Interconnecting wire structure and forming method thereof

A technology of interconnection lines and interlayer dielectric layers, applied in the field of interconnection line structure and its formation, can solve the problems of large stacking thickness, complicated manufacturing process, poor quality, etc., and achieve reduction of stacking thickness and process cost low, quality-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

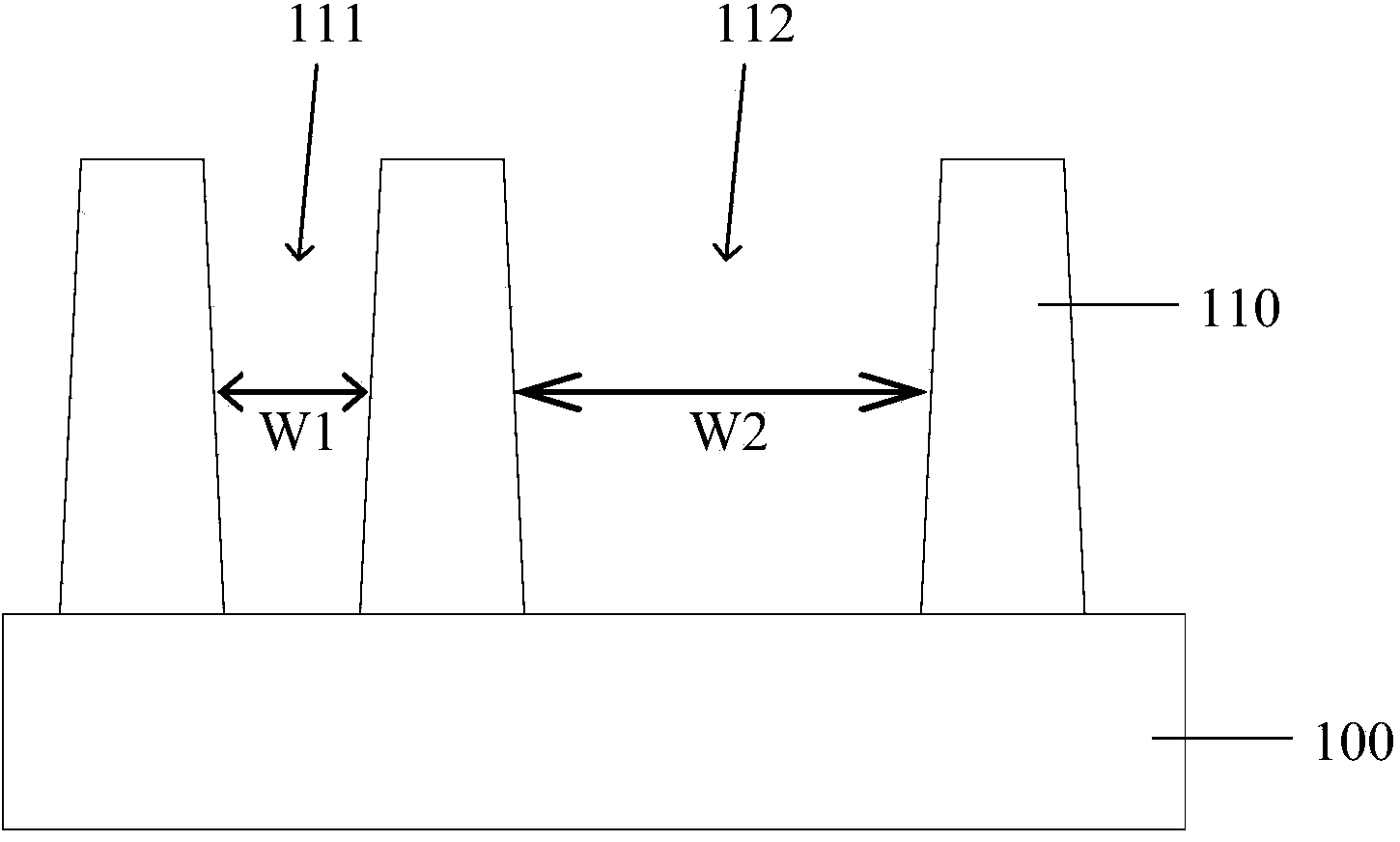

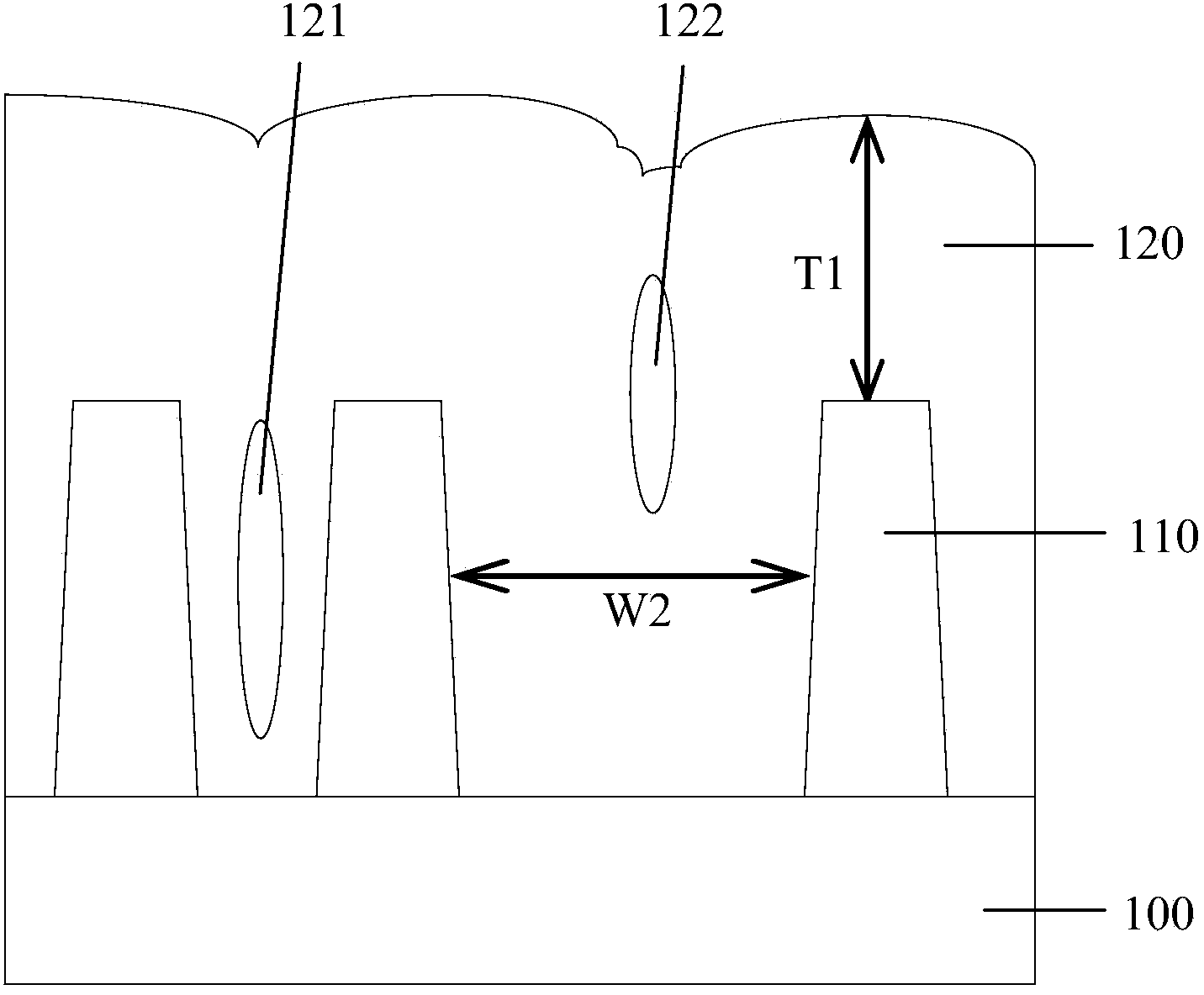

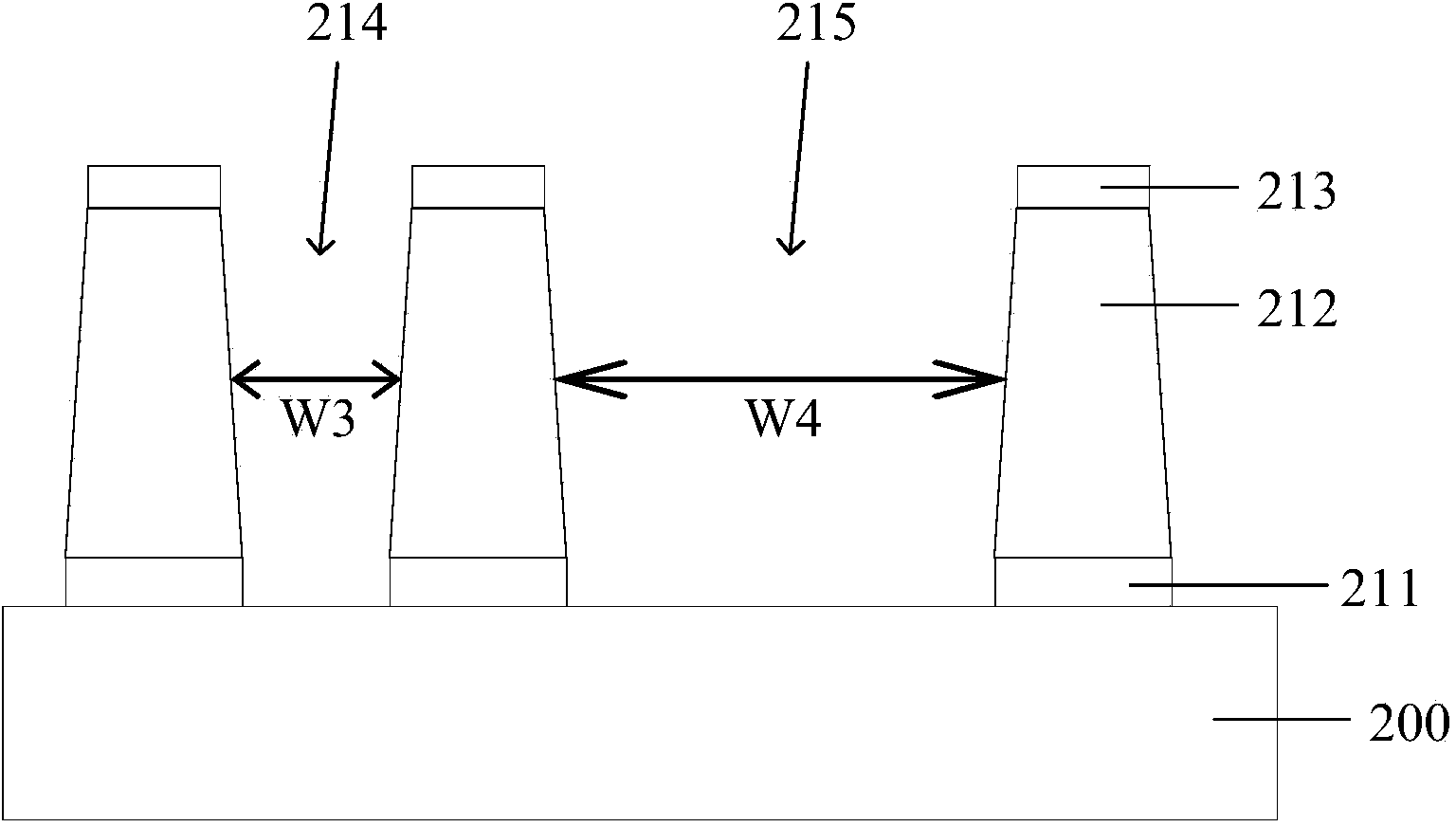

[0039] It can be seen from the description of the background technology that in the existing method for forming the interconnection structure, when the first interlayer dielectric layer is filled with a larger width (for example figure 1 and figure 2 In the case of a groove with a width W2) in the middle, an air gap at a higher position (relative to the upper surface of the interconnect structure) will be formed. In order to prevent the air gap from causing bubble defects on the upper surface of the interconnect structure, the first interlayer dielectric The thickness of the layer is generally large, and a second interlayer dielectric layer with the same thickness needs to be formed on the first interlayer dielectric layer. In addition, after the second interlayer dielectric layer is planarized, it is also necessary to form a second interlayer dielectric layer on the first interlayer dielectric layer. The protective layer is formed on the dielectric layer, and the whole formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com