Fuel cell metal bipolar plate for reinforcing distribution of reactant gas

A metal bipolar plate and fuel cell technology, which is applied to fuel cell components, battery electrodes, circuits, etc., to avoid defects, simplify materials, and increase the effective area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

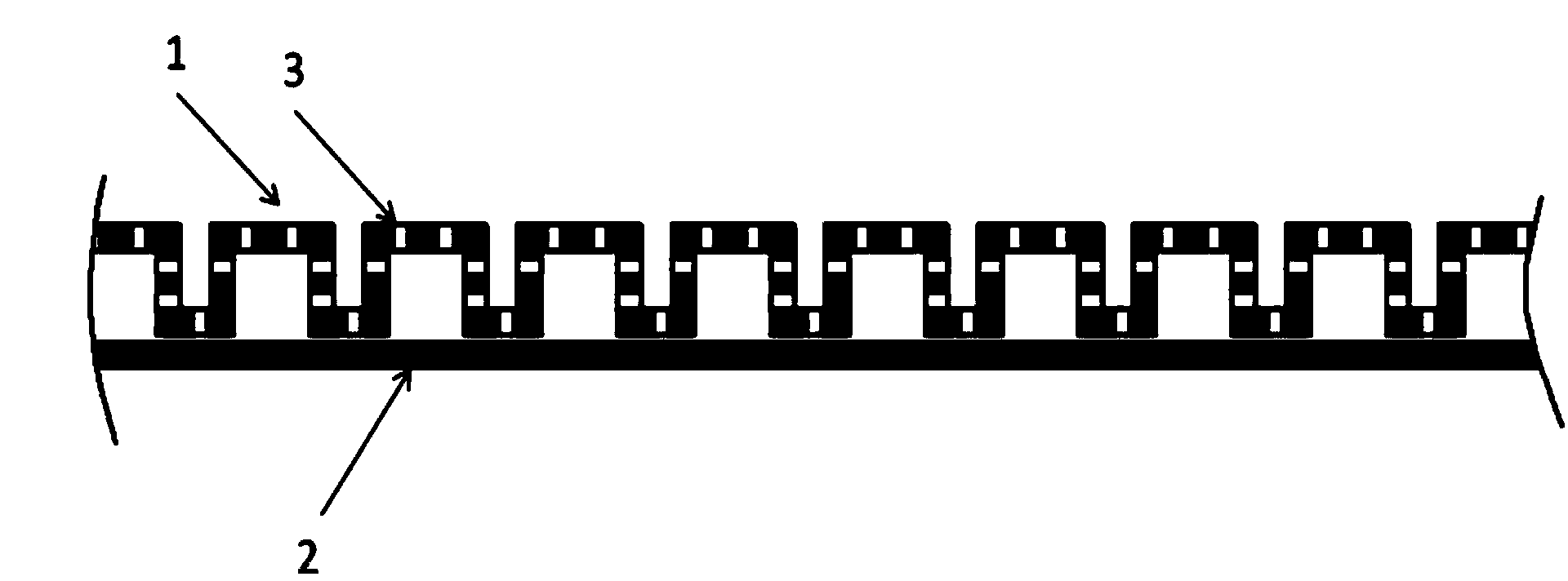

[0027] The upper flow field plate 1 is molded into a flow channel shape by a porous metal sheet; the metal material is titanium alloy, and the surface is gold-plated; the thickness of the porous metal sheet is 0.05mm, the size of the holes on the plate is Φ0.2mm, and the distance between the centers of adjacent holes is 0.3mm; After the flow field, the width of the flow channel is 0.3mm, the depth of the flow channel is 0.3mm, the width of the protrusion is 0.3mm, the height of the protrusion is 0.3mm, and the overall thickness of the flow field is 0.35mm. The thickness of the lower metal sheet is 0.08mm, and the material is a gold-plated titanium alloy plate. The lower metal thin plate 2 and the upper flow field plate 1 are joined by fiber laser welding. Example 2:

Embodiment 2

[0028] The upper flow field plate 1 is molded into a flow channel shape by a porous metal sheet; the metal mesh is made of 316L stainless steel with a carbon layer on the surface; the thickness of the 316L stainless steel plate is 0.1mm, the size of the holes on the plate is 0.1mm, and the distance between the centers of adjacent holes is 0.3mm; After stamping into the flow field, the width of the flow channel is 0.4mm, the depth of the flow channel is 0.2mm, the width of the protrusion is 0.1mm, the height of the protrusion is 0.2mm, the overall thickness of the flow field is 0.3mm, the thickness of the lower metal layer is 0.1mm, and the material is 316L Stainless steel with carbon coating. The lower metal thin plate 2 and the upper flow field plate 1 are pressed together by stack assembly force.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com