High-integration-level fuel cell bipolar plate for optimizing distribution of reaction gas

A highly integrated fuel cell technology, applied in fuel cells, fuel cell components, battery electrodes, etc., to achieve the effects of increasing specific power density, simple structure, and simplifying water management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

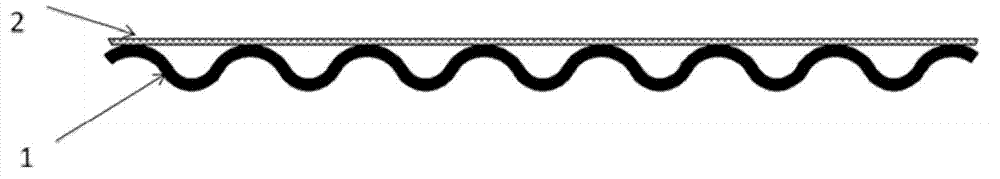

[0021] The upper mesh porous flow field plate 2 is made of gold-plated nickel foam with a thickness of 0.3mm. The lower metal plate 1 is a gold-plated titanium alloy plate with a thickness of 0.08mm; after the gold-plated titanium alloy plate is punched and formed, the width of the channel is 0.8mm, the depth of the channel is 0.3mm, the width of the protrusion is 0.8mm, and the overall thickness is 0.38mm. The lower metal plate 1 and the upper mesh porous flow field plate 2 are directly stacked together. Before the battery or stack is assembled, the metal plate is not embedded in the mesh porous flow field plate, and the two are realized by the assembly force of the battery or stack. touch.

Embodiment 2

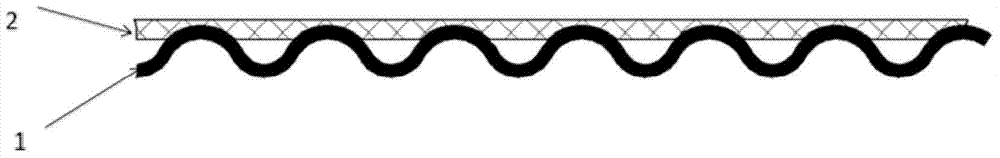

[0023] The upper mesh porous flow field plate 2 is made of carbon-plated stainless steel mesh with a thickness of 0.5mm. The lower metal plate 1 is a carbon-coated 316L stainless steel plate with a thickness of 0.1 mm; after the stainless steel plate is stamped and formed, the width of the channel is 0.4 mm, the depth of the channel is 0.3 mm, the width of the protrusion is 0.4 mm, and the overall thickness is 0.4 mm. The lower metal plate 1 and the upper mesh porous flow field plate are stacked together, and the metal plate is embedded into the mesh porous flow field plate by 20.1 mm by a press under 0.1 MPa. When assembling a cell or stack, it is assembled together with stack components such as membrane electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com