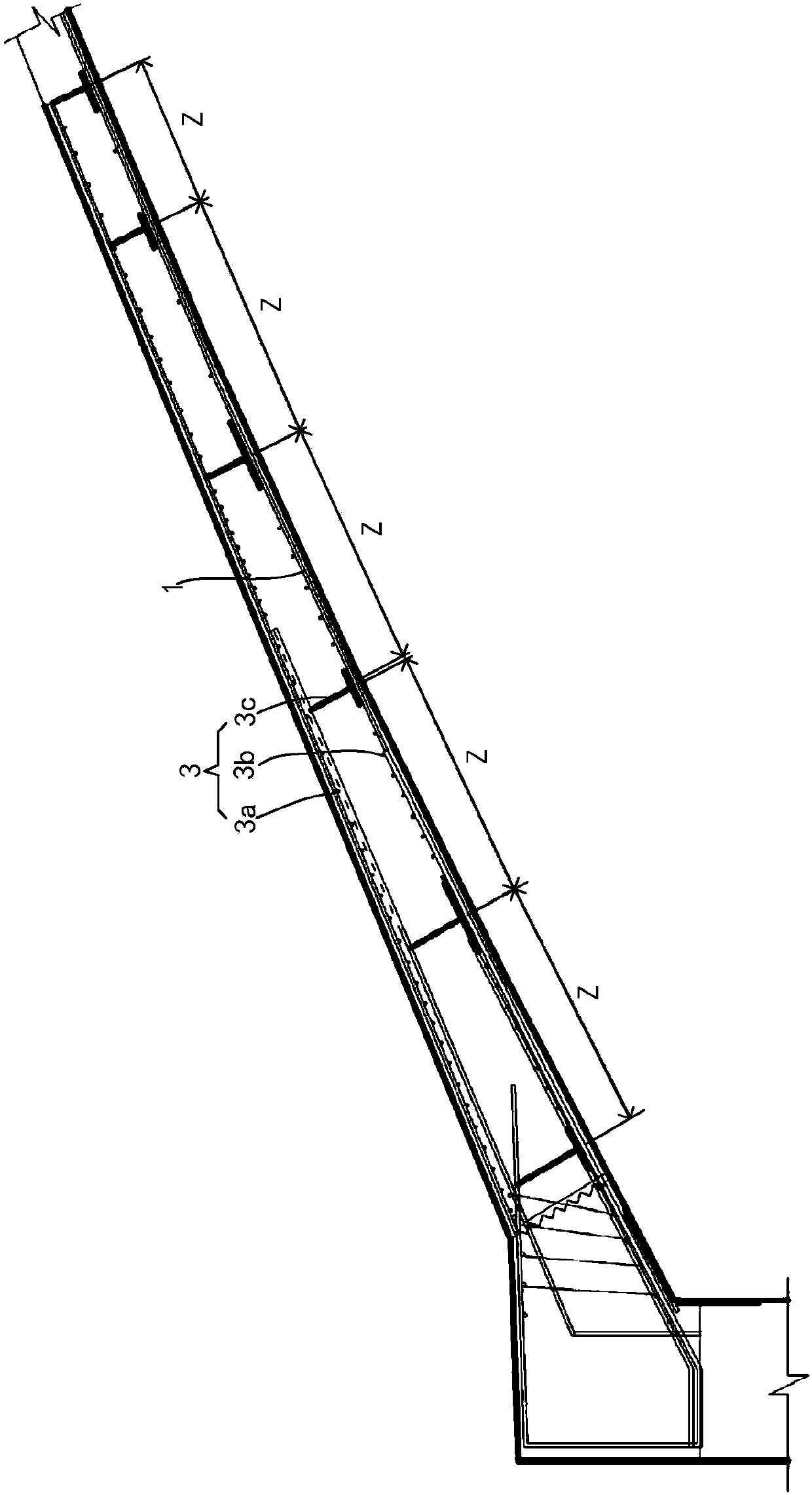

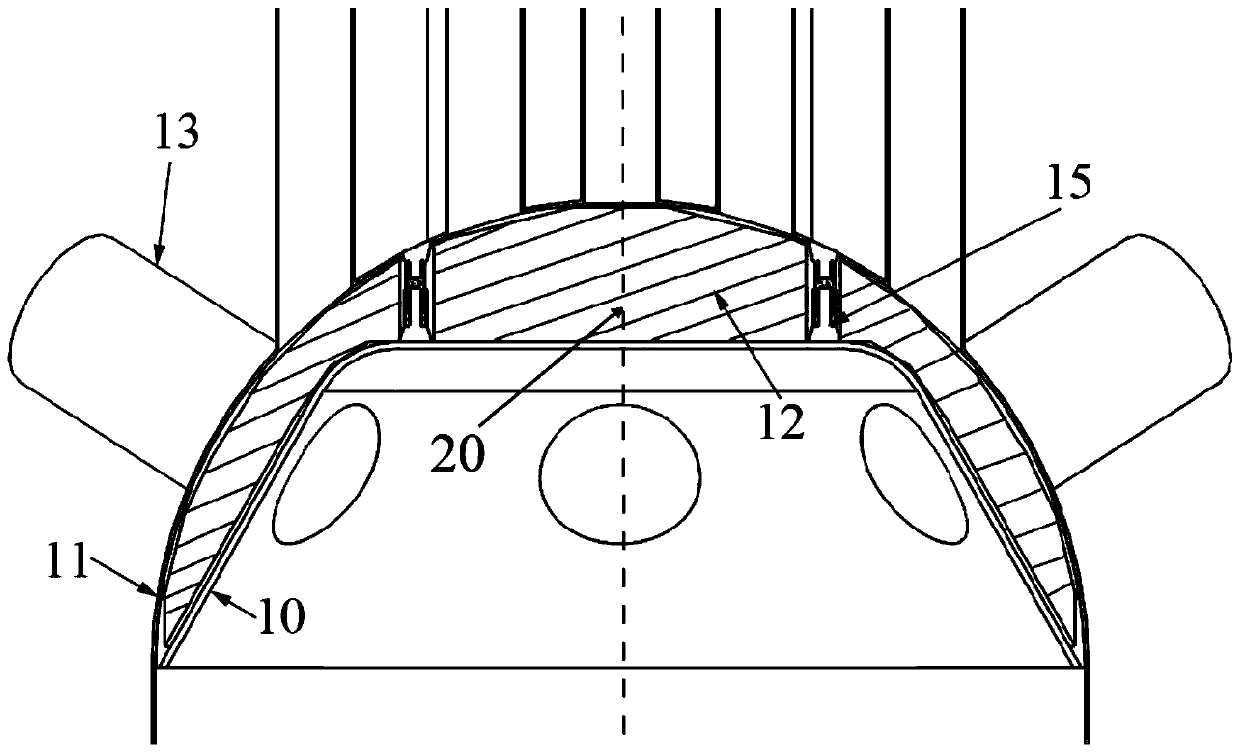

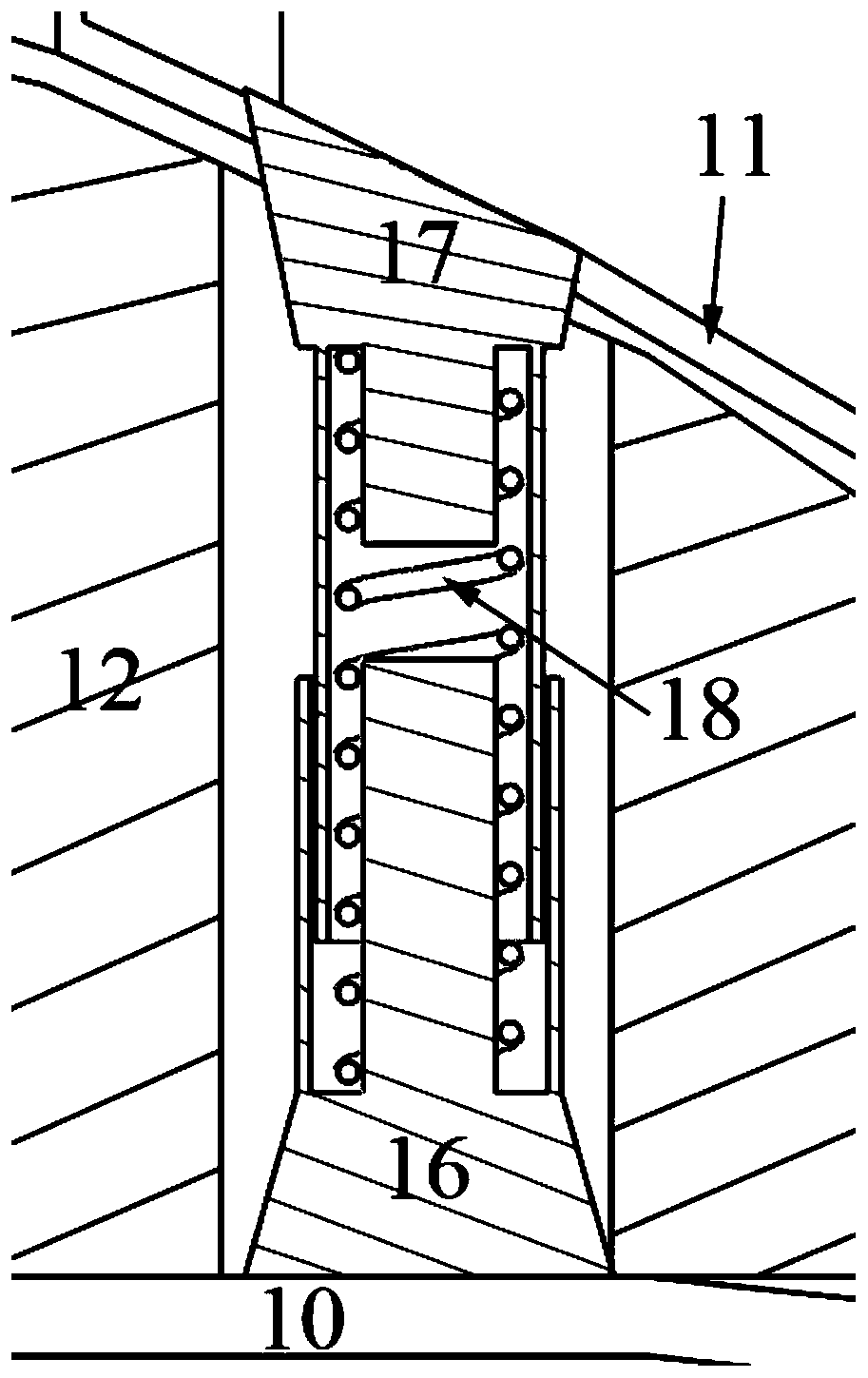

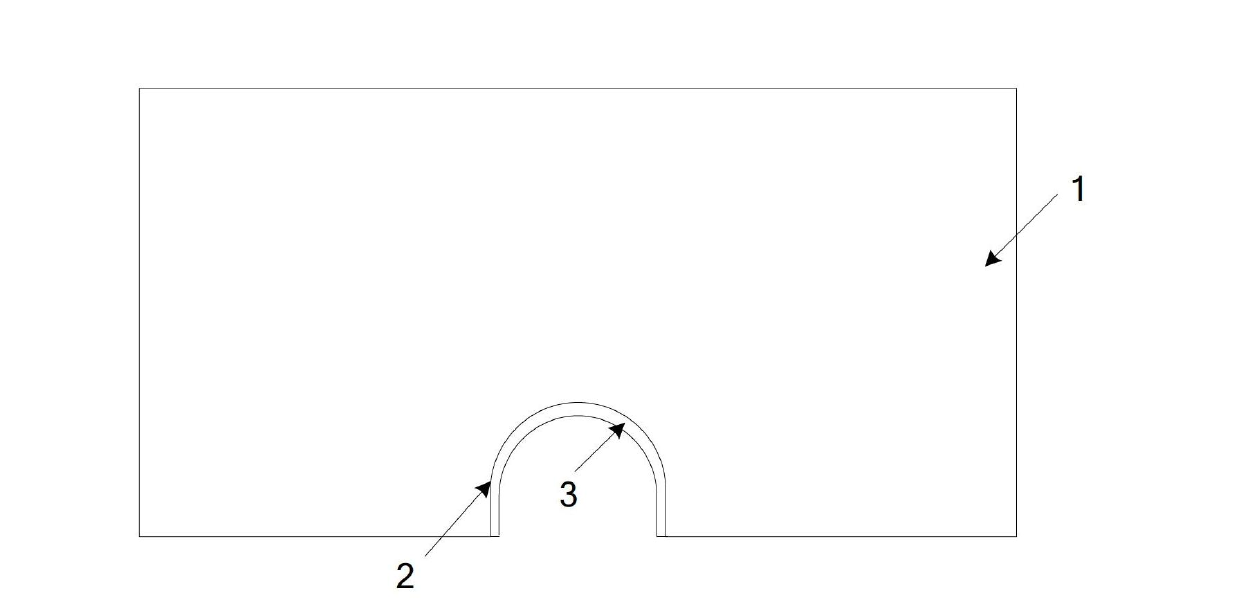

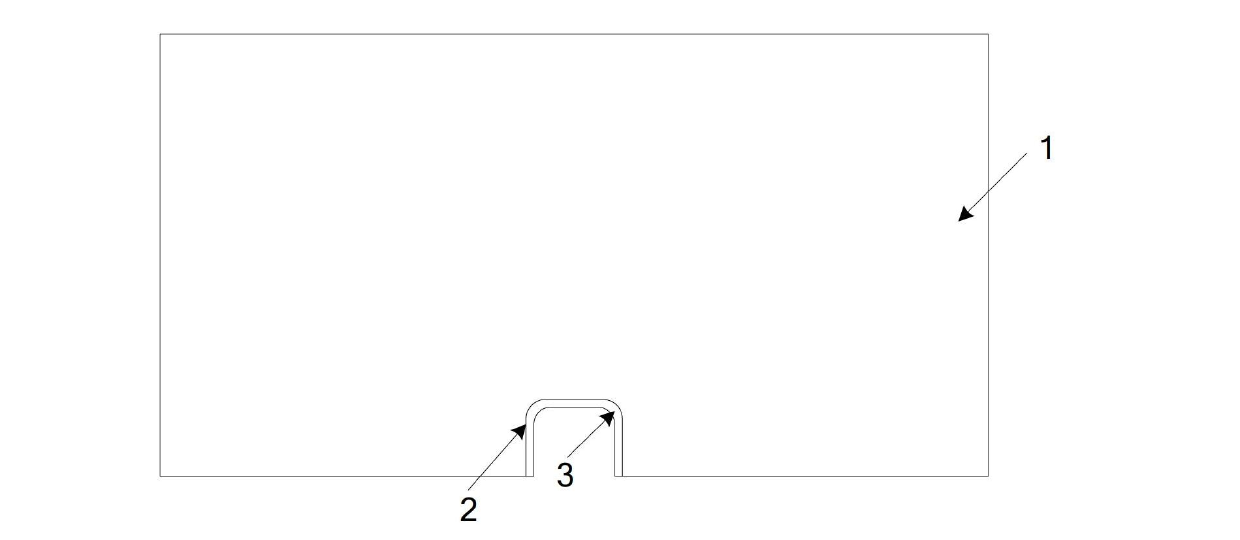

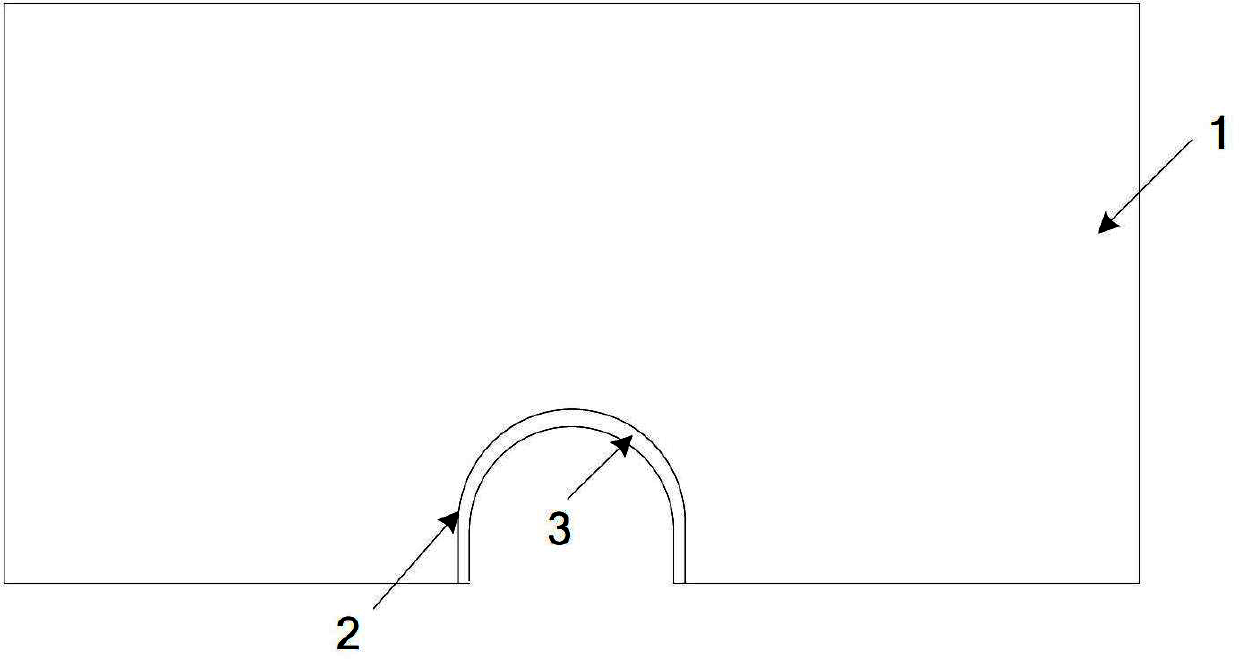

Spherical-segment-shaped dome concrete pouring method

The invention aims to provide a spherical-segment-shaped dome concrete pouring method. The method includes the following steps: a, one or more annular areas encircling the vertical center line of a steel arch top are determined on the steel arch top; b. the annular areas are divided into segments in an odd number, concrete pouring starting points for any two segments symmetrical about the verticalcenter line are two first symmetrical positions symmetrical about the vertical center line, and concrete pouring ending points for any two segments symmetrical about the vertical center line are twosecond symmetrical positions symmetrical about the vertical center line; and c, pouring of one annular area is divided into concrete pouring performed on any two segments synchronously in the peripheral direction and in the same direction, so that the outer wall covering the steel arch top and two concrete blocks holding and wrapping a rebar framework are formed in the annular area, and the two concrete blocks are made to be symmetrical about the vertical center line. The concrete blocks at any moment after pouring starts are in a symmetrical distribution state, and therefore it is avoided that stress of the steel arch top is not uniform.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

Preparation method of porphyrin-based metal organic framework material sensitized oxide type catalyst

ActiveCN111514937AEnhanced light absorptionImprove photocatalytic performanceWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPorphyrin

The invention relates to a preparation method of a porphyrin-based metal organic framework material sensitized oxide type catalyst. The porphyrin-based metal organic framework material sensitized oxide type catalyst is used for visible light catalytic degradation treatment of organic pollutants in water. A porphyrin-based metal organic framework material is used as a sensitizer, silver-cerium double-doped zinc oxide is used, and a sensitizing auxiliary agent is introduced, so that a photo-generated charge transmission channel is constructed, and the photocatalytic degradation performance undera visible light condition is enhanced. By investigating the degradation performance of the composite catalyst on a typical organic pollutant methylene blue in water under a visible light condition, the catalyst has good capacity of degrading organic matters in water under visible light.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for catalyzing and synthesizing spiral carbon nano material by using water-soluble alkali metal carbonate

InactiveCN102390827AHigh puritySolving the problem of difficult removal from carbon nanomaterialsPhysical/chemical process catalystsNanotechnologyPtru catalystNanoparticle

The invention discloses a method for catalyzing and synthesizing a spiral carbon nano material by using water-soluble alkali metal carbonate. The method comprises the following steps of: synthesizing a catalyst precursor; putting the catalyst precursor into a tubular reactor in which temperature can be precisely controlled, feeding helium and thermally treating the catalyst precursor to obtain catalyst alkali metal carbonate nano particles, wherein the thermal treatment temperature is between 400 and 600 DEG C and the thermal treatment time is 3 to 10 hours; after thermal treatment, stopping feeding the helium, then feeding acetylene gas immediately, and catalyzing and splitting the acetylene on the surfaces of the catalyst alkali metal carbonate nano particles, wherein the reaction temperature is between 400 and 600 DEG C and the reaction time is 3 to 8 hours; and thus obtaining the black spiral carbon nano material. In the method, the adopted catalyst is the water-soluble alkali metal carbonate, so the water-soluble alkali metal carbonate can be washed away conveniently and the pure spiral carbon nano material can be obtained; furthermore, the method is environment-friendly and pollution-free; and preparation process and equipment are simple, the reaction temperature is low, the cost is low and large-scale production can be realized.

Owner:NANJING UNIV

Novel space reactor pressure vessel structure

PendingCN110570956AInfluence structureAffect liquidityNuclear energy generationShieldingInternal pressureReactor pressure vessel

The invention provides a novel space reactor pressure vessel structure. The novel space reactor pressure vessel structure comprises an outer pressure vessel, an inner pressure vessel, an upper sealingpressure vessel, a lower reactor core chamber and support plates; and each of the outer pressure vessel and the inner pressure vessel is a hemispherical and cylindrical shell structure, the inner pressure vessel is arranged in the outer pressure vessel, an annular descending channel is formed between the inner pressure vessel and the outer pressure vessel, an upper support plate and a lower support plate are arranged at the upper end and the lower end of the cylindrical section of the inner pressure vessel respectively, the upper sealing vessel is arranged in the hemispherical structure of the inner pressure vessel and is connected with the upper supporting plate, and a space for accommodating a radiation shielding materials is formed between the inner pressure vessel and the upper sealing vessel. The space between the upper sealing pressure vessel and the inner pressure vessel is filled with the radiation shielding material to achieve a certain buffering effect, and a plurality of buffering connectors are arranged between the upper sealing pressure vessel and the inner pressure vessel to enhance the structural stability and the pressure bearing capacity, so the overall structurehas the advantages of simple design, low price, and easiness in machining.

Owner:HARBIN ENG UNIV

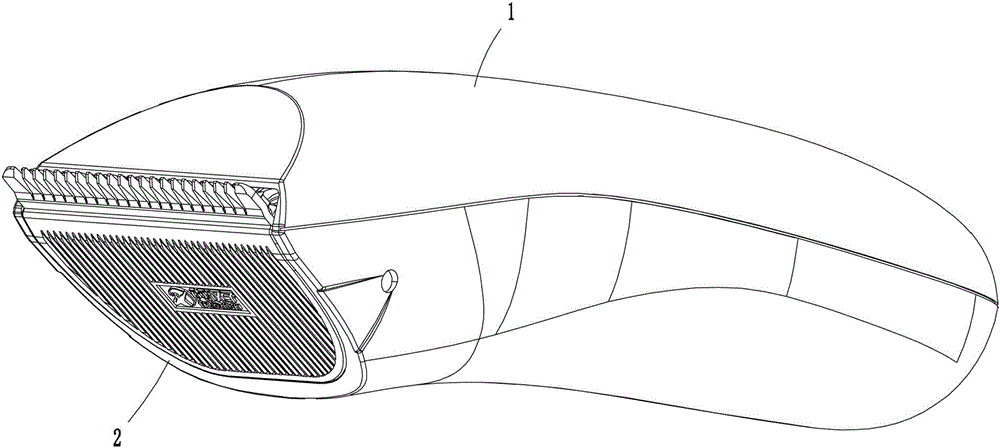

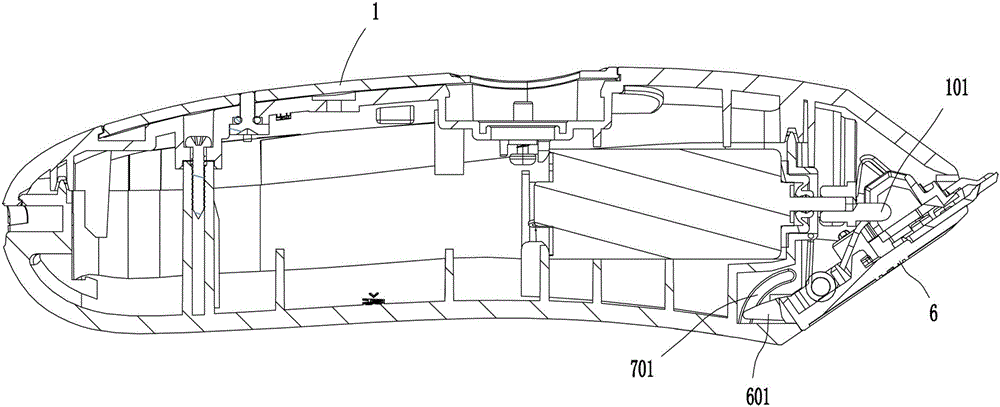

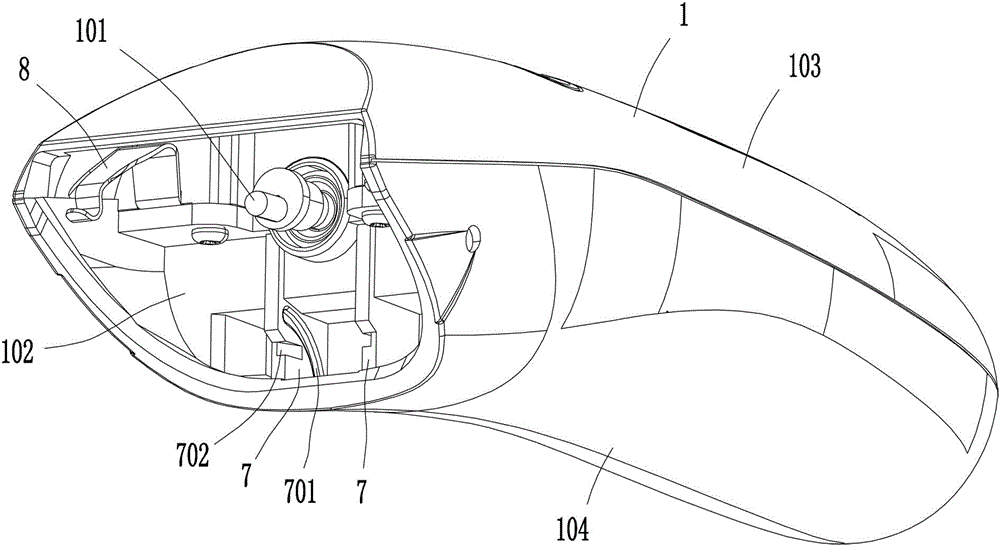

Connection structure of tool bit and host of hair scissors

ActiveCN104890018ANot easy to loseEasy to operateMetal working apparatusDrive shaftSoftware engineering

The invention discloses a connection structure of a tool bit and a host of hair scissors. The connection structure comprises the host and the tool bit; the host comprises a driving shaft; the tool bit comprise a movable blade, a movable tool frame, a fixed blade and a fixed tool frame; the front end of the host is provided with an accommodating groove which is used for accommodating the tool bit; the tool bit is detachably assembled in the accommodating groove; the fixed tool frame is provided with a first connection portion; the host is provided with a second connection portion which is used for being detachably connected with the first connection portion; the first connection portion is connected with the second connection portion in a rotating mode; the fixed tool frame is provided with a third connection portion; the host is provided with a fourth connection portion which is used for being detachably connected with the third connection portion; the third connection portion is fixedly connected with the fourth connection portion; the movable tool frame is provided with a shaft groove which is used for being in insertion joint matched with the driving shaft. According to the connection structure of the tool bit and the host of the hair scissors, the tool bit is not separated from the host when the tool bit is cleaned and the tool bit can be replaced.

Owner:NINGBO ZHENHE ELECTRICAL EQUIP

Light guide plate, backlight module and liquid crystal display device

ActiveCN102681085AEliminate bright spotsDoesn't affect the structure muchMechanical apparatusLight guides for lighting systemsLiquid-crystal displayLight guide

The invention relates to the technical field of a liquid crystal display and provides a light guide plate, a backlight module and a liquid crystal display device. The light guide plate comprises at least one positioning groove arranged at the edge of the light guide plate, wherein a non-transmitting ink layer is arranged on an inner wall of the positioning groove. According to the technical scheme provided by the invention, one part of light irradiated to an area of the positioning groove of the light guide plate by a light source is absorbed by the ink layer arranged at the inner wall of the positioning groove, and the other part of the light is uniformly scattered, so that the intensity and the concentration ratio of light reflection can be reduced. Therefore, no condition that the light in the area of the positioning groove is excessively concentrated exists, and a bright spot phenomenon of the positioning groove is eliminated. According to the technical scheme provided by the invention, only one ink layer is additionally manufactured in the conventional light guide plate, so that no great influences on the structure and the manufacturing process of the conventional light guide plate exist. Therefore, the product properties can be improved without increasing manufacturing time and cost; and the yield is ensured.

Owner:HISENSE VISUAL TECH CO LTD

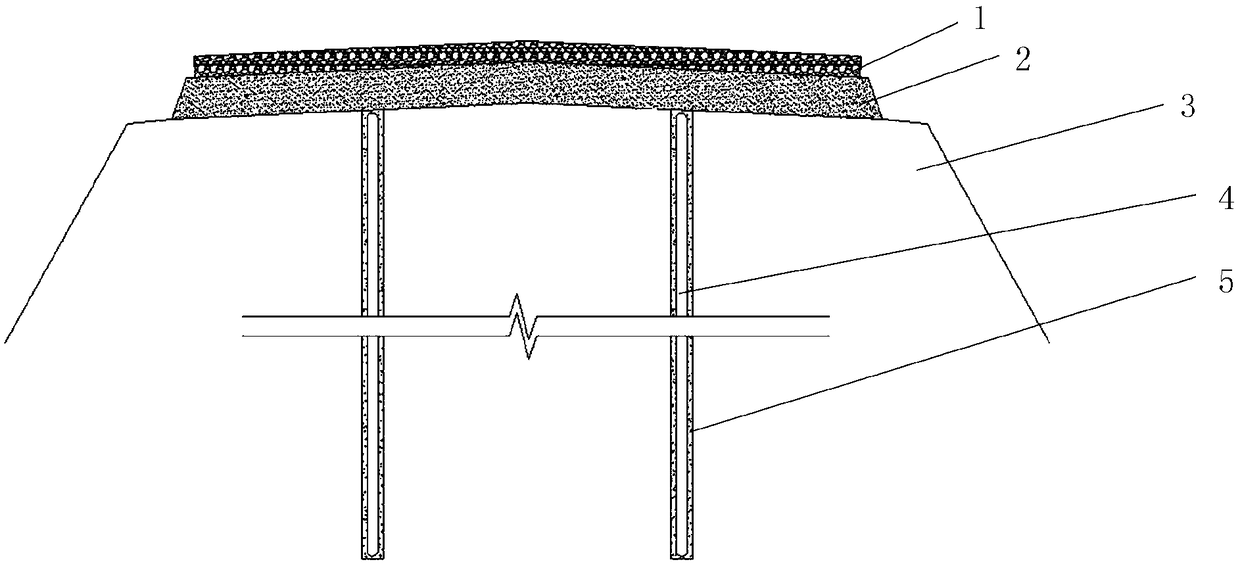

Hot bar roadbed and construction method for controlling seasonal frost damage

The invention discloses a hot bar roadbed for controlling seasonal frost damage, which comprises a water permeable layer, an impermeable layer, a roadbed and a hot bar; The roadbed, the impermeable layer and the permeable layer are laid from bottom to top in turn; The roadbed is provided with a hot bar mounting hole; The hot bar is arranged in the hot bar mounting hole; The hot rod is an airtighthollow structure, and the airtight hollow structure is provided with liquid ammonia. The invention provides a hot bar roadbed and a construction method for controlling seasonal frost damage, which isused for controlling and eliminating the generation and development of seasonal frost damage of roadbed, and ensuring the stability of roadbed and the safety of operation in low temperature season.

Owner:JIANGXI THE SECOND CONSTR

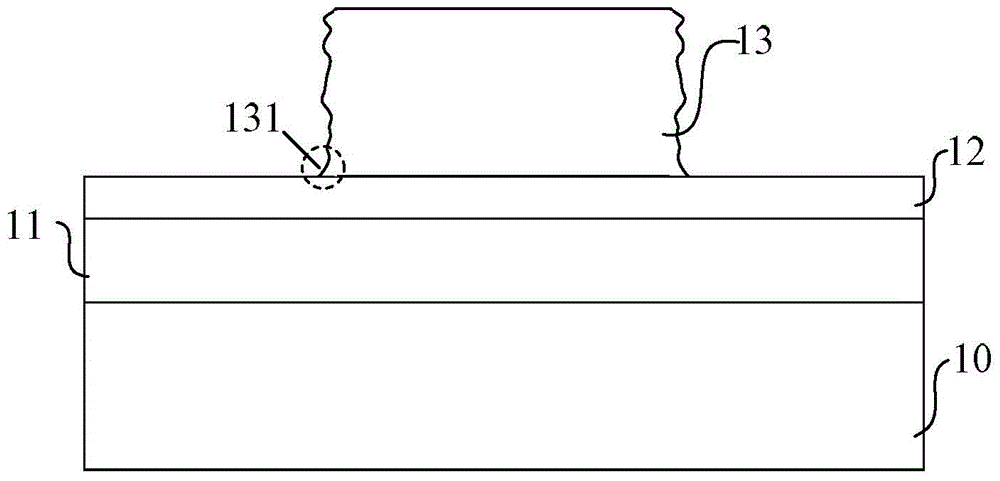

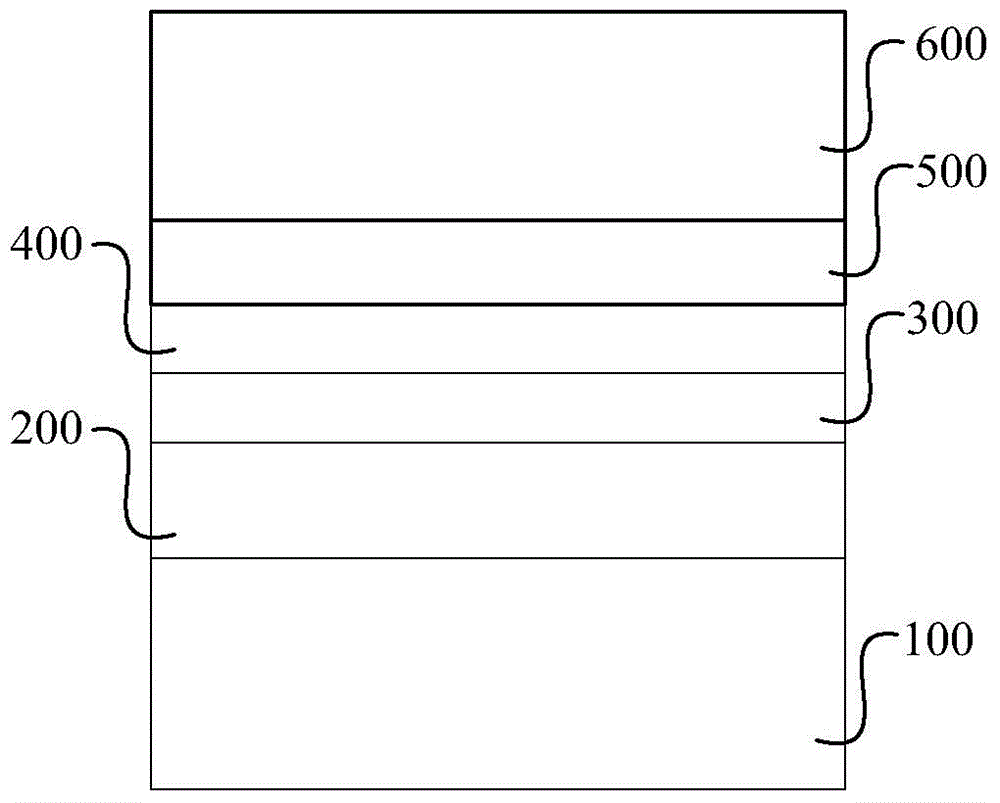

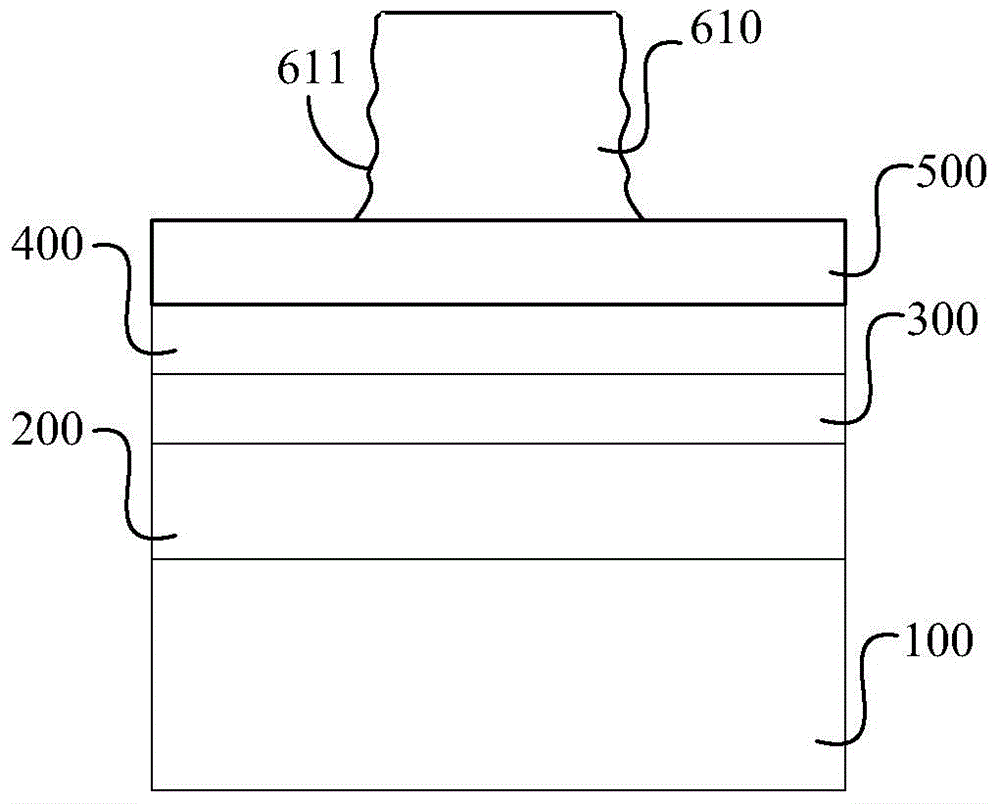

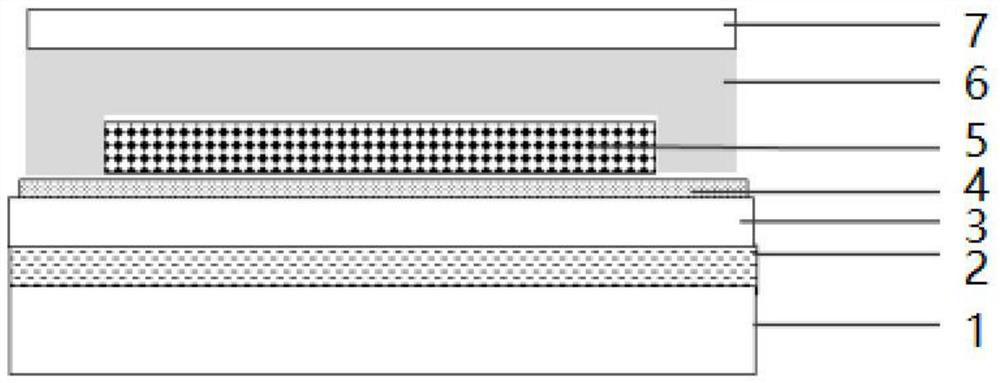

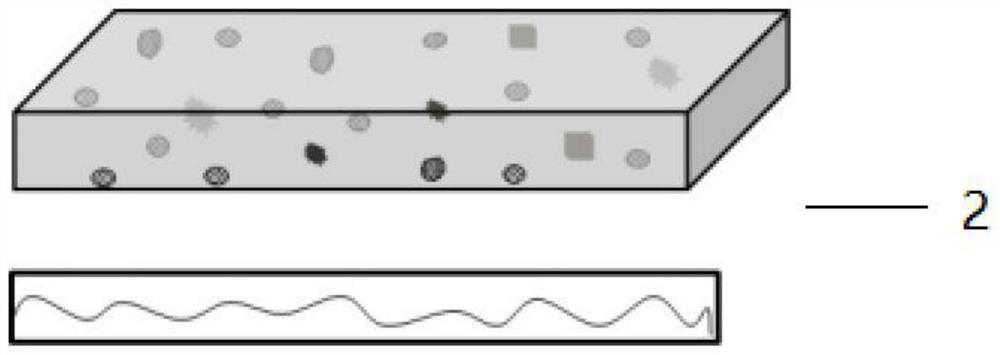

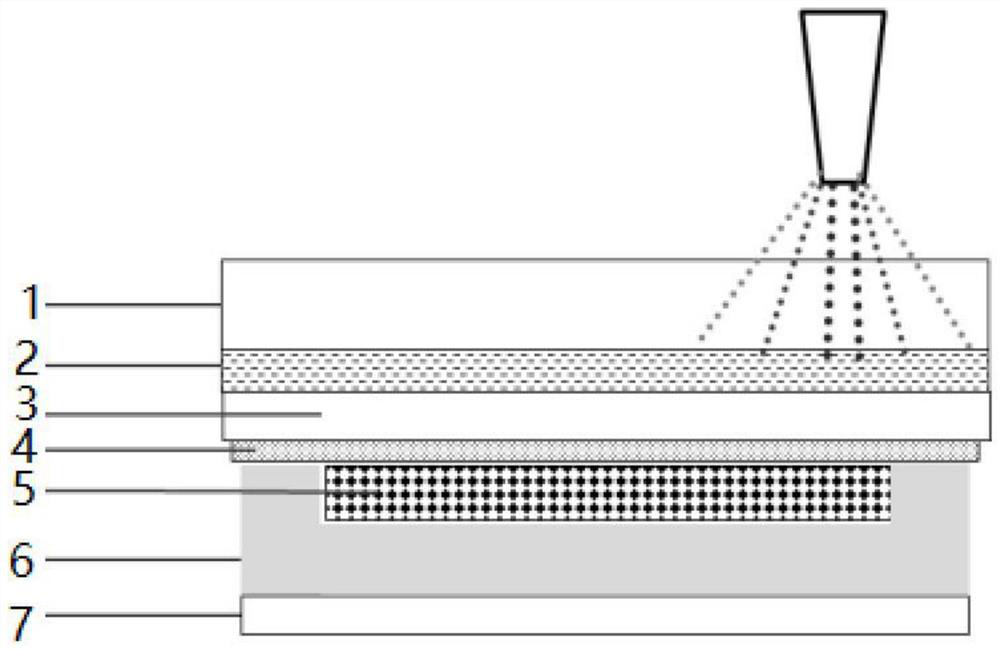

Preparation method of flexible display panel

PendingCN112164707AInfluence structureFinal product manufactureSolid-state devicesPhoto irradiationLight energy

The invention discloses a preparation method of a flexible display panel, and the method comprises the following steps: coating a material layer on a substrate, wherein the material layer is used forabsorbing and reflecting laser; coating a PI solution on the material layer, and heating and drying the PI solution in stages to form a flexible substrate layer; manufacturing a TFT array film layer on the flexible substrate layer; manufacturing a light-emitting layer, manufacturing a thin film packaging layer on the light-emitting layer, and coating the light-emitting layer with the thin film packaging layer; cutting the flexible display panel with the substrate; and irradiating the material layer by laser to separate the flexible substrate layer from the substrate. In the substrate strippingprocess, the interaction between laser and microscopic particles of a material on the surface of the material is a full-quantization energy exchange process. After the laser is incident to the surface of the material, part of the light energy with the energy of E0 is reflected, and the remaining energy is absorbed by the object. In the invention, the material layer absorbs and reflects the laser,and residual laser energy does not penetrate through the flexible substrate to influence the TFT array structure.

Owner:FUJIAN HUAJIACAI CO LTD

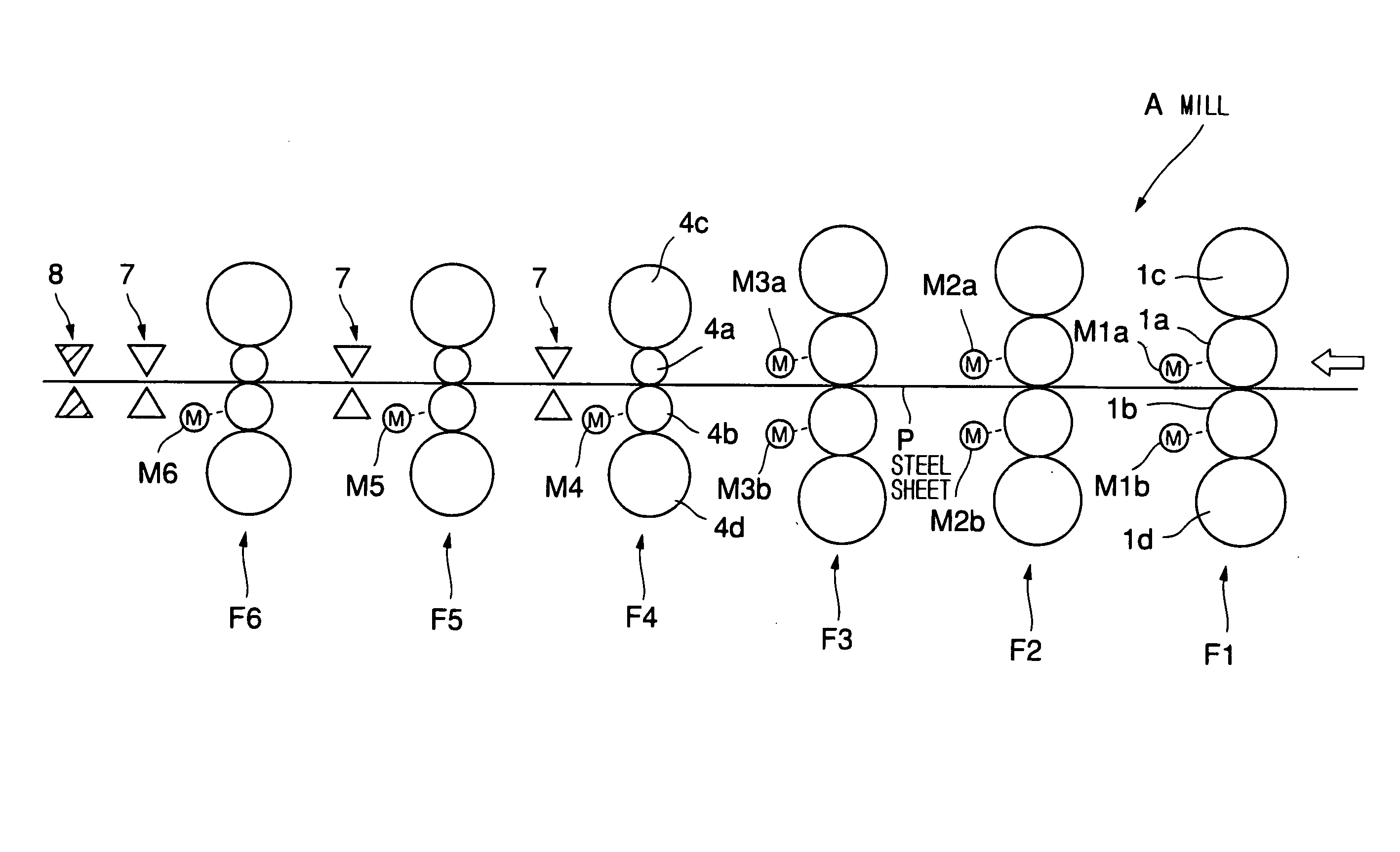

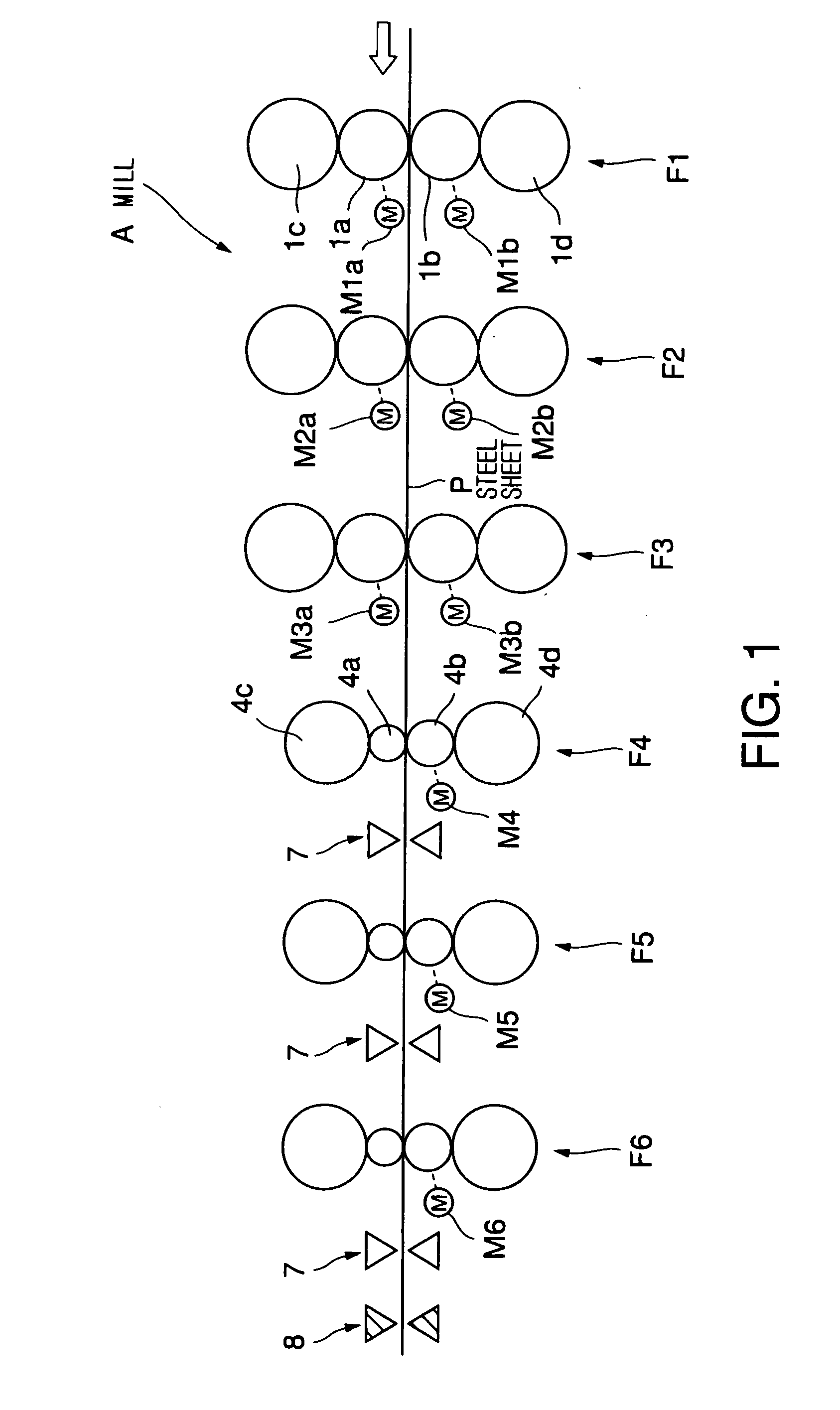

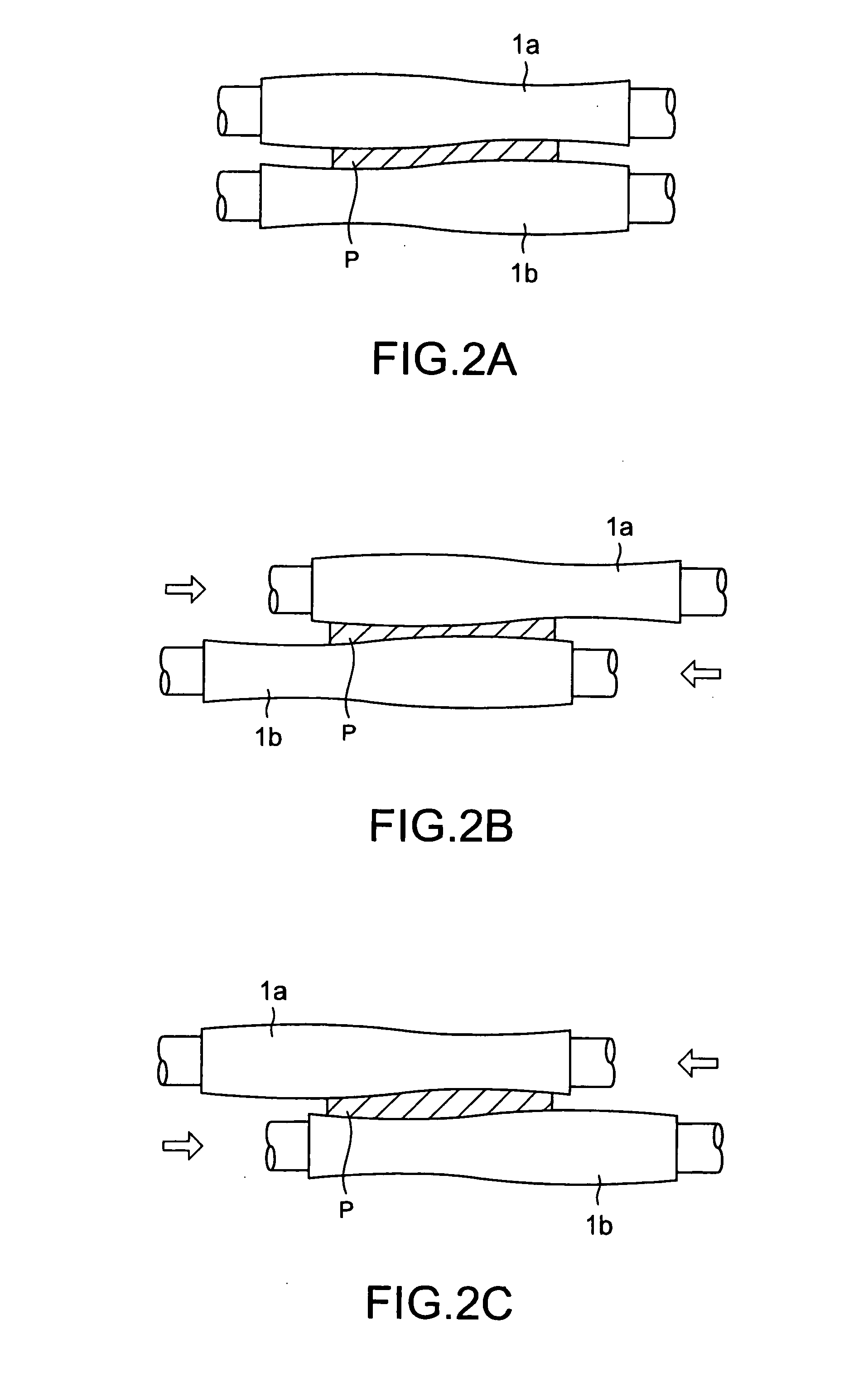

Continous hot-rolling facility

InactiveUS20050016242A1Guaranteed smooth productionGood energyMetal rolling stand detailsRollsDrive motorMaterials science

A continuous hot-rolling mill includes an upper rolling unit including a plurality of rolling stands, and a lower rolling unit including a plurality of rolling stands and disposed downstream with respect to the upper rolling unit in a workpiece passing direction in which a workpiece to be rolled is passed. The two or more rolling stands of the lower rolling unit are differential or very-small-diameter rolling stands. Each of the two or more differential or very-small-diameter rolling stands of the lower rolling unit is provided with a drive motor having a capacity greater than that of any one of drive motors included in the rolling stands disposed upstream the differential or very-small-diameter rolling stands. The continuous hot-rolling mill is suitable for producing hot-rolled, fine-grained steel sheets and is excellent in sheet passing abilities for preventing the steel sheet from meandering and for rolling the steel sheet in a desired shape.

Owner:NAKAYAMA STEEL WORKS +1

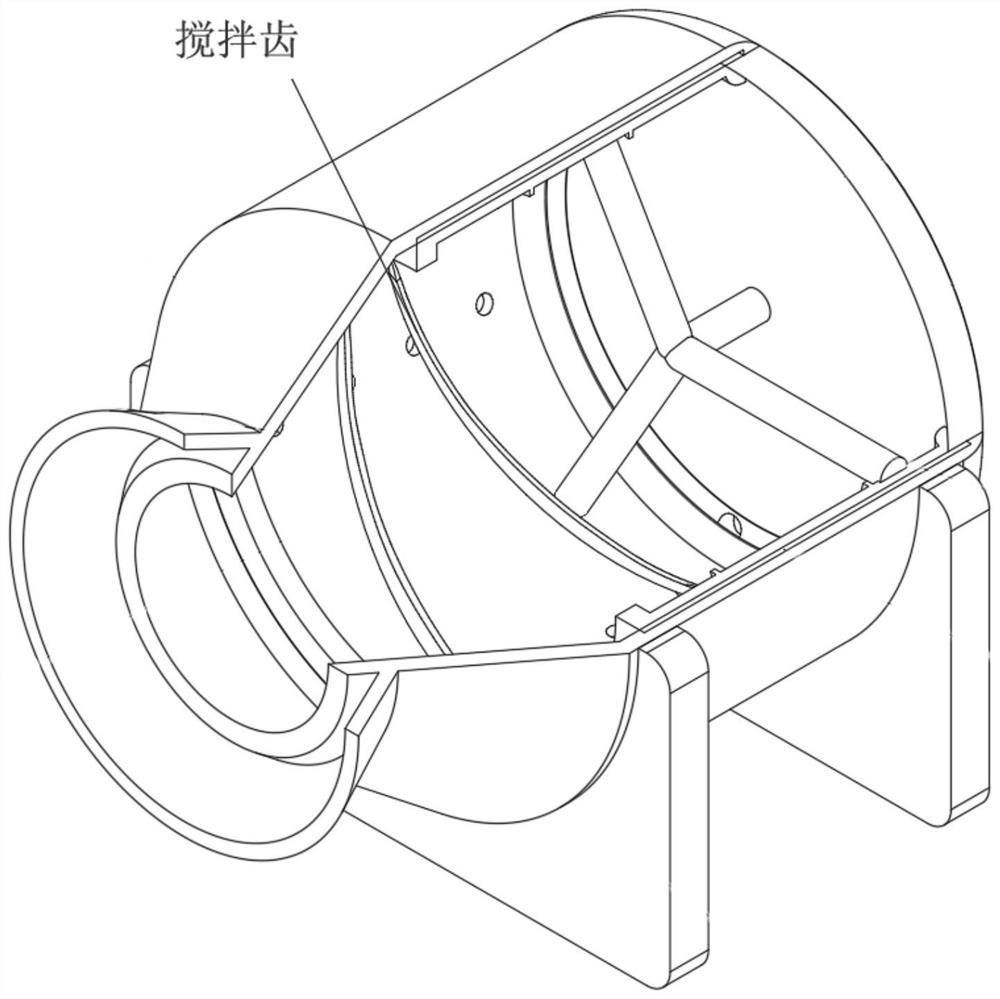

Preparation method of carboxymethyl cellulose fiber

ActiveCN114478809ASolve the problem that it is difficult to dissolve into spinning dope and make fibers by wet spinningNo effect on structureChemical/physical/physico-chemical moving reactorsCarboxymethyl cellulosePolymer science

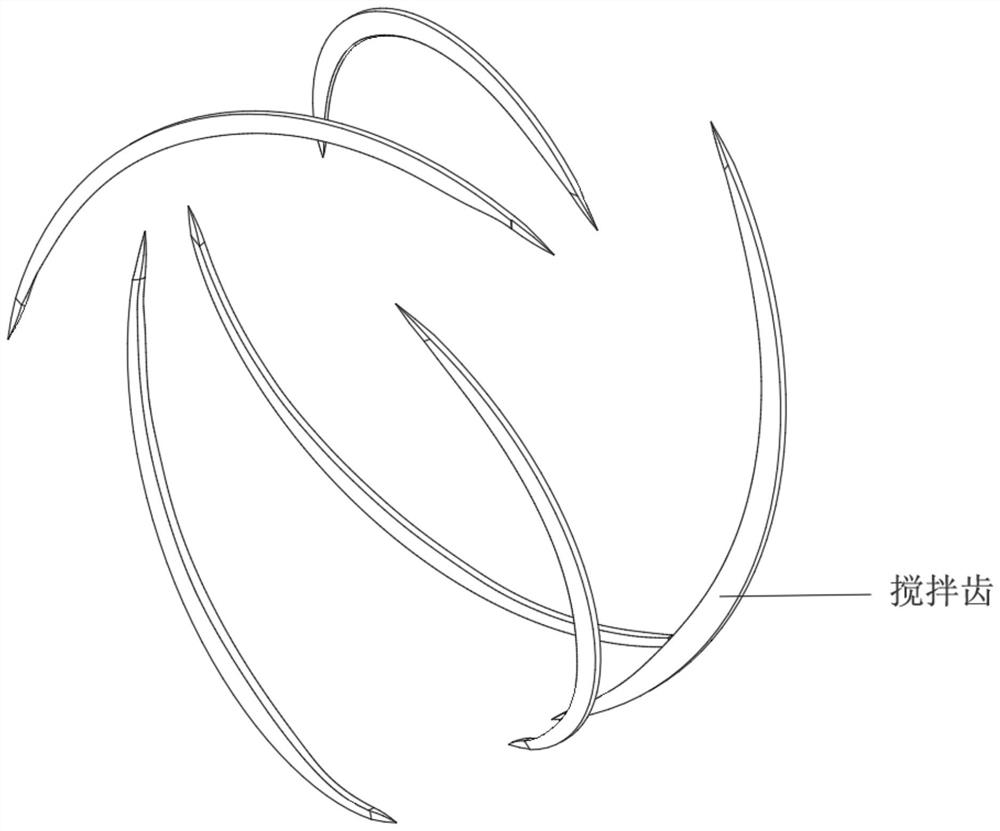

The invention provides a preparation method of carboxymethyl cellulose fibers. The preparation method comprises the steps of alkalization, etherification and post-treatment. Cellulose fiber is used as a raw material and is carried out in an organic solvent, so that the initial structure of the cellulose fiber can be reserved, and the structure and the form of the fiber are basically not influenced. Cetyltrimethylammonium bromide is added during etherification, so that the surface tension of the fiber is reduced, the hydrophilicity of the fiber is improved, and the reaction efficiency is improved; meanwhile, hexadecyl trimethyl ammonium bromide is used as a brominating agent, free bromide ions in the system directly participate in the reaction during etherification, and the fibers are brominated to form a new grafted copolymer, so that the wettability and adsorbability of the fibers are improved, and the fibers can quickly adsorb exudate after being made into medical dressing, so that wounds are kept dry, and the breeding of bacteria is reduced. According to the invention, the stirring reaction pot is improved, so that the influence on the structure and form of the fiber caused by the problems of fiber hanging, winding, caking and the like during etherification is avoided.

Owner:浙江隆腾新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com