Patents

Literature

30results about How to "Reduce stack thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Touch sensing film structure

ActiveCN103941904AWith water and oxygen barrier functionReduce stack thicknessInput/output processes for data processingTouch SensesComputer science

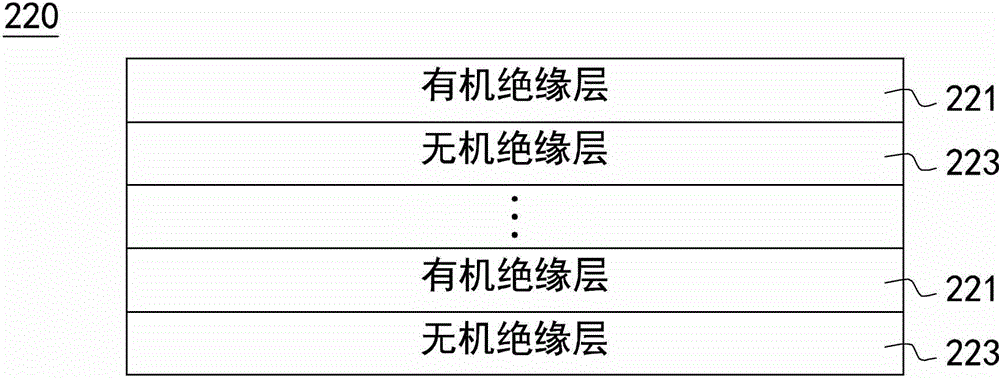

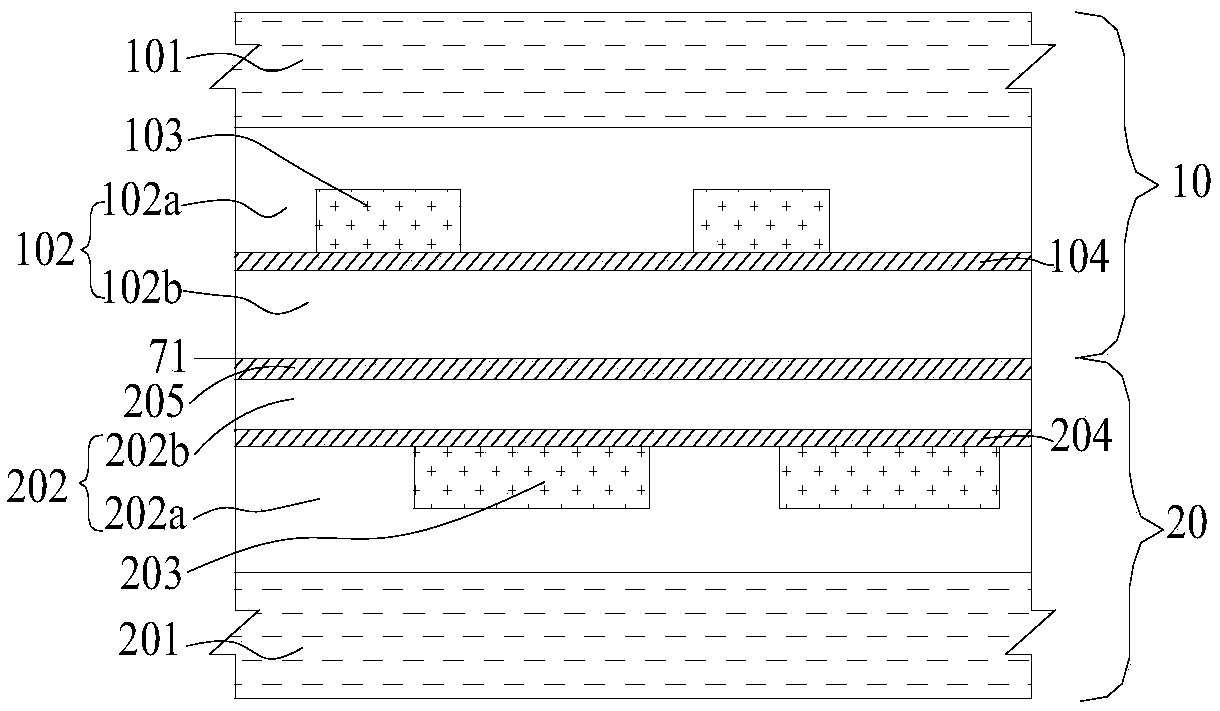

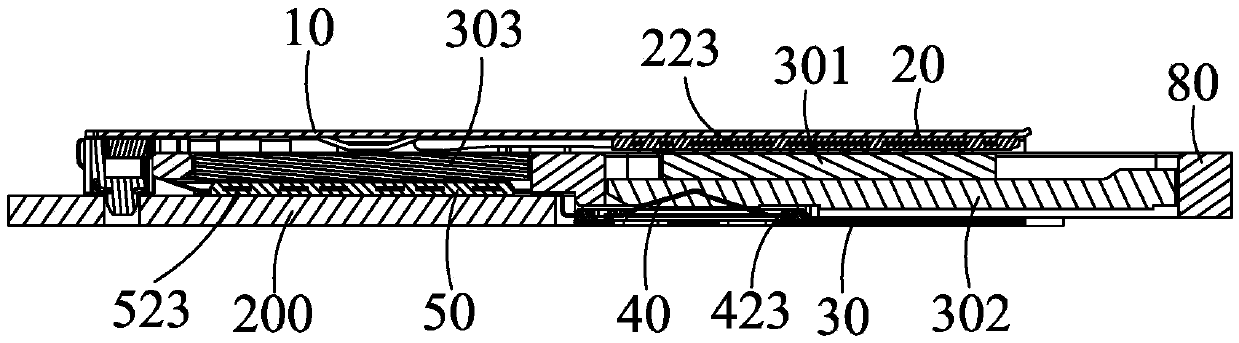

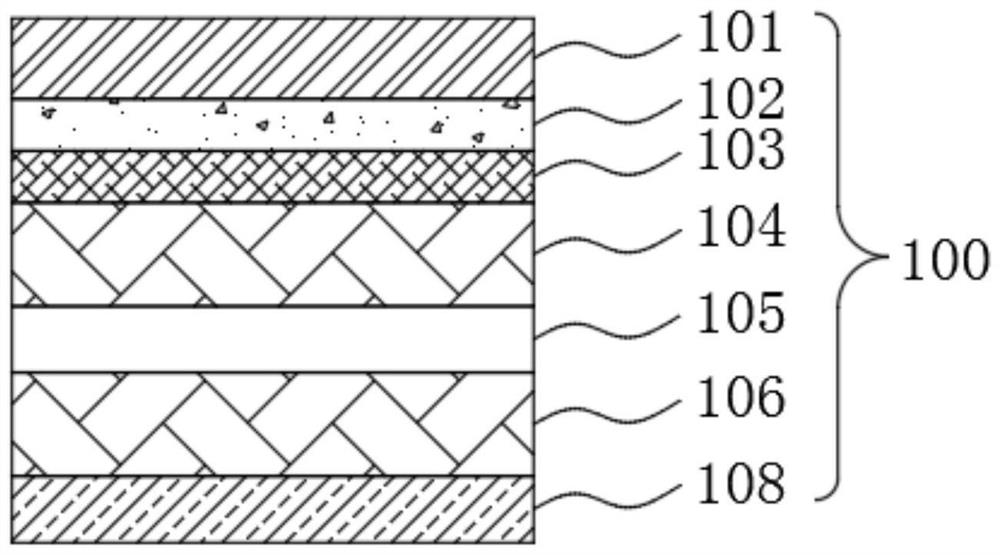

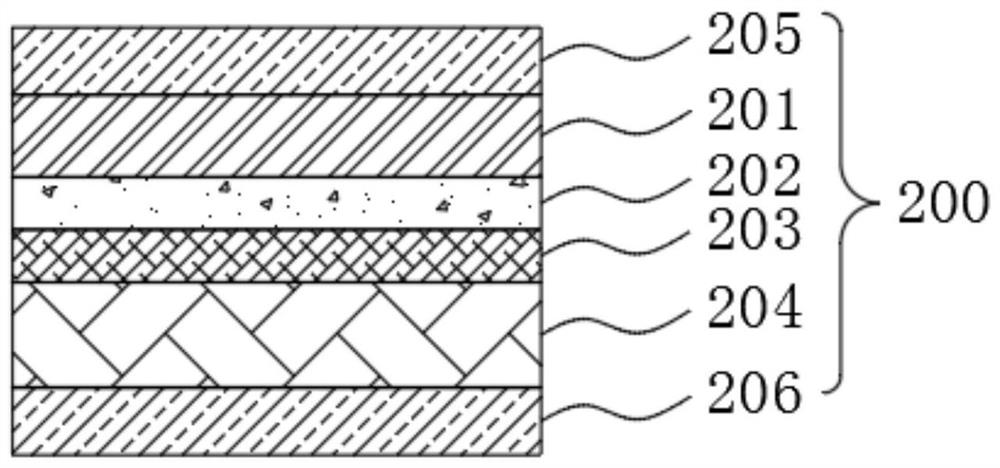

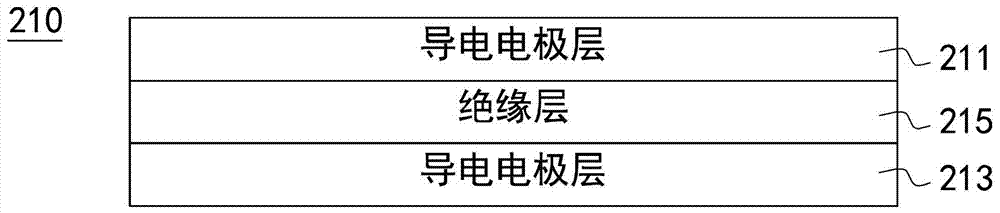

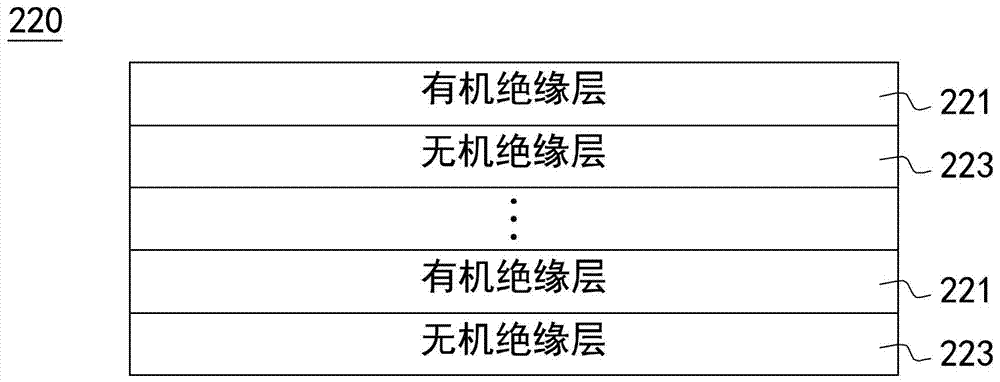

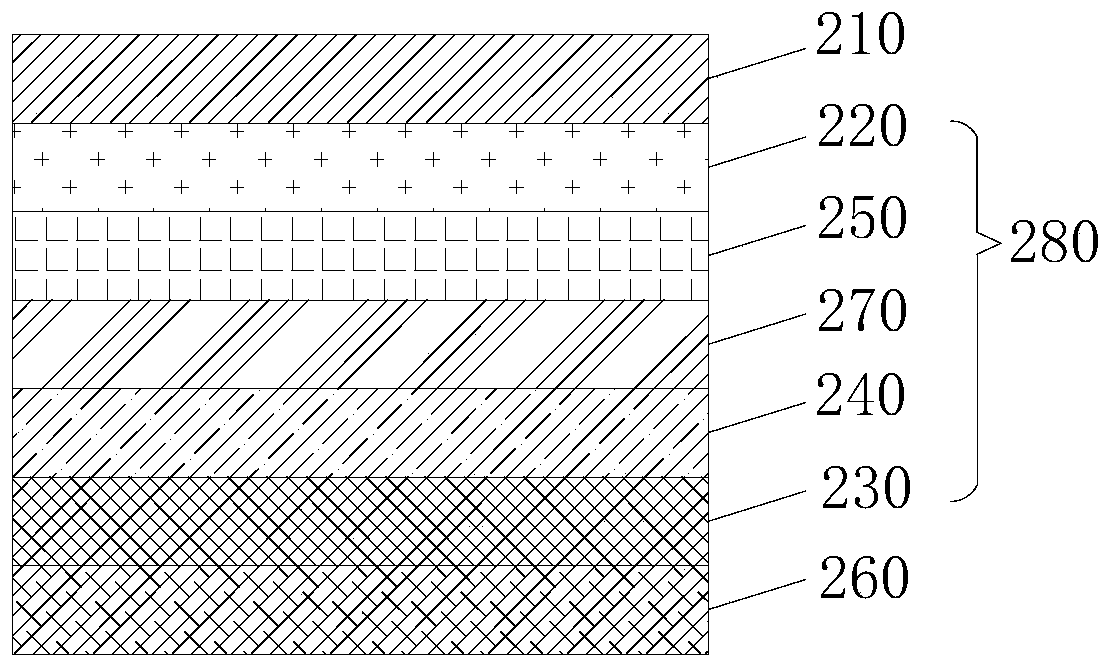

A touch sensing film structure including a touch-sensitive device layer, a barrier layer and a flexible substrate is provided. The touch-sensitive device layer has a first surface and a second surface opposite to the first surface. The barrier layer is formed on the first surface or the second surface or integrated with the touch-sensitive device layer to form a multi-function layer. The flexible substrate can stack with the barrier layer and the touch-sensitive device layer, or stack with the multi-function layer.

Owner:HANNSTAR DISPLAY CORPORATION

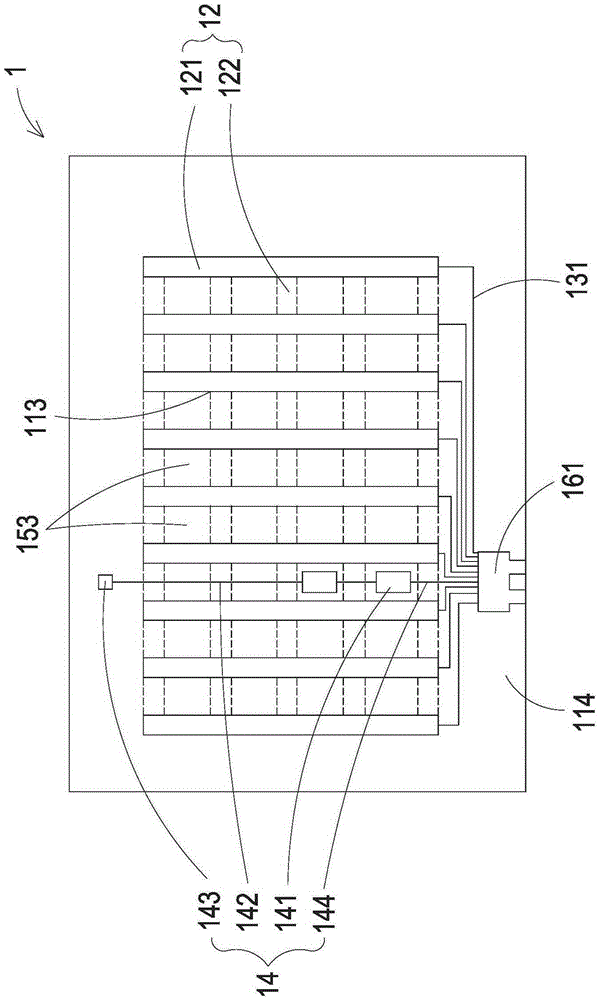

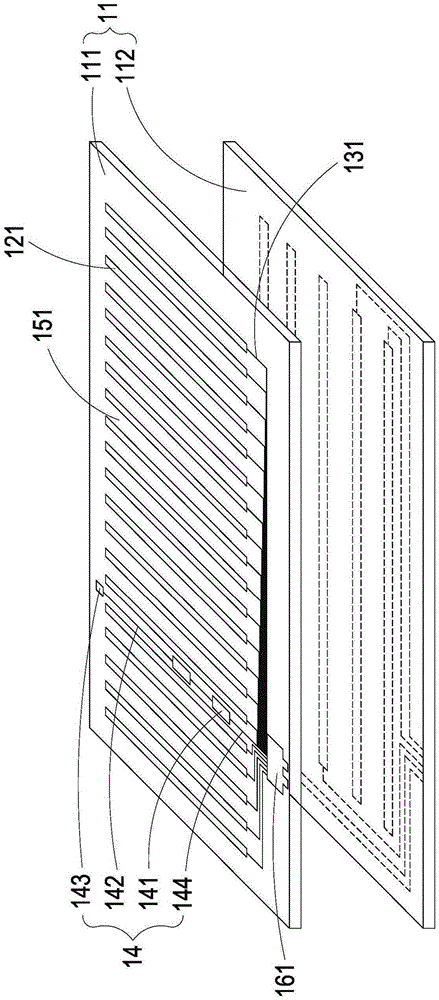

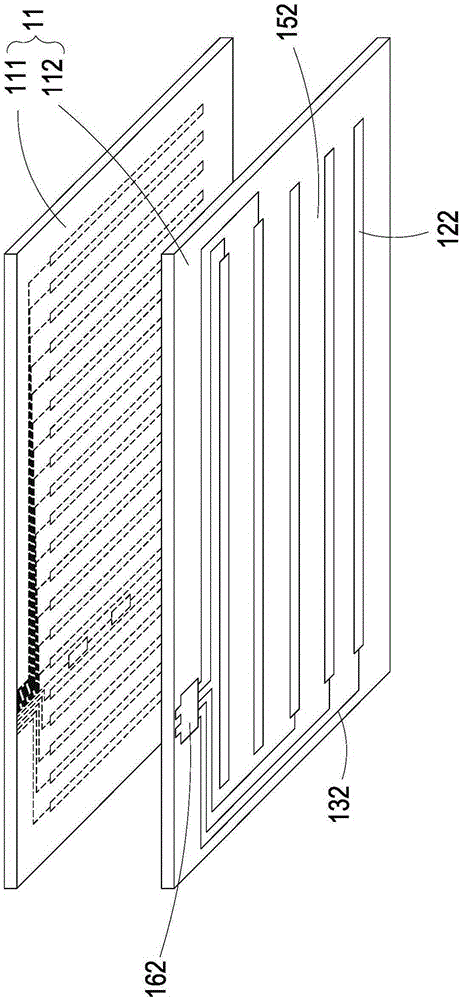

Touch module with transparent antenna and touch display apparatus using same

PendingCN106708309AHigh sensitivityDoes not affect build sizeElongated active element feedAntenna detailsVertical projectionCover glass

A touch display apparatus with a transparent antenna and a touch display apparatus using same are disclosed. The touch display apparatus including a cover glass, a display module, and a touch module. The touch module is disposed between the cover glass and the display module. The touch module includes a transparent substrate, a metal mesh touch sensor, and an antenna. The metal mesh touch sensor is disposed on at least one surface of the transparent substrate and configured to form a viewable area, wherein the viewable area comprises at least an overlapping dummy area free of a vertical projection of the metal mesh touch sensor. The antenna is disposed on the at least one surface of the transparent substrate, and at least portion of the antenna being located in the overlapping dummy area, wherein the antenna and the metal mesh touch sensor are insulated from each other.

Owner:J TOUCH CORPORATION

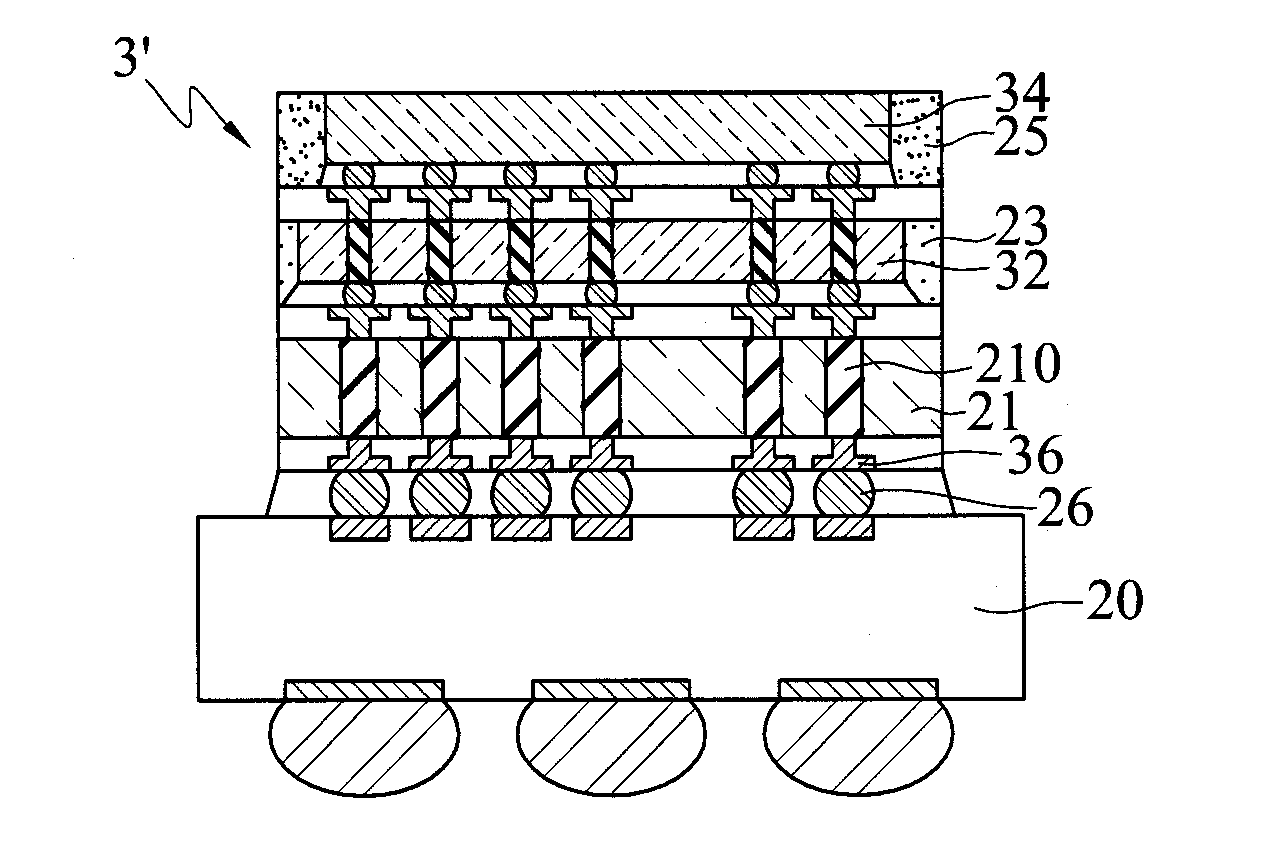

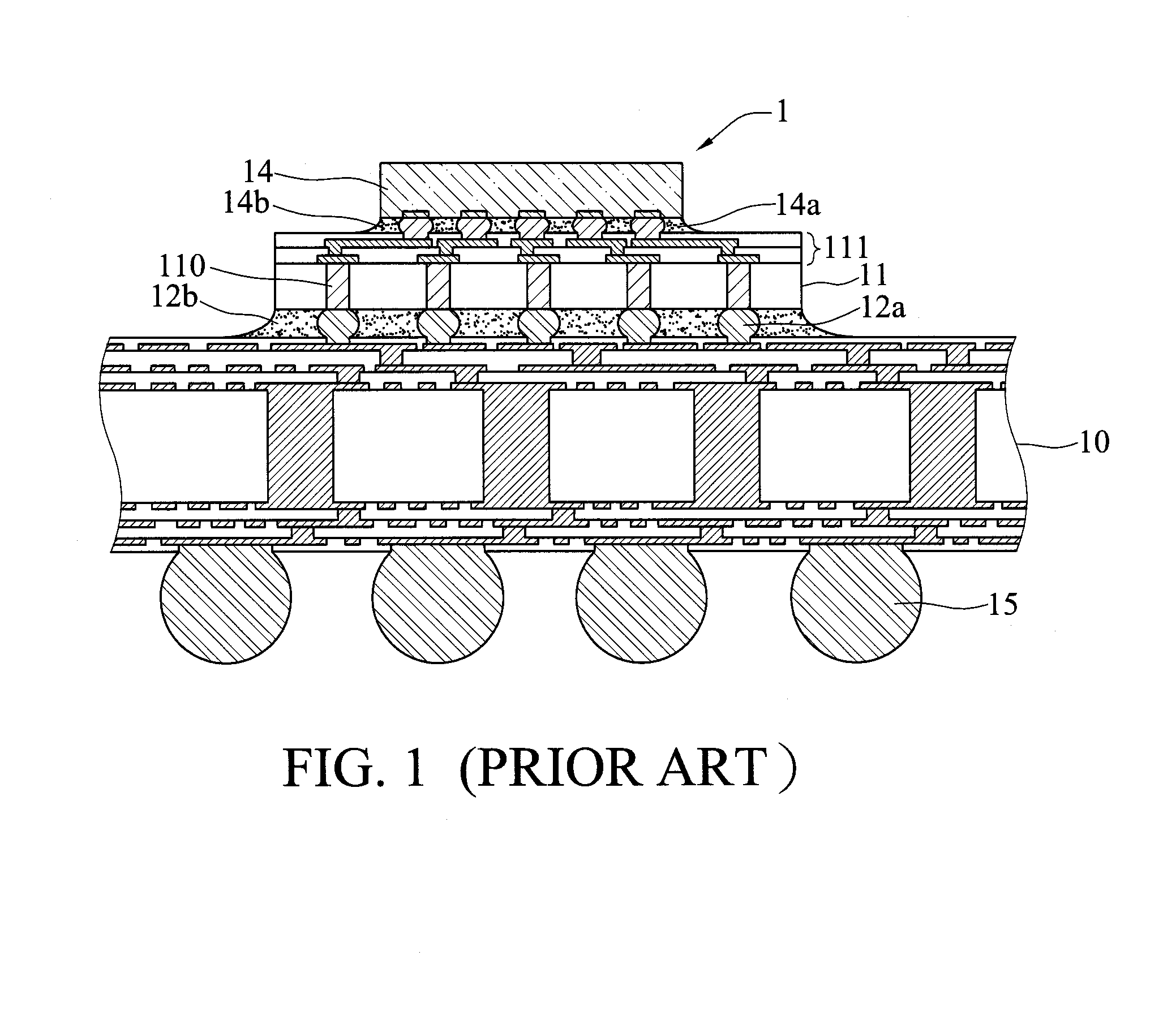

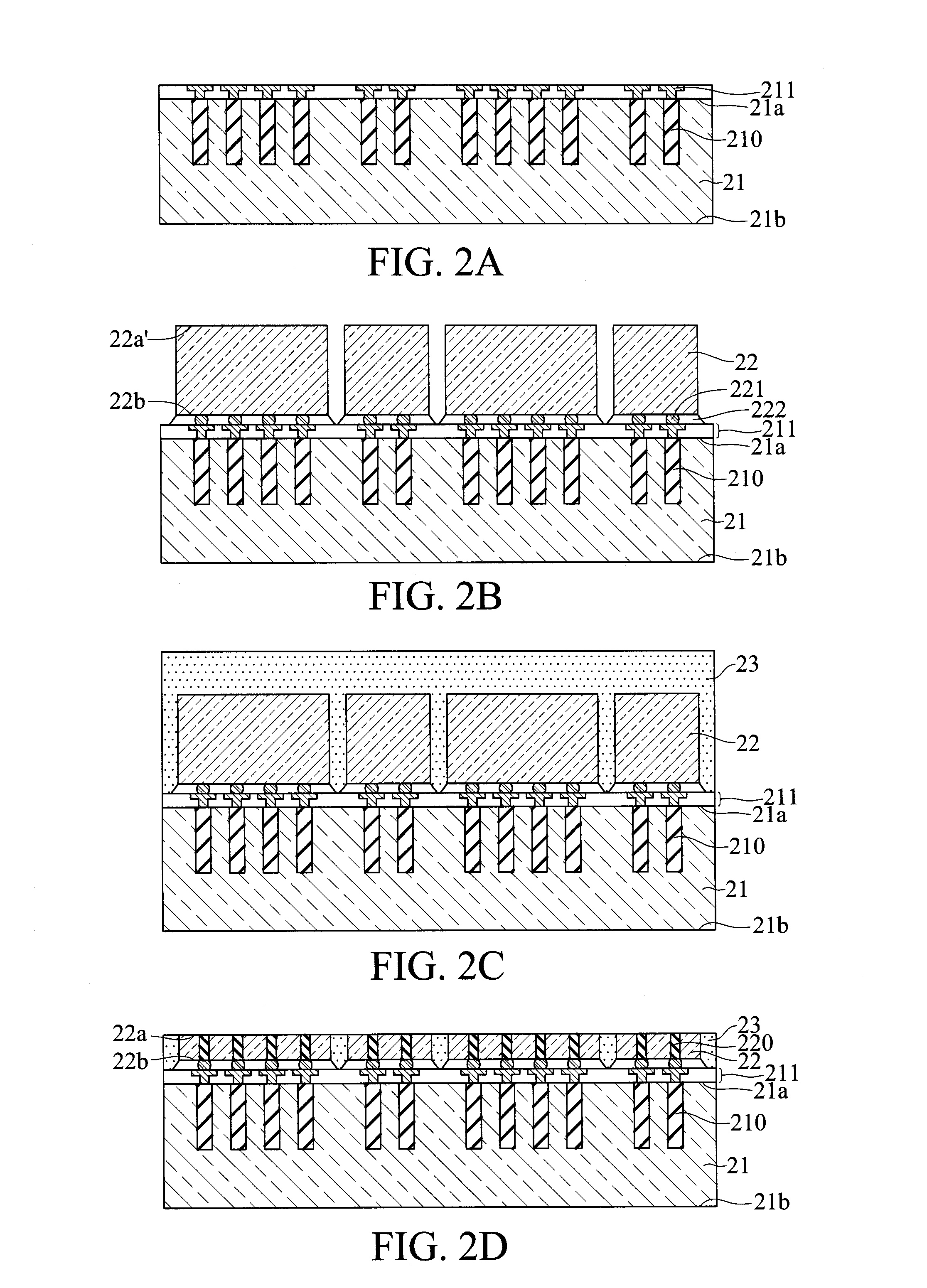

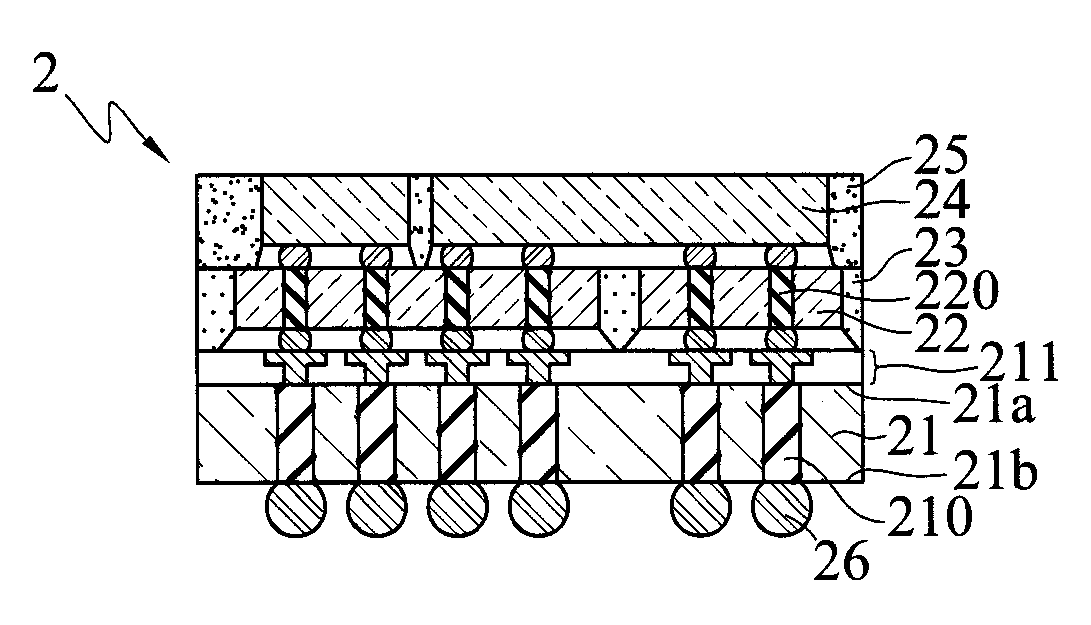

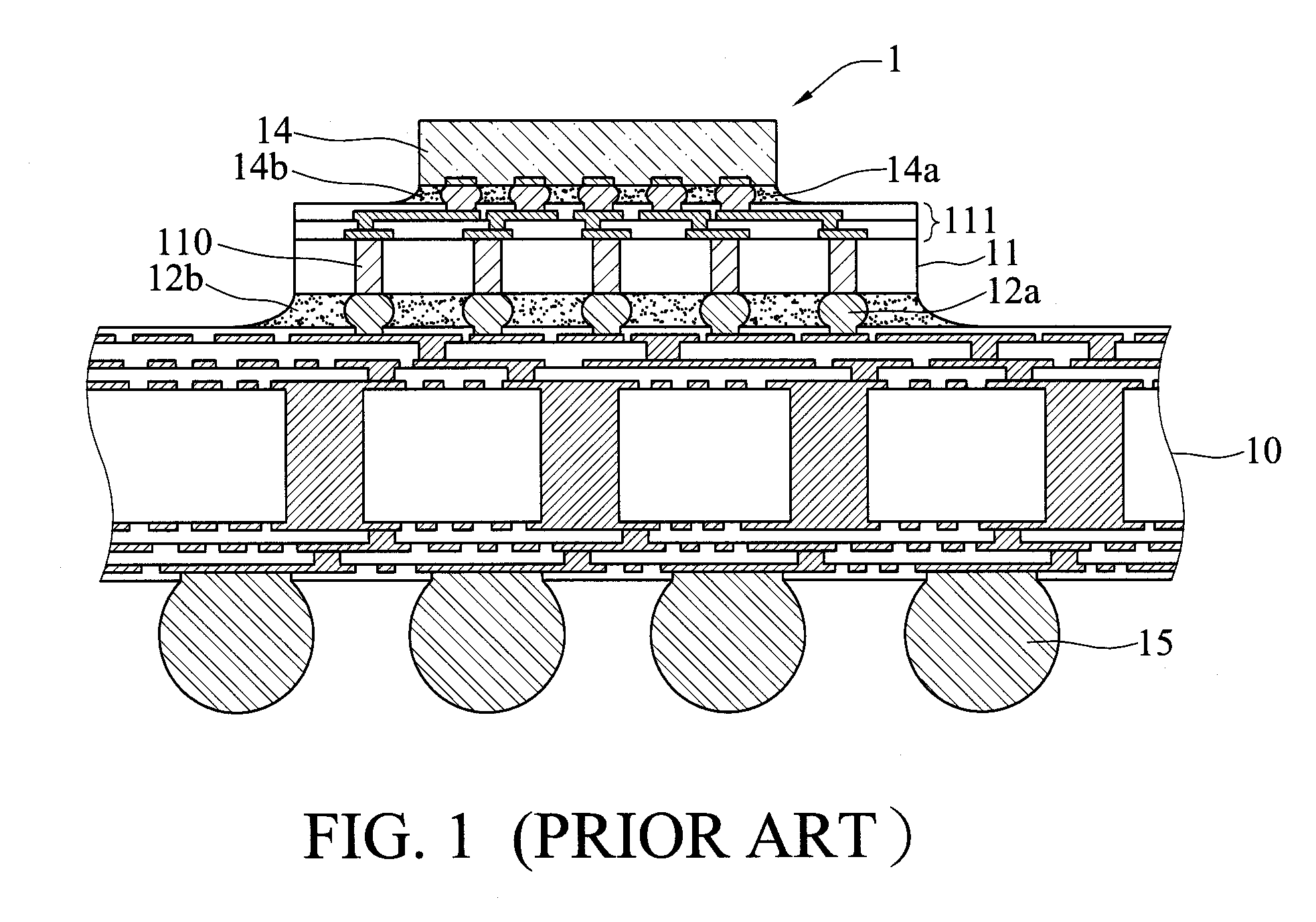

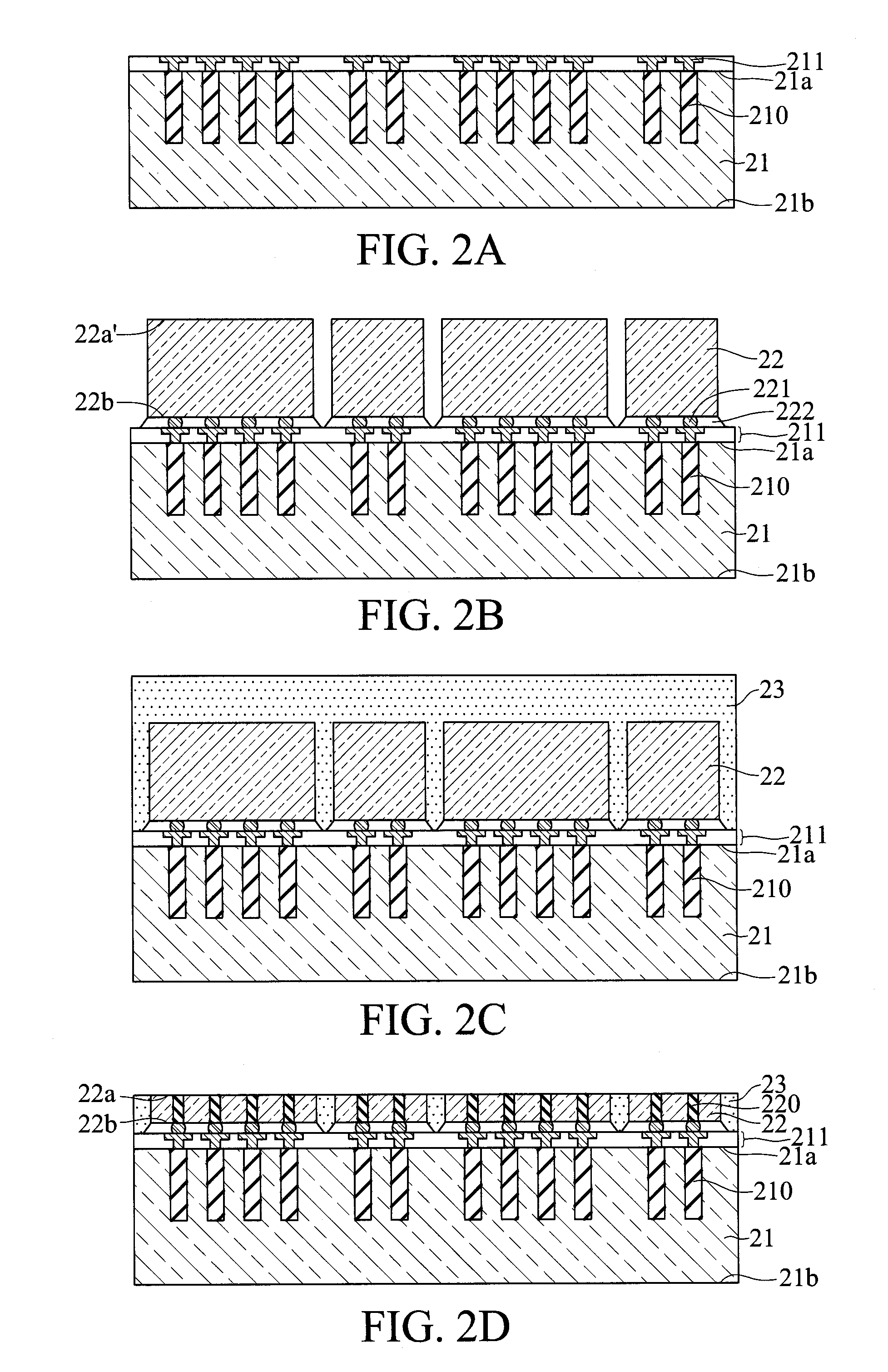

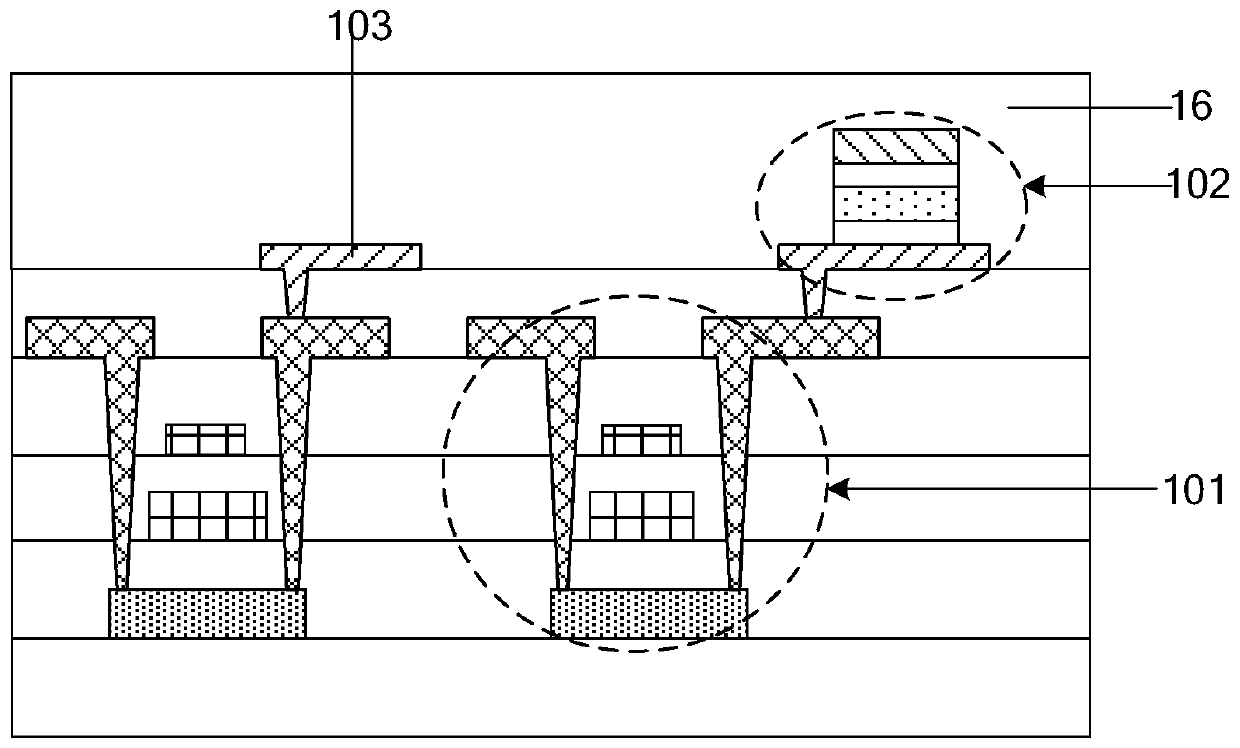

Semiconductor package and fabrication method thereof

ActiveUS20140264928A1Reduce stack thicknessImprove productivitySemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor components

A fabrication method of a semiconductor package is disclosed, which includes the steps of: disposing a plurality of first semiconductor elements on an interposer; forming a first encapsulant on the interposer for encapsulating the first semiconductor elements; disposing a plurality of second semiconductor elements on the first semiconductor elements; forming a second encapsulant on the first semiconductor elements and the first encapsulant for encapsulating the second semiconductor elements; and thinning the interposer, thereby reducing the overall stack thickness and preventing warpage of the interposer.

Owner:SILICONWARE PRECISION IND CO LTD

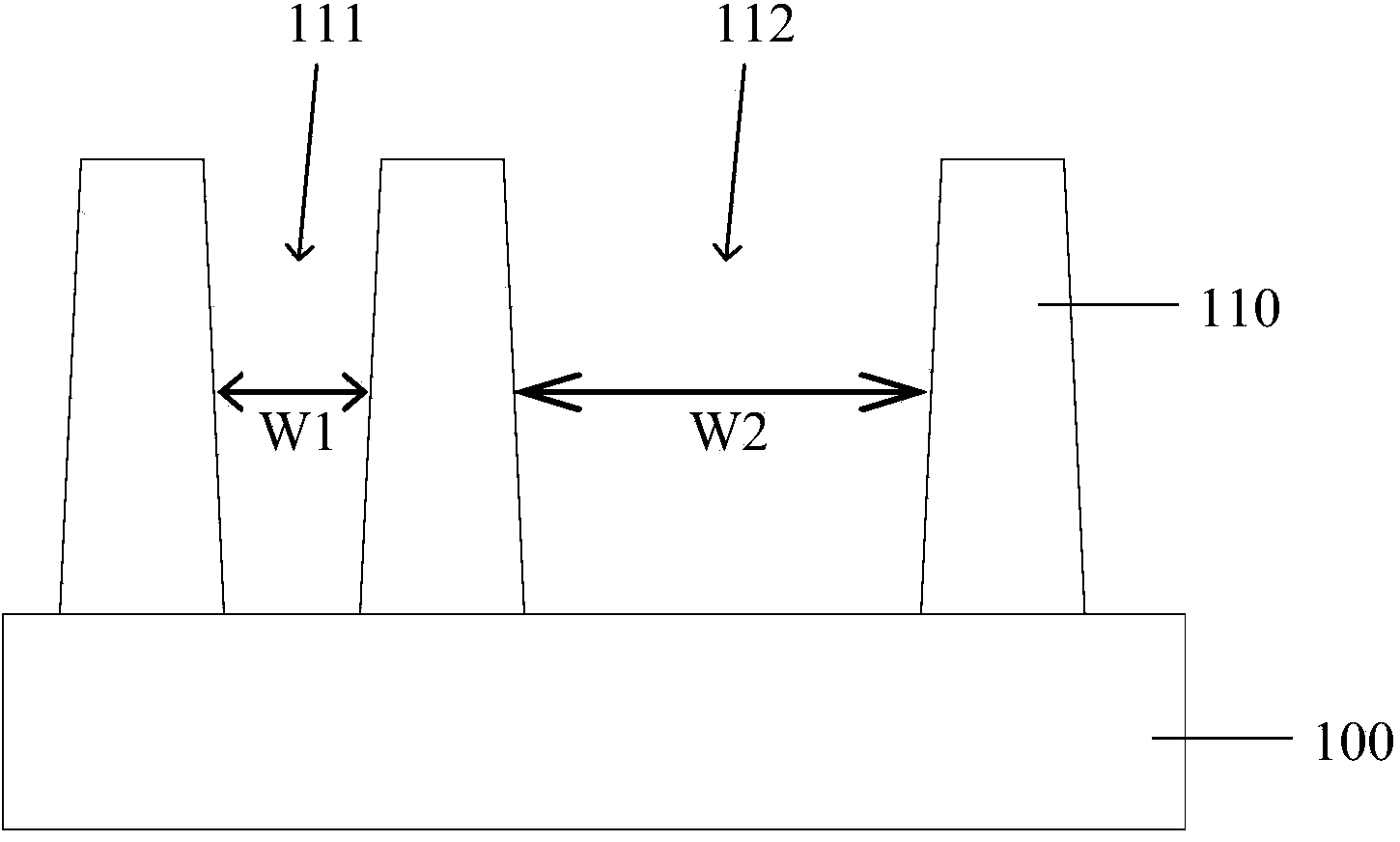

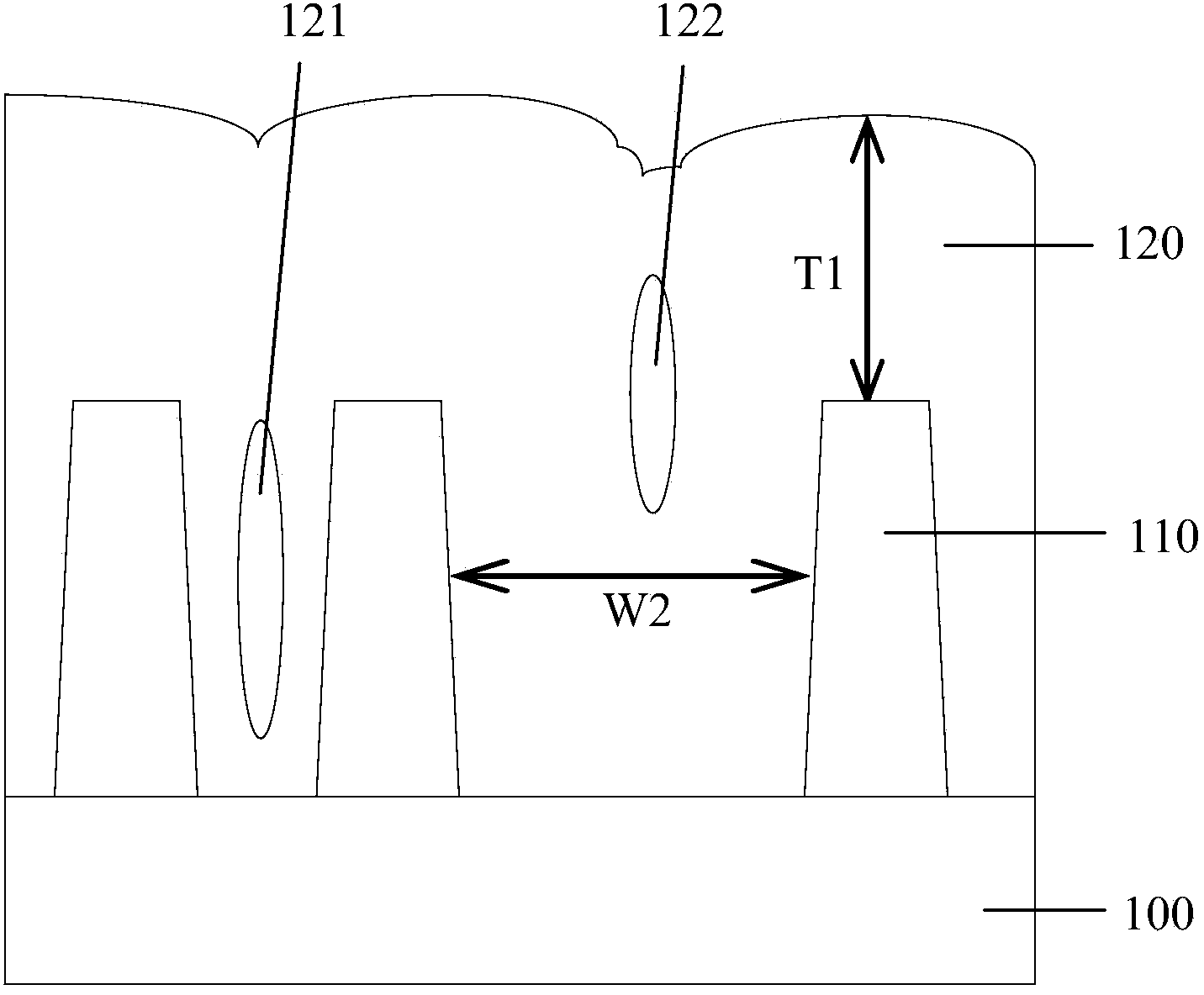

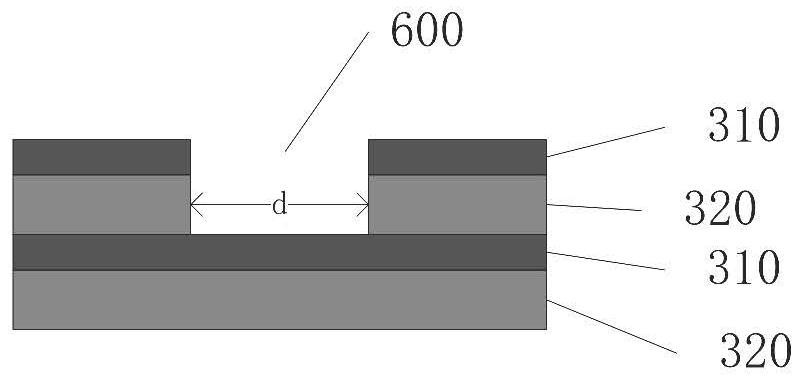

Interconnecting wire structure and forming method thereof

ActiveCN103871964AReduce thicknessReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The invention relates to an interconnecting wire structure and a forming method thereof. A semiconductor substrate is provided; the forming method of the interconnecting wire structure comprises the steps of forming multiple independent interconnecting wires on the semiconductor substrate, wherein grooves are formed between adjacent interconnecting wires; forming a first interlayer dielectric layer to cover the interconnecting wires, and filling a groove in part of the first interlayer dielectric layer until an opening is formed; forming a second interlayer dielectric layer to cover the first interlayer dielectric layer, wherein the opening is sealed by the second interlayer dielectric layer to form an air gap; flattening the second interlayer dielectric layer. The interconnecting wire structure formed by the forming method is improved in quality, and the forming method is simple in process and low in process cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Thin 3D fan-out packaging structure and wafer-level packaging method

PendingCN109300837ASolving Deposition Quality IssuesReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesWafer-level packagingPrinted circuit board

The invention discloses a thin 3D fan-out packaging structure and a wafer-level packaging method. Grooves and blind holes whose depths are smaller than those of the grooves are made in a carrier plate; a lining is deposited on the inner wall of the blind hole; a dielectric layer is deposited on at least the bottom of the groove; the blind hole is filled with a metal material; a chip is buried in the groove; a chip welding pad or the blind hole metal material is connected through metal rewiring; the second surface of the carrier plate is thinned, and the metal material in the blind hole is exposed; an electrical derivation point is made on the metal rewiring or the metal material, a stacking chip or a printed circuit board is electrically connected with the chip welding pad through the electrical derivation points on the first surface and the second surface of the carrier plate, and 3D fan-out packaging is realized. The TSV and the lining are firstly made, the TSV and lining depositionquality problem can be solved, and ultra-high density interconnection is better realized; and the dielectric layer is deposited on the bottom part of the groove, the chip can be protected from being etched, and after the carrier plate is thinned, the height difference between the dielectric layer and the TSV hole can accommodate part of second electrical derivation points, and the stacking thickness is reduced.

Owner:HUATIAN TECH KUNSHAN ELECTRONICS

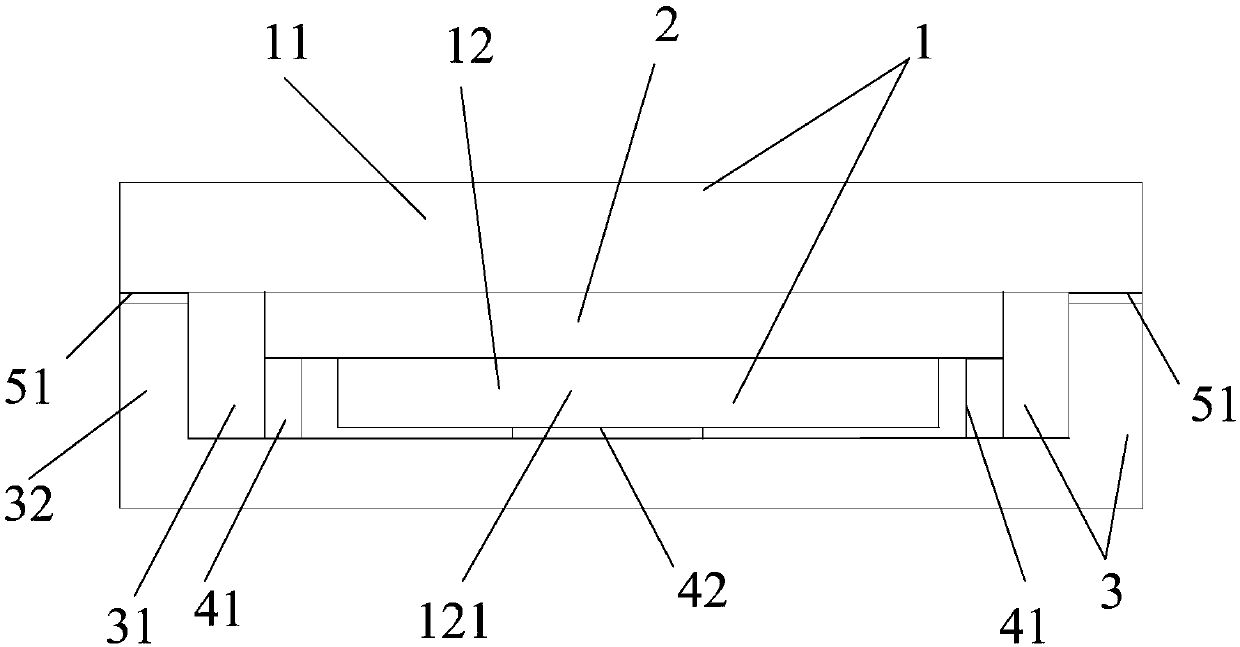

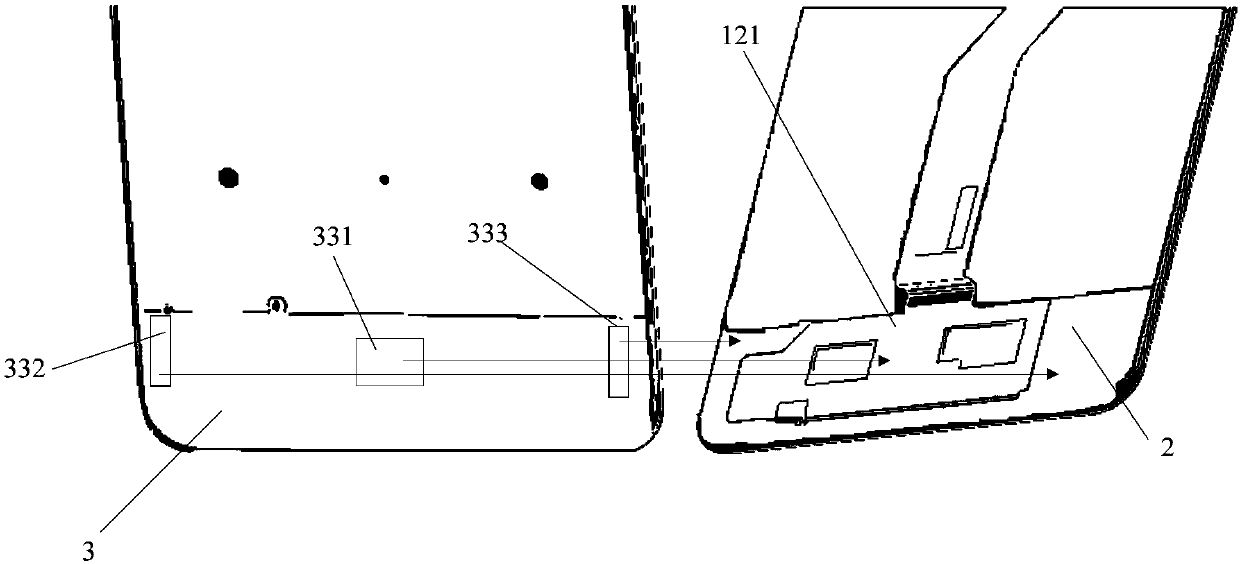

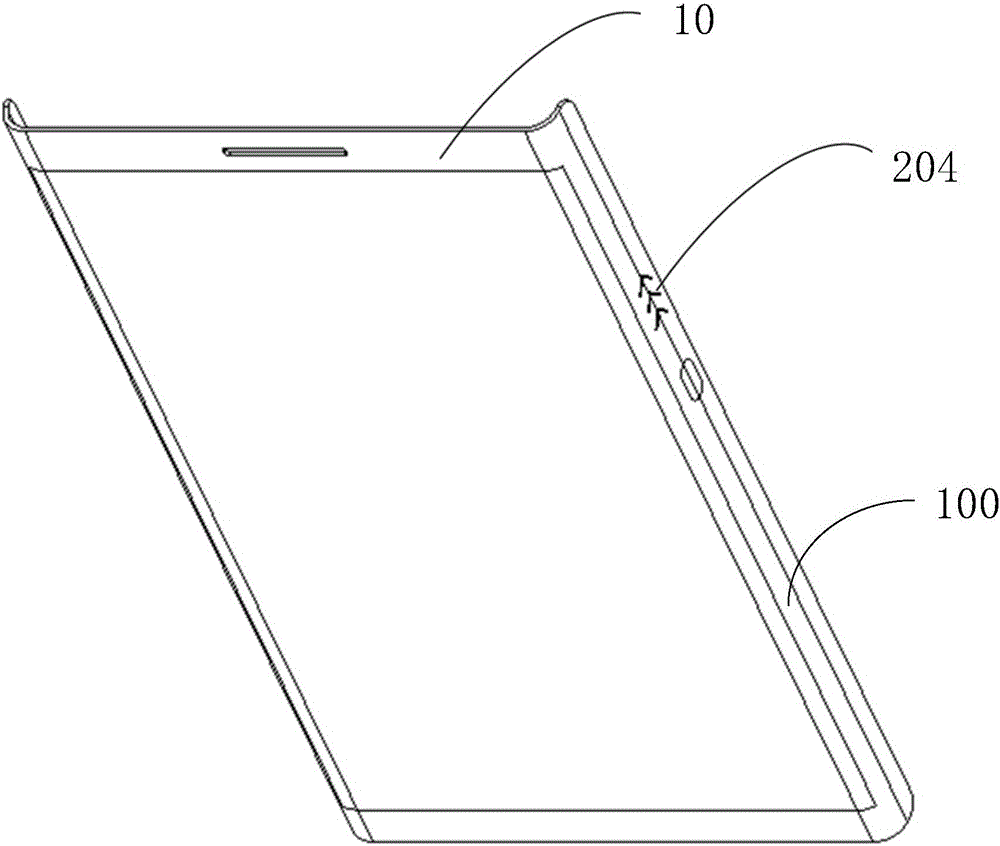

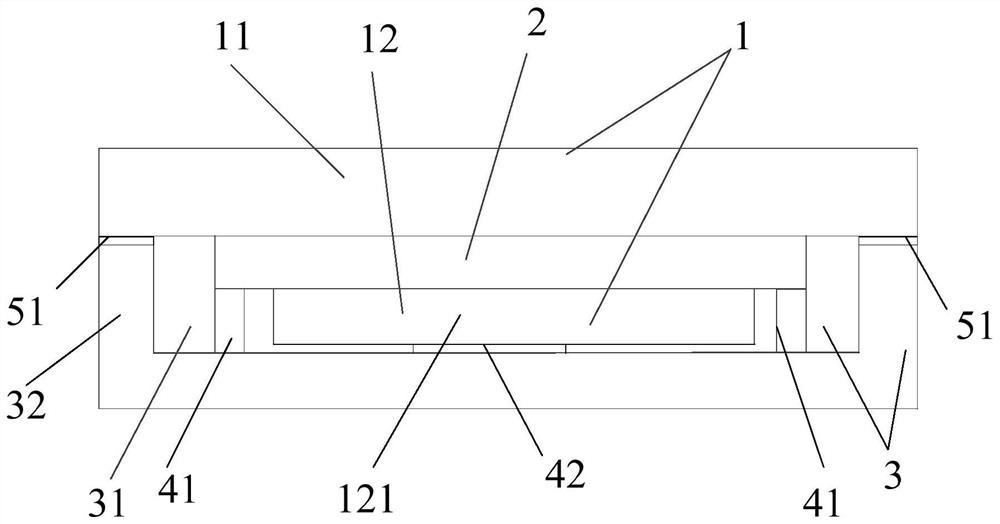

Terminal device

ActiveCN109618030AImprove temperature riseImprove cooling effectModifications by conduction heat transferTelephone set constructionsFlexible circuitsTerminal equipment

The invention provides a terminal device, comprising the following parts: a display module, comprising a display structure and a flexible circuit board; a metal structure, arranged between the displaystructure and the flexible circuit board and respectively attached to the display structure and the flexible circuit board, wherein the area of the attaching end surface of the metal structure the islarger than the area of the attaching end surface of the preset area of the flexible circuit board, and is smaller than the area of the attaching end surface of the display structure; a metal middleframe, comprising a groove and ends disposed on both sides of the groove, wherein the predetermined area of the flexible circuit board and the metal structure are disposed in the groove, and the endsare in contact with the display structure. The terminal device provided by the embodiment of the invention can reduce the stack thickness of the whole machine, provide a ground return path and excellent shielding performance, and can improve the temperature rise problem of the terminal device and improve the heat dissipation effect of the terminal device.

Owner:VIVO MOBILE COMM CO LTD

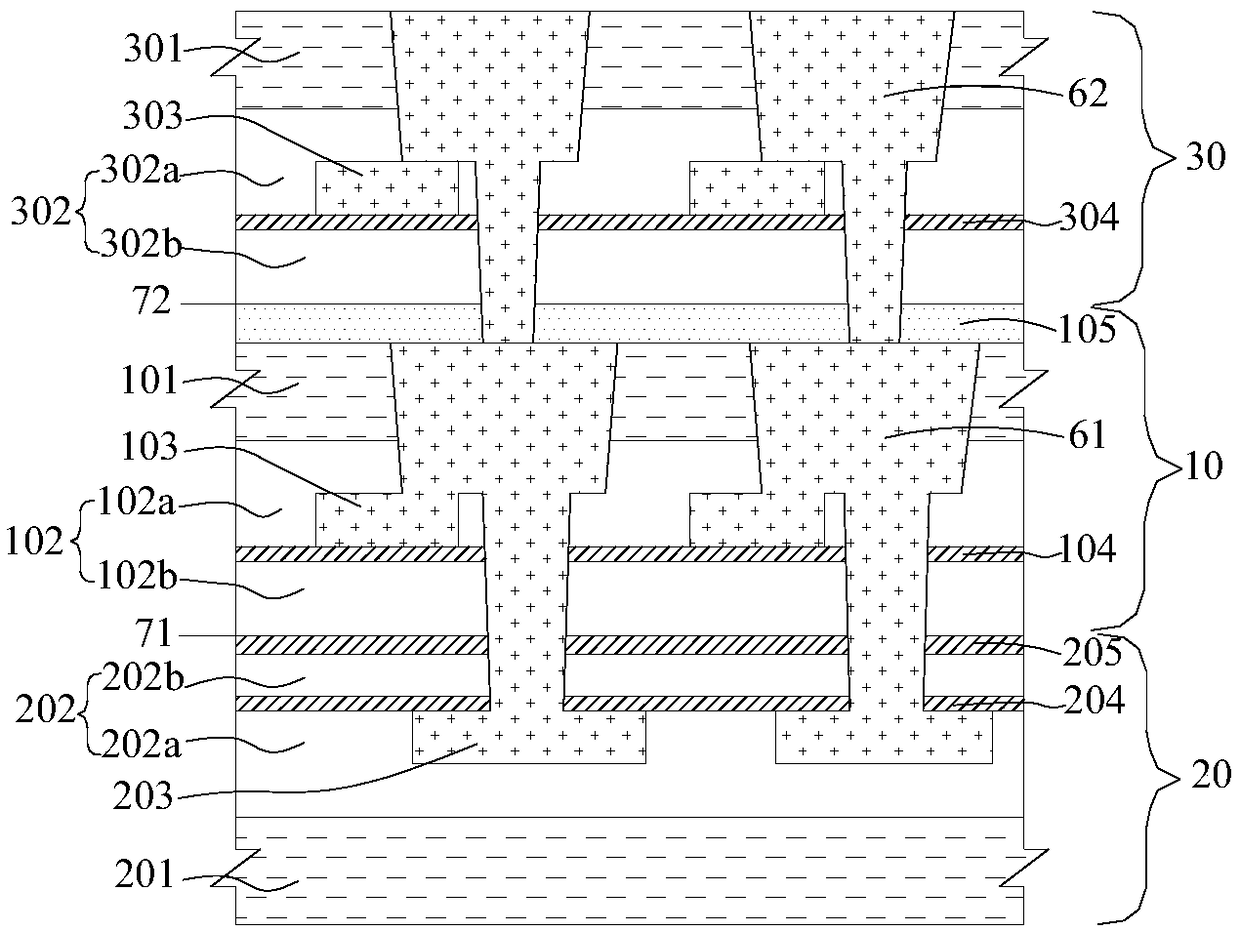

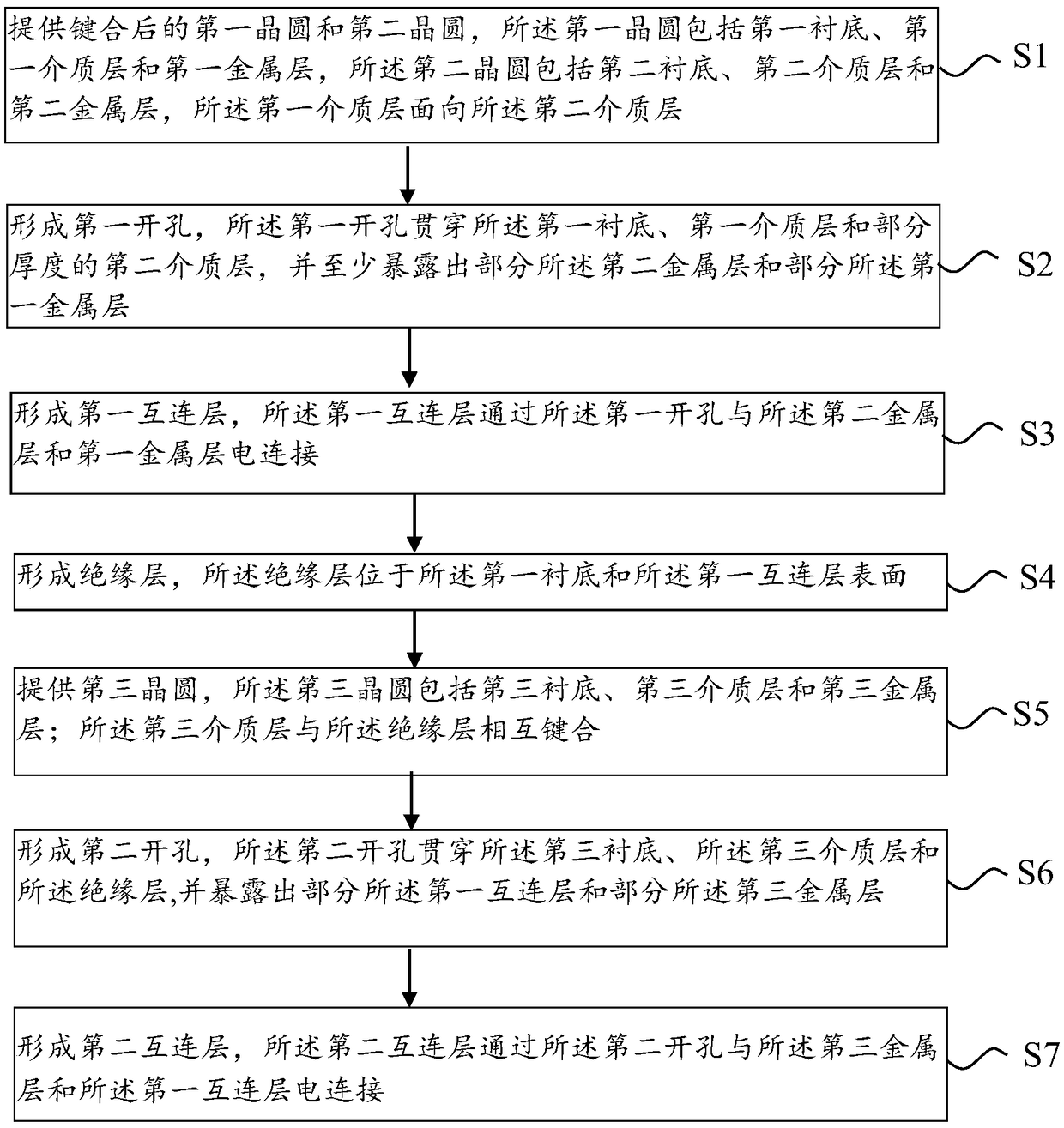

Multi-wafer stack structure and forming method thereof

ActiveCN109166840AAchieve stackingReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesWafer stackingInterconnection

Owner:WUHAN XINXIN SEMICON MFG CO LTD

Semiconductor package and fabrication method thereof

ActiveUS9324582B2Reduce stack thicknessReduce manufacturing costSemiconductor/solid-state device detailsSolid-state devicesInterposerSemiconductor package

A fabrication method of a semiconductor package is disclosed, which includes the steps of: disposing a plurality of first semiconductor elements on an interposer; forming a first encapsulant on the interposer for encapsulating the first semiconductor elements; disposing a plurality of second semiconductor elements on the first semiconductor elements; forming a second encapsulant on the first semiconductor elements and the first encapsulant for encapsulating the second semiconductor elements; and thinning the interposer, thereby reducing the overall stack thickness and preventing warpage of the interposer.

Owner:SILICONWARE PRECISION IND CO LTD

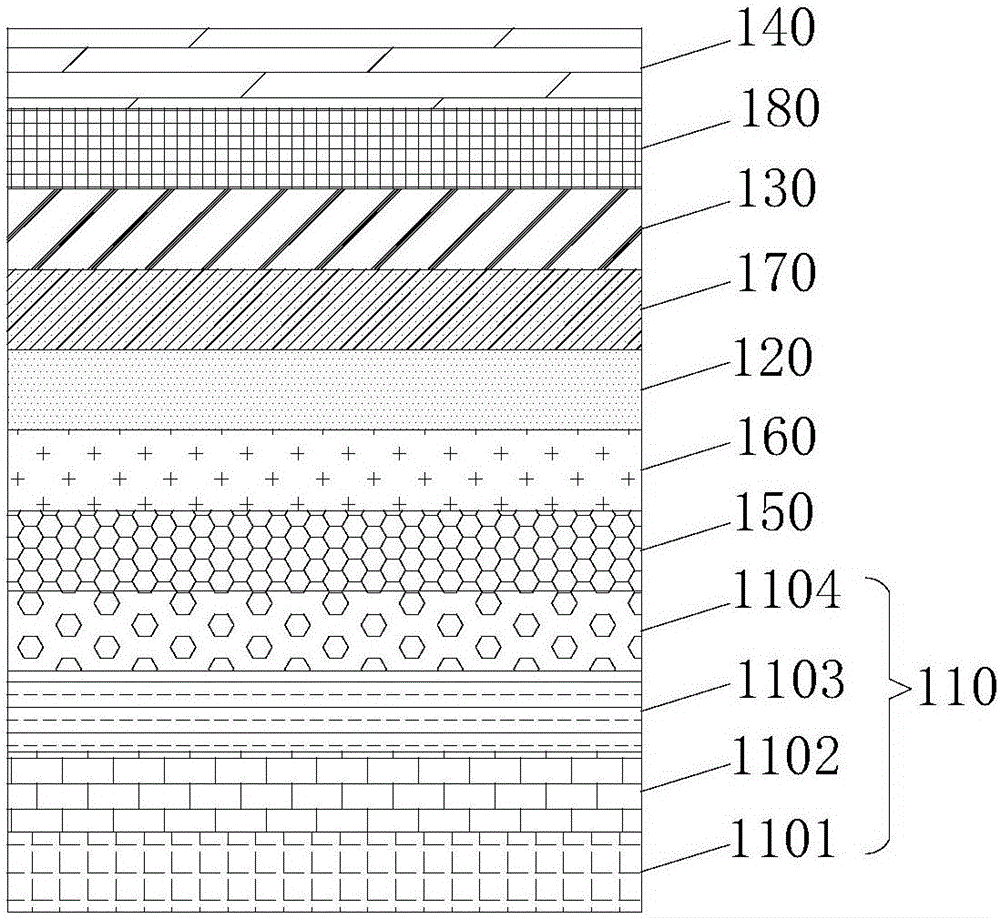

Touch display panel

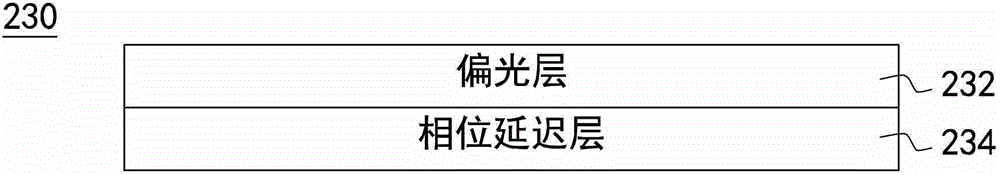

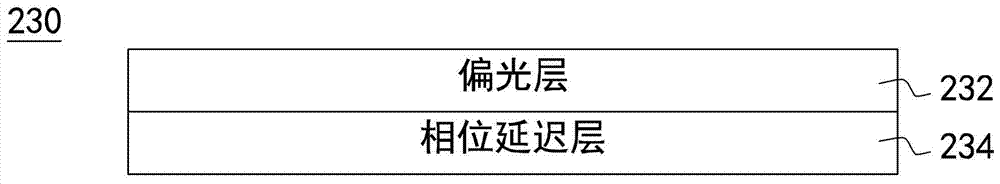

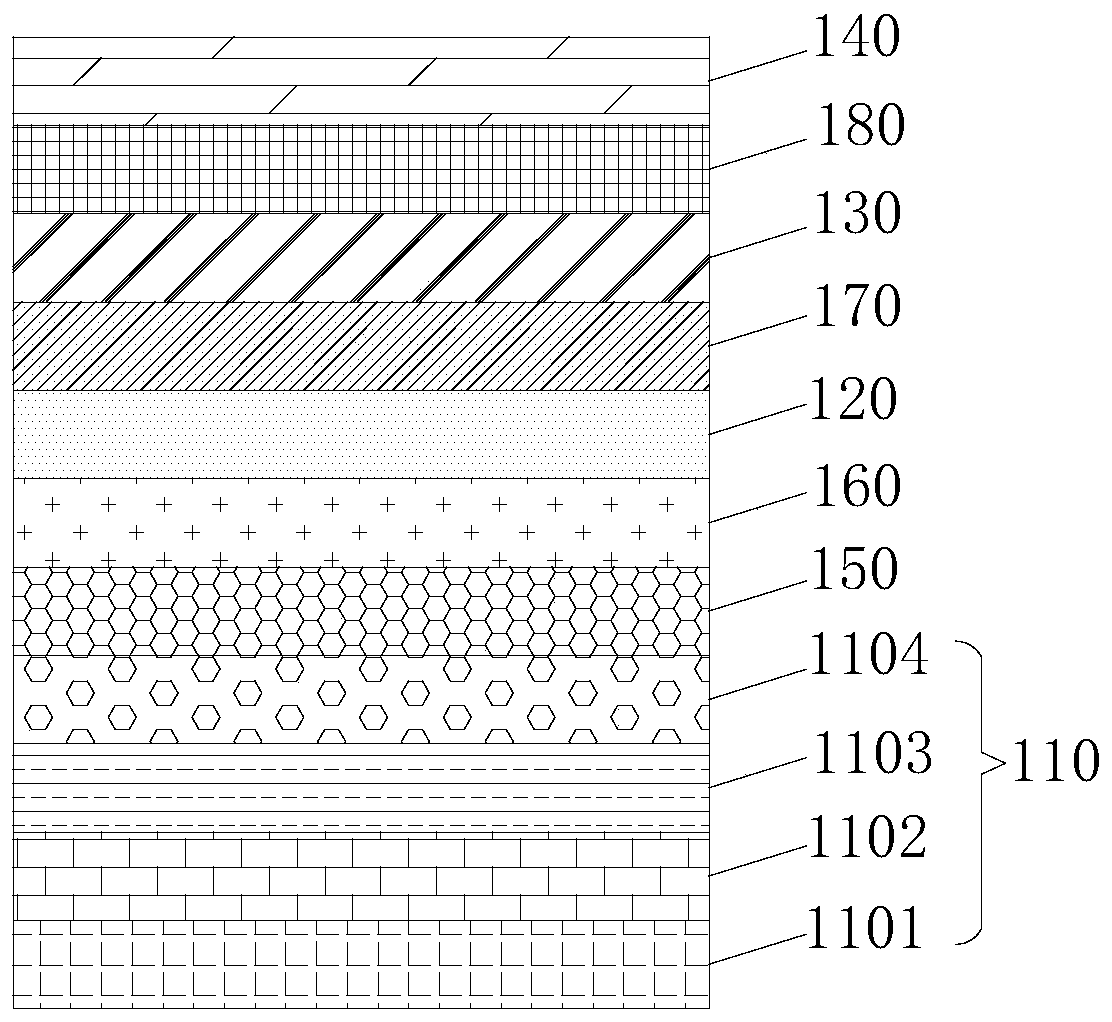

ActiveCN106383614AReduce stack thicknessImprove bending resistanceNon-linear opticsInput/output processes for data processingComposite filmOptical transmittance

The invention discloses a touch display panel. The touch display panel comprises a display module, a linear polarizer and a composite film, wherein the linear polarizer is formed at one side of the display module; the composite film is arranged between the linear polarizer and the display module and comprises a 1 / 2 lambda wave plate, a 1 / 4 lambda wave plate, a first touch electrode layer and a second touch electrode layer; the 1 / 4 lambda wave plate is formed at the side, far from the linear polarizer, of the 1 / 2 lambda wave plate; the first touch electrode layer is formed at any side of the 1 / 4 lambda wave plate; the second touch electrode layer is formed at any side of the 1 / 2 lambda wave plate; the first touch electrode layer and the second touch electrode layer are insulated from each other. The touch display panel has the beneficial effects that touch film layers are internally arranged between the linear polarizer and the display module and are respectively bonded and fixed with the 1 / 2 lambda wave plate and the 1 / 4 lambda wave plate to form the integrated composite film, so that the lamination thickness of the panel is reduced, thus increasing the bending resistance and optical transmittance of the panel, meeting the lightening and thinning requirements of products and being applicable to flexible display panels.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Terminal device shell and terminal device

InactiveCN105786283AReduce demandReduce thickness requirementsInput/output processes for data processingTerminal equipmentEngineering

Owner:BOE TECH GRP CO LTD +1

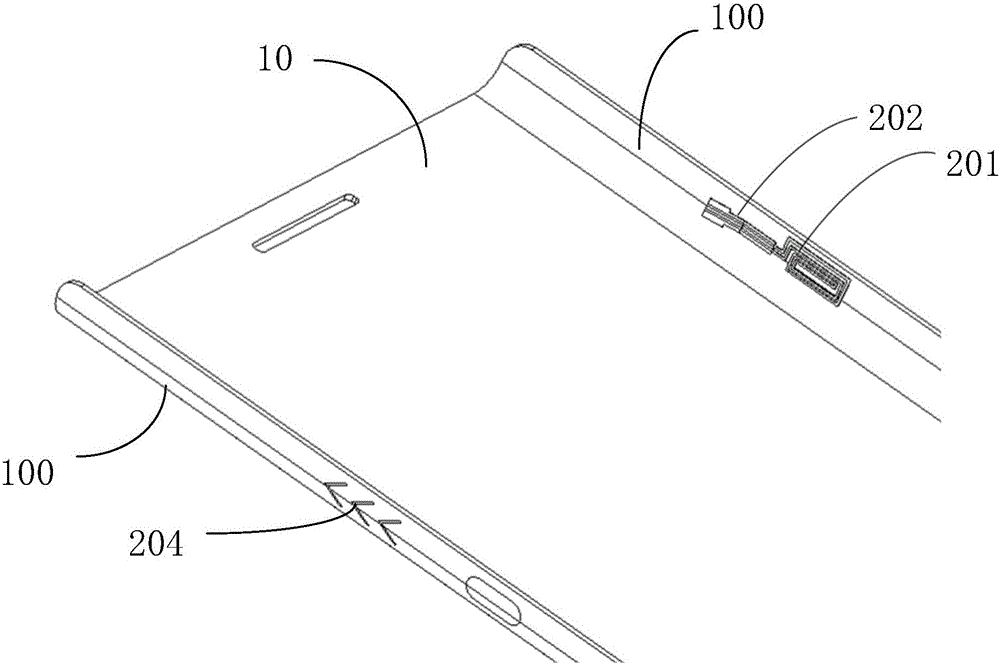

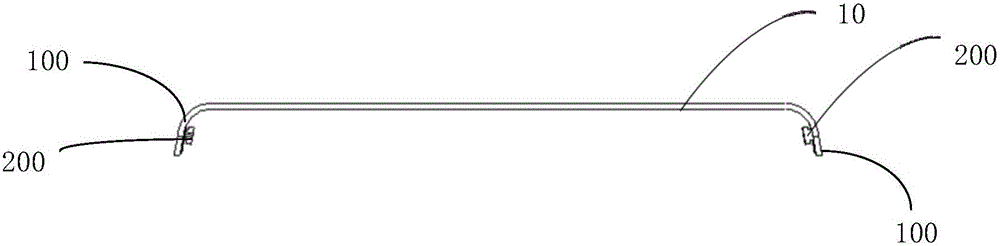

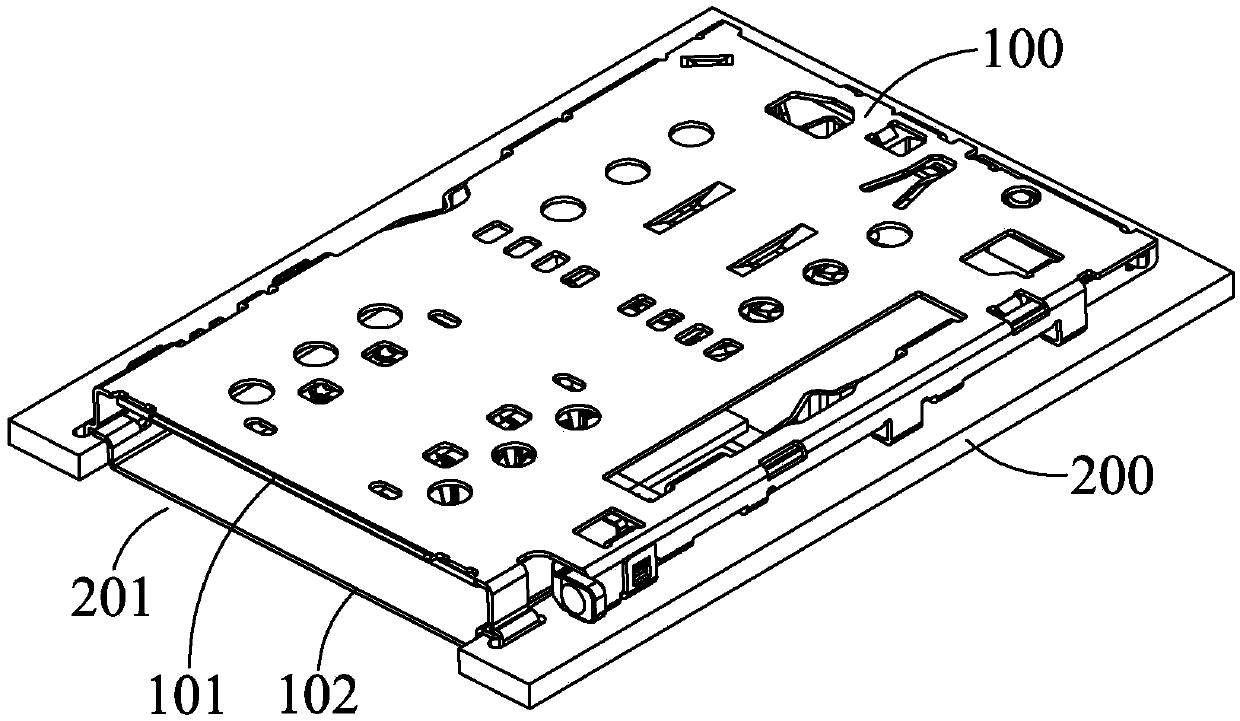

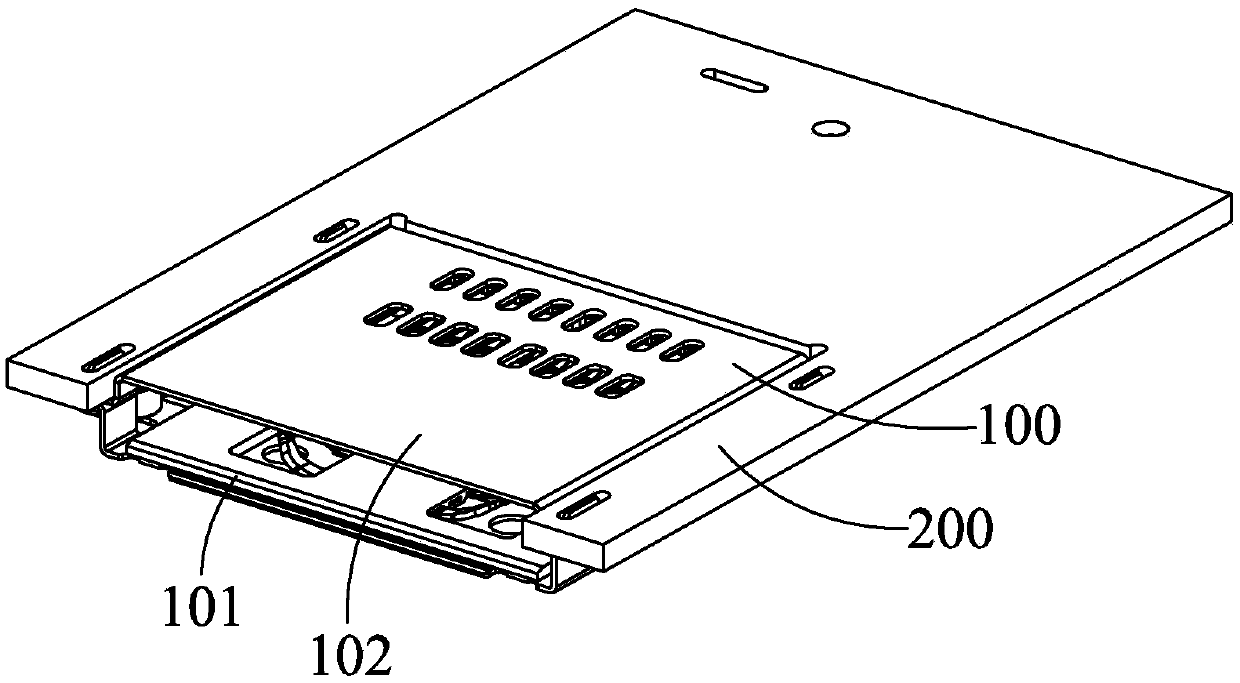

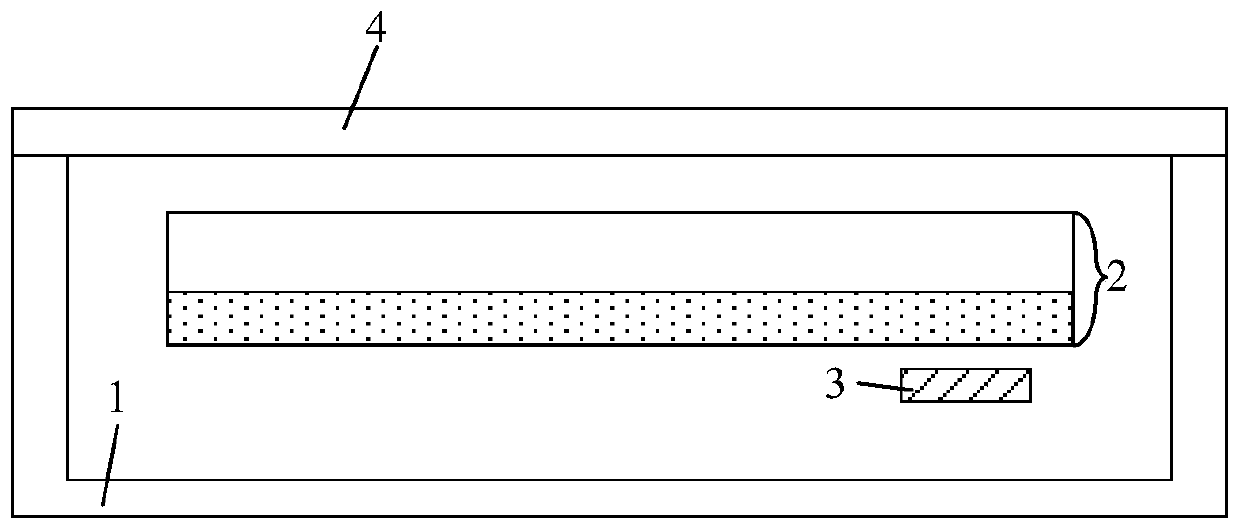

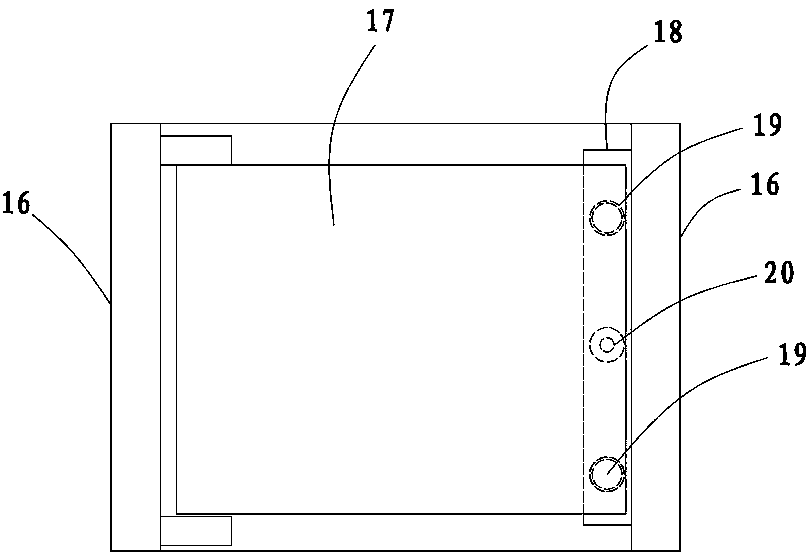

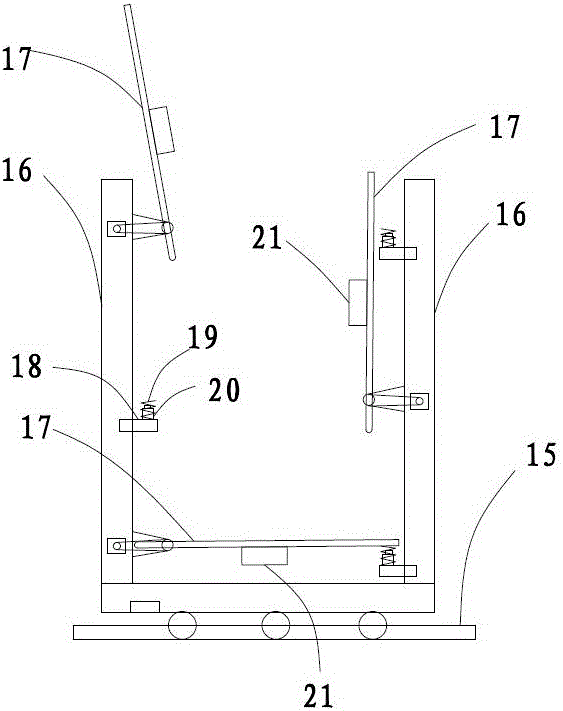

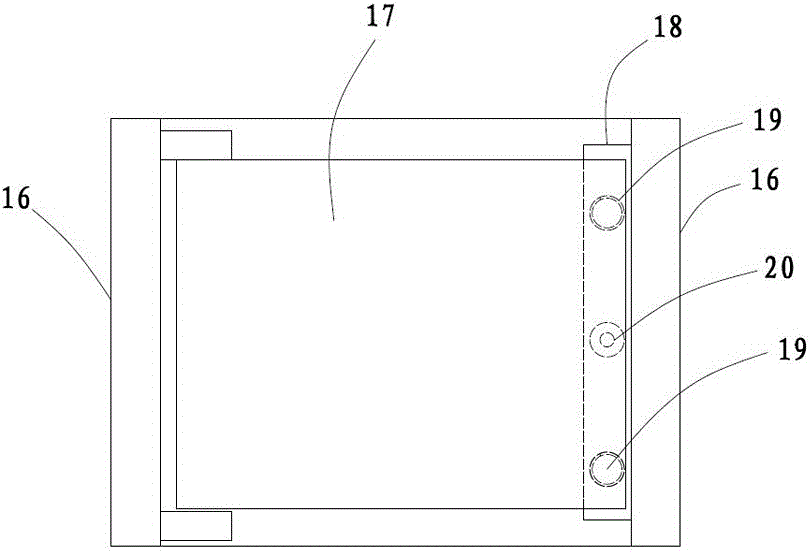

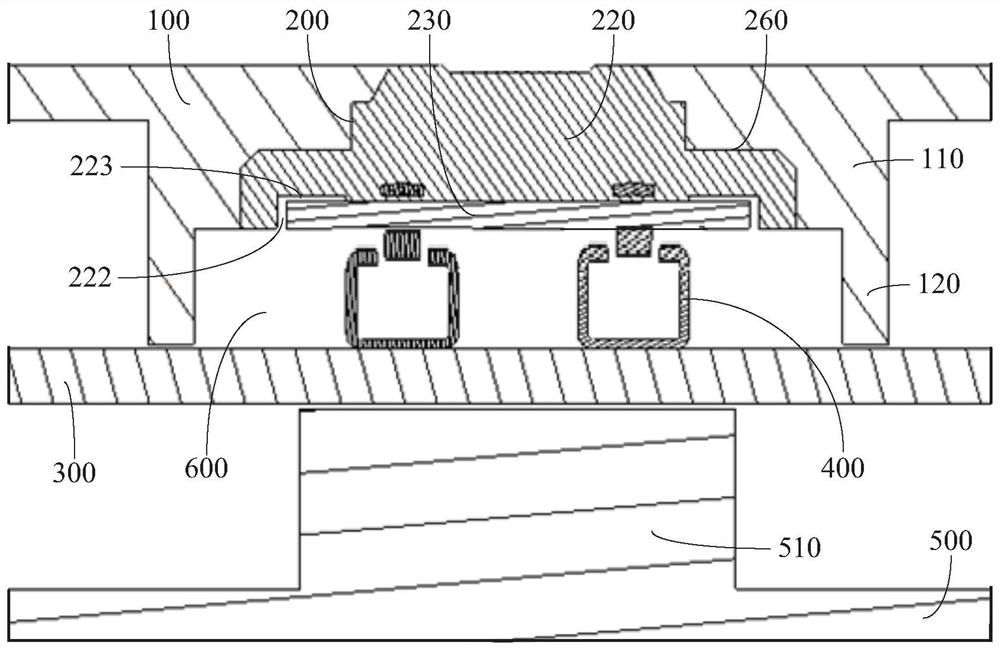

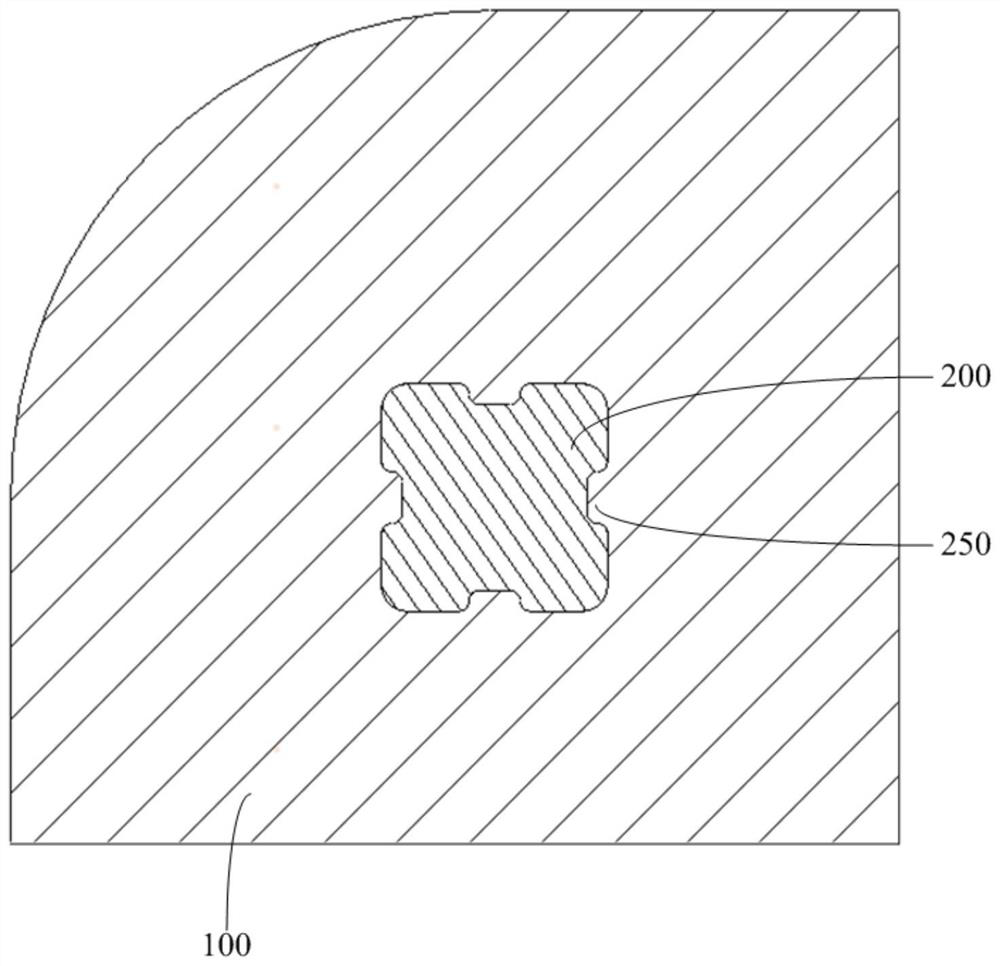

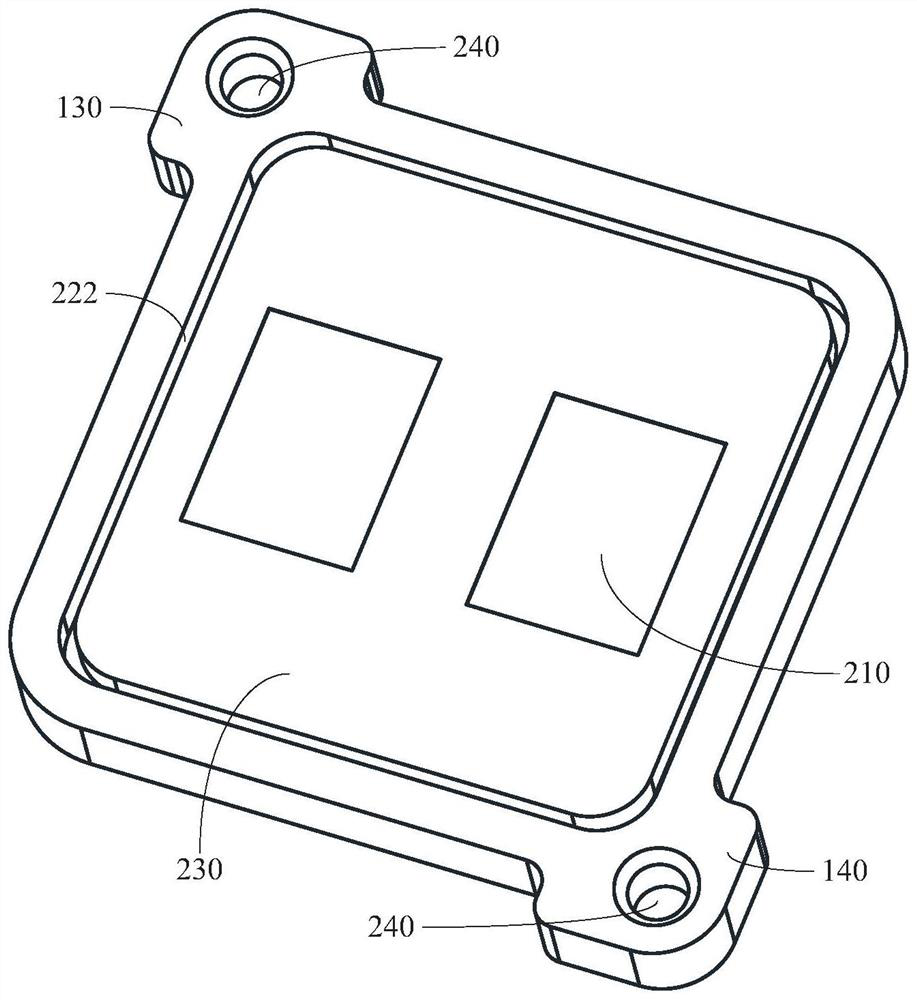

All-in-one card holder

PendingCN109638493AShorten the lengthSave spaceCoupling contact membersTransmissionCard holderElectronic component

The present invention discloses an all-in-one card holder comprising an upper housing assembly and a lower housing assembly that are buckled together, wherein the upper housing assembly includes an upper metal housing and an upper terminal module disposed on the upper metal housing; the lower housing assembly includes a lower metal housing and a lower terminal module disposed on the lower metal housing. When the all-in-one card holder is mounted on a circuit board, a portion of the upper metal housing extending rearwards beyond the lower metal housing is located above the circuit board to mount an electronic component on the circuit board. At least a part of the structure of the lower housing assembly is installed in a gap of the circuit board in a sink manner, thereby decreasing the stacking thickness of the all-in-one card holder and the circuit board, and further assisting the ultrathin feature of an electronic device equipped with the all-in-one card holder.

Owner:昆山惠乐精密工业有限公司

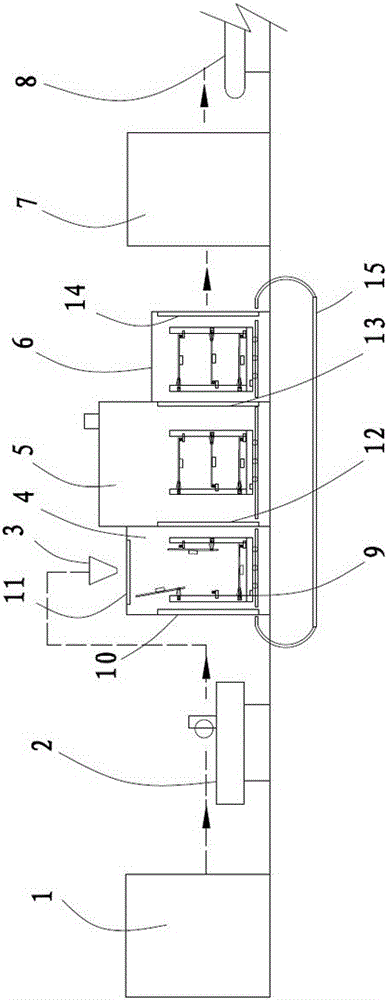

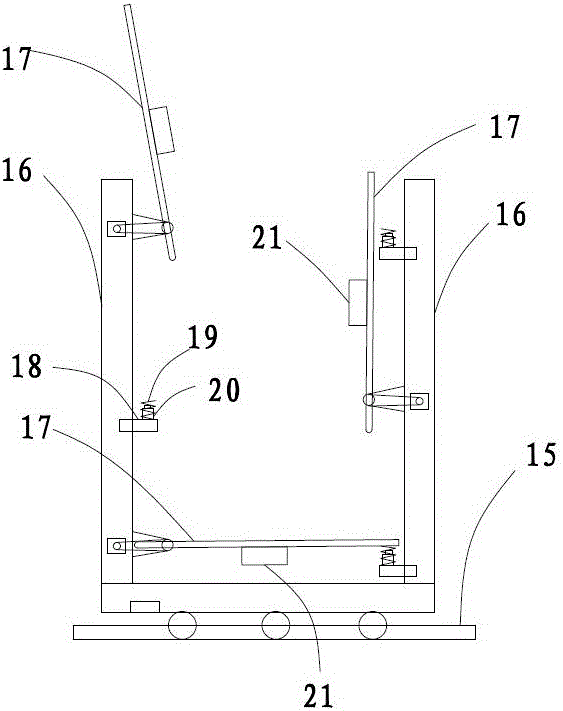

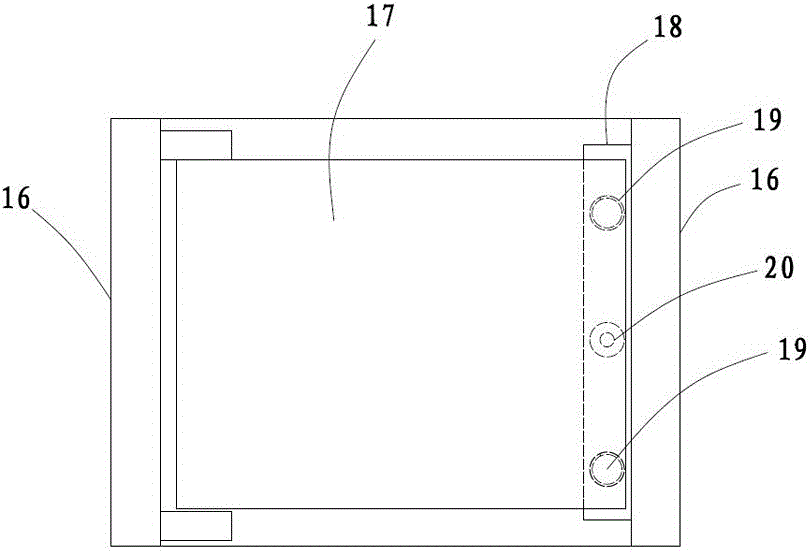

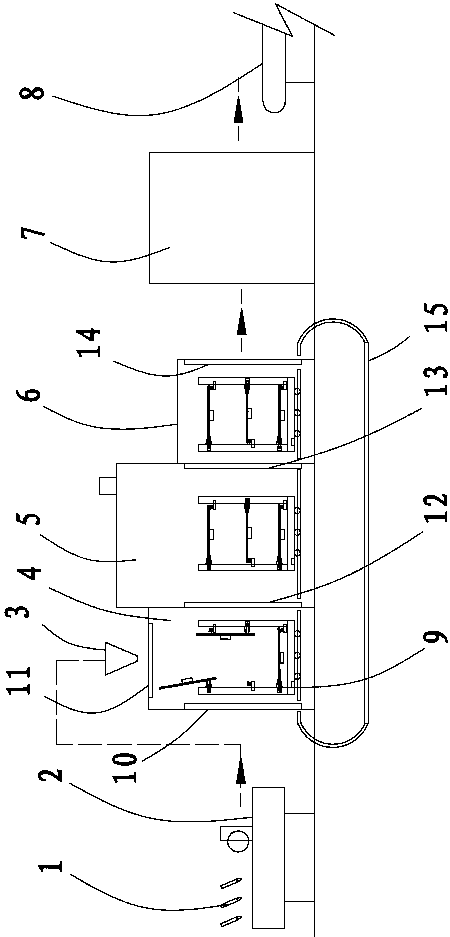

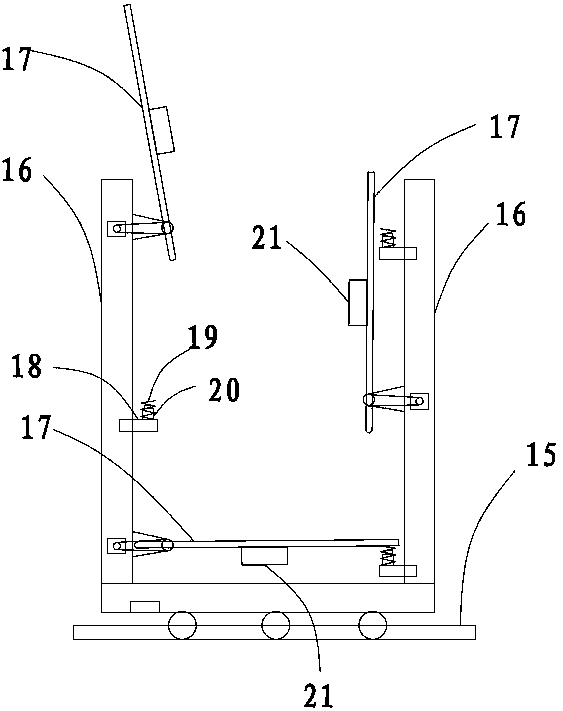

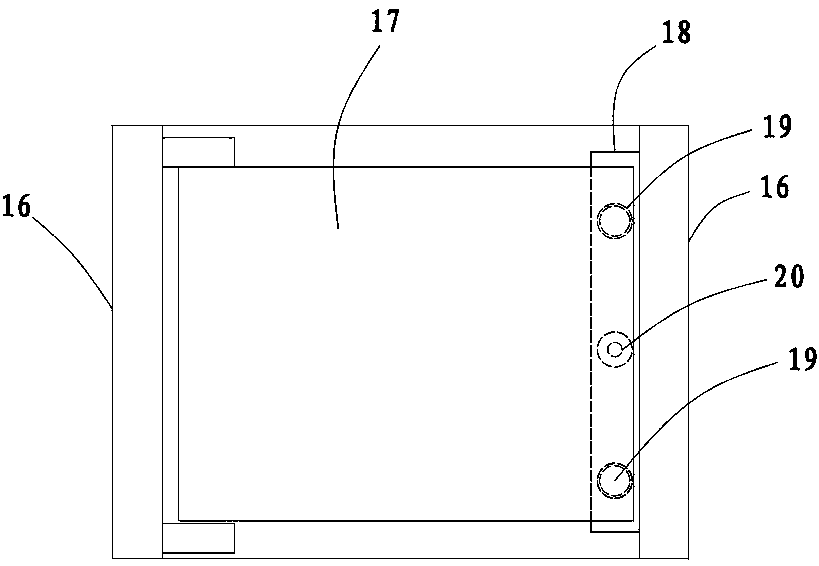

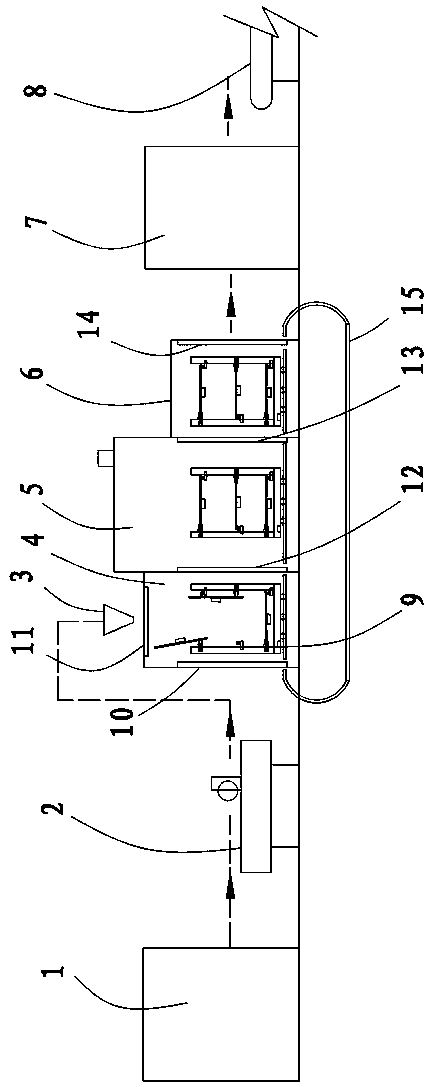

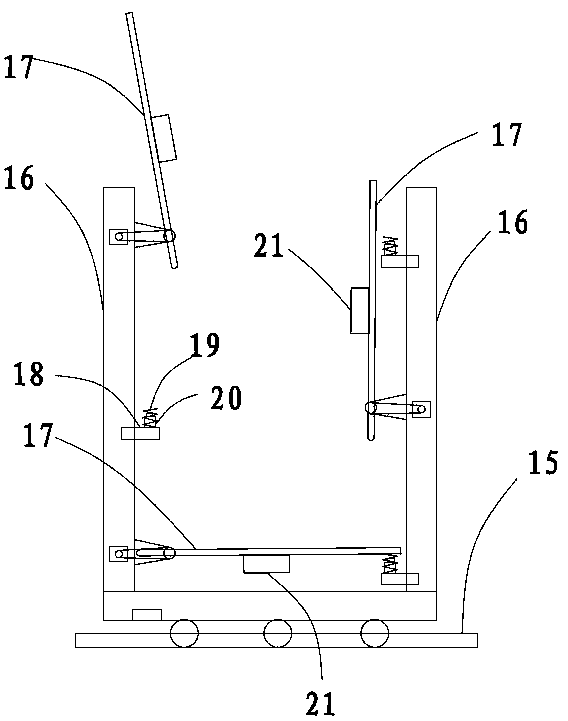

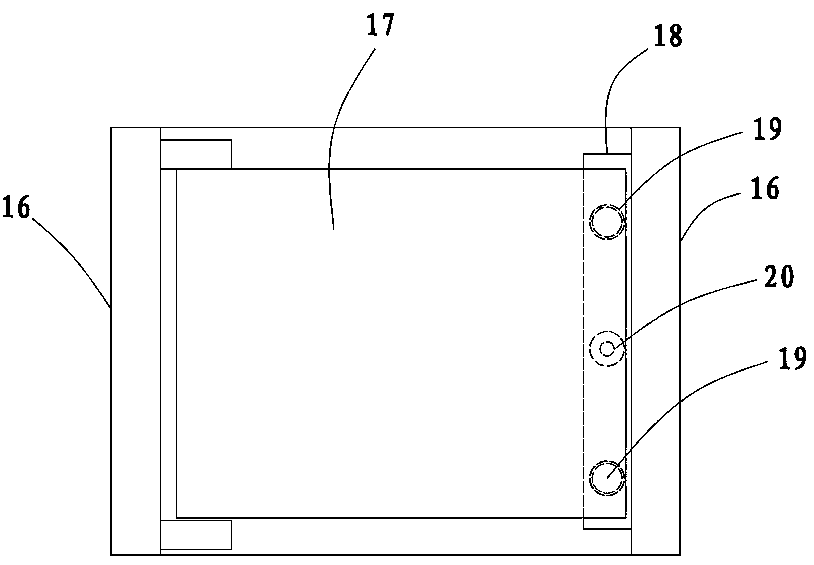

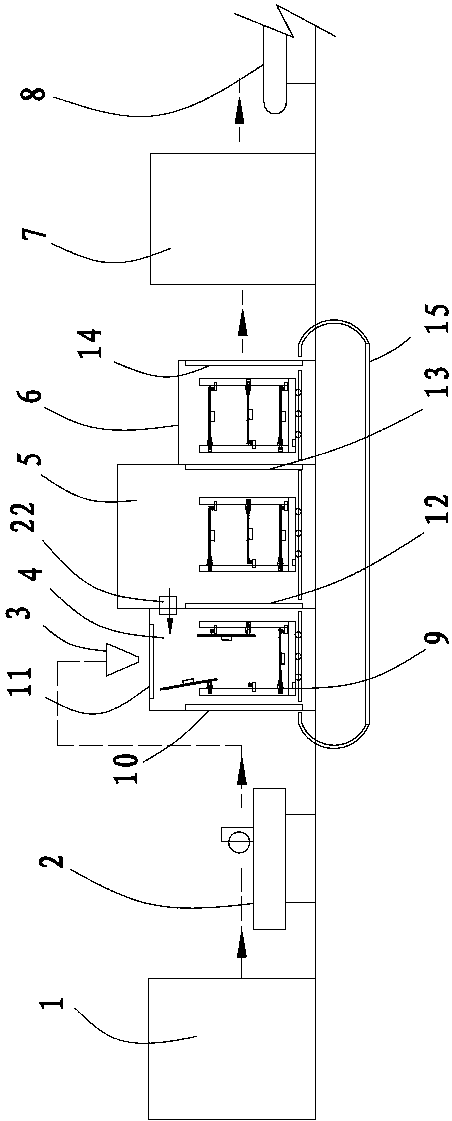

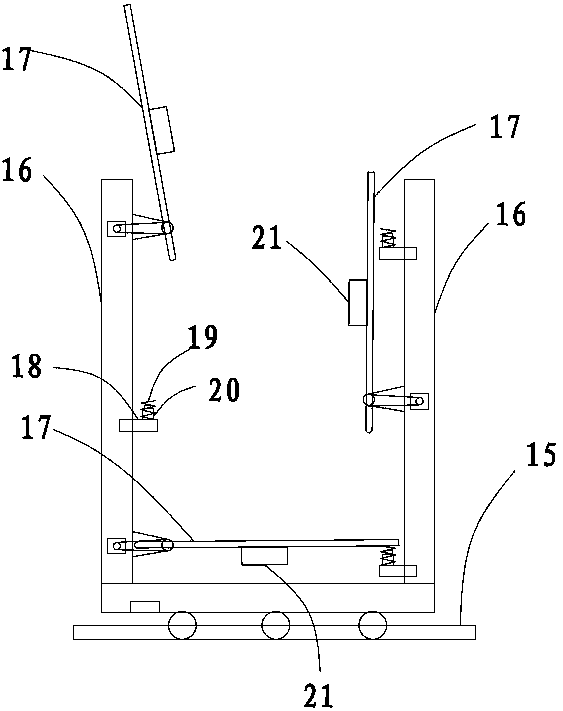

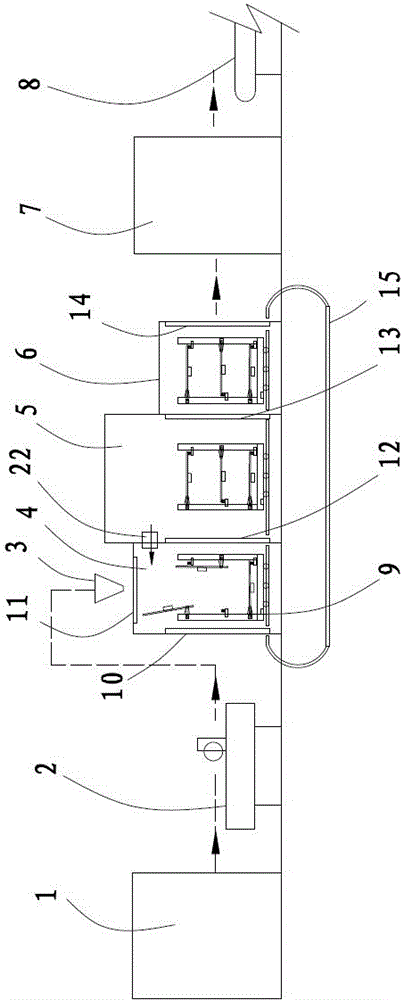

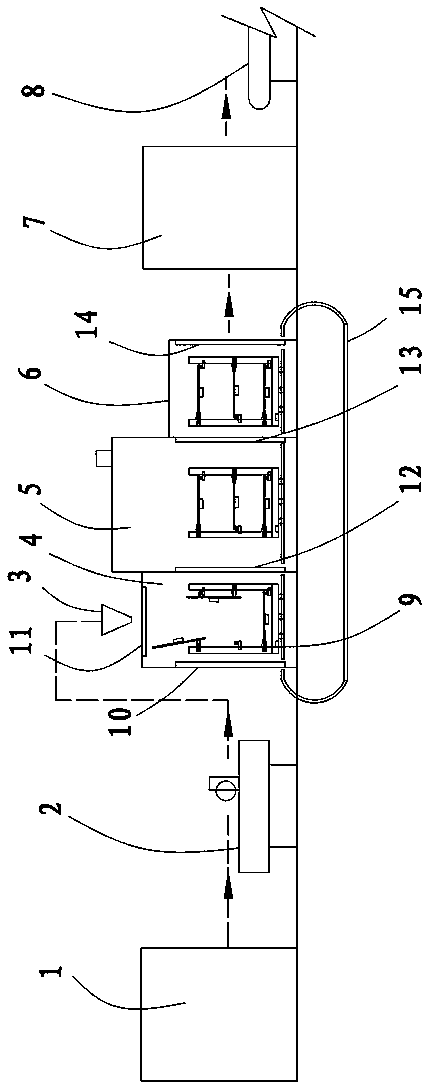

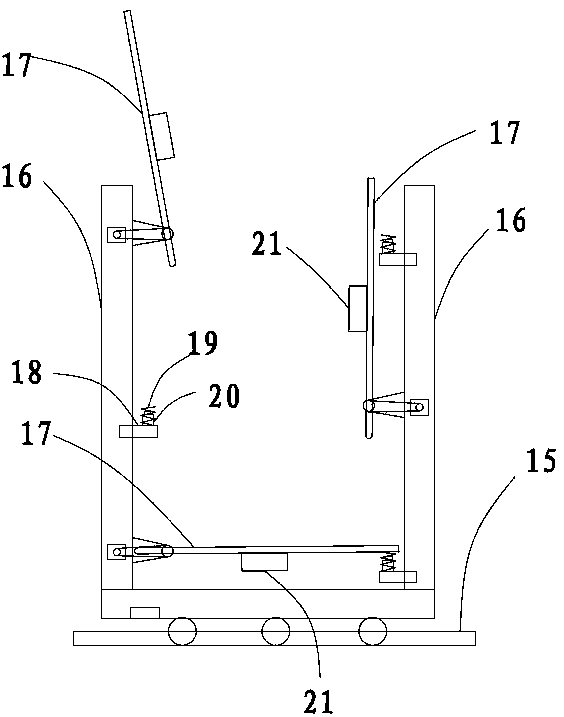

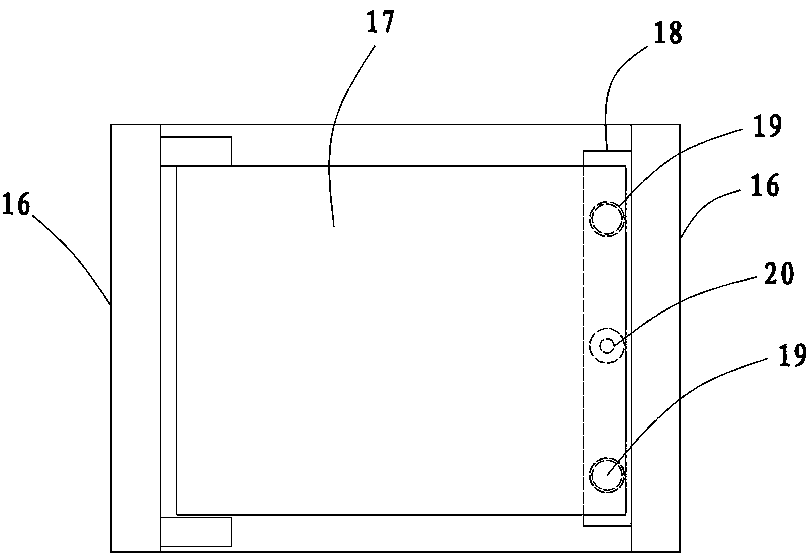

Shellfish freeze-drying processing device and method thereof

ActiveCN106234550AKeep the flavorReduce stack thicknessFood freezingMeat/fish preservationFlavorGreenhouse

The invention relates to a shellfish freeze drying processing device and a method thereof. According to the invention, the problem that dried shellfish quality is affected when shellfish is heated during the traditional shellfish drying processing is solved. The device successively comprises a freeing chamber, a slicer, a vacuum freeze-drying chamber, a temperature returning chamber and a packing machine. After standing and sand-spitting of shellfish, meat and shell are separated; after separation and cleaning of shellfish meat, the cleaned shellfish meat is put into the freezing chamber and frozen in the environment of minus 4 to 0 DEG C; frozen shellfish meat is sliced; after slicing of shellfish meat, the shellfish meat slices are put in layers in a stock rack and then sent into the vacuum freeze-drying chamber to be freeze-dried in a vacuum environment of minus 45 to minus 35 DEG C; after drying, shellfish meat is put into the temperature returning chamber to return to the temperature of minus 10 DEG C; and packaging is carried out finally. After drying processing, original flavor of shellfish can be better maintained. Before vacuum freeze-drying, the multi-layer stock rack is adopted for layered stock preparation, vibration and flattening, thus reducing stacking thickness of shellfish meat during the vacuum freeze-drying process, enhancing drying efficiency and guaranteeing the drying effect.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Shellfish slicer

ActiveCN106172690BKeep the flavorReduce stack thicknessMeat/fish preservationBivalves processingFlavorNoble gas

The invention relates to a shellfish slicing processing device, and aims to solve the problem that the quality of dried shellfish is influenced since heating is adopted in the traditional shellfish drying processing process. The device sequentially comprises a slicing machine, a vacuum freeze-drying chamber, a temperature returning chamber and a packaging machine, wherein a vacuum environment at a temperature of minus 45-35 DEG C is arranged in the vacuum freeze-drying chamber; natural temperature returning is adopted in the temperature returning chamber, and a noble gas is adopted as a protective gas in the temperature returning chamber. According to the device, the shellfish slicing and drying processing is completed in a mode of slicing, vacuum freeze-drying and temperature-returning package in sequence, so that the original flavor of the shellfish can be well maintained after drying; before vacuum freeze-drying, materials are prepared on a multi-layer preparation shelf layer by layer and are flattened by vibration, so that the stacking thickness of shellfish in the vacuum freeze-drying process can be reduced, the drying efficiency can be improved, and the drying effect can be guaranteed.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

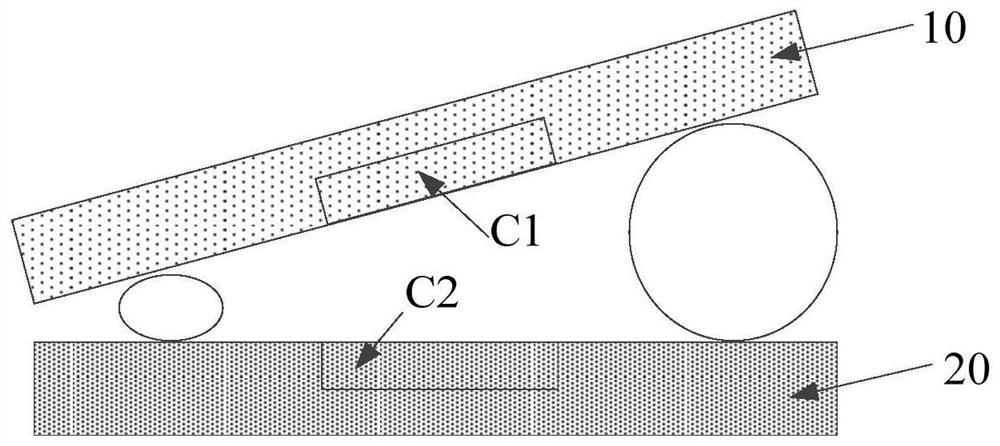

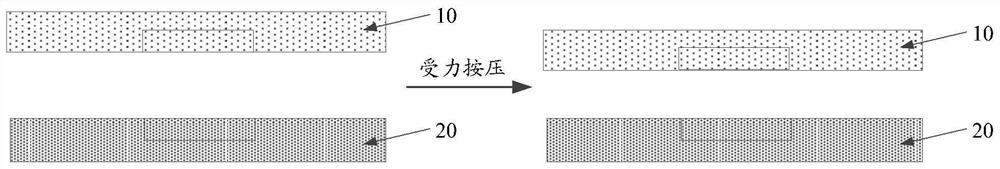

Pressure-sensitive key and electronic equipment

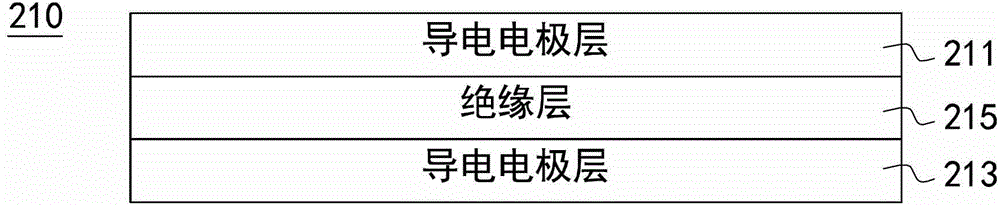

ActiveCN113346890AReduce stack thicknessElectronic switchingPrinted circuit aspectsCapacitanceControl theory

The invention provides a pressure-sensitive key and electronic equipment. The pressure-sensitive key comprises a first circuit board, a second circuit board, a first capacitor, a second capacitor and a first connecting piece, the first surface of the first circuit board is opposite to the second surface of the second circuit board; the first surface is provided with a first capacitor, the second surface is provided with a second capacitor, and the first capacitor and the second capacitor are oppositely arranged; the first end of the first connecting piece is connected with the first surface, and the second end of the first connecting piece is connected with the second surface; and the first connecting piece is used for limiting the first surface and the second surface to be parallel to each other. According to the embodiment of the invention, the pressure-sensitive key does not need to be arranged on the surface of the electronic equipment, so that the overall stacking thickness of the electronic equipment is reduced, and the electronic equipment is lighter and thinner.

Owner:VIVO MOBILE COMM CO LTD

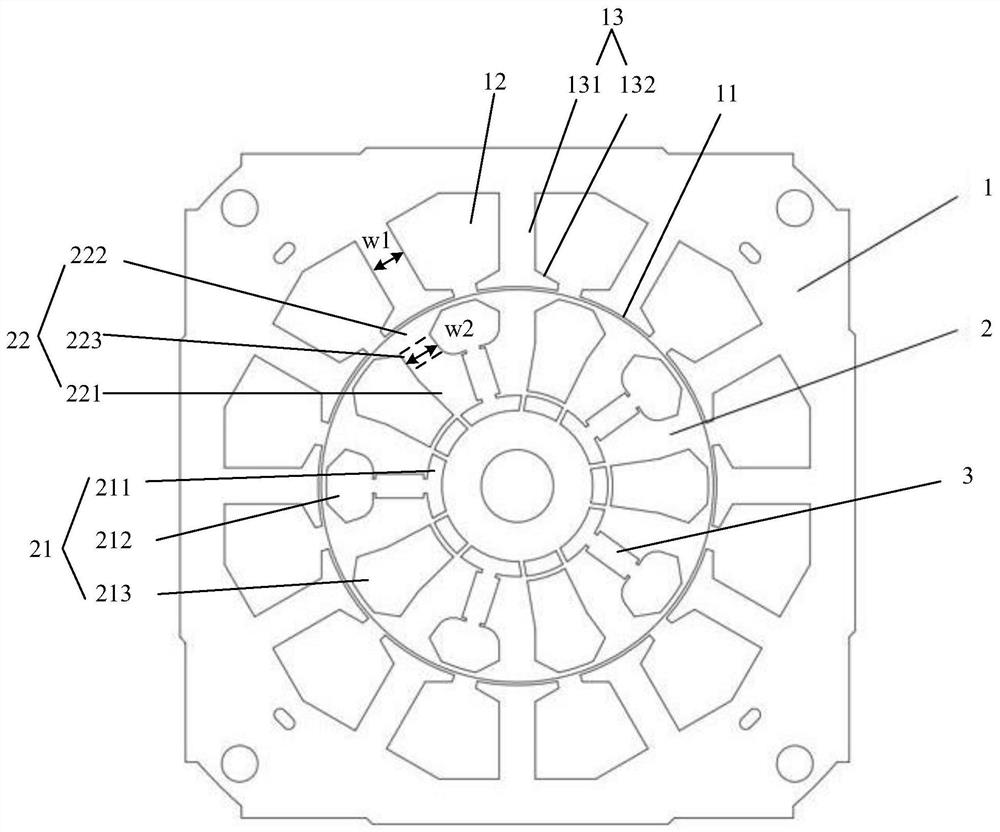

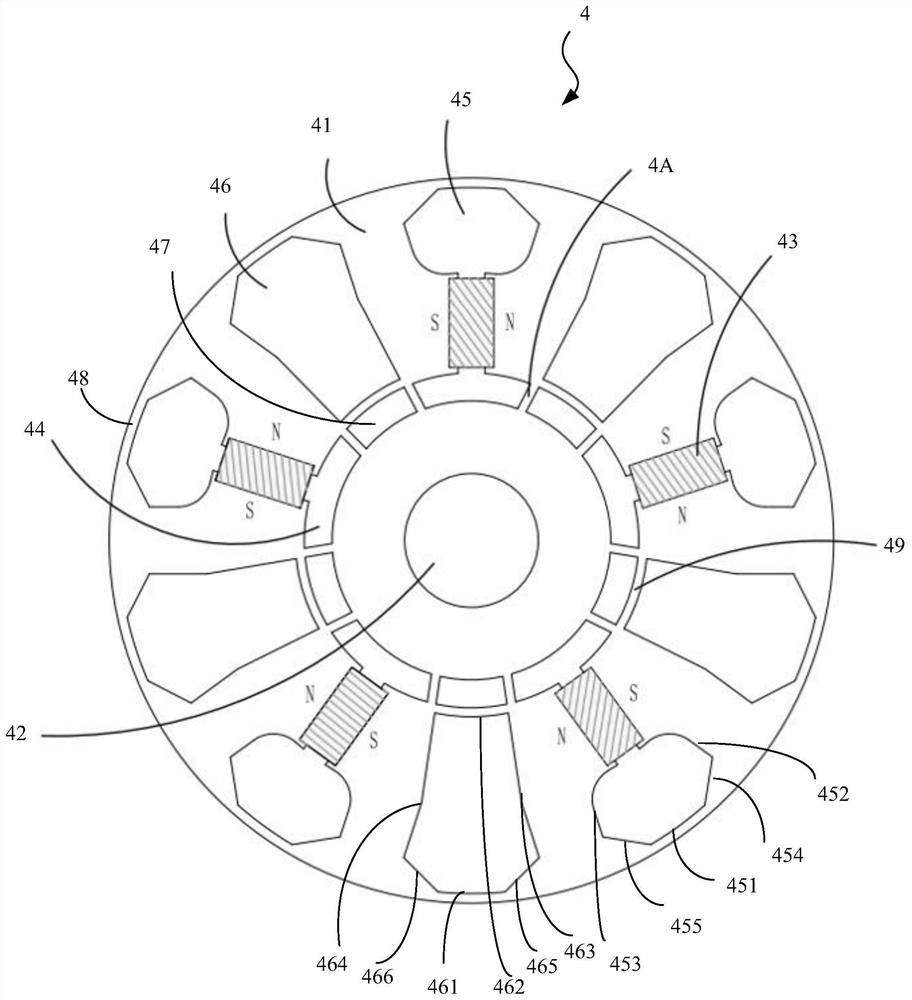

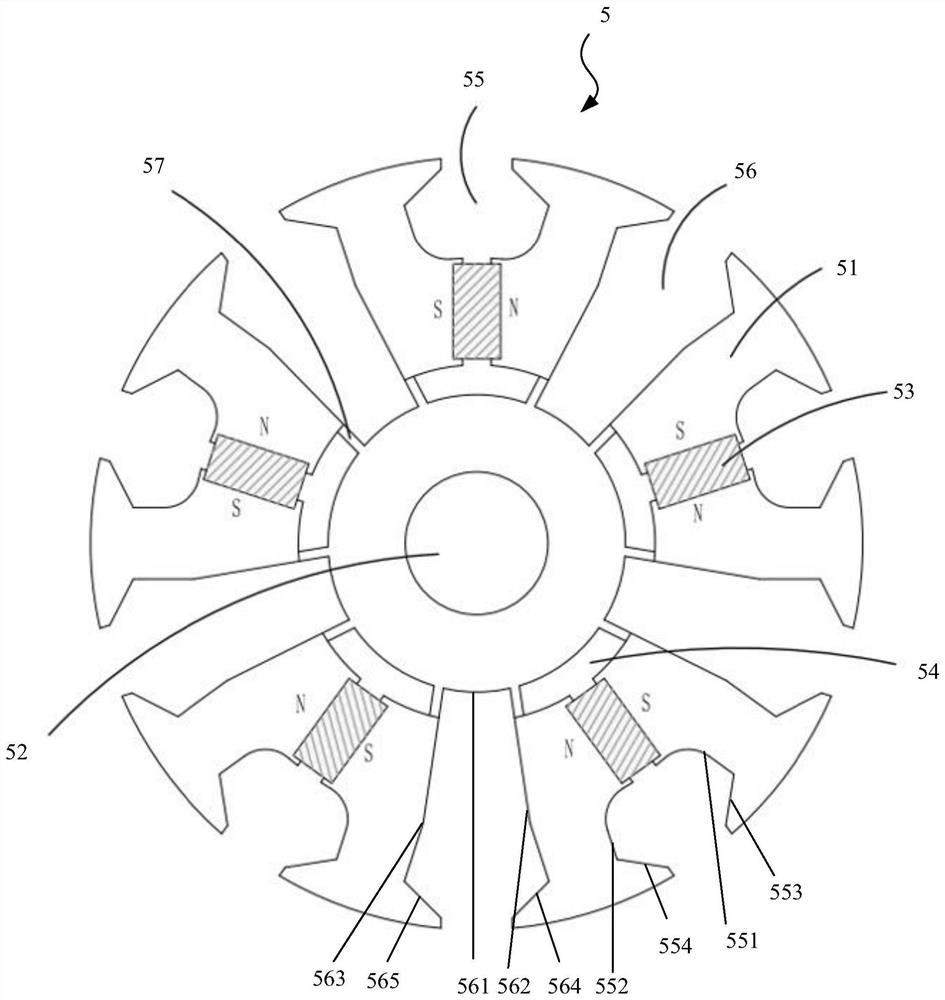

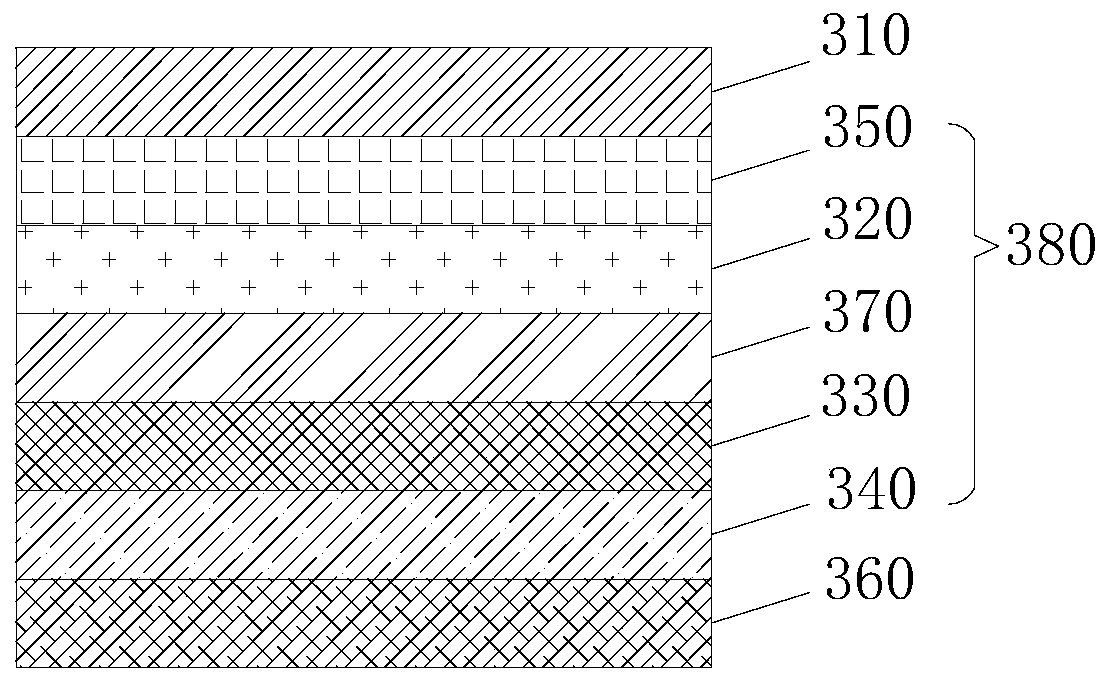

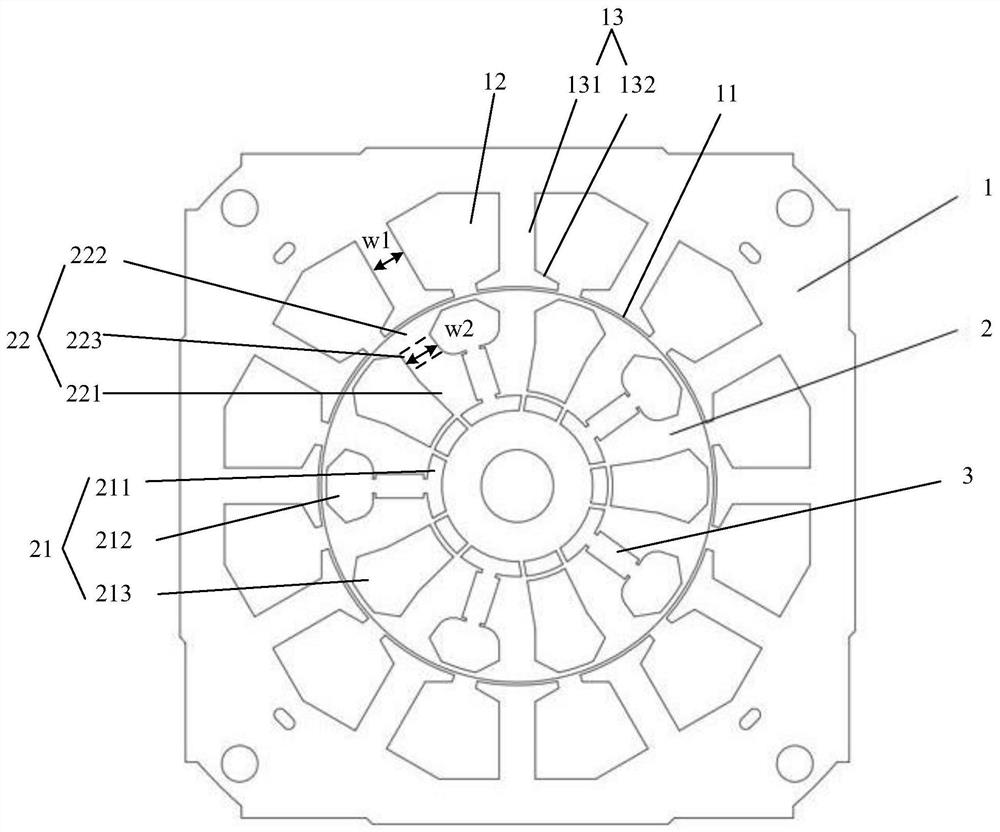

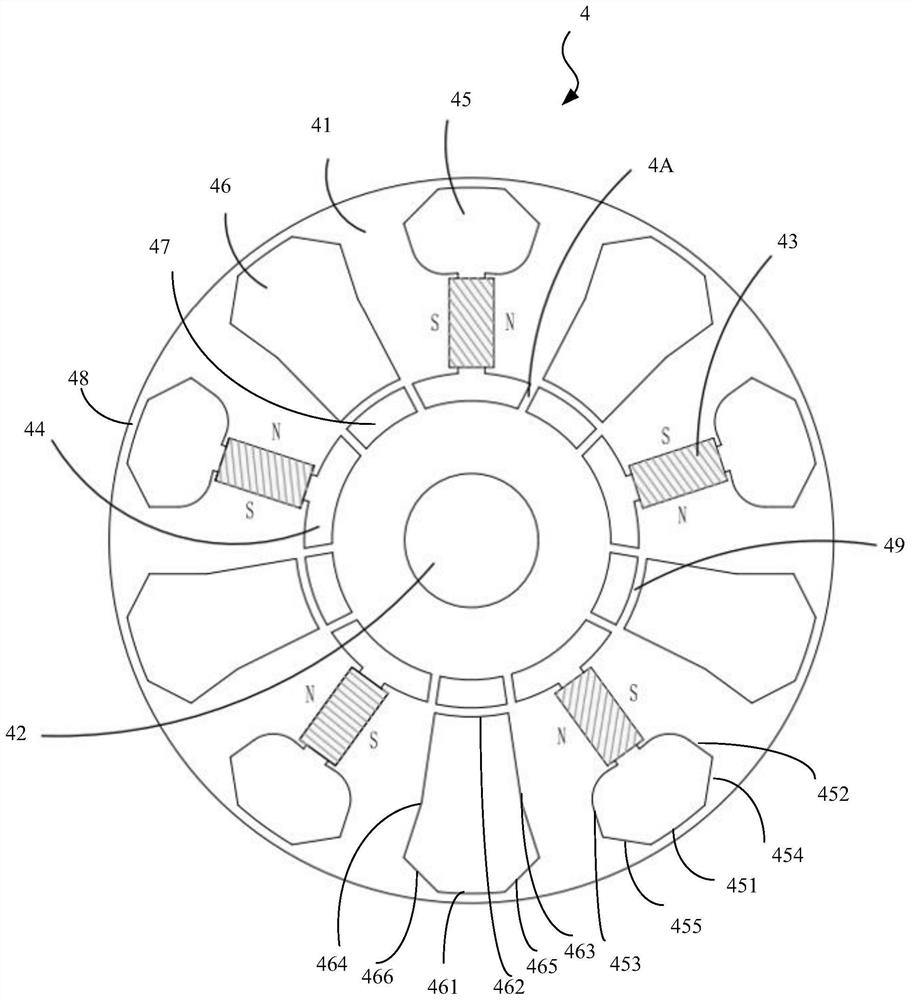

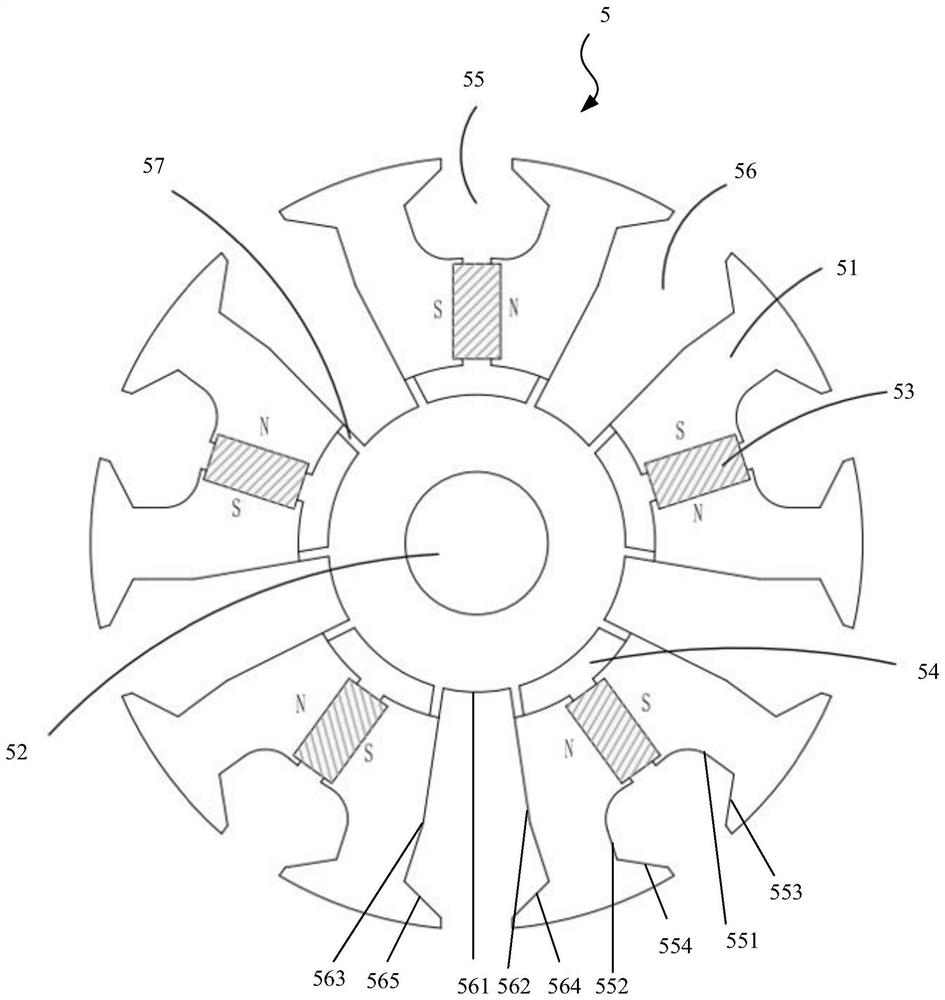

Motor and washing machine

ActiveCN112350477AReduce magnetic leakageReduce dosageSynchronous machine detailsMagnetic circuit rotating partsLaundry washing machineElectric machine

The invention discloses a motor and a washing machine. The motor comprises a stator iron core, wherein the stator iron core is provided with an axial through hole, the inner wall of the stator iron core is provided with a plurality of open slots along the circumferential direction, a stator tooth is formed between two adjacent open slots, and the stator tooth at least comprises an equal-width partwith equal tooth width; a rotor core which is arranged in the through hole, wherein a plurality of mounting grooves used for arranging the permanent magnets are formed in the rotor core in the circumferential direction, and a magnetic isolation area used for magnetic isolation and a magnetic conduction area used for magnetic conduction are arranged in the area, outside the mounting grooves, of the rotor core; the magnetic conductive area comprises a first area adjacent to the mounting groove, a second area adjacent to the outer periphery of the rotor core, and a third area connecting the first area and the second area, the width of the third area is equal, and the value range of the width of the third area is + / -0.5 mm of the width of the equal-width part. The power density of the motor can be improved on the premise of reducing the use amount of permanent magnet materials, so that the stack thickness and the axial size of the motor are reduced.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

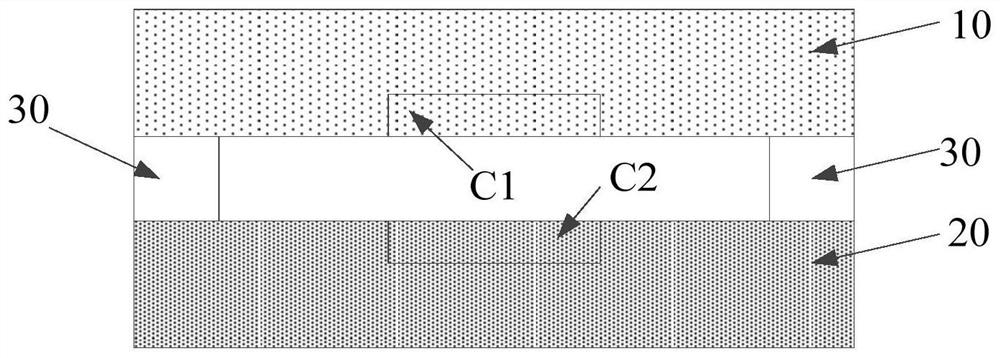

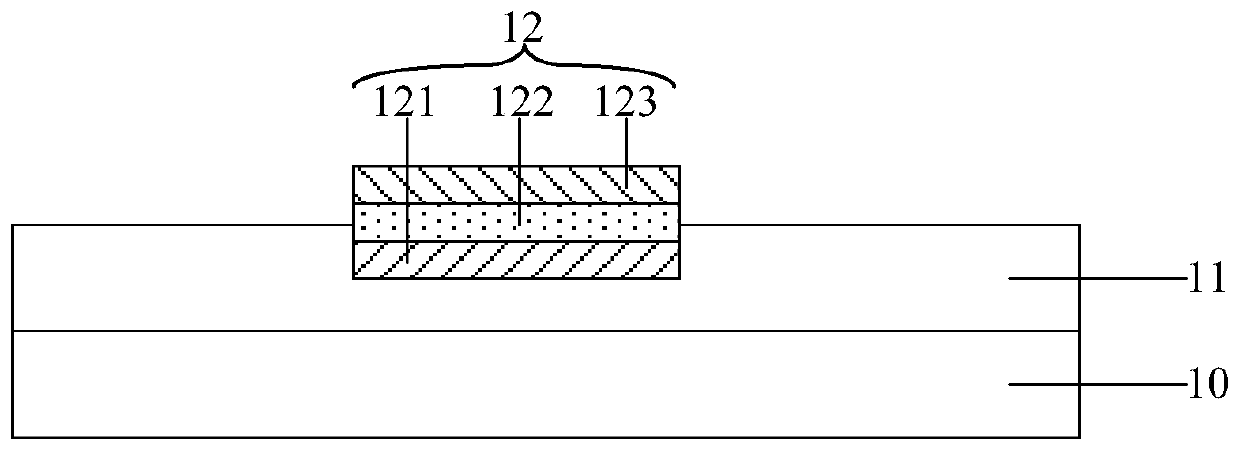

Substrate and preparation method thereof and display device

ActiveCN110676297AImprove deformationReduce stack thicknessSolid-state devicesSemiconductor/solid-state device manufacturingSuperimpositionDisplay device

An embodiment of the invention provides a substrate and a preparation method thereof and a display device, relates to the technical field of display, and can solve the problem of substrate deformationcaused by overlarge superimposition stress of a line recognition unit and an insulating layer. The substrate comprises a substrate body, the insulating layer and the line recognition unit, wherein the insulating layer and the line recognition unit are arranged on the substrate body. The insulating layer is provided with a groove; and at least one part of the line recognition unit is located in the groove.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

Shellfish drying and processing device

ActiveCN106261466BKeep the flavorReduce stack thicknessFood preservationFreeze-dryingProcess engineering

The present invention relates to a drying and processing device of shellfish and solves the problem that during the traditional drying and processing processes of the shellfish, the heating affects the quality of the dried shellfish. The device successively comprises a freezing room, a slicing machine, a vacuum freeze-drying room, a temperature returning room and a packaging machine. The freezing temperature in the freezing room is kept to be -4 to 0 DEG C, the vacuum environment of the vacuum freezing-drying room is at the temperature of -45 to -35 DEG C, and the temperature returning room uses natural temperature returning and rare gas as a protective gas. The shellfish slicing and drying processes are finished in the forms of first freezing, then slicing, then vacuum freeze-drying, and then temperature returning and packaging, so that the dried and processed shellfish can keep the original flavor better. Before the vacuum freeze-drying, multi-layered material preparing racks are used to conduct layered material preparing and the shellfish is vibrated to be spread to be flat, the stacking thickness of the shellfish meat in the vacuum freeze-drying processes is reduced, the drying efficiency is omproved and the drying effects are ensured.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

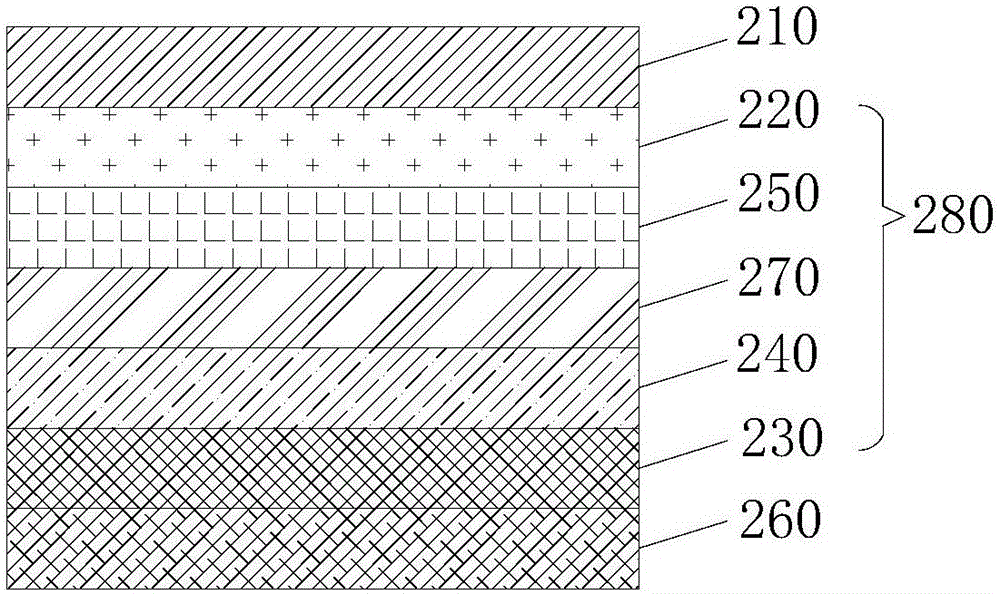

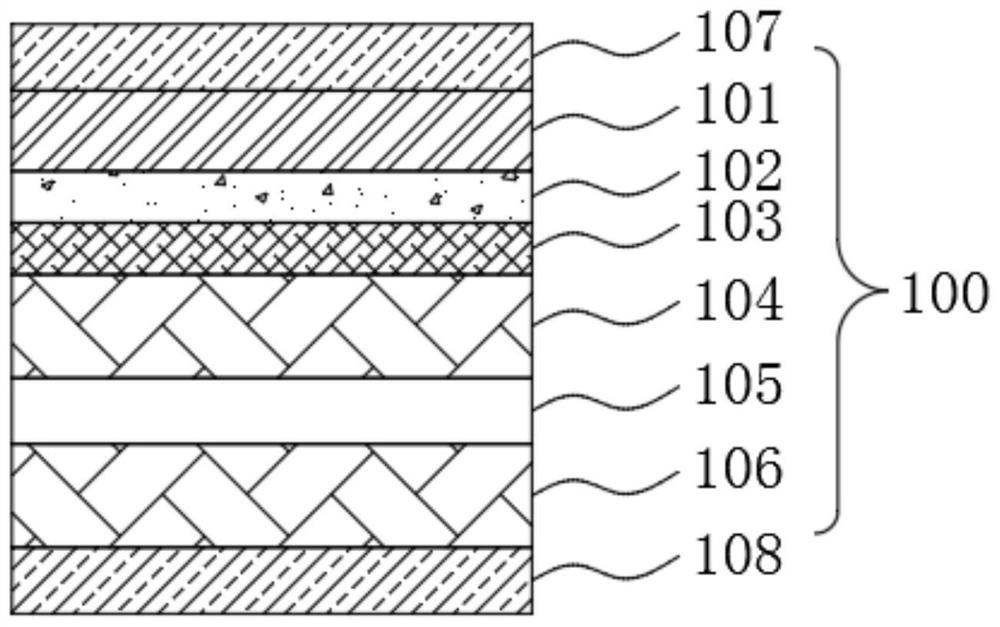

High-frequency covering film with high electromagnetic shielding function and preparation method thereof

PendingCN112533353AImprove electromagnetic shielding functionHigh hardnessMagnetic/electric field screeningCross-talk/noise/interference reductionCopper foilDrill hole

The invention discloses a high-frequency covering film with a high electromagnetic shielding function and a preparation method thereof. The high-frequency covering film sequentially comprises an insulating layer, a bonding layer, a copper foil layer, a first high-frequency bonding layer, a high-frequency insulating layer and a second high-frequency bonding layer from top to bottom, the high-frequency insulating layer is an insulating layer of which the dielectric coefficient is lower than 4.0 and the dielectric loss is lower than 0.015 (@ 10GHz); and the first high-frequency bonding layer andthe second high-frequency bonding layer are both resin adhesive layers with the dielectric coefficient being lower than 4.0, the dielectric loss being 0.002-0.010 (@ 10 GHz) and the water absorption being 0.001-0.5%. According to the invention, the shielding rate can be up to more than 100dB; the dielectric property is good, the dielectric loss is 0.003-0.010 at 10 GHz, and the dielectric coefficient is lower than 4.0; the mechanical property is good, and machining processes such as drilling and hole filling can be coped with; a thick dielectric layer can be designed within a large thickness range, so that signal transmission loss under high frequency is reduced; and soldering tin is good in heat resistance, plate explosion is avoided in the FPC and PCB assembling process, and gas escape is facilitated and plate explosion is avoided through drilling, hole filling and other process designs.

Owner:KUSN APLUS TEC CORP +1

A cold processing device for shellfish

ActiveCN106212628BPrevent moistureKeep the flavorMeat/fish preservationBivalves processingVacuum pumpingFreeze-drying

The invention relates to a shellfish cold-processing device, and solves the problem that the quality of dry shellfish is influenced by the fact that heating exists in the traditional shellfish drying and processing process. The shellfish cold-processing device comprises a freezing chamber, a slicing machine, a vacuum freeze-drying chamber and a packaging machine in sequence, wherein the freezing temperature of the freezing chamber maintains between -4 DEG C and 0 DEG C; the vacuum freeze-drying chamber is a vacuum environment with the temperature between -45 DEG C and -35 DEG C; a material preparing chamber is arranged on the inlet side of the vacuum freeze-drying chamber; a vacuum-pumping valve is arranged between the vacuum freeze-drying chamber and the material preparing chamber; the vacuum-pumping valve exhausts air from the vacuum freeze-drying chamber to the material preparing chamber. The shellfish cold-processing device finishes slicing cold processing on the shell fish by the forms of freezing, slicing, performing vacuum freeze-drying and packaging, so the original flavor of the shellfish can be maintained well; the materials are prepared layer by layer by multiple layers of material preparing frames and are vibrated and flattened, so that the stacking thickness of the shellfish meat in the vacuum freeze-drying process is reduced; air is exhausted from the vacuum freeze-drying chamber to the material preparing chamber to conduct precooling, so that the drying efficiency is improved and the drying effect is guaranteed.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Shellfish cold-processing device

ActiveCN106212628AReduce stack thicknessImprove drying efficiencyMeat/fish preservationBivalves processingFreezing chamberFlavor

The invention relates to a shellfish cold-processing device, and solves the problem that the quality of dry shellfish is influenced by the fact that heating exists in the traditional shellfish drying and processing process. The shellfish cold-processing device comprises a freezing chamber, a slicing machine, a vacuum freeze-drying chamber and a packaging machine in sequence, wherein the freezing temperature of the freezing chamber maintains between -4 DEG C and 0 DEG C; the vacuum freeze-drying chamber is a vacuum environment with the temperature between -45 DEG C and -35 DEG C; a material preparing chamber is arranged on the inlet side of the vacuum freeze-drying chamber; a vacuum-pumping valve is arranged between the vacuum freeze-drying chamber and the material preparing chamber; the vacuum-pumping valve exhausts air from the vacuum freeze-drying chamber to the material preparing chamber. The shellfish cold-processing device finishes slicing cold processing on the shell fish by the forms of freezing, slicing, performing vacuum freeze-drying and packaging, so the original flavor of the shellfish can be maintained well; the materials are prepared layer by layer by multiple layers of material preparing frames and are vibrated and flattened, so that the stacking thickness of the shellfish meat in the vacuum freeze-drying process is reduced; air is exhausted from the vacuum freeze-drying chamber to the material preparing chamber to conduct precooling, so that the drying efficiency is improved and the drying effect is guaranteed.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

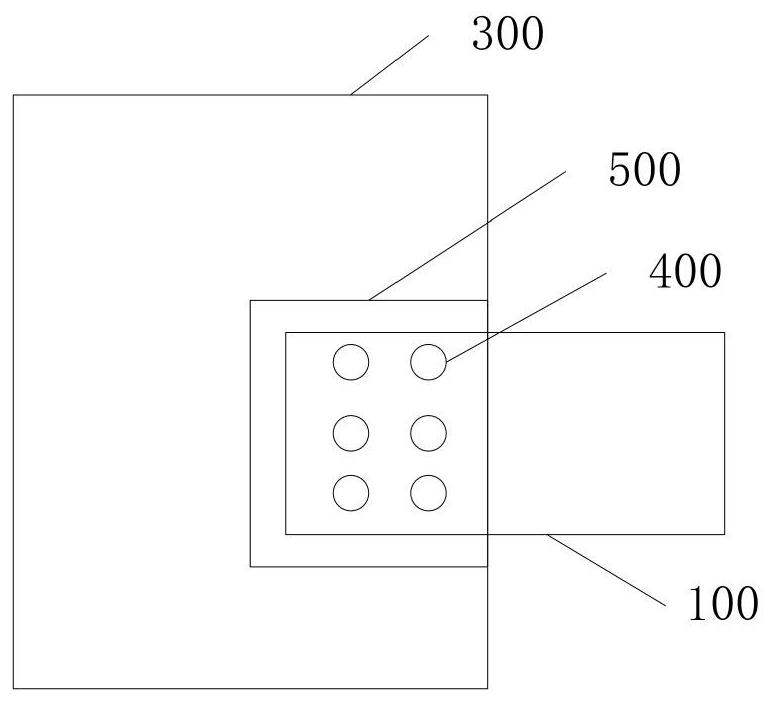

Electronic equipment

ActiveCN113670444AReduce thicknessConducive to the development of light and thinRadiation pyrometryThermometer applicationsElectrical connectionEngineering

The invention discloses electronic equipment. The electronic equipment comprises a first shell (100) which is provided with a through hole, a temperature sensor module (200) which is arranged in the through hole and is provided with a first electric connection part (210) and afirst circuit board (300). The first circuit board (300) is provided with a second electric connection part (400), the second electric connection part (400) is electrically connected with the first electric connection part (210), and the temperature sensor module (200) is connected with the first shell (100) in an injection molding mode. According to the scheme, the problems that the shell structure of the electronic equipment is low in strength and the electronic equipment is thick can be solved.

Owner:VIVO MOBILE COMM CO LTD

a terminal device

ActiveCN109618030BImprove temperature riseImprove cooling effectModifications by conduction heat transferTelephone set constructionsFlexible circuitsTerminal equipment

Owner:VIVO MOBILE COMM CO LTD

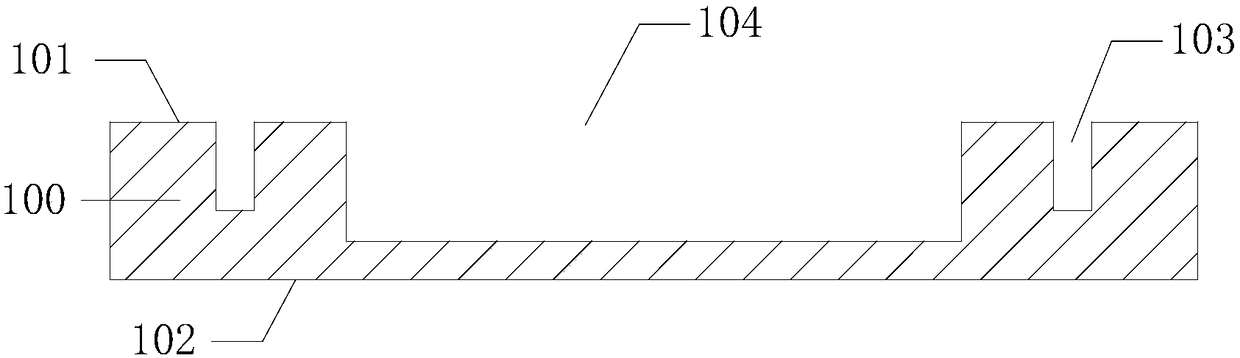

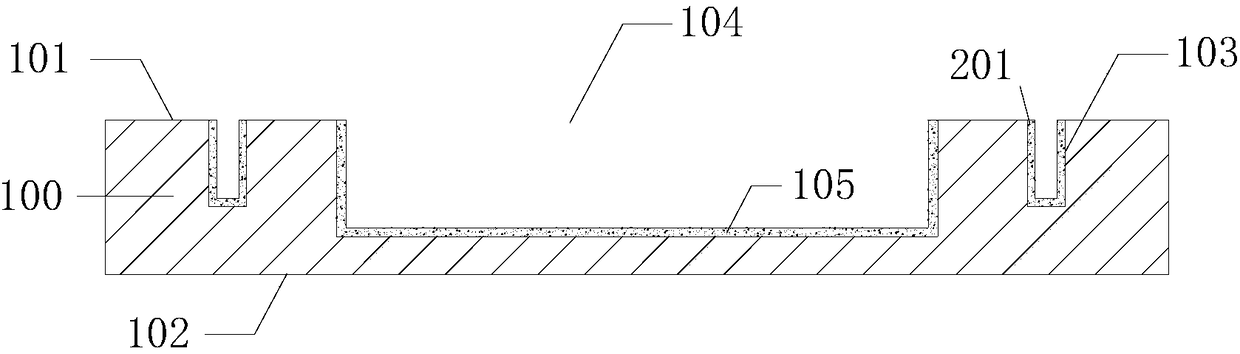

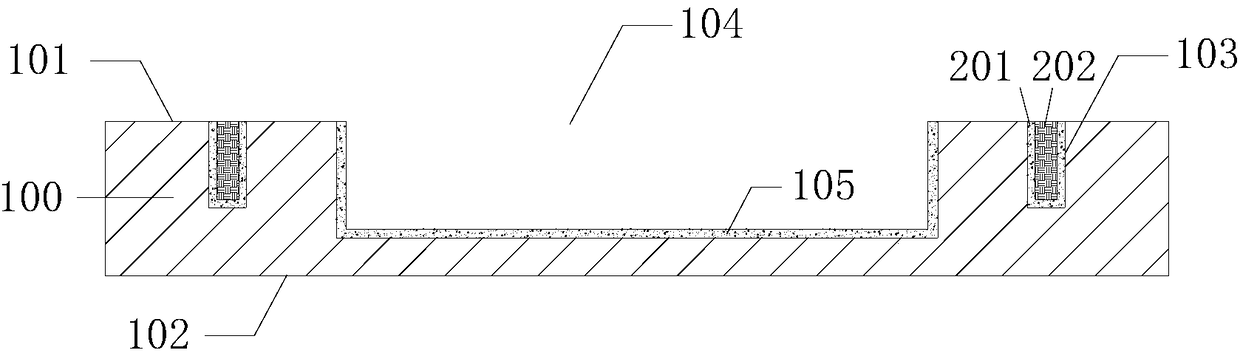

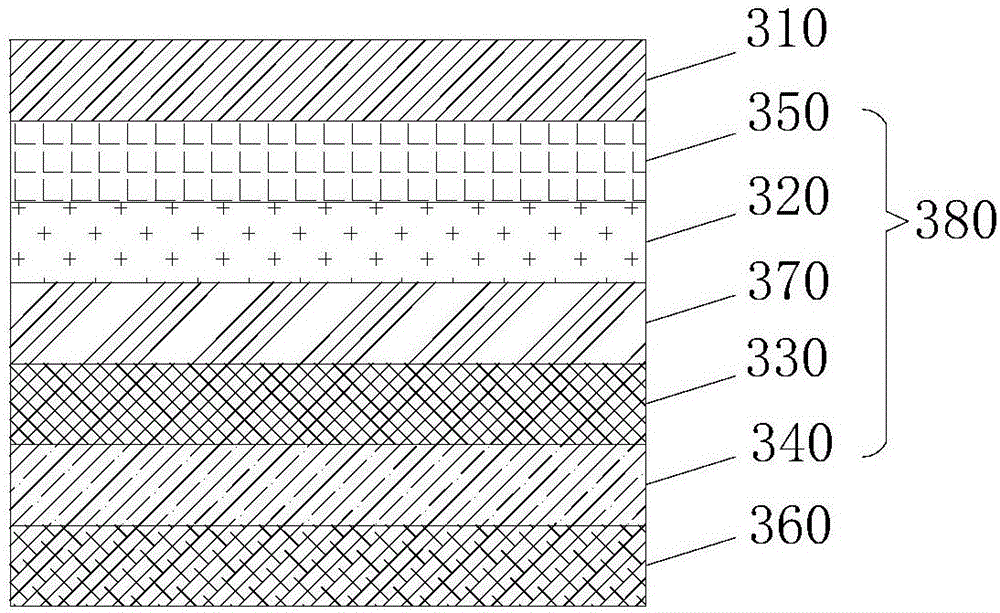

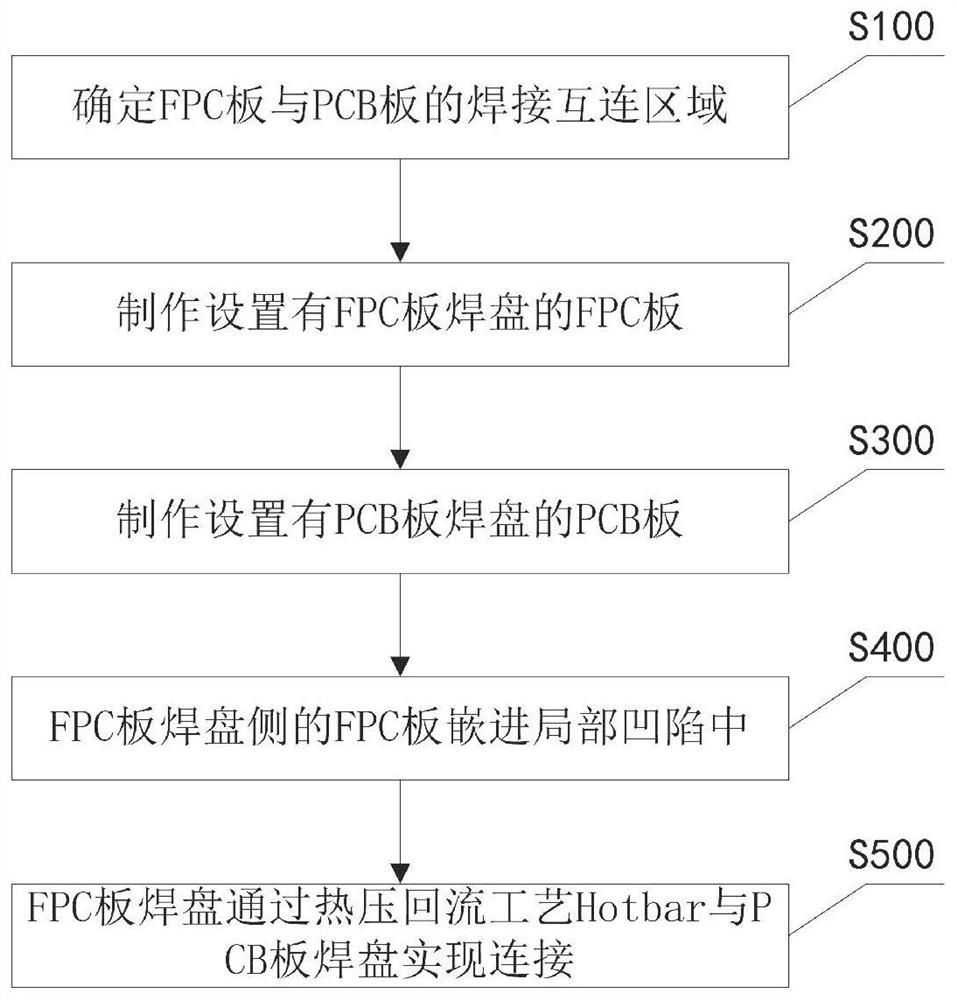

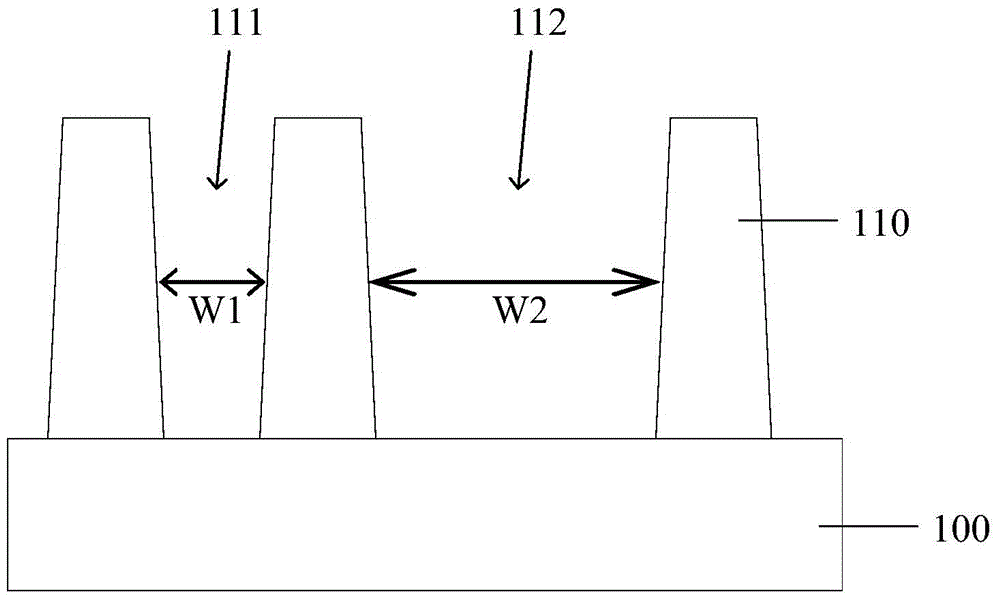

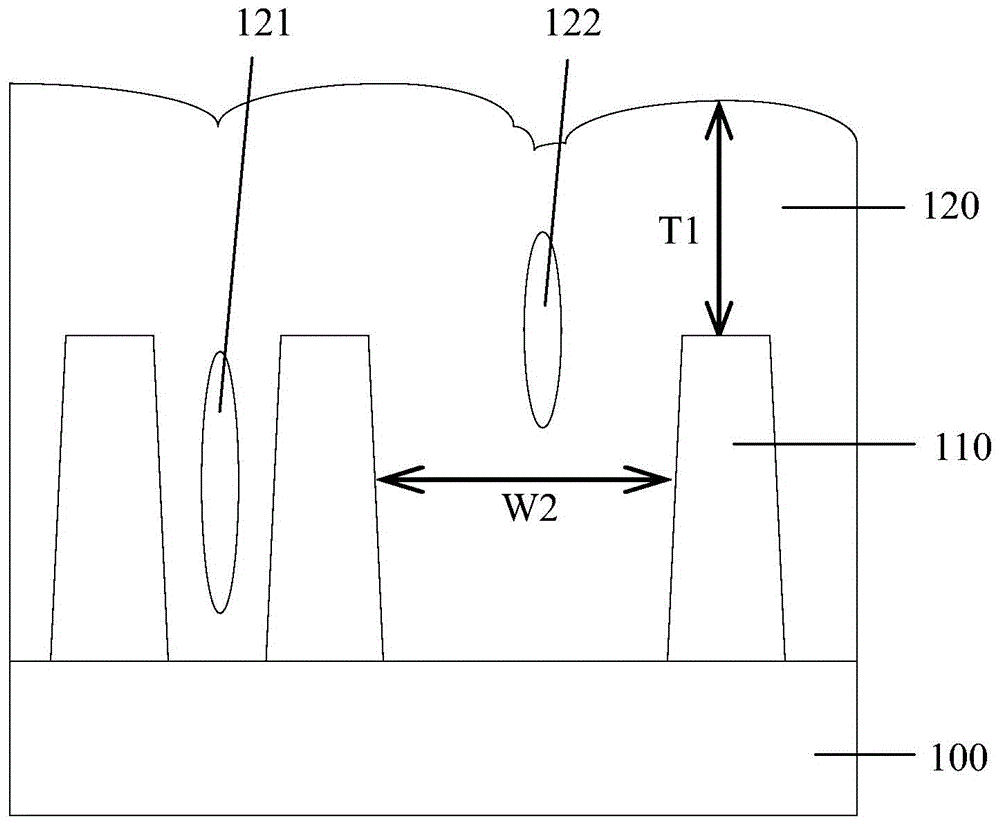

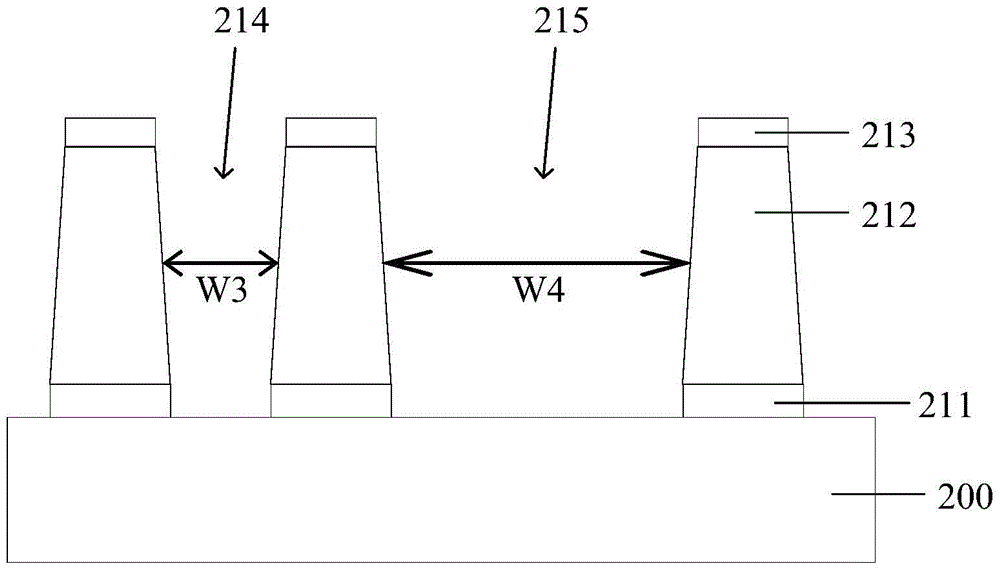

Flexible board and hard board connection structure and manufacturing method thereof

PendingCN113438807AReduce stack thicknessRealize the thinning of the whole machinePrinted circuit assemblingElectrical connection printed elementsCopper foilMechanical engineering

The invention provides a flexible board and hard board connection structure and a manufacturing method thereof. The flexible board and hard board connection structure comprises an FPC and a PCB. The PCB is provided with a welding interconnection area, a plurality of PCB pads are arranged in the welding interconnection area of the PCB, the FPC is provided with a plurality of FPC pads, and the FPC pads are connected with the PCB pads through a hot-pressing reflow process hotbar. The size of a welding interconnection area of the PCB is greater than or equal to the boundary dimension of the FPC at the bonding pad side of the FPC, a local recess is formed in the welding interconnection area of the PCB, and the bottom of the local recess does not exceed the upper surface of a copper foil layer at the bottommost layer of the PCB; and the FPC at the FPC bonding pad side is embedded into the local recess. According to the invention, the stacking thickness of the soft board and the hard board when the hotbar technology is adopted for interconnection can be reduced.

Owner:DONGGUAN ELF EDUCATIONAL SOFTWARE CO LTD

Interconnect structure and method of forming the same

ActiveCN103871964BReduce thicknessReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringPartial filling

The invention relates to an interconnecting wire structure and a forming method thereof. A semiconductor substrate is provided; the forming method of the interconnecting wire structure comprises the steps of forming multiple independent interconnecting wires on the semiconductor substrate, wherein grooves are formed between adjacent interconnecting wires; forming a first interlayer dielectric layer to cover the interconnecting wires, and filling a groove in part of the first interlayer dielectric layer until an opening is formed; forming a second interlayer dielectric layer to cover the first interlayer dielectric layer, wherein the opening is sealed by the second interlayer dielectric layer to form an air gap; flattening the second interlayer dielectric layer. The interconnecting wire structure formed by the forming method is improved in quality, and the forming method is simple in process and low in process cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A freeze-dried shellfish processing device and method

ActiveCN106234550BKeep the flavorReduce stack thicknessFood freezingMeat/fish preservationFlavorFreeze-drying

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

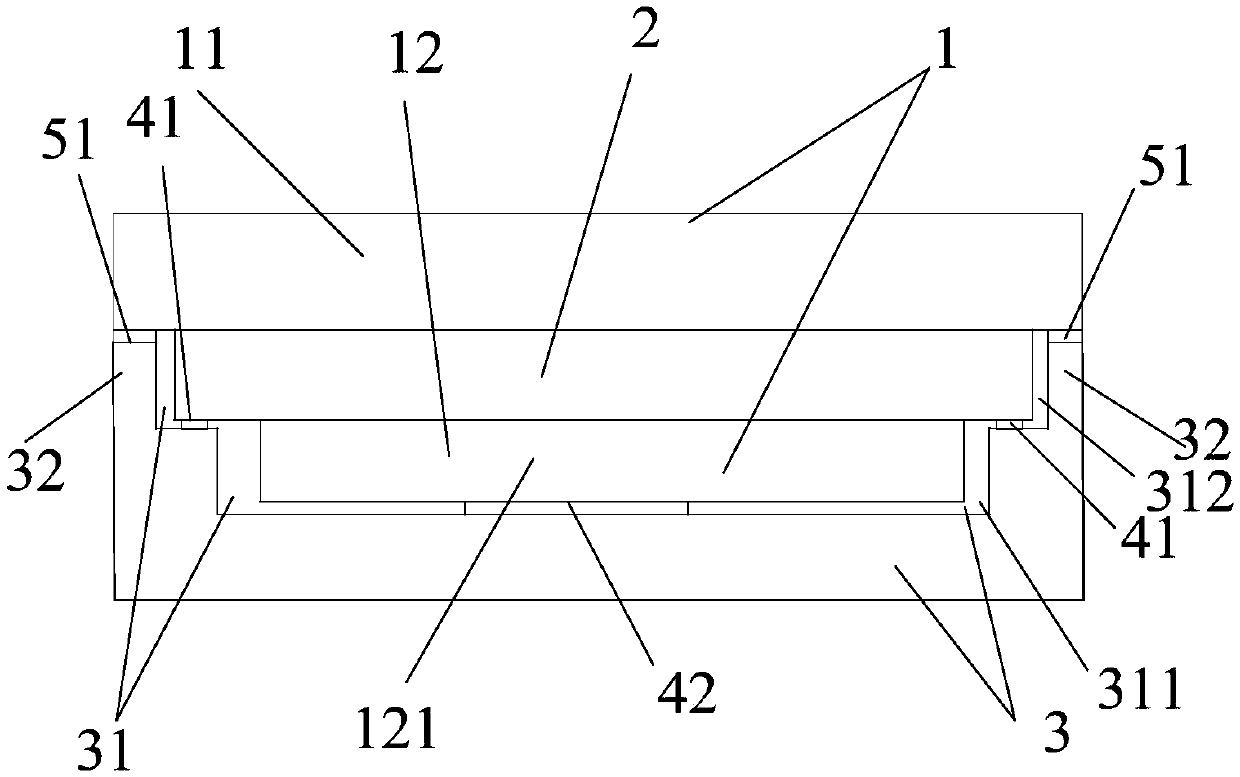

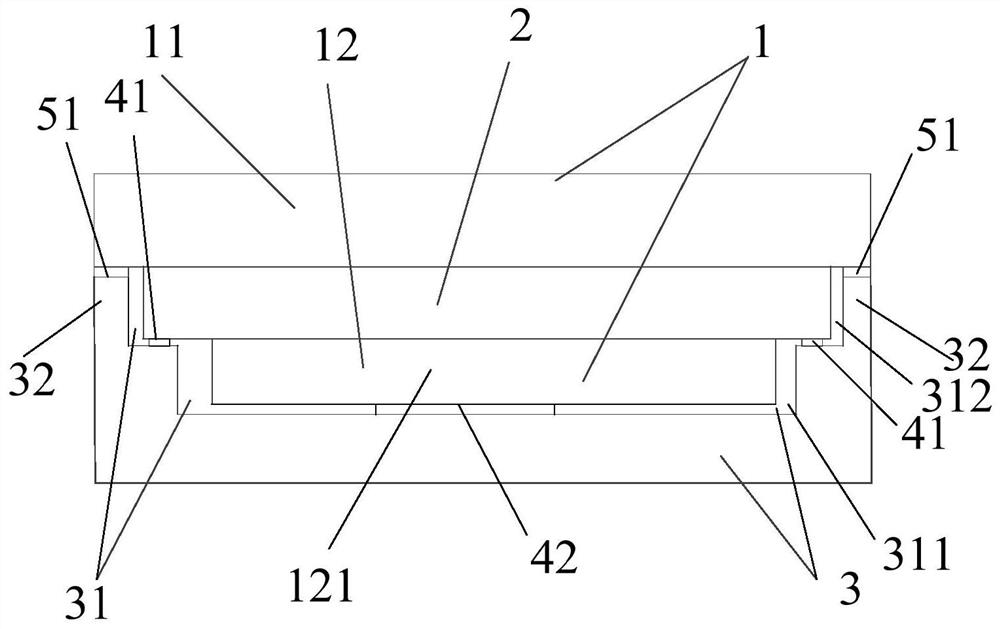

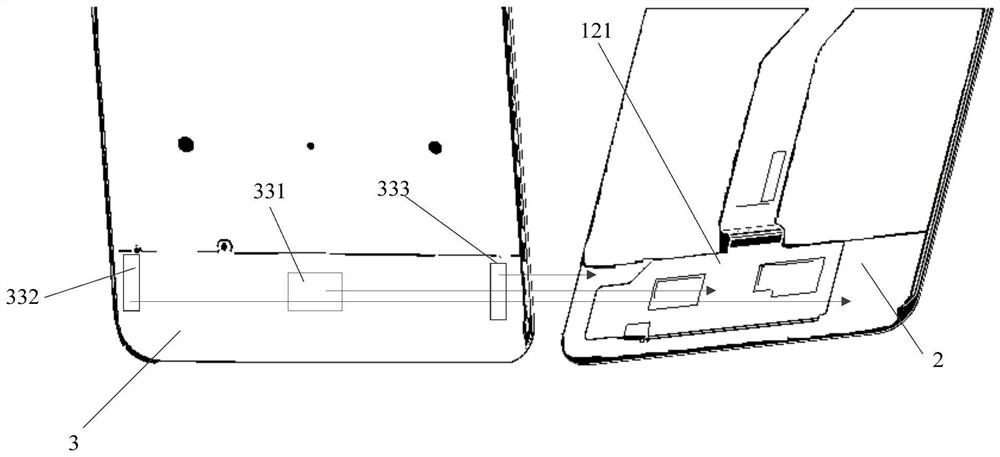

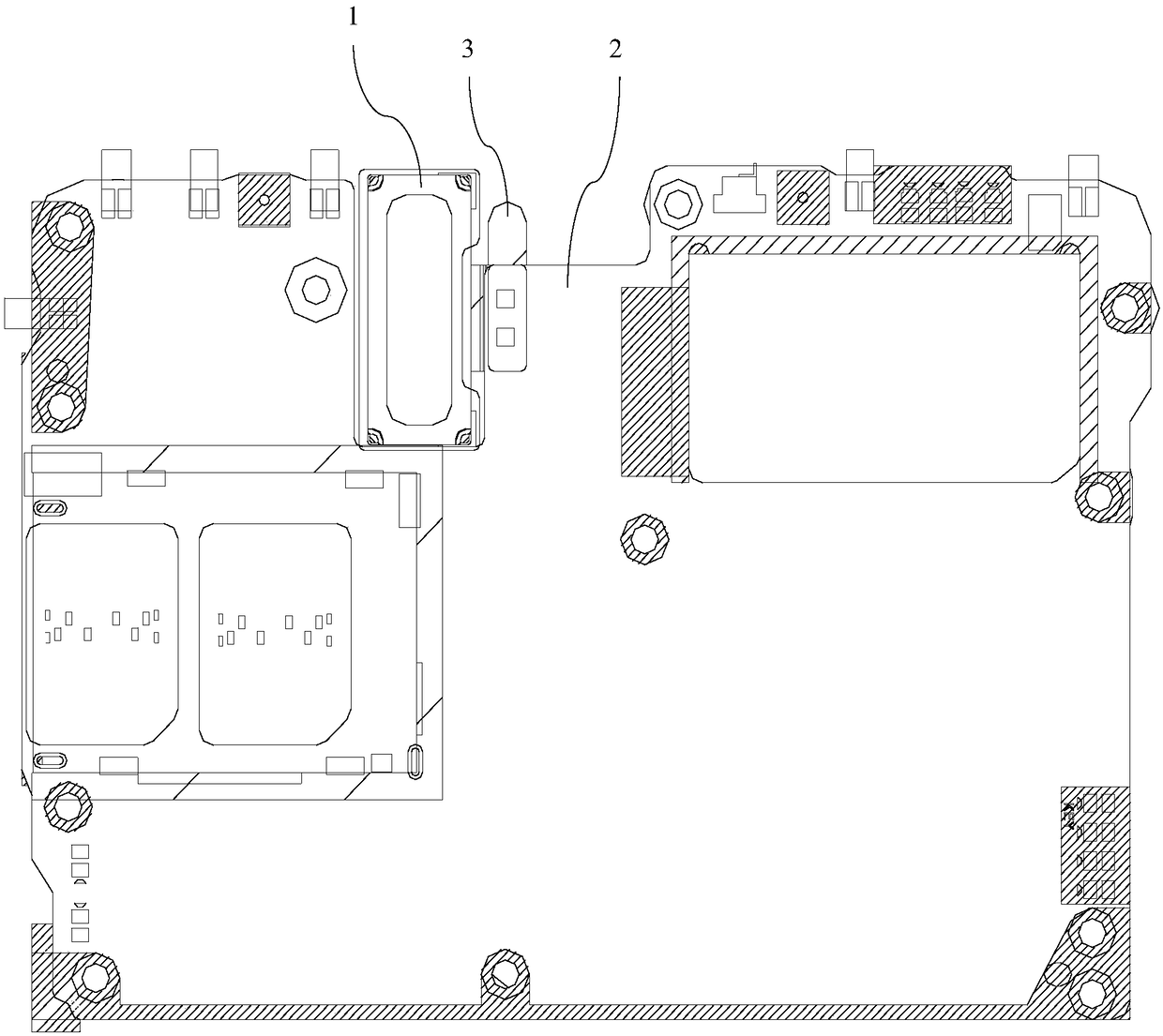

Plate-breaking type receiver assembling component and assembly method thereof and mobile terminal

InactiveCN108390974ASave thickness spaceSave layout spaceTelephone set constructionsElectricityGps receiver

The invention relates to a plate-breaking type receiver assembling component and an assembly method thereof and a mobile terminal. The plate-breaking type receiver assembling component comprises a shell, wherein the shell comprises a front shell and a rear shell which are mutually covered; a receiver and a main control board are arranged in the shell; a containing hole used for containing the receiver is arranged in the main control board; the receiver is arranged in the containing hole; the receiver is separated from the main control board; and the receiver is electrically connected to the main control board through a conduction piece. According to the plate-breaking type receiver assembling component, the receiver is arranged in the containing hole of the main control board, the conduction piece is compressed through the back shell in order to be switched to the main control board, so that the stacking thickness of the whole machine can be effectively reduced, a problem of insufficient space is solved, the thickness space is saved, and the layout space of the main control board is effectively reduced, and thus the whole area of the main control board is smaller, the cost is saved, multiple purposes are achieved, and the thickness of the whole machine is reduced particularly.

Owner:NUBIA TECHNOLOGY CO LTD

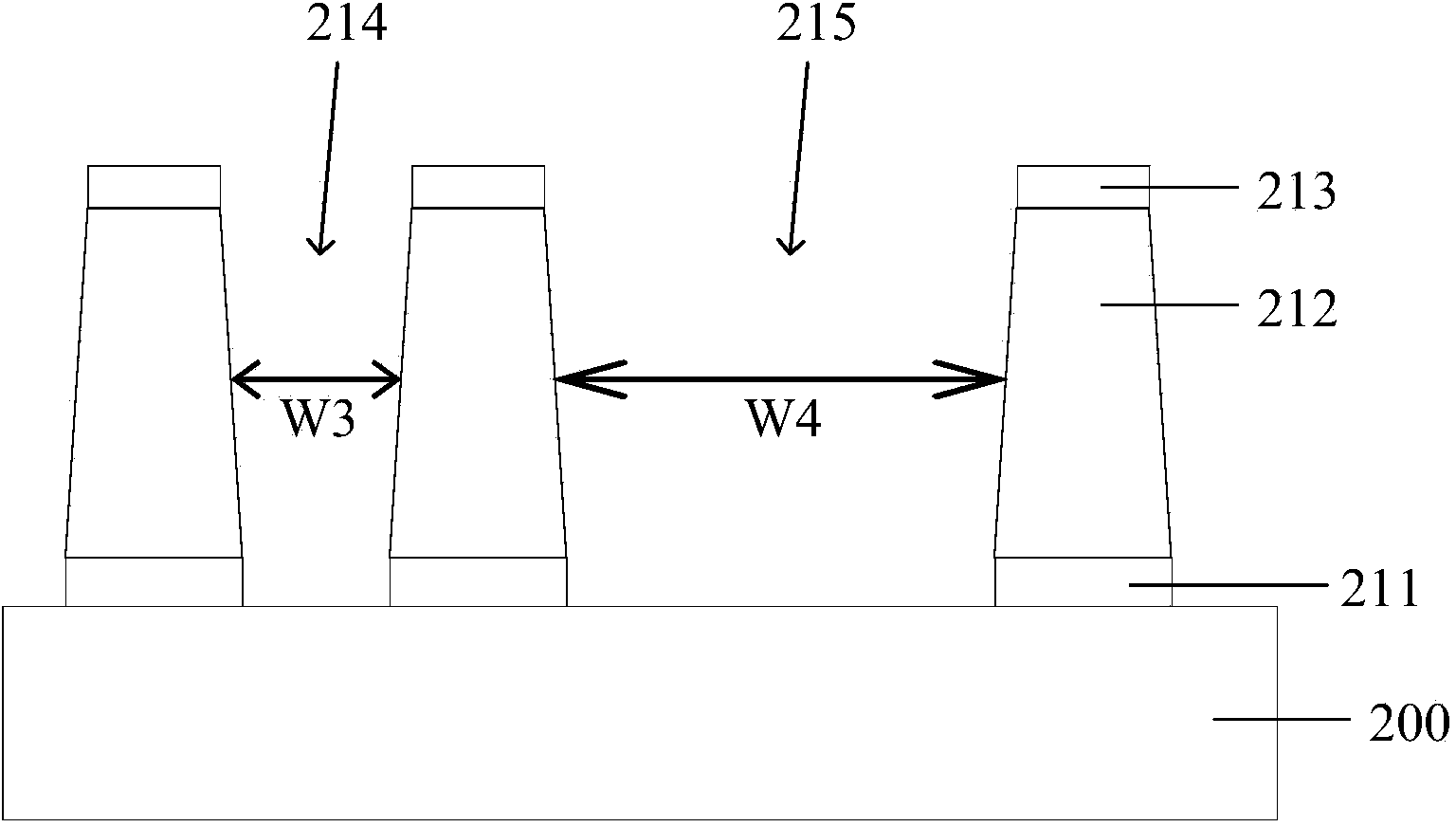

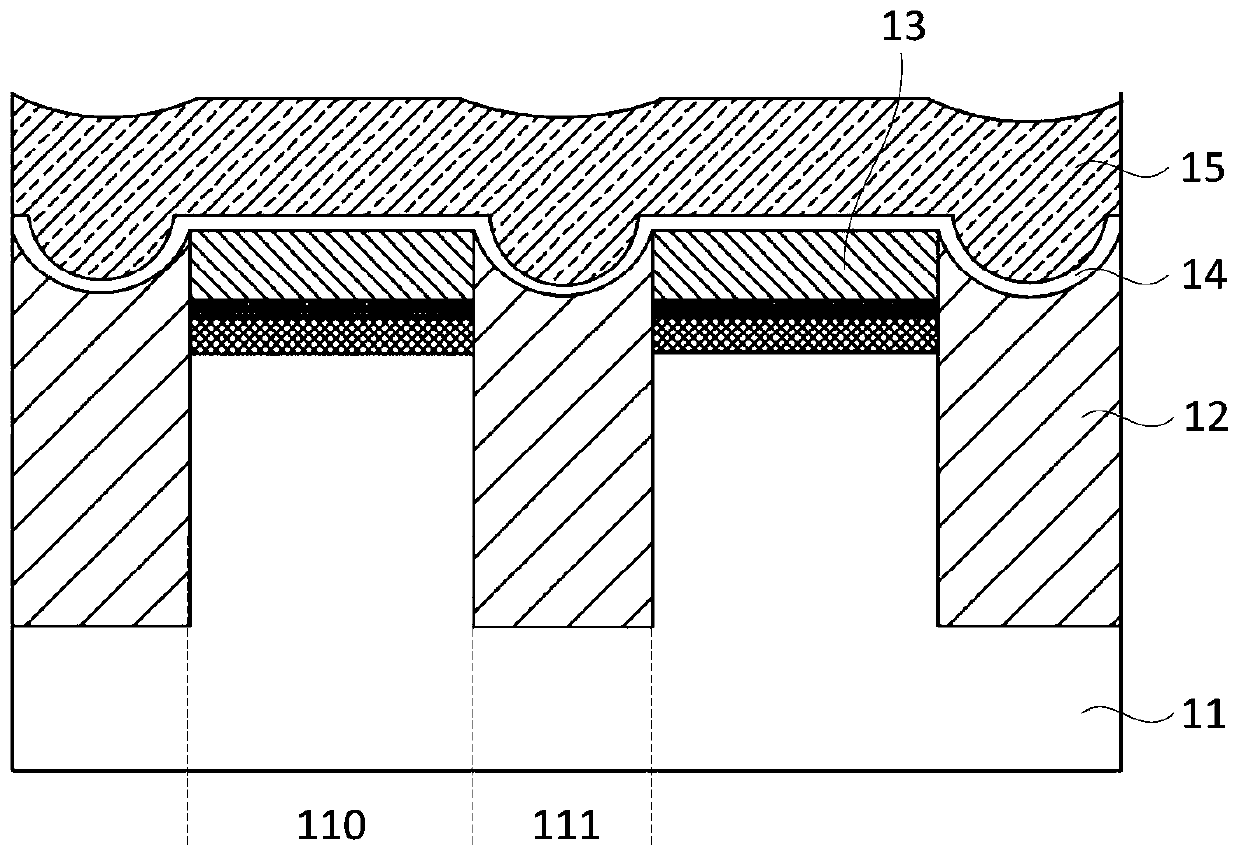

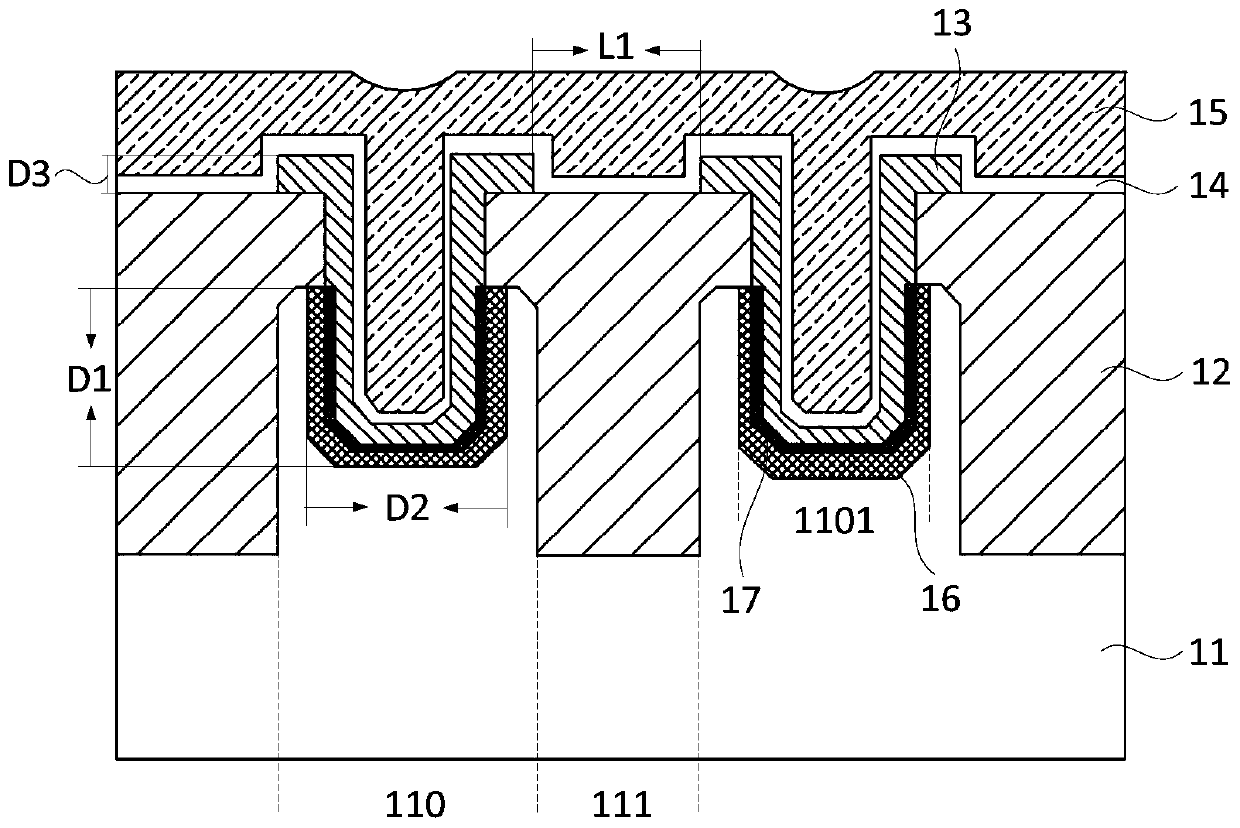

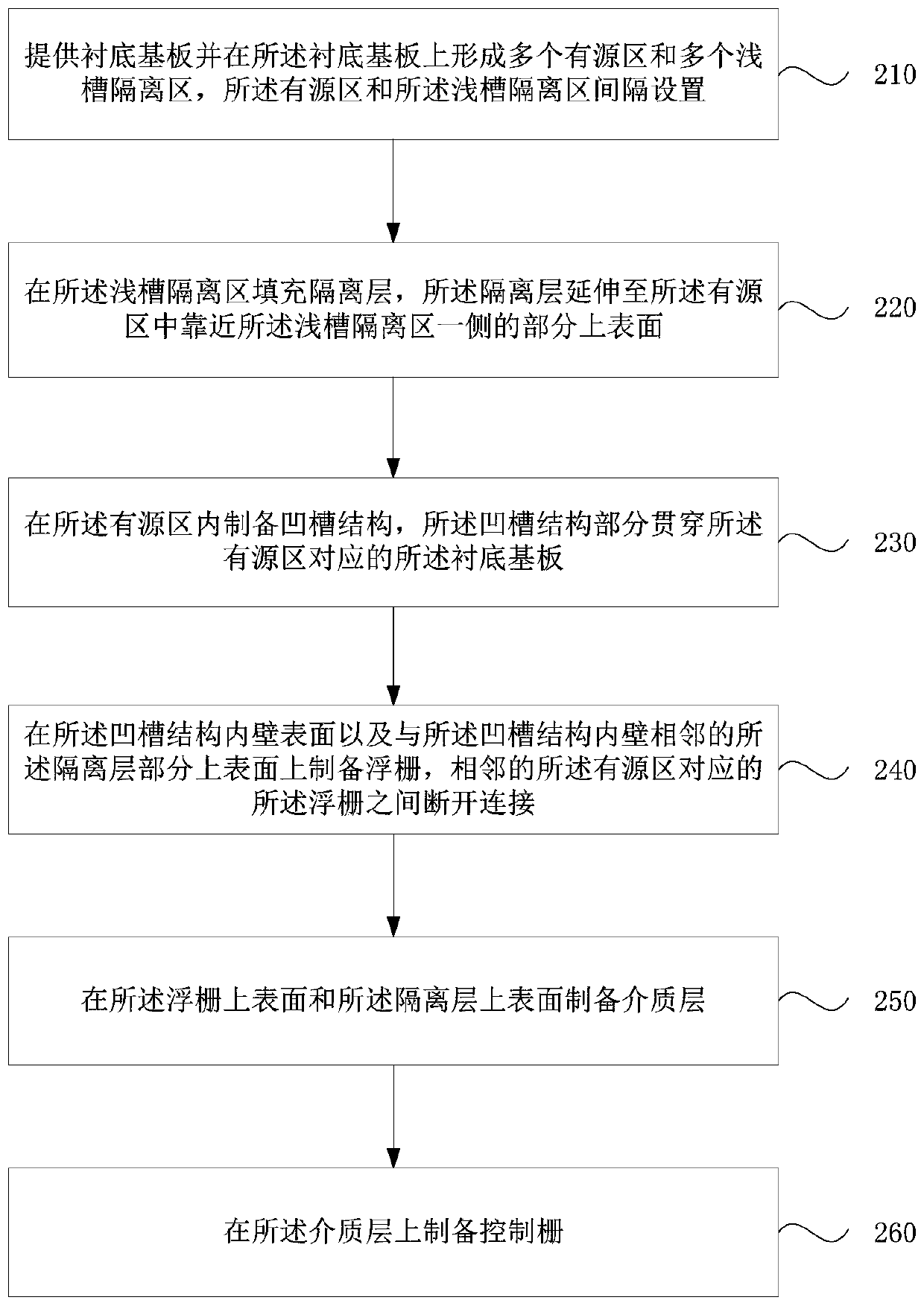

Memory and preparation method thereof

PendingCN110021604AIncrease the effective contact areaReduce power consumptionSolid-state devicesSemiconductor devicesIsolation layerEngineering

The invention discloses a memory and a preparation method thereof. The memory comprises a substrate, an isolation layer, a groove structure, floating gates, a dielectric layer, and a control gate, wherein the substrate comprises a plurality of active regions and a plurality of shallow trench isolation regions, and the active regions and the shallow trench isolation regions are arranged at intervals; the isolation layer is filled in the shallow trench isolation regions, wherein the isolation layer extends to a part of the upper surfaces, close to one side of the shallow trench isolation regions, of the active regions; the groove structure is located in the active regions, and the groove structure partially penetrates through the substrate corresponding to the active regions; the floating gates are located on the surface of the inner wall of the groove structure and extend to the upper surface of the isolation layer along the inner wall of the groove structure, and the floating gates corresponding to the adjacent active regions are disconnected; the dielectric layer is located on the upper surfaces of the floating gates and the upper surface of the isolation layer; and the control gate located on the dielectric layer. The memory provided by the embodiment of the invention has relatively low power consumption and relatively high yield and reliability.

Owner:GIGADEVICE SEMICON SHANGHAI INC +1

Touch film structure

ActiveCN103941904BWith water and oxygen barrier functionReduce stack thicknessInput/output processes for data processingThin membraneEngineering

The invention provides a touch film structure, which includes a touch element layer, a barrier layer and a flexible substrate. The touch element layer has opposite first surface and second surface. The barrier layer is formed on the first surface or the second surface or integrated with the touch element layer to form a multifunctional film layer. The flexible substrate is stacked with the touch element layer, barrier layer or multifunctional film layer.

Owner:HANNSTAR DISPLAY CORPORATION

A touch display panel

ActiveCN106383614BReduce stack thicknessImprove bending resistanceNon-linear opticsInput/output processes for data processingComposite filmOptical transmittance

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Motor and washing machine

ActiveCN112350477BReduce magnetic leakageReduce dosageMagnetic circuit rotating partsSynchronous machine detailsLaundry washing machineElectric machine

The invention discloses a motor and a washing machine. The motor includes: a stator core, the stator core is provided with an axially through hole, the inner wall of the stator core is provided with a plurality of open slots along the circumference, and stator teeth are formed between two adjacent open slots, and the stator teeth include at least Equal width part with equal tooth width; rotor core, the rotor core is set in the through hole, and a plurality of installation grooves for setting permanent magnets are opened on the rotor core along the circumferential direction, and the rotor core is in the area outside the installation groove A magnetic isolation area for magnetic isolation and a magnetic permeation area for magnetic conduction are set; wherein, the magnetic permeation area includes: a first area adjacent to the installation groove, a second area adjacent to the outer periphery of the rotor core, and a connection between the first area and the second area. In the third area of the area, the width of the third area is equal to the width, and the value range of the width of the third area is ±0.5 mm from the width of the equal width portion. On the premise of reducing the amount of permanent magnet materials, the power density of the motor can be increased, thereby reducing the stacked thickness of the motor and the axial dimension of the motor.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com