Patents

Literature

35results about How to "Avoid Bubble Defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of ultra-low-carbon, low-silicon, low-manganese and low-aluminum steel continuous casting blank

ActiveCN109943680AGuarantee the stability of deoxidation effectGuaranteed liquidityManufacturing convertersProcess efficiency improvementChemical compositionManganese

The invention relates to a production method of ultra-low-carbon, low-silicon, low-manganese and low-aluminum steel continuous casting blank. The continuous casting blank is composed of the followingchemical components of, in percentage by mass, less than or equal to 0.004% of C, less than or equal to 0.006% of Si, less than or equal to 0.06% of Mn, less than or equal to 0.010% of P, less than orequal to 0.010% of S, less than or equal to 0.004% of Alt, less than or equal to 0.02% of Cu, less than or equal to 0.02% of Cr and less than or equal to 0.02% of Ni, and the balance Fe and inevitable impurities; and the production process route of the continuous casting blank comprises the following steps of molten iron pretreatment, desulfurization, converter smelting, LF refining, RH vacuum treatment and continuous casting. Through the converter smelting, the LF refining, the RH vacuum treatment and the continuous casting technology, so that the chemical components are obtained to meet therequirement of the molten steel, the deoxidization effect and the liquidity of the molten steel are ensured, and casting by a small square billet continuous casting machine to obtain a steel billet with good surface and internal quality.

Owner:SGIS SONGSHAN CO LTD

Method for rectangular continuous casting production of low-carbon low-silicon steel

The invention discloses a method for rectangular continuous casting production of low-carbon low-silicon steel. The method includes the procedures of smelting of a converter, LF refining and rectangular blank continuous casting. In the procedure of smelting of the converter, manganese alloying is performed through low-carbon ferromanganese, and the terminal point carbon content of the converter is controlled to be 0.04 or below; in the steel discharging process, aluminum ingots are adopted for deoxidization; in the LF refining procedure, manganese component adjustment is performed through low-carbon ferromanganese, deoxidization is performed through an aluminum-based deoxidization agent, aluminum component adjustment is performed through an aluminum wire, molten steel calcium treatment is performed through a calcium and ferrum wire, and the soft blow time is not shorter than 10 min before leaving; in the rectangular blank continuous casting procedure, an argon-sealed protective sleeve is adopted for a large pack, integrated tundish is adopted for protective casting, a carbon-free covering agent is added in the initial stage of casting of a continuously-cast first pack, and the superheat degree of tundish molten steel is controlled to be 20-40 DEG C. According to the method, by reasonably controlling the aluminum content of molten steel, continuous casting bubble defects are avoided, it is also avoided that castability of high-aluminum-content molten steel is poor, and cost of a deoxidization agent is reduced.

Owner:TANGSHAN IRON & STEEL GROUP

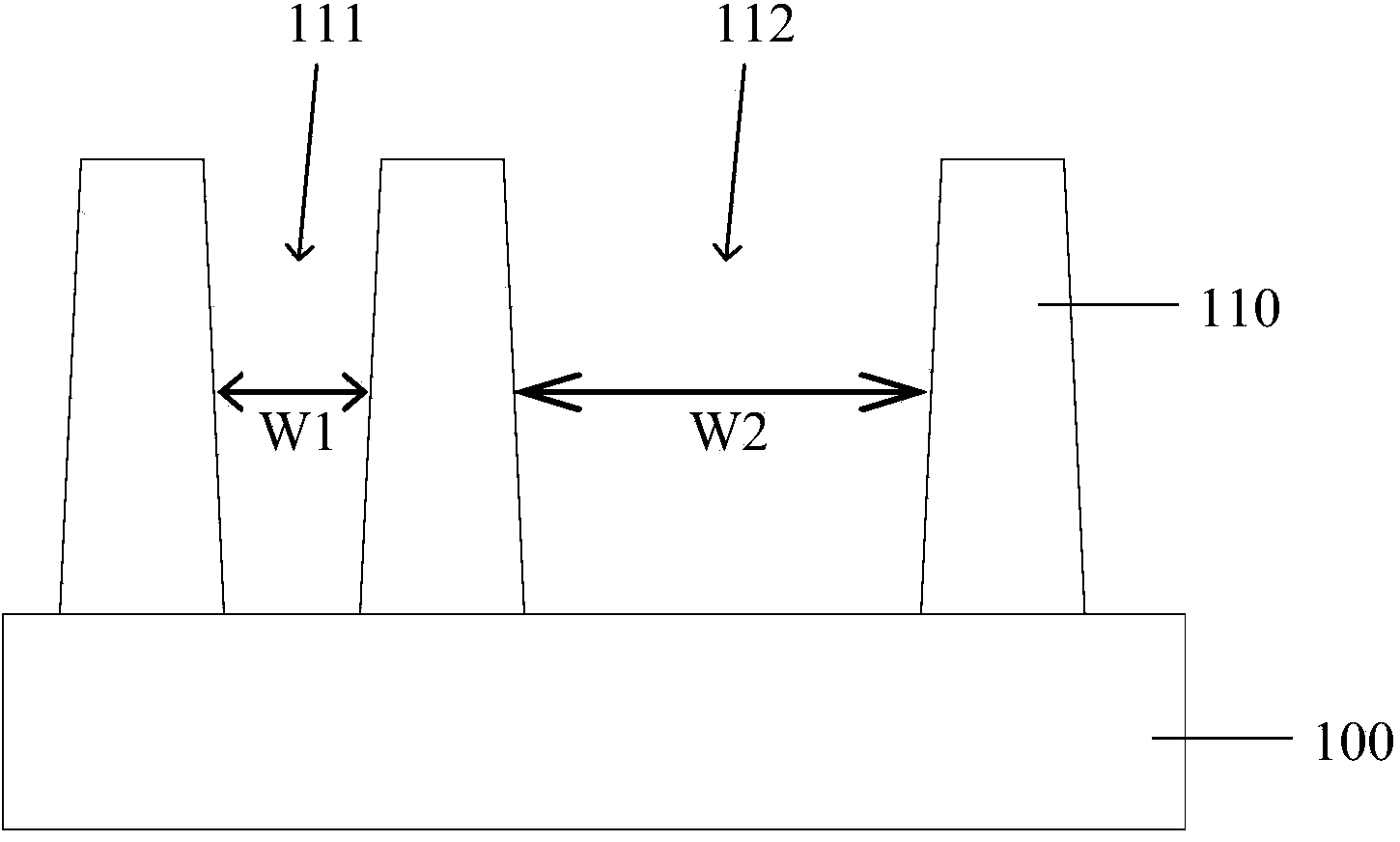

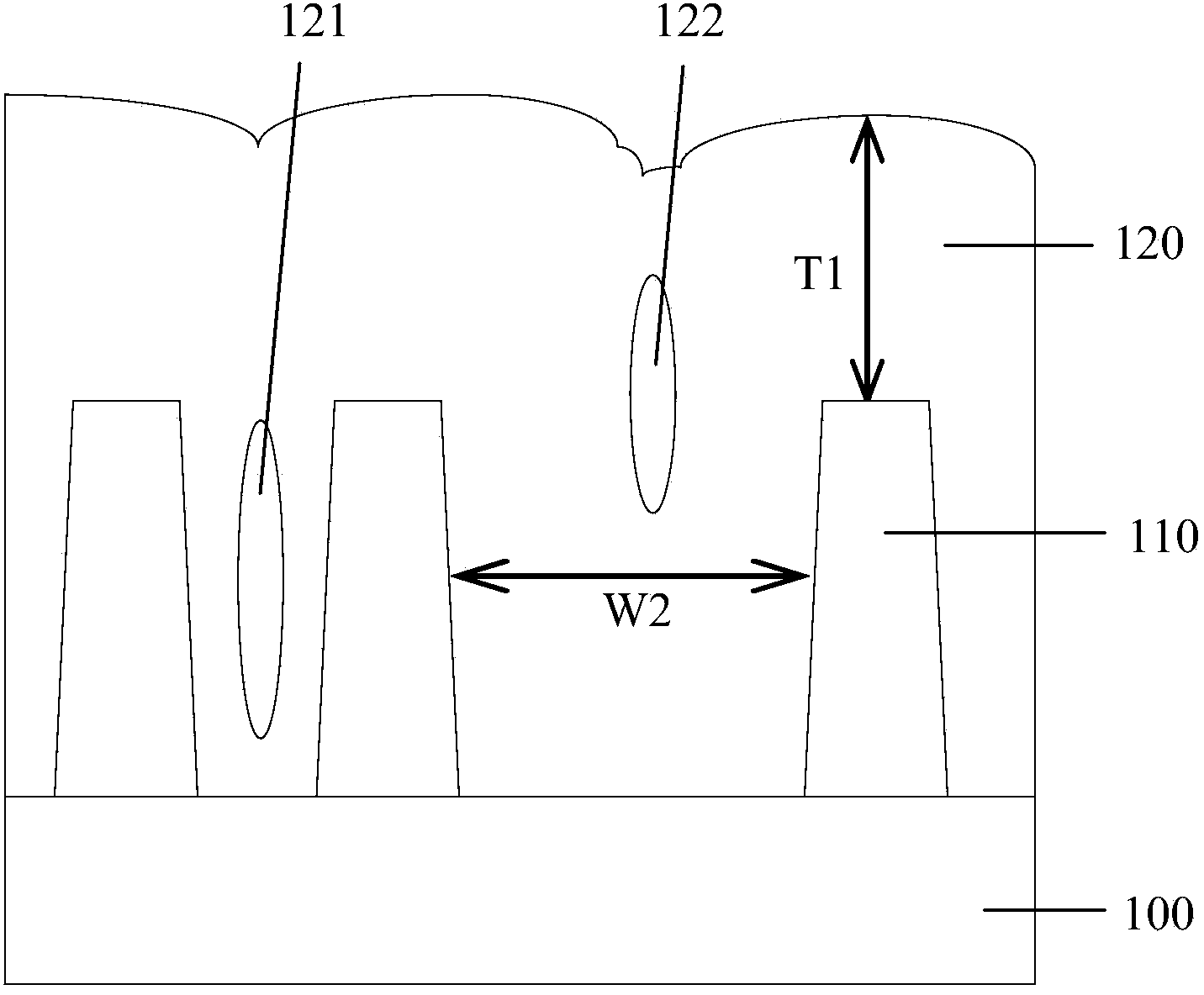

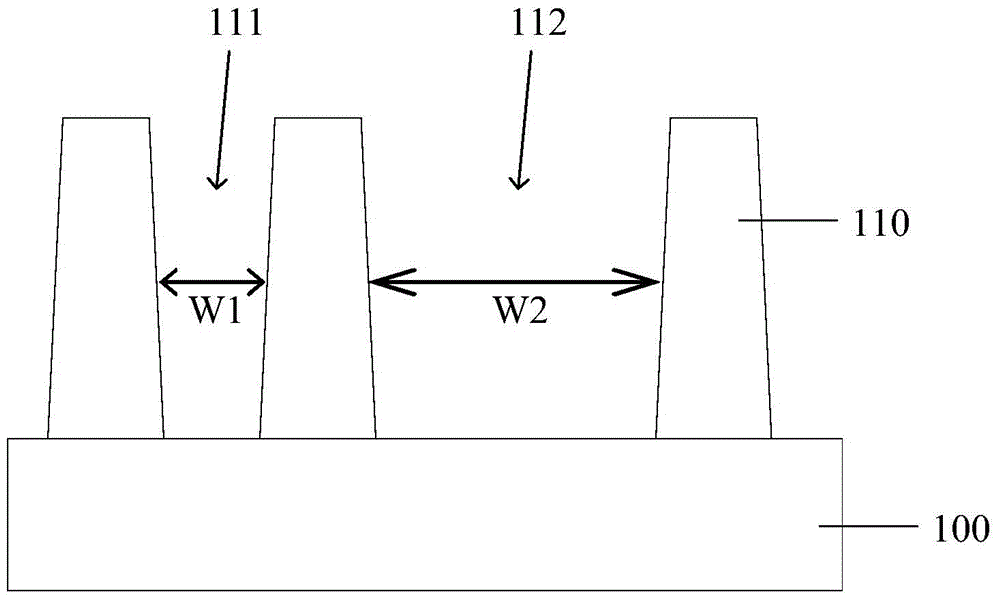

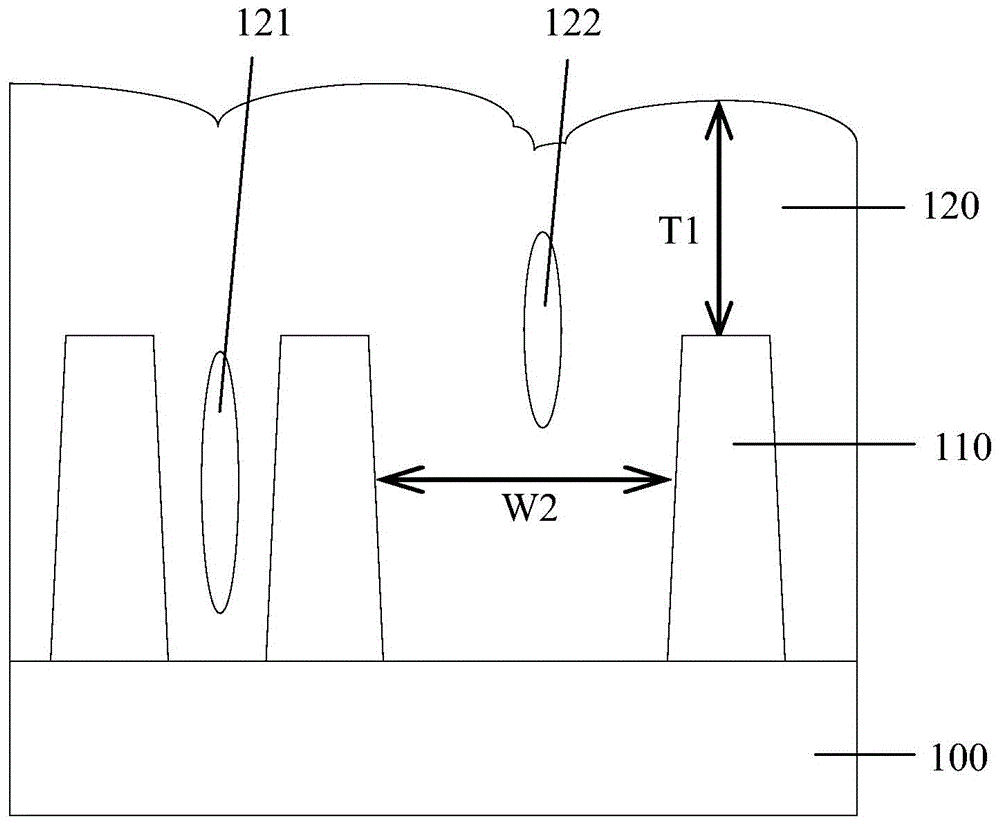

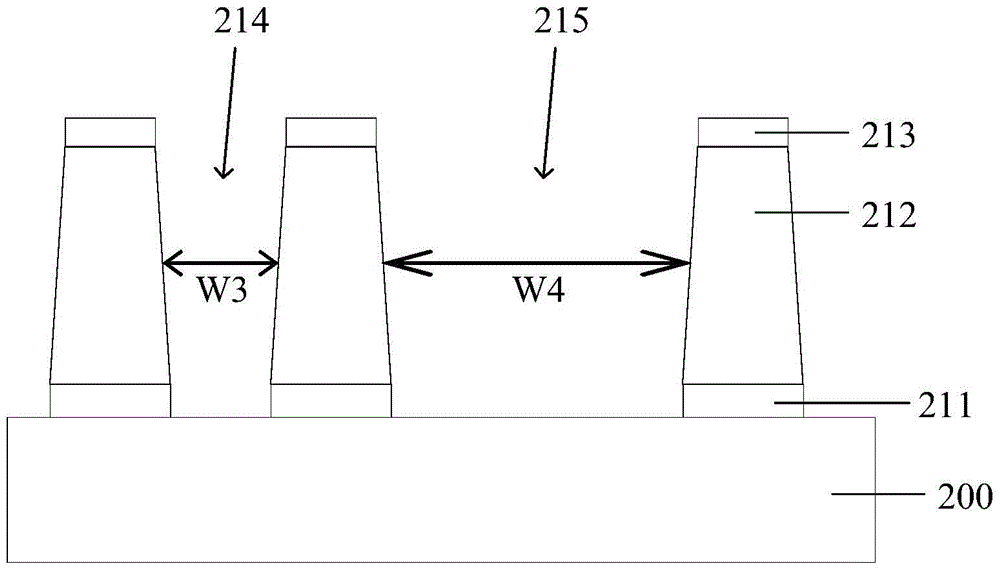

Interconnecting wire structure and forming method thereof

ActiveCN103871964AReduce thicknessReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringDielectric layer

The invention relates to an interconnecting wire structure and a forming method thereof. A semiconductor substrate is provided; the forming method of the interconnecting wire structure comprises the steps of forming multiple independent interconnecting wires on the semiconductor substrate, wherein grooves are formed between adjacent interconnecting wires; forming a first interlayer dielectric layer to cover the interconnecting wires, and filling a groove in part of the first interlayer dielectric layer until an opening is formed; forming a second interlayer dielectric layer to cover the first interlayer dielectric layer, wherein the opening is sealed by the second interlayer dielectric layer to form an air gap; flattening the second interlayer dielectric layer. The interconnecting wire structure formed by the forming method is improved in quality, and the forming method is simple in process and low in process cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

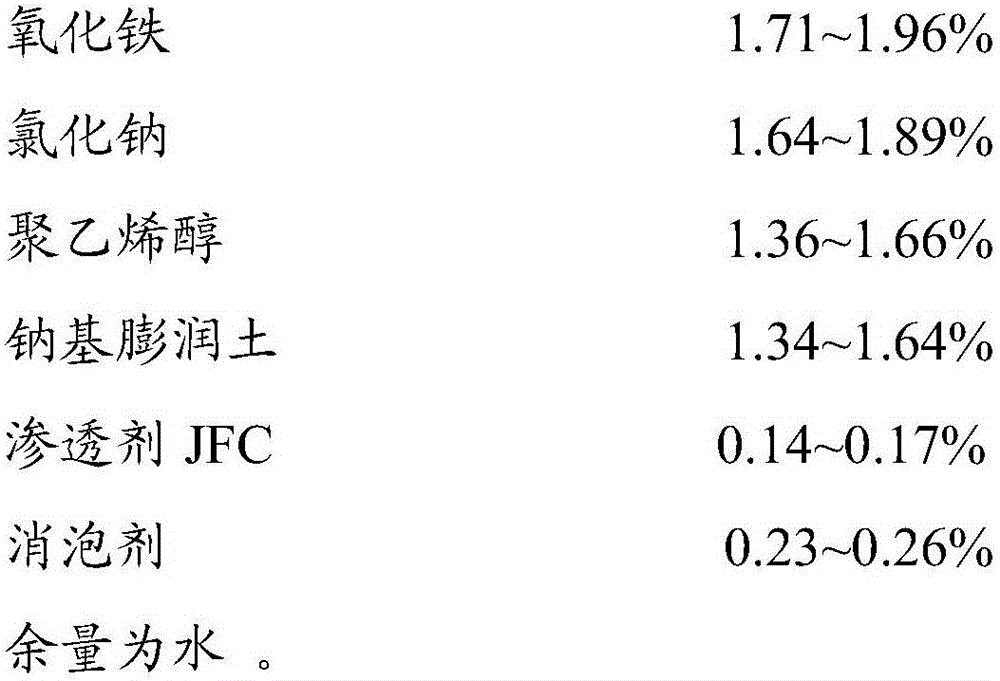

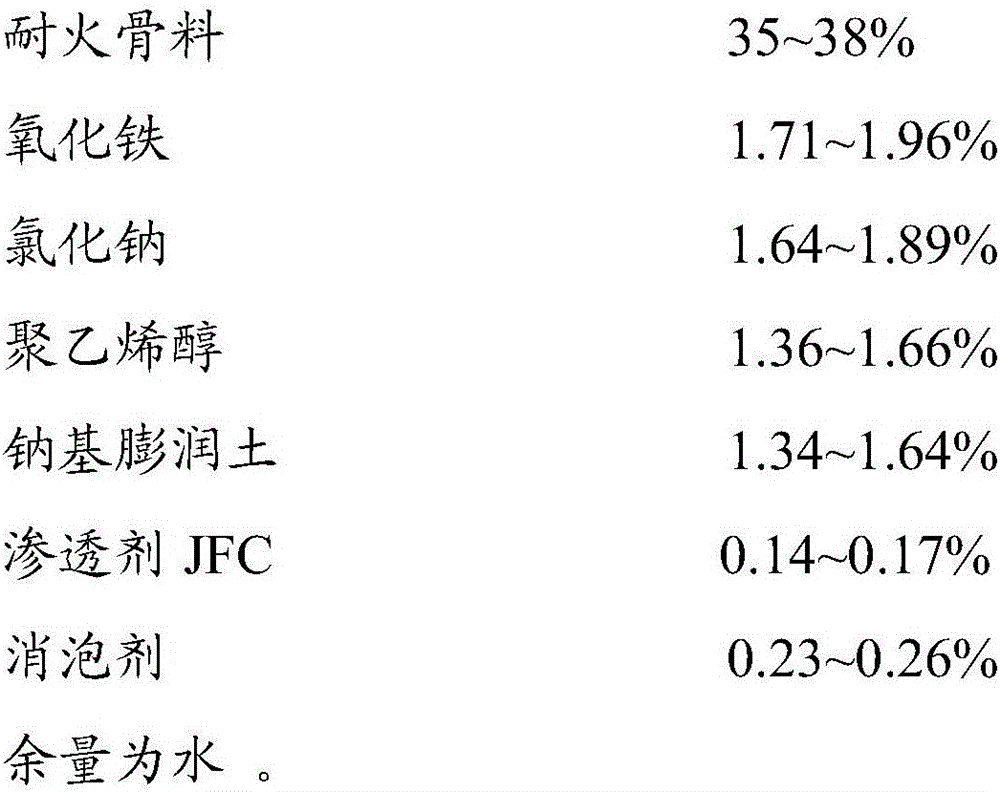

Water-based casting coating for precoated sand casting and preparation method thereof

The invention provides a water-based casting coating for precoated sand casting and a preparation method thereof. The powdery casting coating provided by the invention is prepared from the following components in percentage by weight: 35 to 38 percent of refractory aggregate, 1.71 to 1.96 percent of ferric oxide, 1.64 to 1.89 percent of sodium chloride, 1.36 to 1.66 percent of polyving akohol, 1.34 to 1.64 percent of sodium bentonite, 0.14 to 0.17 percent of penetrating agent JFC, 0.23 to 0.26 percent of defoamer, and the balance water. The water-based casting coating for precoated sand casting provided by the invention can enable the surface finishment of castings casted by precoated sand to achieve the surface finishment effect of lost-wax precision castings.

Owner:HUBEI UNIV OF TECH

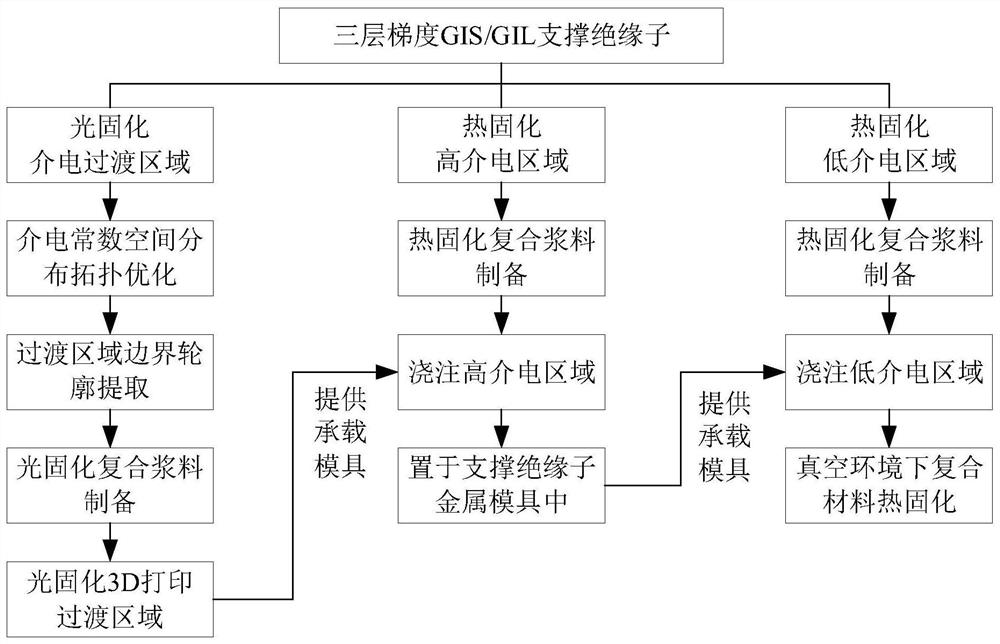

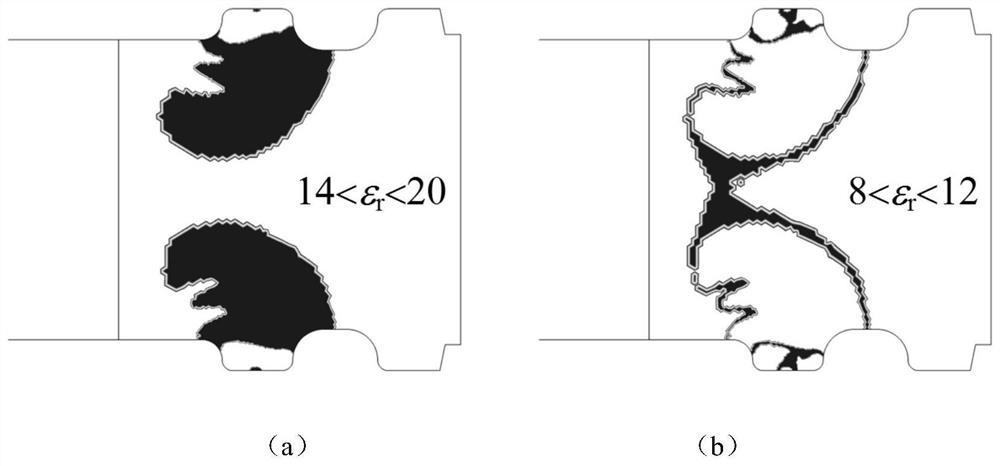

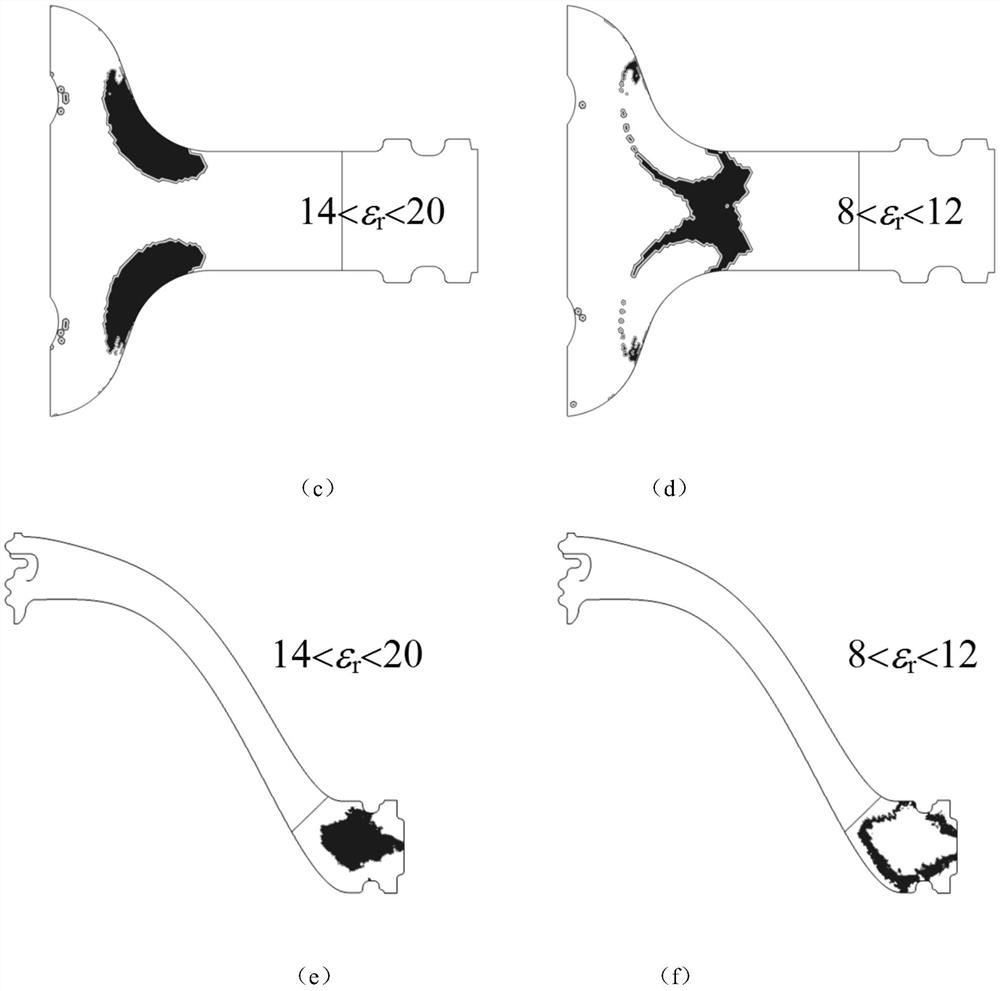

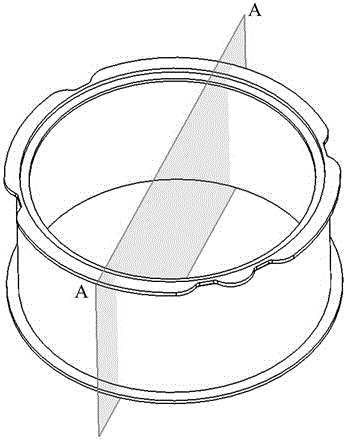

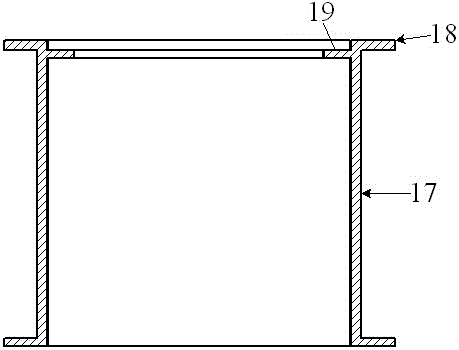

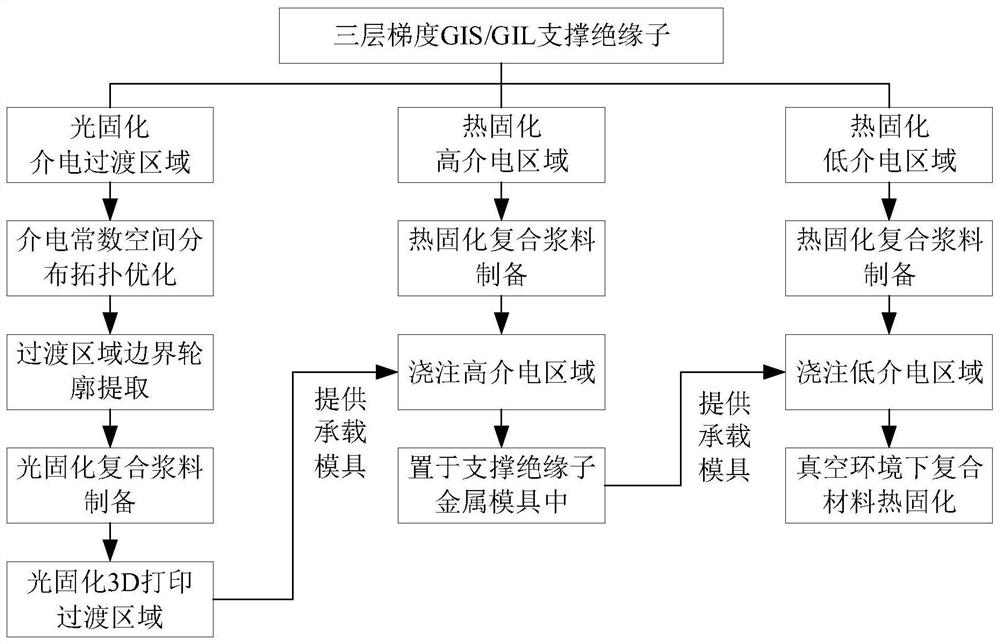

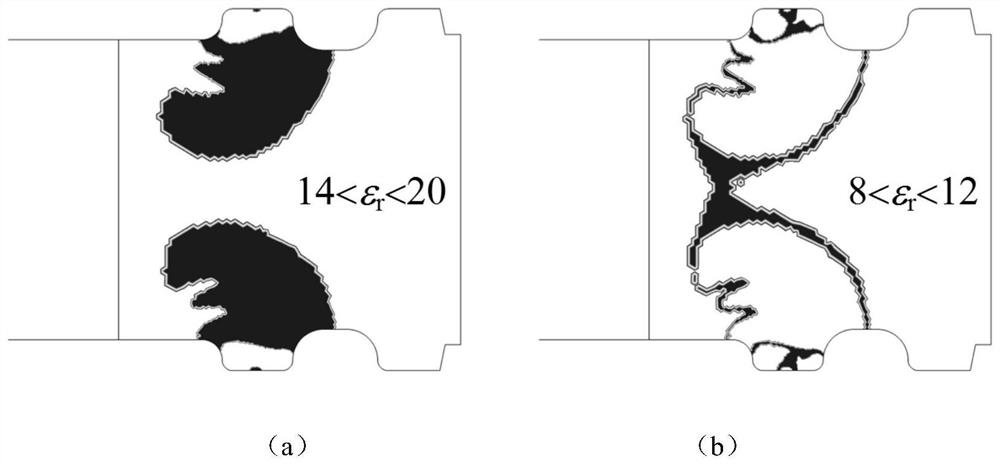

Preparation method of three-layer gradient GIS/GIL supporting insulator

ActiveCN113284684AGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

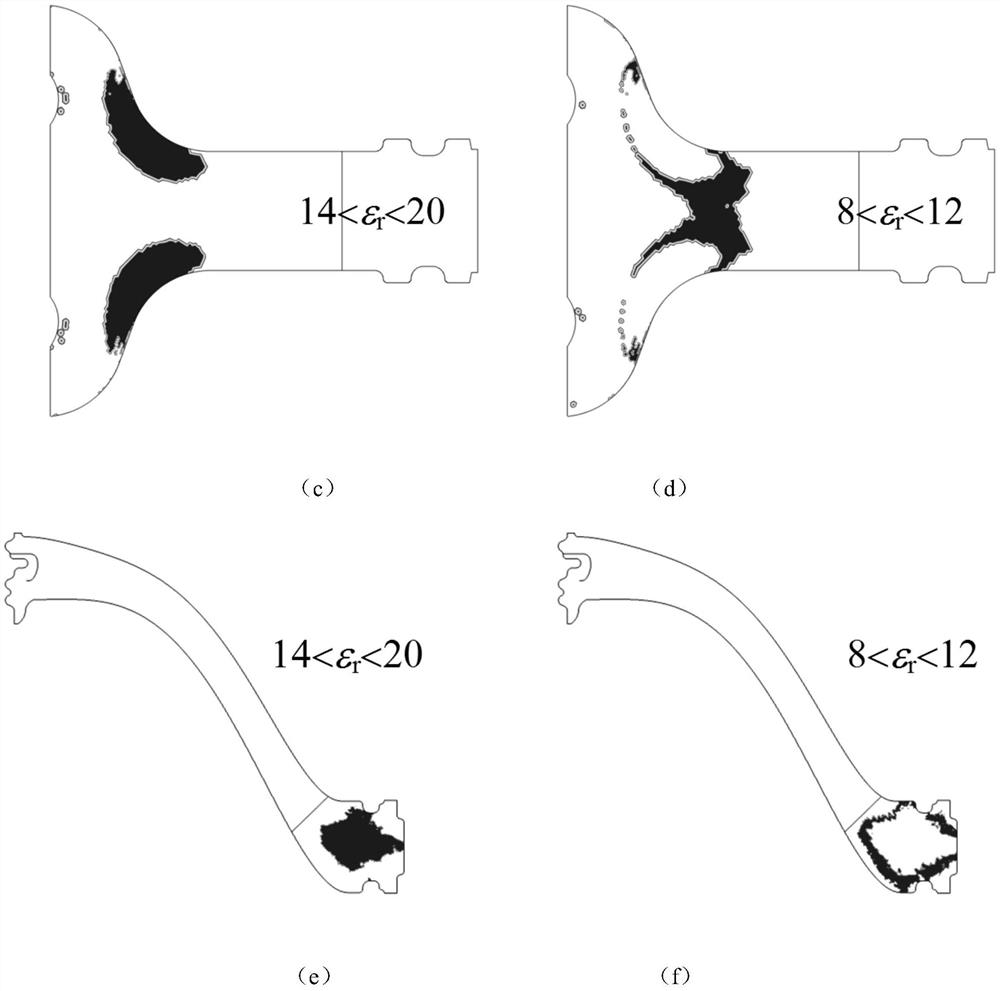

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator, which aims at reducing the electric field intensity of an insulator along a surface or a local region as an optimization target, and solves the optimal spatial distribution of a dielectric constant in the supporting insulator by using a variable density algorithm. According to the optimization result, the dielectric constant change area is divided into a dielectric constant transition area and a high dielectric area, the combination contour of the dielectric constant transition area is extracted, and then a hollow dielectric constant transition area with a support and a resin sprue gate is generated through photocuring 3D printing; a thermocurable high-dielectric composite material is prepared by adopting a high-dielectric filler / polymer blending mode, and then the high-dielectric composite material is poured into the dielectric constant transition area and integrally put into a metal mold for fixing; and a thermocurable high-dielectric composite material is prepared in a low-dielectric filler / polymer blending mode, then the thermocurable high-dielectric composite material is poured into a metal mold, and the three-layer gradient GIS / GIL supporting insulator can be obtained after curing is completed in vacuum.

Owner:XI AN JIAOTONG UNIV

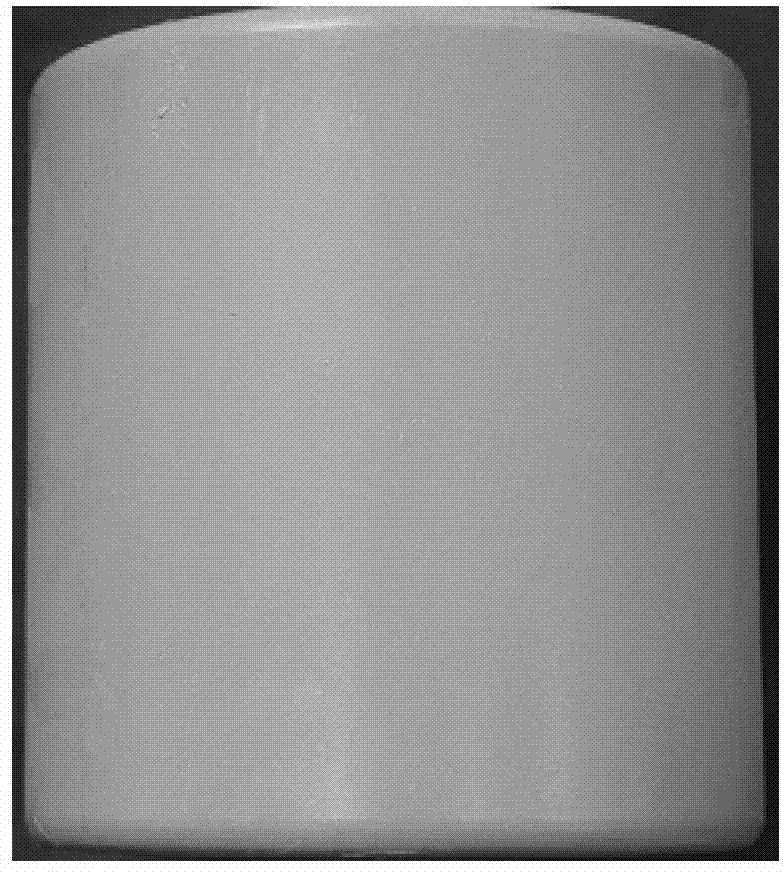

Method for preparing large-size sapphire single crystals by means of bubble generation

InactiveCN106894087AMeet growth needsAvoid crackingPolycrystalline material growthUsing seed in meltSingle crystalCrystallinity

The invention provides a method for preparing large-size sapphire single crystals by means of bubble generation. The method includes loading, vacuum, heating dissolving, seeding, shouldering, stripping, equal-diameter growing, pulling, annealing, blowing-out, argon filling cooling and blowing-in steps and the like. The method has the advantages that original technological procedures for growing 85 kg crystals are improved to obtain the method, the single crystallinity of the crystals is guaranteed by the aid of the stripping step, cracking of the crystals can be effectively prevented, defects such as small-angle crystal boundary stress and the like can be effectively overcome, the high-quality 120 kg-grade sapphire single crystals with the sizes of phi 350*380 mm can be prepared by the aid of the method, and requirements on sapphire growth in the current military and civil fields in China further can be met.

Owner:青海顺心精工科技有限公司

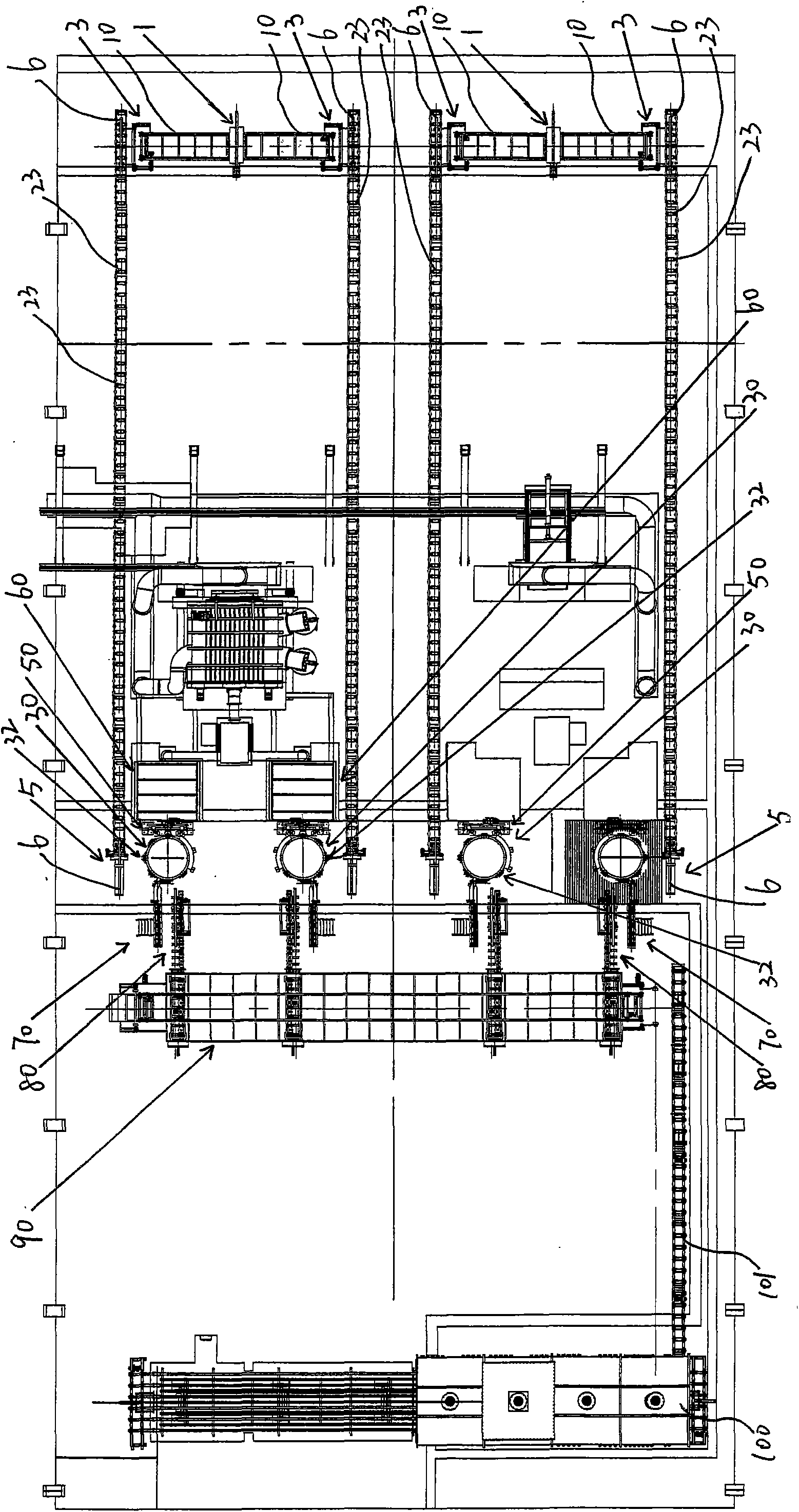

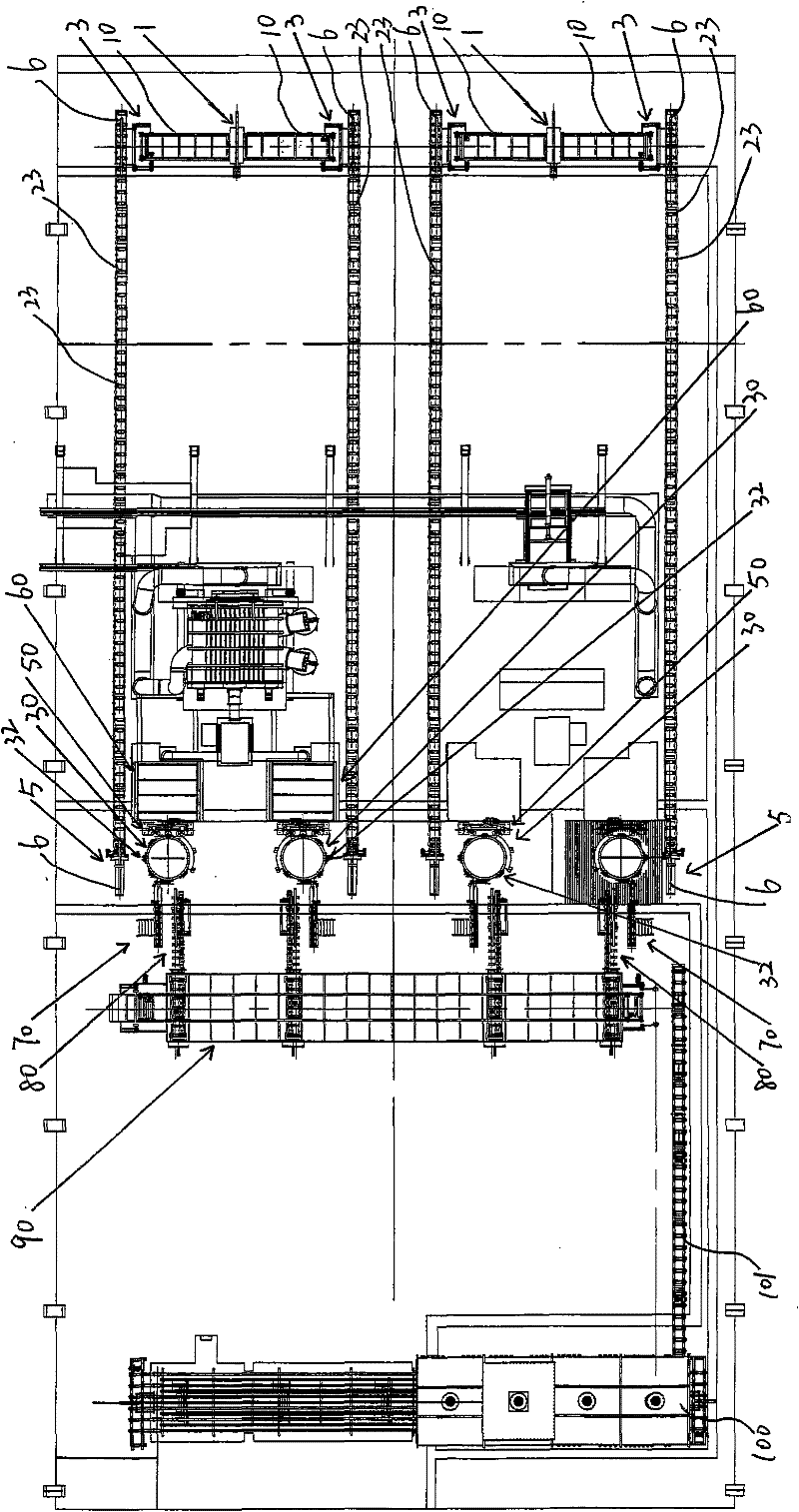

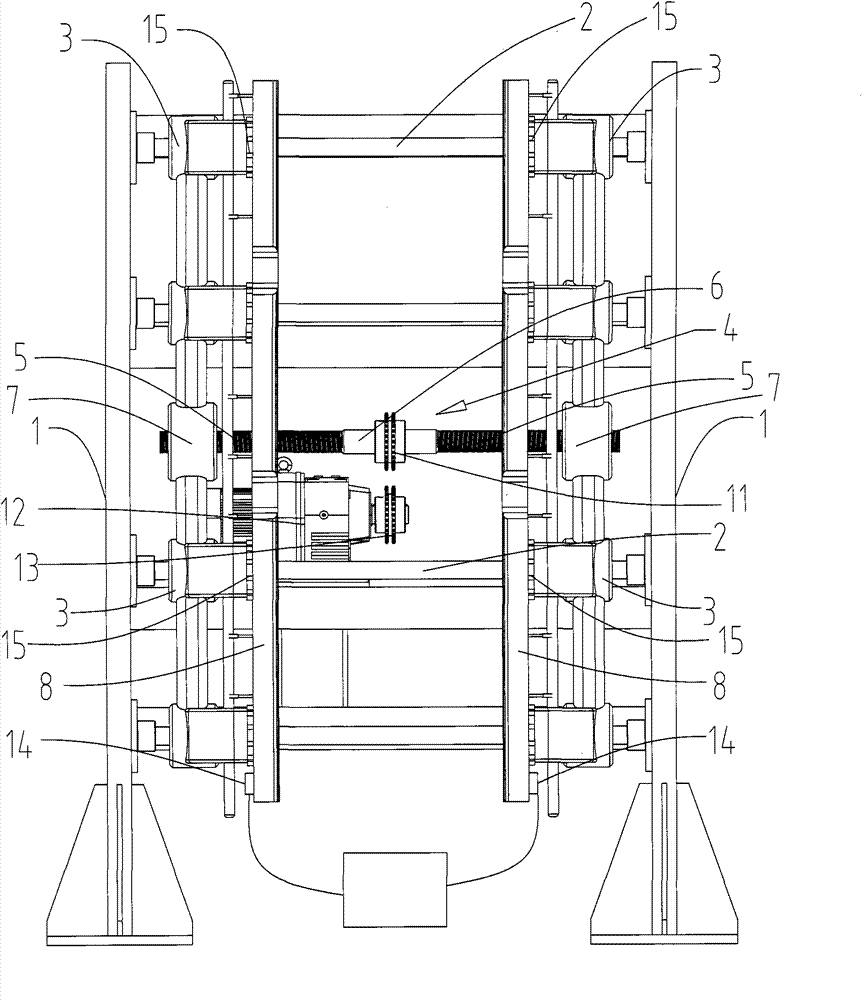

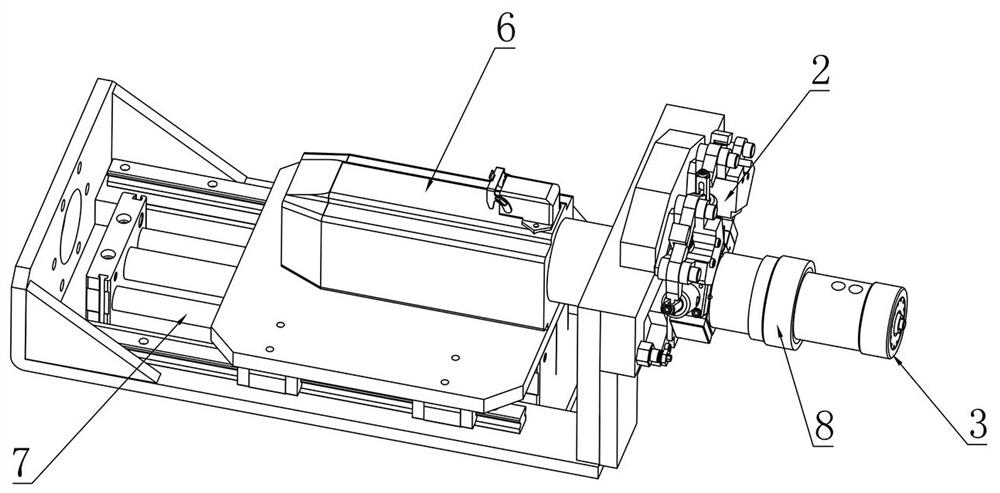

Copper and aluminium composite bar casting system

The invention discloses a copper and aluminium composite bar casting system comprising a head manufacturing device, a transmission chain, a material loading device, a plurality of driving rollers, a tipping gear, a casting machine with a spring clip, a locating clip, a vibration device on the locating clip, a low-voltage casting device, an unloading tipping gear, a material supporting conveyer and a material storage conveyer. The invention realizes the automation of the copper and aluminium composite bar casting, lowers the labor intensity of workers and improves working efficiency.

Owner:SUZHOU ZHONGMENZI TECH

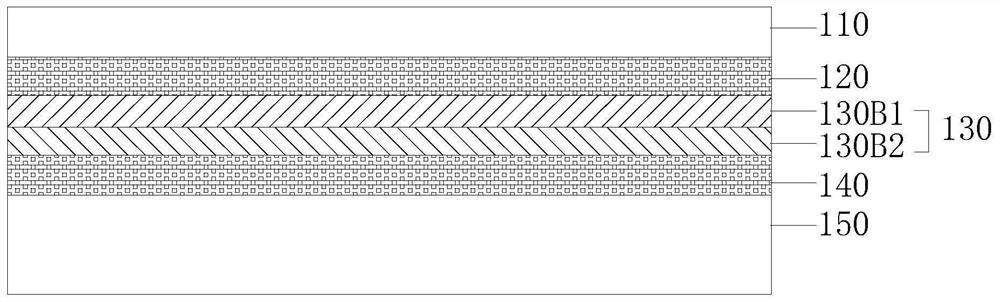

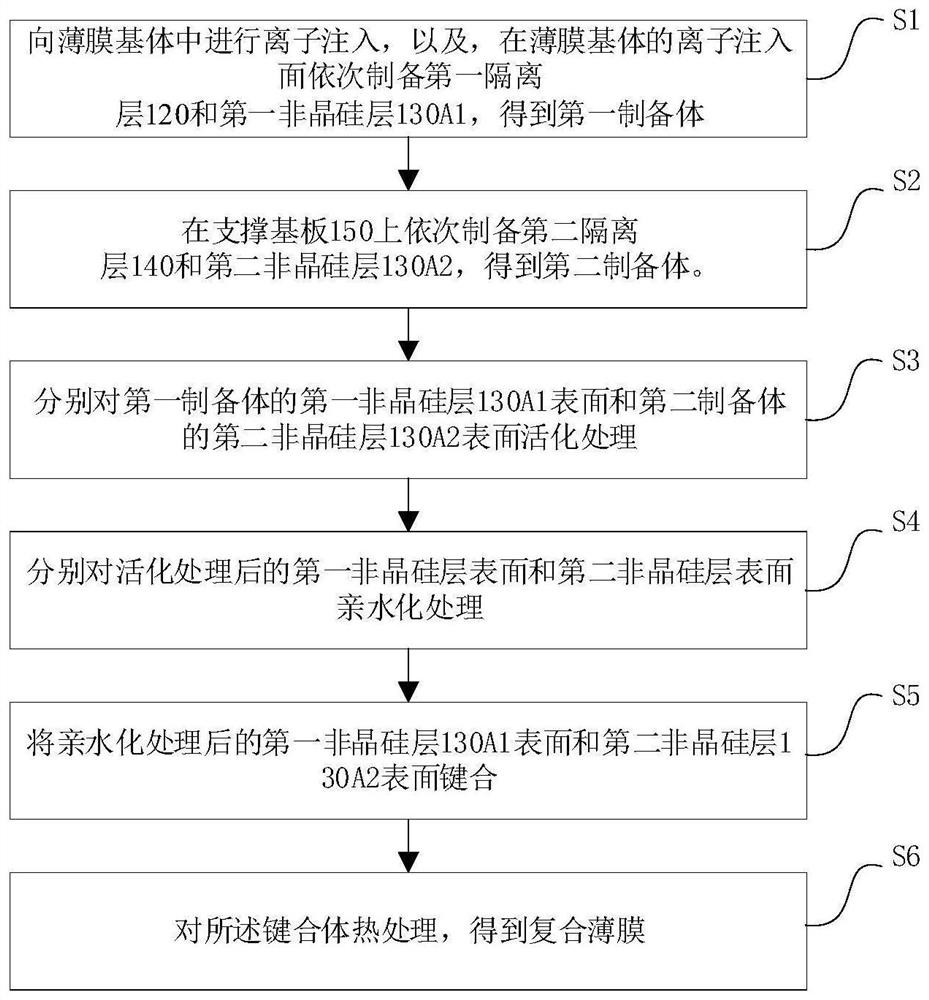

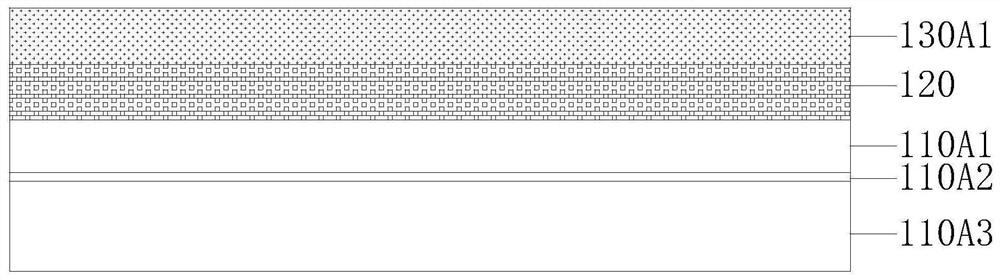

Composite film, preparation method and electronic component

ActiveCN112420914ASolve the phenomenon that the film substrate is prone to peeling off from the support substrateAvoid Bubble DefectsPiezoelectric/electrostrictive devicesComposite filmSilicon monoxide

The invention discloses a composite film, a preparation method and an electronic component. The composite film comprises a film substrate, a first isolation layer, a bonding layer, a second isolationlayer and a support substrate which are stacked in sequence, wherein the bonding layer is formed by performing hydrophilic bonding on a first amorphous silicon layer and a second amorphous silicon layer and then performing heat treatment, and the bonding layer comprises a first silicon oxide layer and a second silicon oxide layer. Through bonding of the first amorphous silicon layer and the secondamorphous silicon layer, the composite film has good bonding capability, so that the problem that a film substrate is easy to peel off from a support substrate in the subsequent cutting process of the prepared composite film is solved. Meanwhile, water molecules exist between the first silicon oxide layer and the second silicon oxide layer, so that the water molecules between the first silicon oxide layer and the second silicon oxide layer can be diffused into the first isolation layer and the second isolation layer, and the defect that bubbles are generated in the functional film layer in the film substrate due to generation of water vapor is avoided.

Owner:JINAN JINGZHENG ELECTRONICS

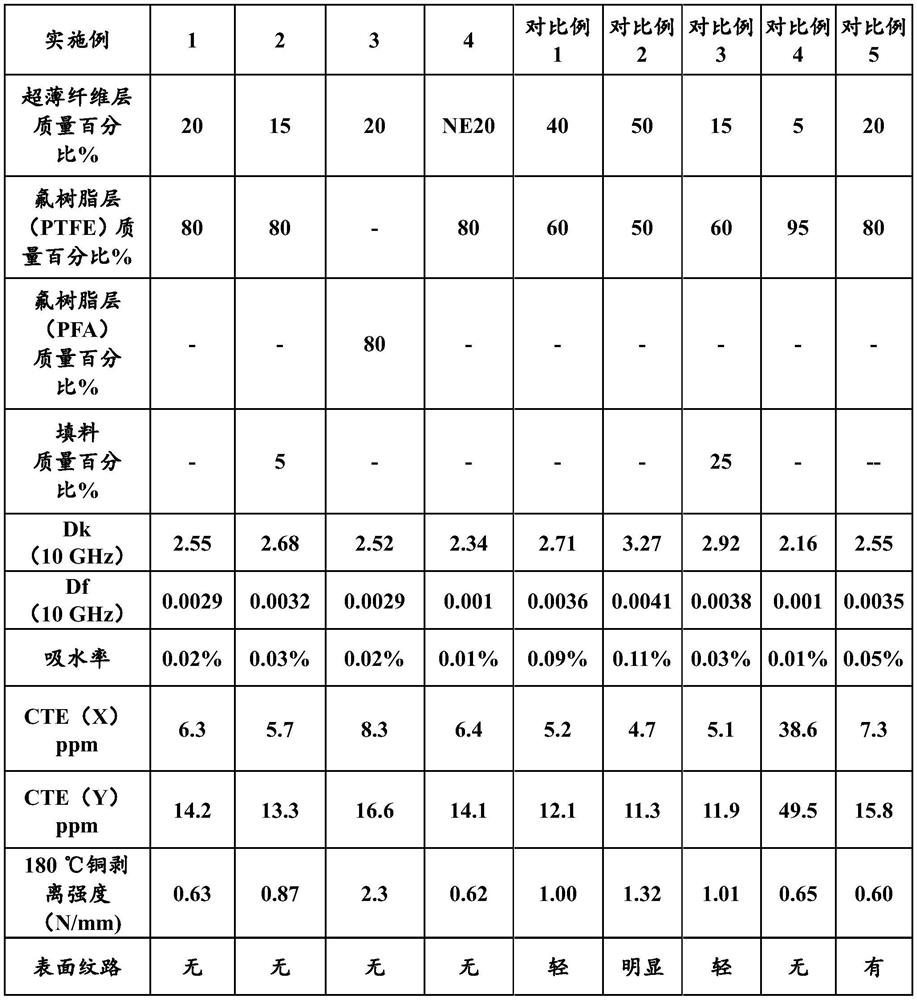

Preparation method of flexible insulating plate, obtained flexible insulating plate, flexible laminated plate and preparation method and application thereof

InactiveCN112519357AIncrease contentReduce the difficulty of impregnationLamination ancillary operationsSynthetic resin layered productsDielectric lossFiber reinforcement

The invention provides a preparation method of a flexible insulating plate, the obtained flexible insulating plate, a flexible laminated plate and a preparation method and application thereof, the preparation method of the flexible insulating plate comprises the following steps: dipping an ultrathin fiber layer with a thickness of 8-25 [mu] m in a glue solution of a first fluororesin, and carryingout first curing to obtain a prepreg; coating or spraying the glue solution of the second fluororesin to the two sides of the prepreg, curing for the second time, and repeatedly coating or spraying and curing until the total mass percent of the first fluororesin and the second fluororesin is 60%-95% so as to obtain a semi-finished product; carrying out heat treatment on the semi-finished productto obtain a fiber-reinforced fluororesin layer; and laminating and forming one, two or more fiber reinforced fluororesin layers to obtain the flexible insulating plate. The flexible insulating plate and the flexible laminated plate have the characteristics of low dielectric loss, small thickness, good flexibility and the like, and have a greater application prospect in future high-frequency and miniaturized devices.

Owner:RUISHENG NEW ENERGY DEV CHANGZHOU +1

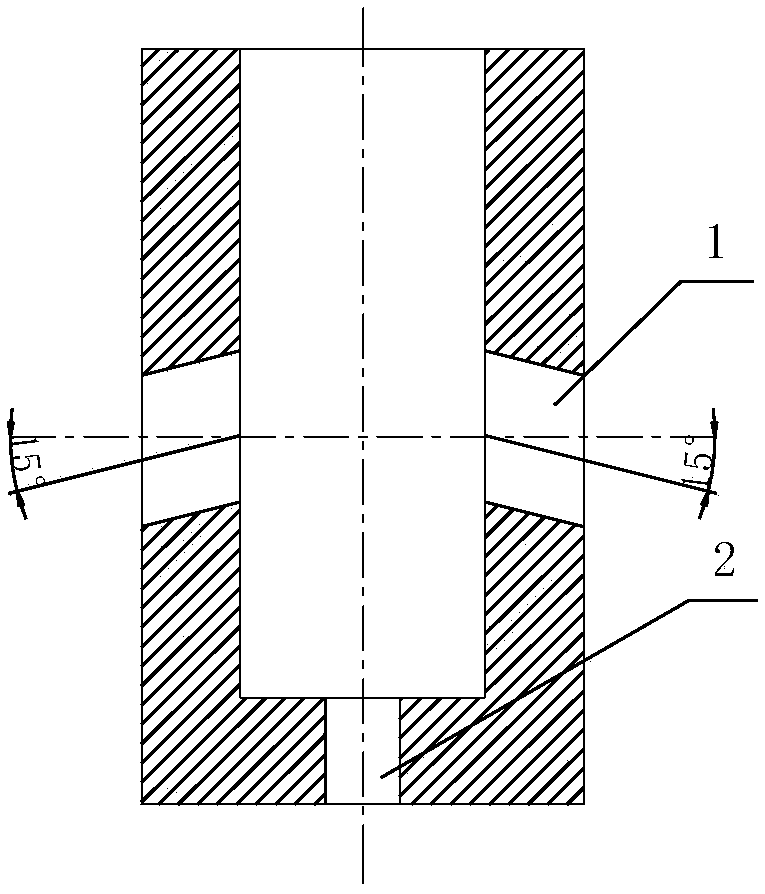

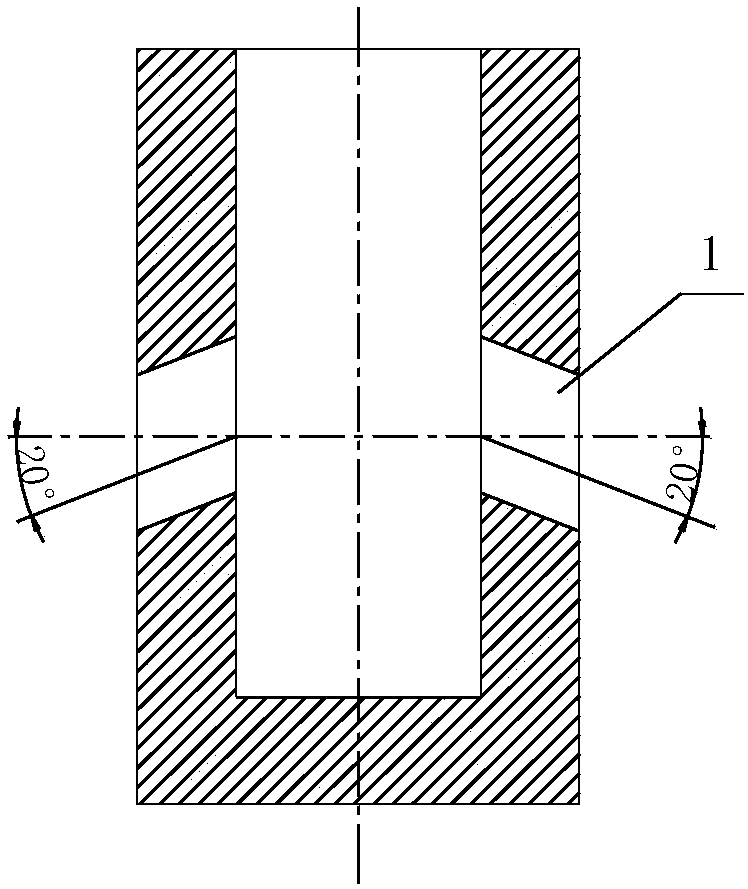

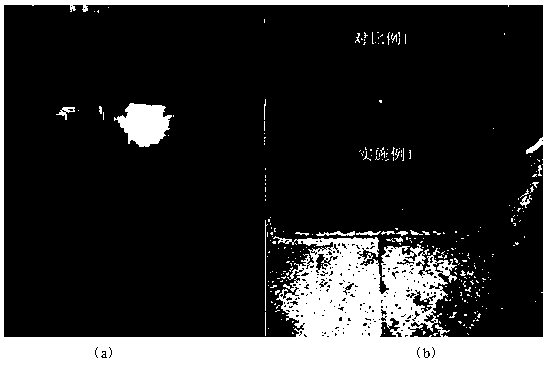

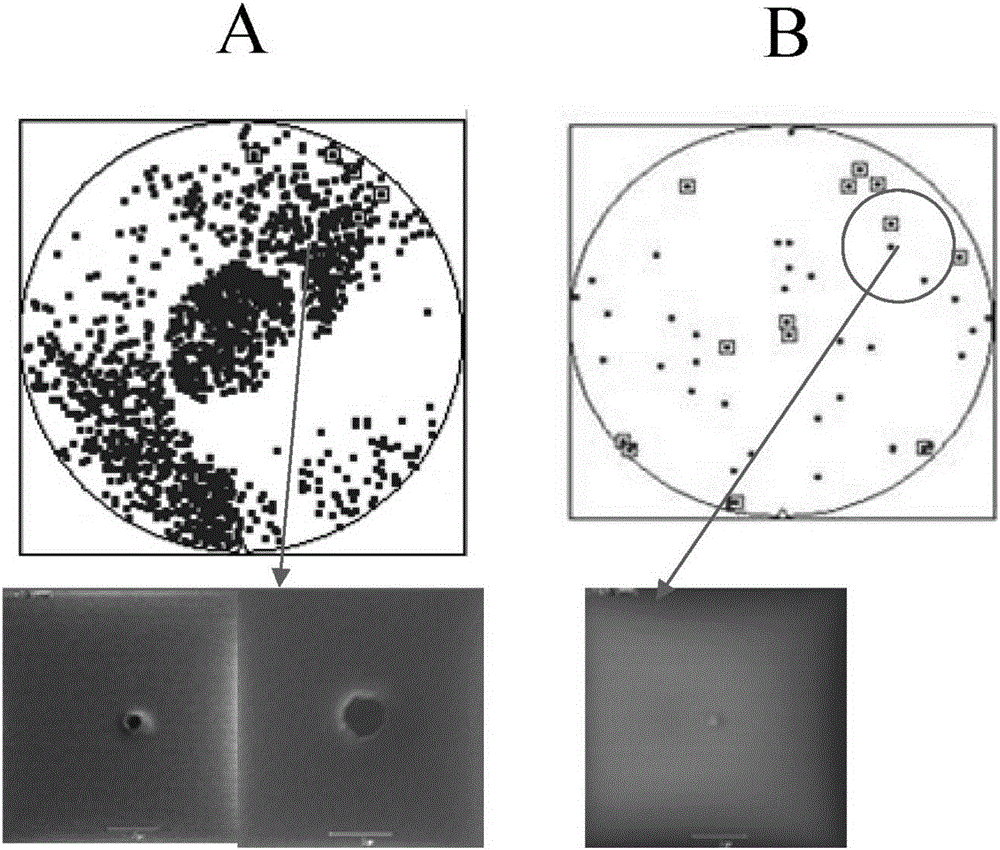

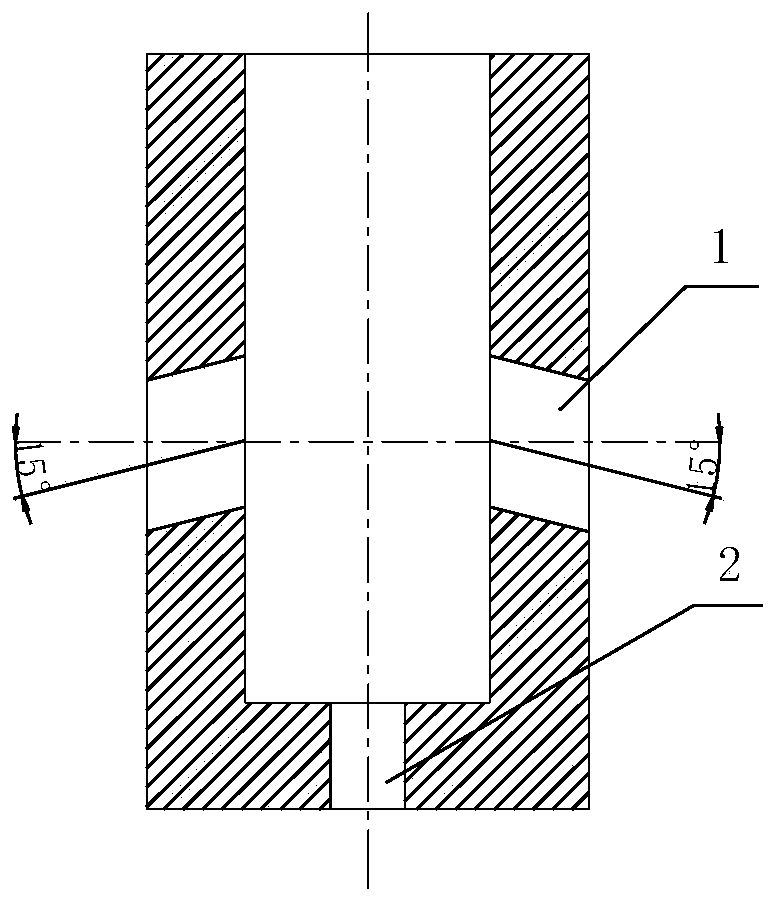

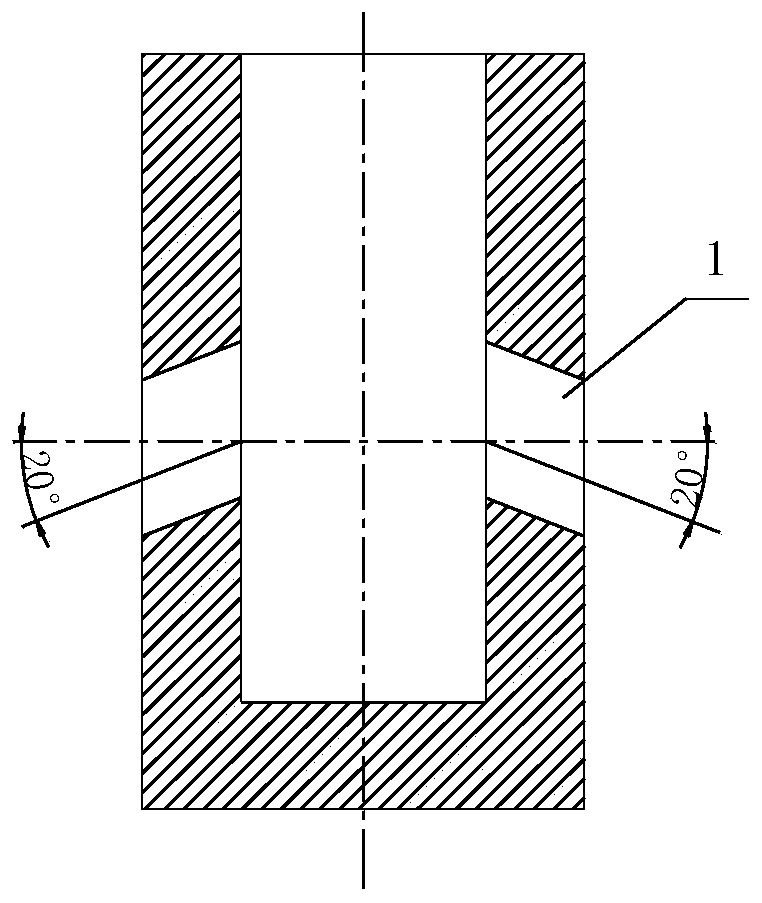

Method for reducing bubble defect of slab Cr-containing steel grade casting blank

The invention relates to a method for reducing a bubble defect of a slab Cr-containing steel grade casting blank. Argon gas in a tundish is operated at a small flow rate, the argon gas flow rate of astopper rod in the tundish is less than or equal to 2.0 NL / min, and the argon gas flow rate of an upper nozzle is less than or equal to 2.0 NL / min; in the casting process, the minimum single-flow steel passing is not less than 2.4 tons / min; when the slab width is less than or equal to 1500 mm, three-hole immersive nozzle is used for continuous casting, the inclination angle of the holes in both sides is at 15 degrees, and the area ratio of vertical hole steel passing to the total steel passing is 5-18%; when the slab width is larger than 1500 mm and is small than or equal to 2200 mm, a two-hole immersive nozzle without vertical holes are used for continuous casting, and the inclination angle of the nozzle of water in the two holes are at 20 degrees; the superheat degree of molten steel ofthe tundish is not less than 12 DEG C; and the distance from the top edge of a discharge hole of the immersive nozzle to the liquid level of the molten steel in a crystallizer is 100-160 mm. Accordingto the method, the bubble defect generated by steel grades containing Cr more than or equal to 0.15% is avoided, and the defect of edge portion "peeling"-like formed by bubble exposure rolling elongation in the casting blank rolling process is eliminated. The product quality of the steel grade is improved.

Owner:ANGANG STEEL CO LTD

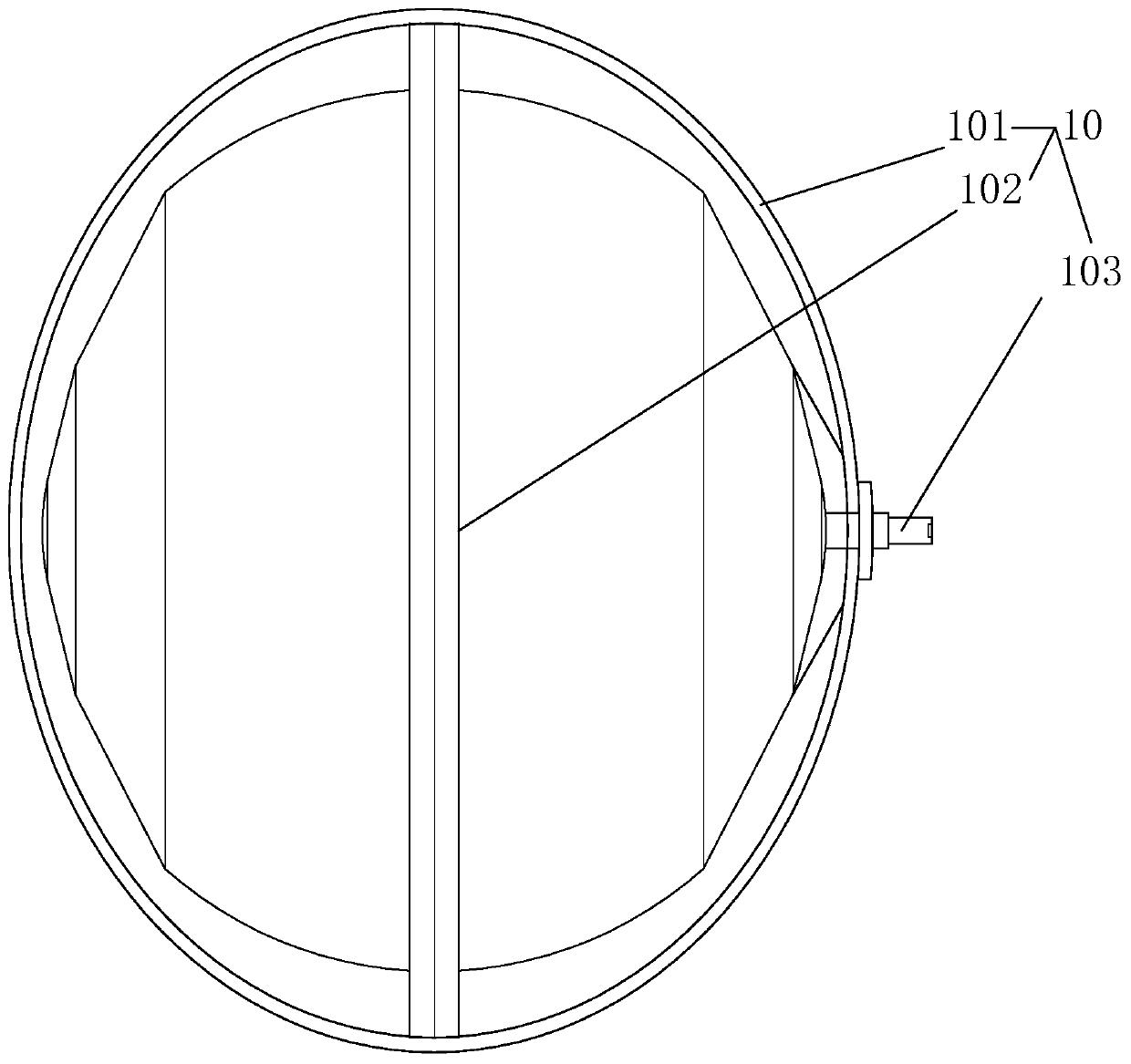

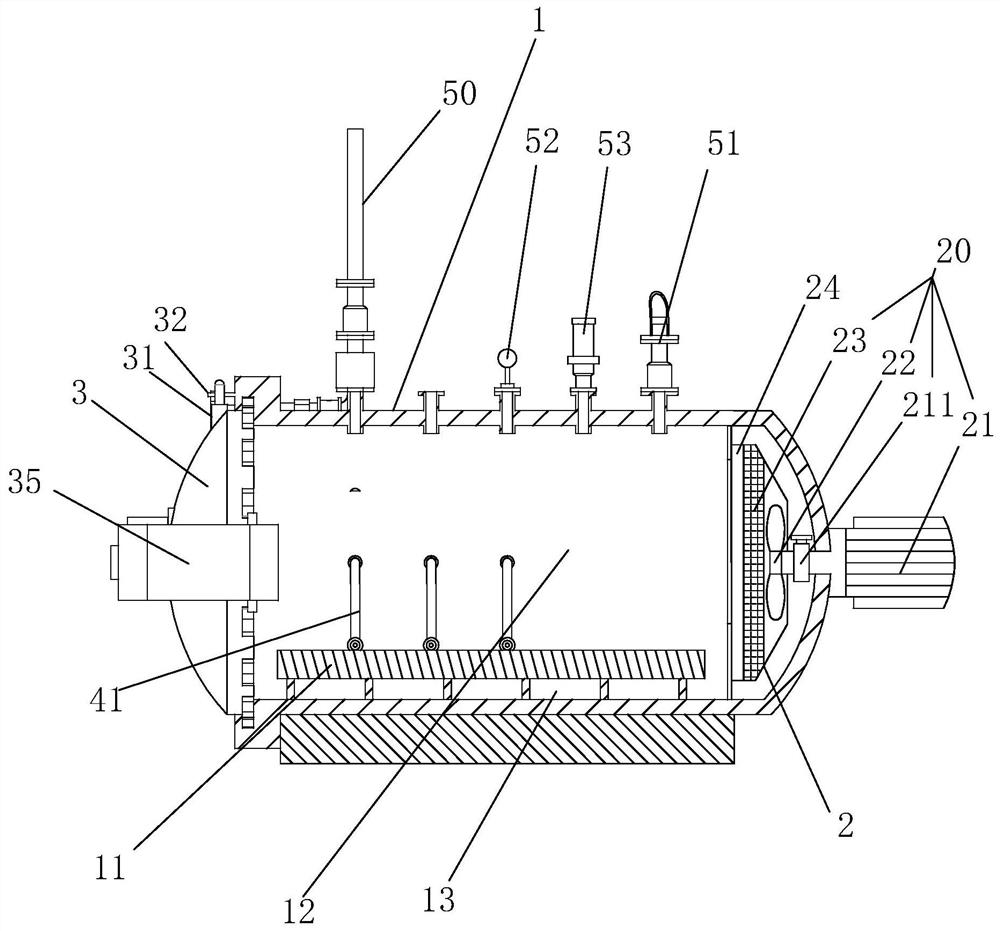

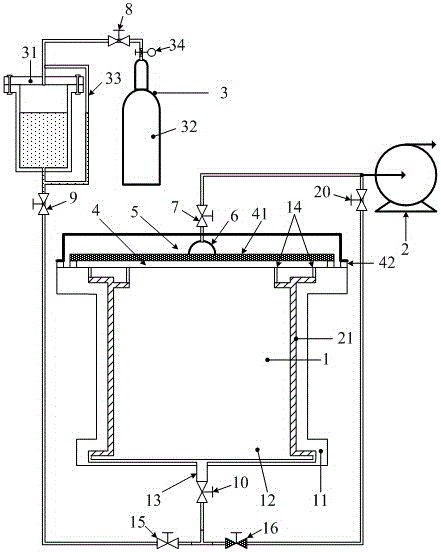

Vacuum autoclave used for motorcycle helmet production and motorcycle helmet forming process

ActiveCN110815865AIncrease productivityDoes not affect heat curingDomestic articlesMotor cycling helmetPumping vacuum

The invention relates to a vacuum autoclave used for motorcycle helmet production and a motorcycle helmet forming process. The vacuum autoclave comprises an autoclave body and a forming device. The forming device comprises a vacuum bag, a forming mould arranged in the vacuum bag, and a connector connected to the vacuum bag and communicating with the forming mould. One end of the autoclave body isfixedly connected with a closed component. A heating device is arranged in the closed component. The other end of the autoclave body is connected with an autoclave door. The autoclave body is connected with a vacuumizing device used for communicating with the connector. A gas exhausting device and a gas inlet pipe are arranged on the outer wall of the autoclave body in the length direction of theautoclave body in sequence. The gas inlet pipe communicates with a gas inlet device. By means of the vacuum autoclave used for motorcycle helmet production and the motorcycle helmet forming process, the impact strength of a motorcycle helmet is effectively improved, the product quality is improved, and the problem that the impact strength of a motorcycle helmet is low is solved.

Owner:湖北爱骑士体育用品有限公司

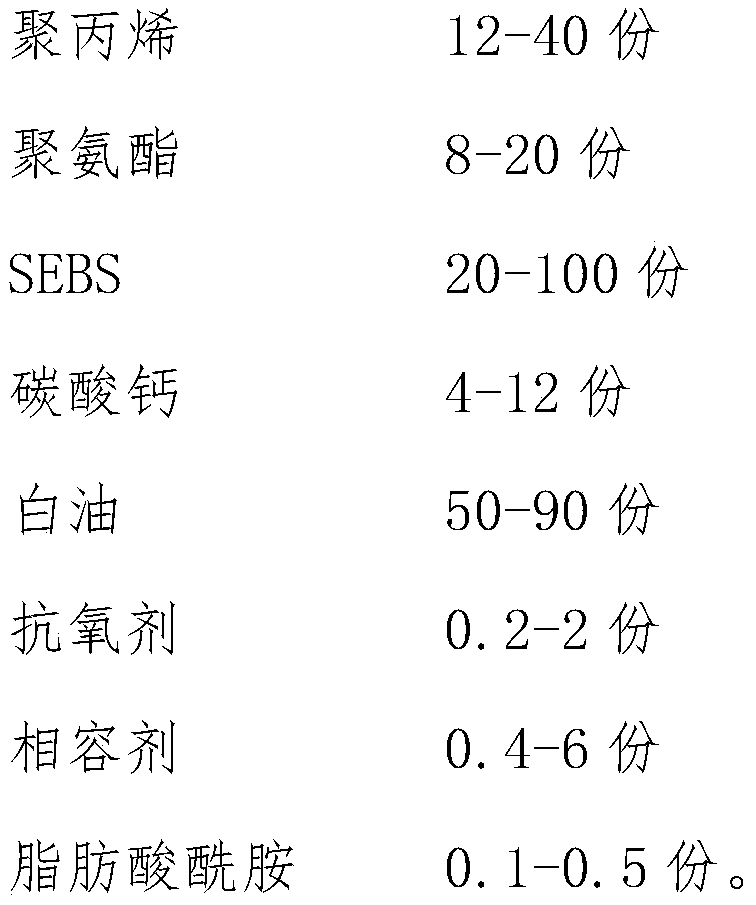

TPE insulating material

InactiveCN110218459AImprove extrusion fluiditySmooth demouldingPlastic/resin/waxes insulatorsLiquid organic insulatorsMasterbatchProcess equipment

The invention discloses a TPE insulating material. The TPE insulating material comprises the following components in parts by weight: 12 to 40 parts of polypropylene, 8 to 20 parts of polyurethane, 20to 100 parts of SEBS, 4 to 12 parts of calcium carbonate, 50 to 90 parts of white oil, 0.2 to 2 parts of an antioxidant, 0.4 to 6 parts of a compatibilizer and 0.1 to 0.5 part of fatty acid amide. The material provided by the invention has the following advantages: the extrusion fluidity of a TPE material is improved, so the material is smoothly demolded; the molding time of the material is shortened by 10%, so the efficiency of production is greatly improved; a filling material and a colorant can be uniformly and continuously dispersed in masterbatches, so color difference is avoided from occurring; dispersion uniformity of the components in the TPE material is improved, so the material is easily plasticized; the temperature of processing can be reduced by 20 to 30 DEG C, so the defect of foam is avoided from occurring; and after the material is used, the abrasion coefficient of the TPE material can be reduced, and the service life of processing equipment (a roller and the like) canbe prolonged.

Owner:JIANGSU ZHONGLI GRP CO LTD +3

Wafer structure for bonding and forming method and bonding method thereof

PendingCN114864465AAvoid Bubble DefectsImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesStructural engineeringWafer bonding

The invention provides a wafer structure for bonding and a forming method and a bonding method thereof. The bonding method comprises the following steps: providing a first wafer and a second wafer; and aligning the first wafer and the second wafer by using the first mark area and carrying out bonding. According to the wafer structure for bonding and the forming method and the bonding method thereof, the thickness of the edge of the wafer is smaller than the thickness of the center of the wafer, the bubble defect generated after wafer bonding can be avoided, and the reliability of a device is improved.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

Vacuum autoclave for motorcycle helmet production and motorcycle helmet molding process

ActiveCN110815865BOvercoming the defects of air bubblesAvoid Bubble DefectsDomestic articlesMotor cycling helmetVacuum pumping

The invention relates to a vacuum autoclave used for the production of motorcycle helmets and a motorcycle helmet molding process. The vacuum bag and the joint connected with the forming mold; one end of the autoclave body is fixedly connected with a closure; the closure is provided with a heating device; the other end of the autoclave body is connected with a tank door; Vacuum pumping device; the outer wall of the autoclave is provided with an exhaust device and an air intake pipe sequentially along its length direction; the air intake pipe is connected with an air intake device. The invention has the functions of effectively improving the impact resistance strength of the motorcycle helmet and improving product quality. Solved the problem of low impact strength of motorcycle helmets.

Owner:湖北爱骑士体育用品有限公司

A casting coating for coated sand mold and preparation method thereof

ActiveCN107414016BDry fastReduce moisture contentFoundry mouldsFoundry coresSurface finishCarboxymethyl cellulose

Owner:保定保蒙新型材料科技有限公司

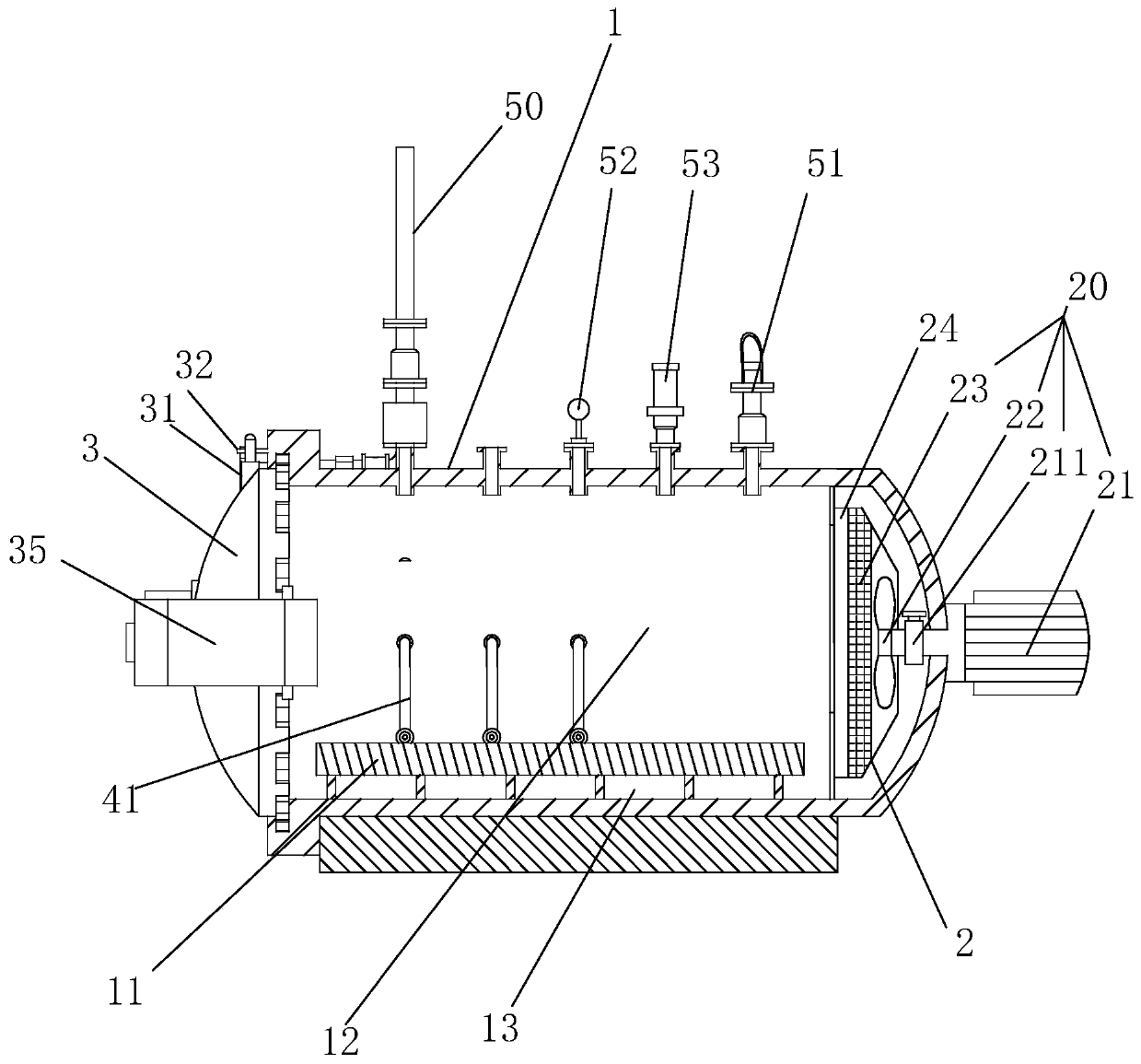

Forming device and forming method of a polymer-based composite material

The invention discloses a forming device and a forming method for a polymer matrix composite material. The forming device comprises an injection system, a mould system and a vacuum system, wherein the mould system comprises a forming mould, a semi-permeable mould cavity and a bag film mould cavity; the forming mould comprises a female mould, a male mould and a forming mould cavity; a glue discharging hole and a glue filling hole are formed in the upper end and the lower end of the forming mould cavity respectively; the glue filling hole is connected with the forming mould cavity and the injection system; the glue discharging hole is connected with the forming mould cavity and the semi-permeable mould cavity; the semi-permeable mould cavity is wrapped with the bag film mould cavity and connected with the vacuum system through a gas channel; the semi-permeable mould cavity is packaged by adopting a semi-permeable film I and a sealing adhesive tape I; the semi-permeable film I is a thin film permeable by gas but impermeable by resin glue. The forming method can effectively avoid bubble defects, the cost is low, the quality is stable and uniform, one-step integral forming is realized, the process efficiency is high, the product quality is good, bubbles generated in a preparation process can be discharged in real time, and a high-performance composite product with characteristics of full dipping, uniform fiber distribution and smooth double surfaces is prepared.

Owner:NAT UNIV OF DEFENSE TECH

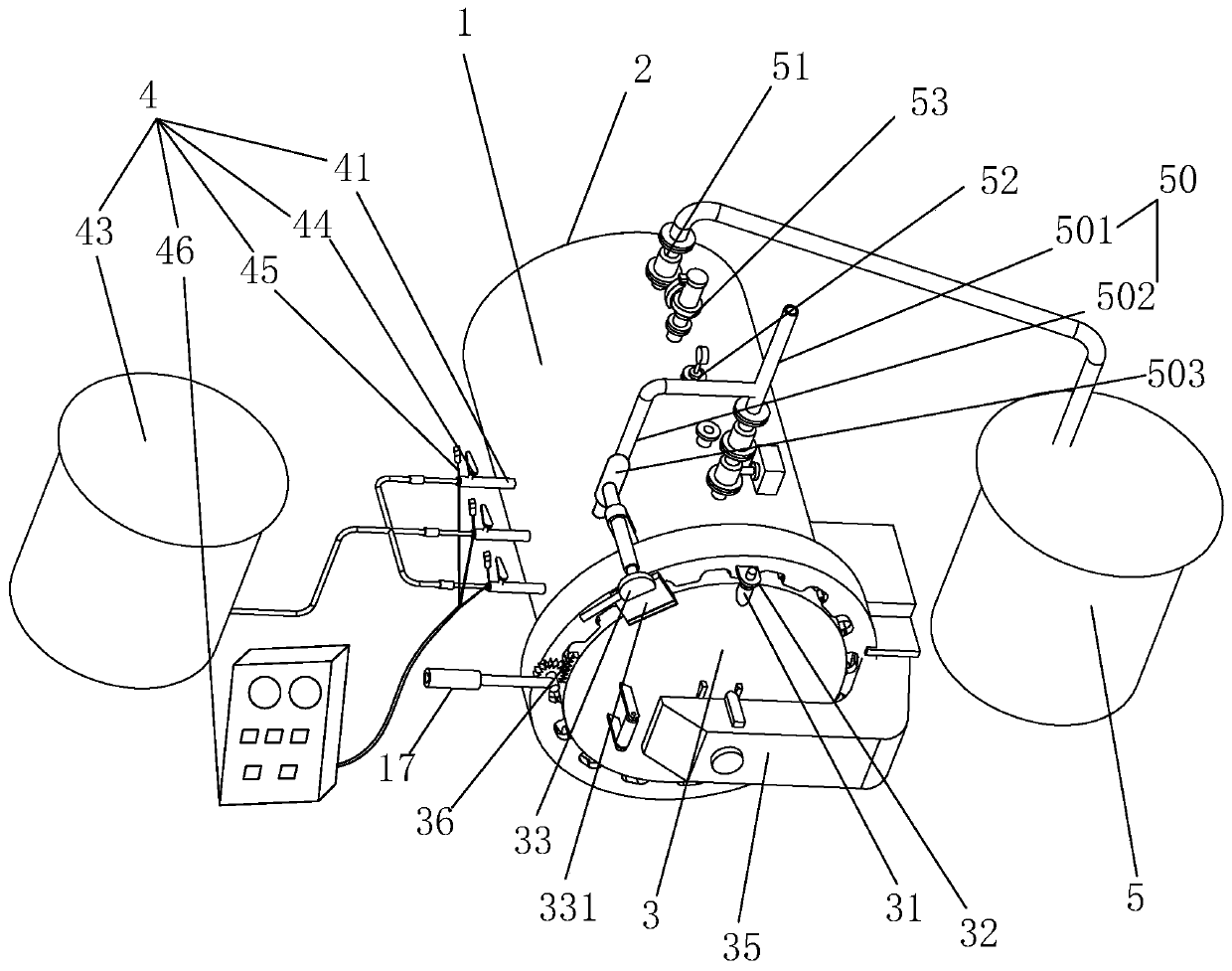

Copper and aluminium composite bar casting system

The invention discloses a copper and aluminium composite bar casting system comprising a head manufacturing device, a transmission chain, a material loading device, a plurality of driving rollers, a tipping gear, a casting machine with a spring clip, a locating clip, a vibration device on the locating clip, a low-voltage casting device, an unloading tipping gear, a material supporting conveyer and a material storage conveyer. The invention realizes the automation of the copper and aluminium composite bar casting, lowers the labor intensity of workers and improves working efficiency.

Owner:SUZHOU ZHONGMENZI TECH

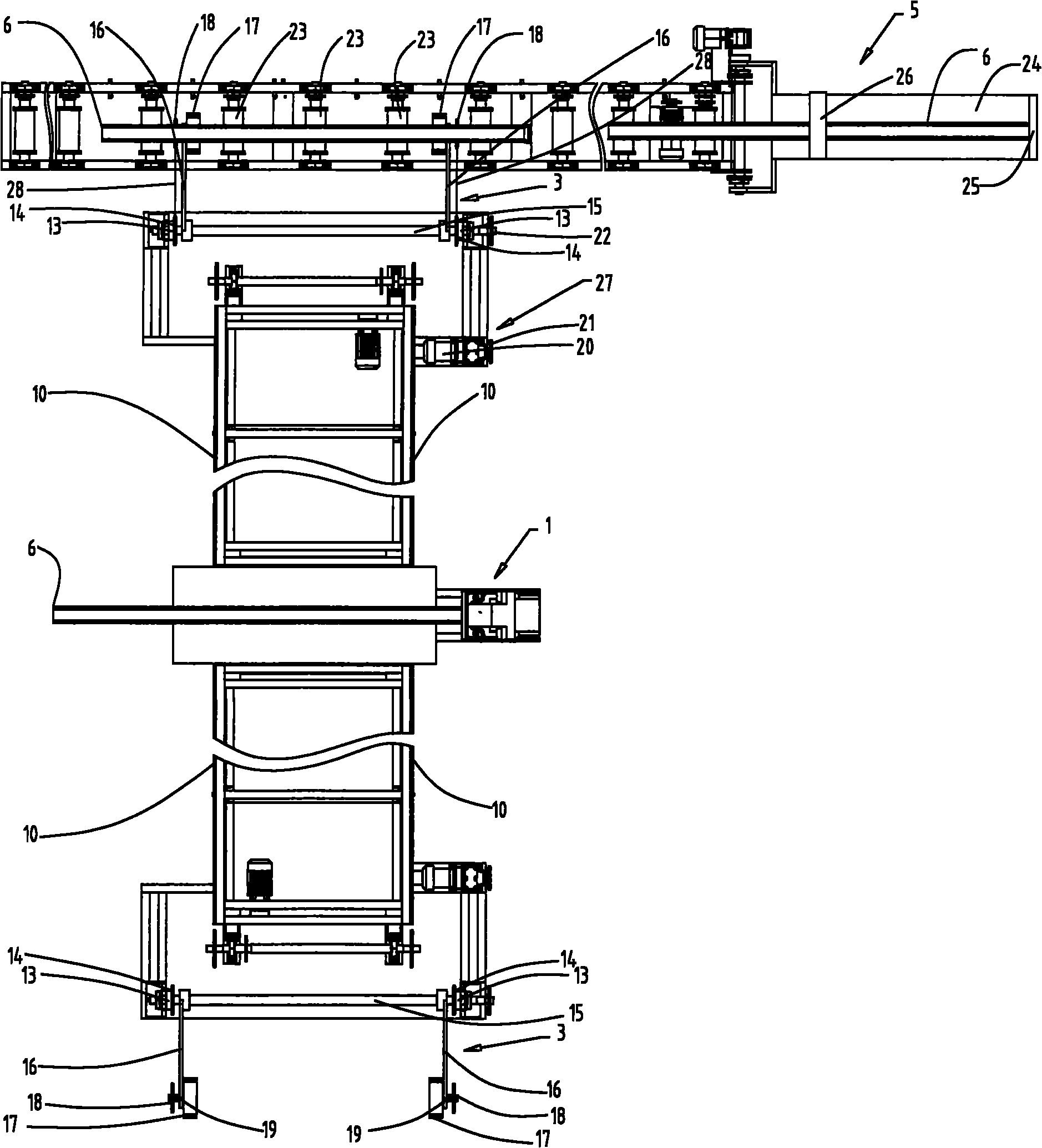

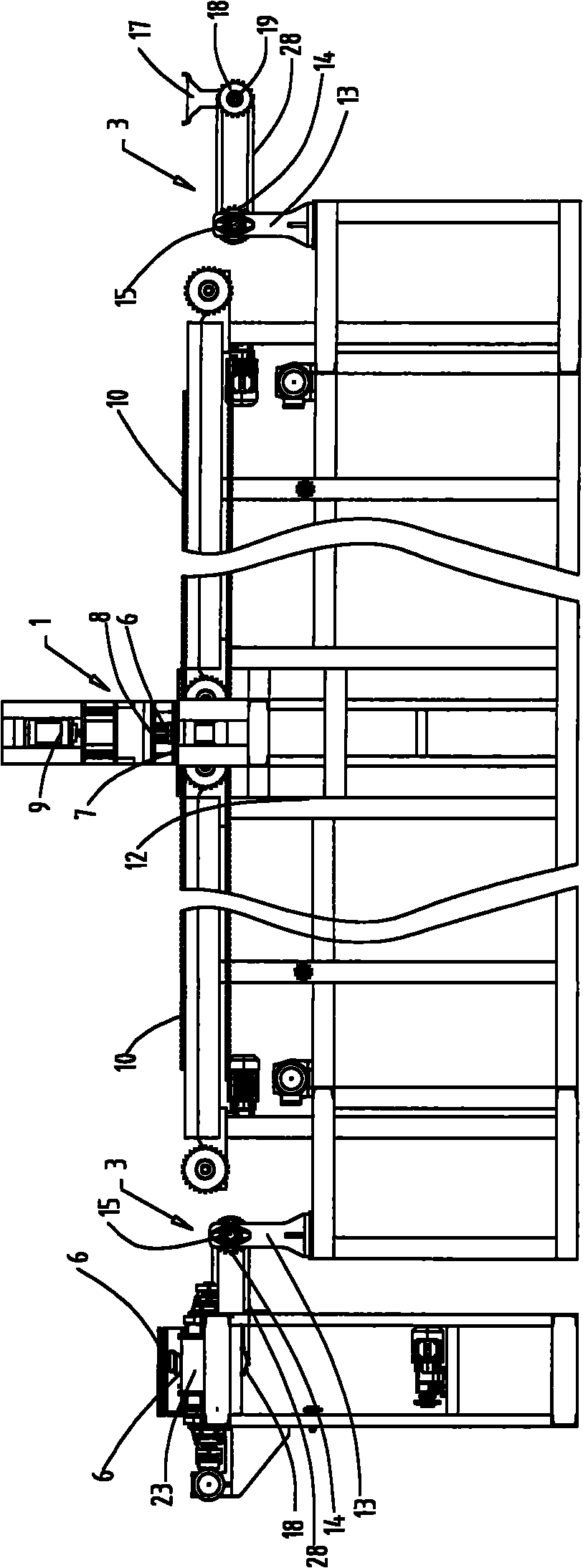

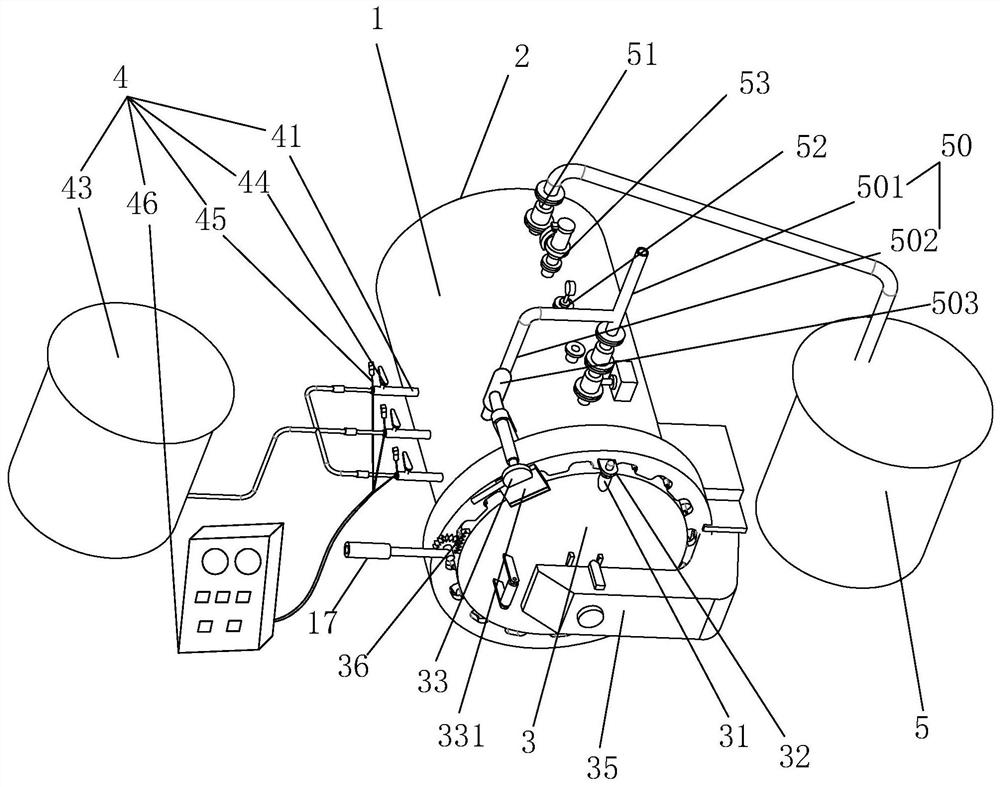

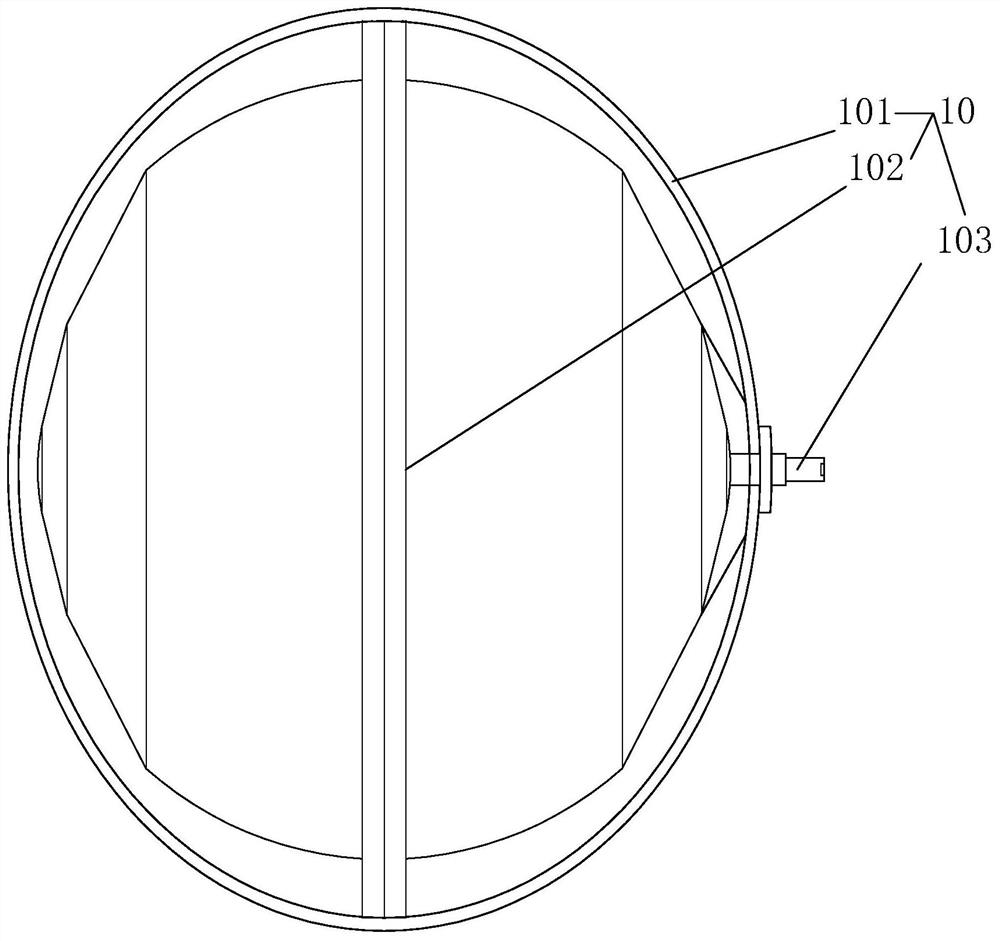

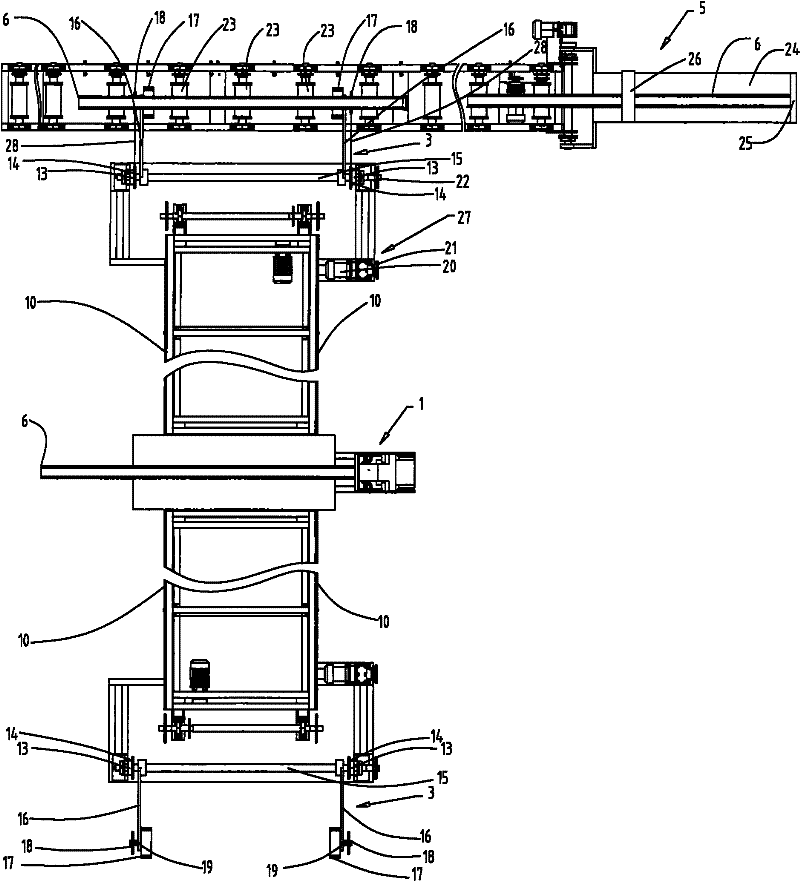

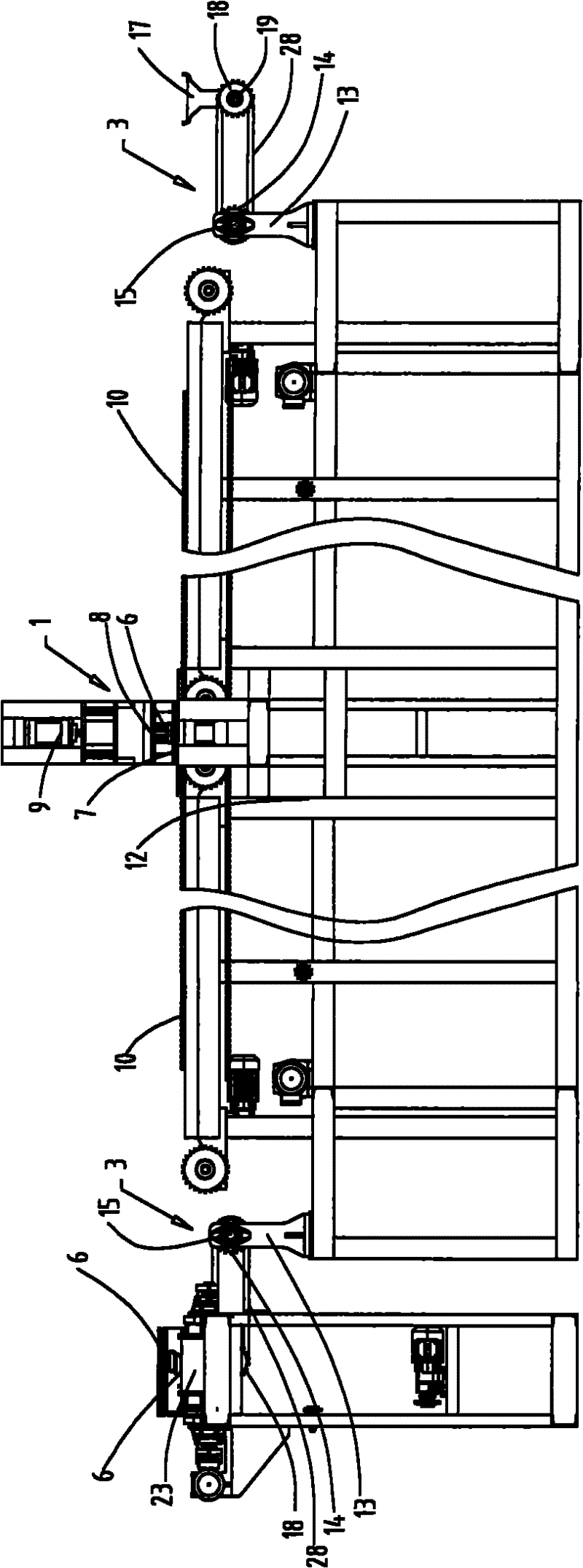

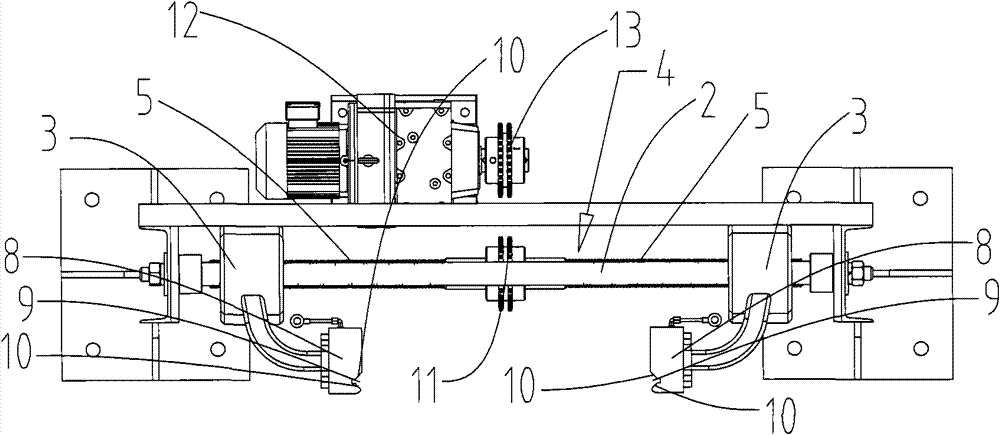

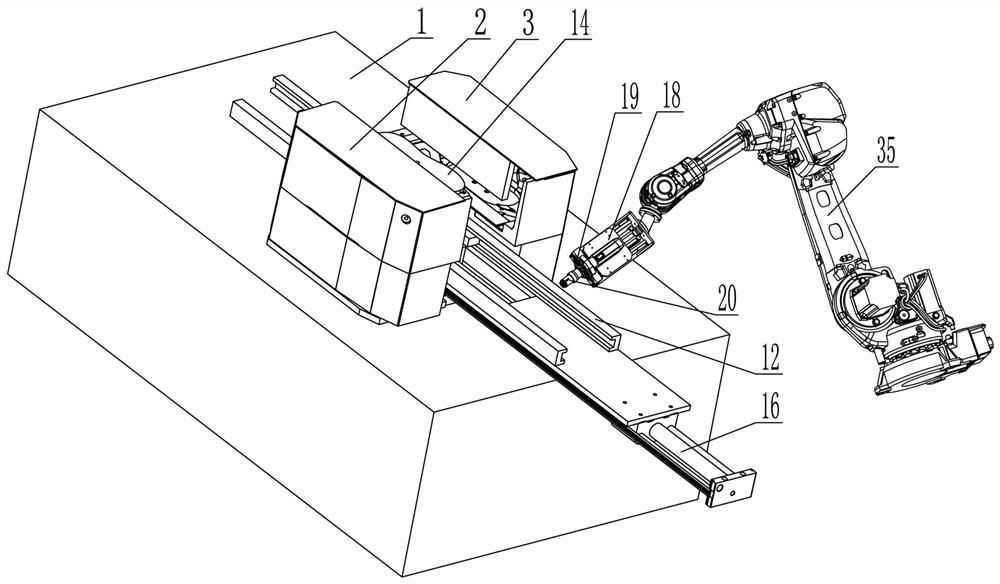

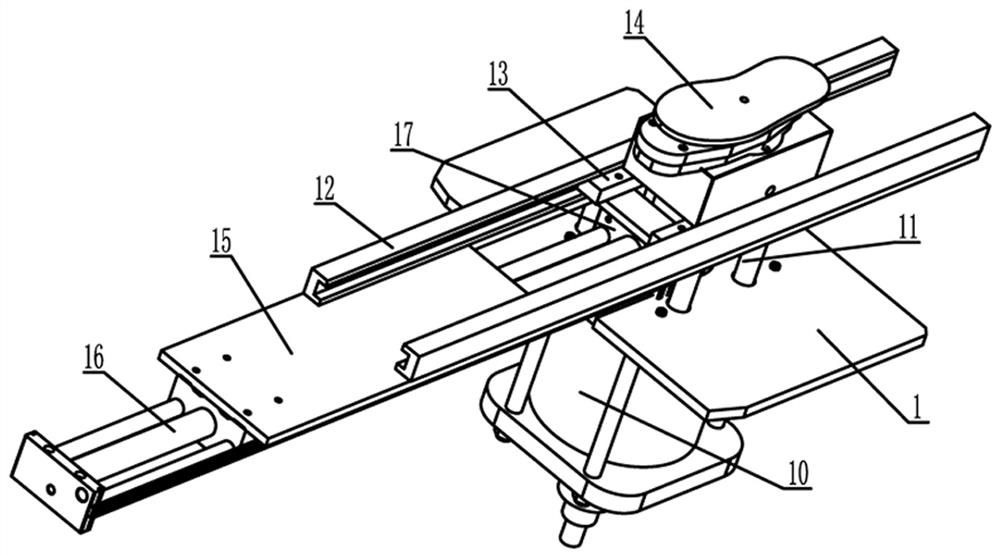

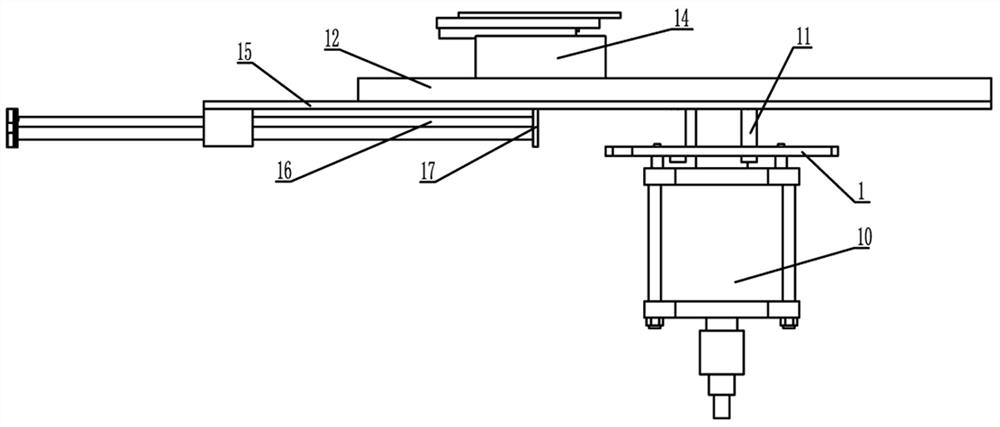

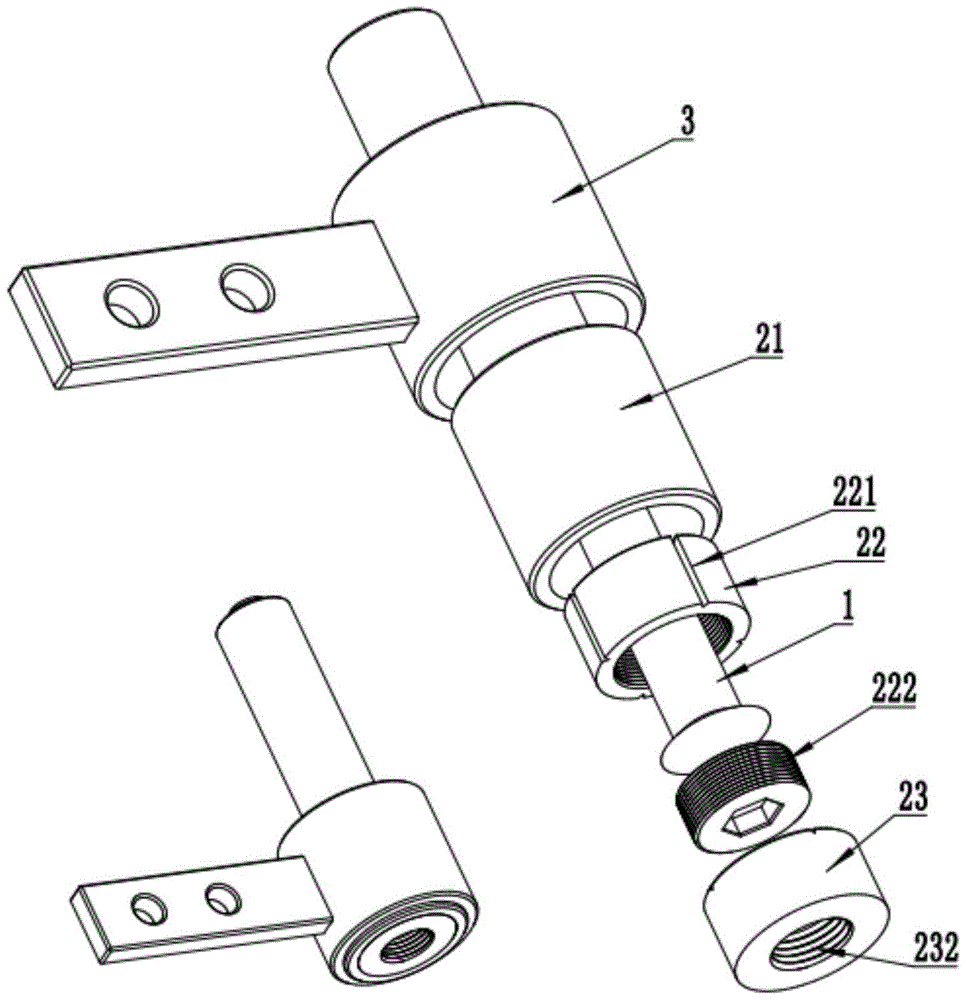

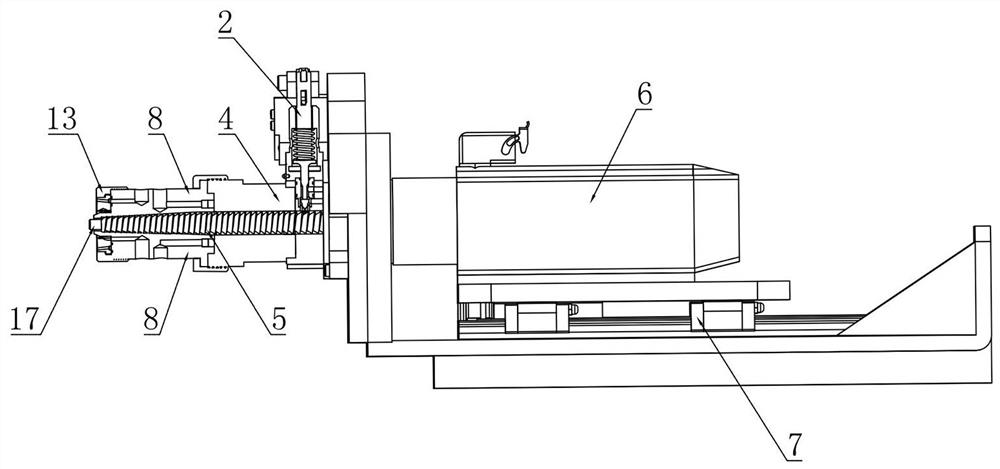

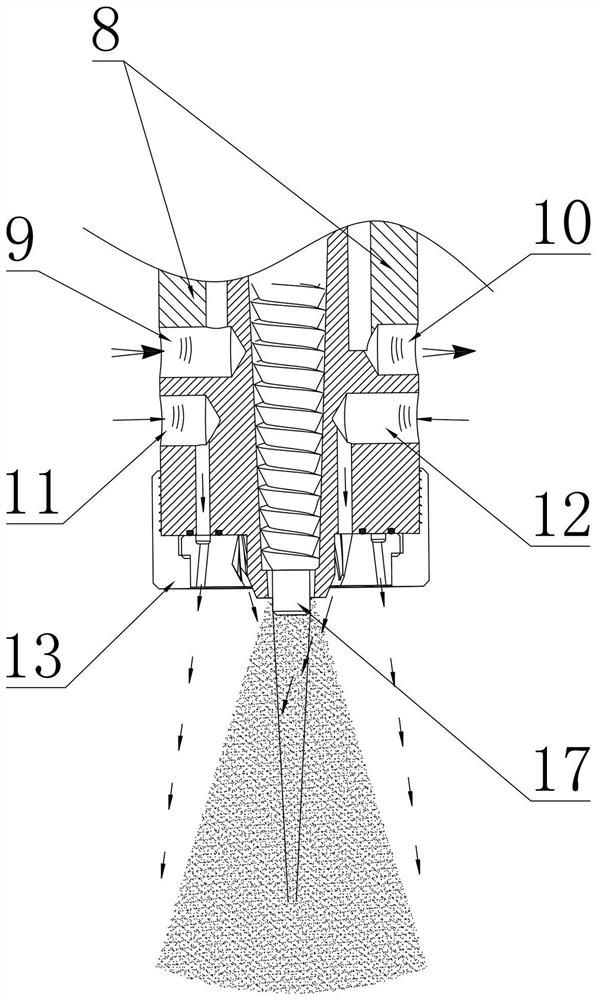

Oscillating device of locating clip in copper-aluminum composite busbar gating system

The invention discloses an oscillating device of a locating clip in a copper-aluminum composite busbar gating system. The locating clip comprises a primary connecting piece and a secondary connecting piece both of which can perform open and close movements, as well as a pair of clamp splices respectively arranged on the primary connecting piece and the secondary connecting piece through flexible pieces. The oscillating device comprises an oscillator fixed on the pair of clamp splices and used for driving the clamp splices to oscillation up and down. When the clamp splices hold a copper-aluminum composite busbar, gas mixed into aluminum liquid in a copper tube can be discharged by up and down oscillation of the copper-aluminum composite busbar with the clamp splices through the oscillator, thus avoiding bubble defects, improving the density of aluminum products, ensuring crystal lattices of aluminum products to be uniform, enhancing the combination between the copper tube and aluminum products, and also increasing the metal ductility of the copper-aluminum composite busbar, and guaranteeing the product quality.

Owner:SUZHOU ZHONGMENZI TECH

A preparation method of a three-layer gradient gis/gil support insulator

ActiveCN113284684BGuaranteed mechanical strengthImprove electrical strengthAdditive manufacturing apparatusAdditive manufacturing with liquidsDielectricMetal mold

The invention discloses a preparation method of a three-layer gradient GIS / GIL supporting insulator. Taking reducing the electric field strength along the surface or local area of the insulator as the optimization goal, a variable density algorithm is used to solve the optimal spatial distribution of the internal dielectric constant of the supporting insulator; As a result, the area where the dielectric constant changed was divided into a dielectric constant transition area and a high dielectric area, and the combined contour of the dielectric constant transition area was extracted, and then a hollow with support and resin pouring opening was generated by photocuring 3D printing. The dielectric constant transition region; a high dielectric filler / polymer blend is used to prepare a thermally curable high dielectric composite material, and then the high dielectric composite material is poured into the dielectric constant transition region and placed into a metal mold as a whole The thermally-curable high-dielectric composite material is prepared by blending low-dielectric fillers / polymers, and then poured into metal molds. After curing in vacuum, three-layer gradient GIS / GIL supporting insulators can be obtained .

Owner:XI AN JIAOTONG UNIV

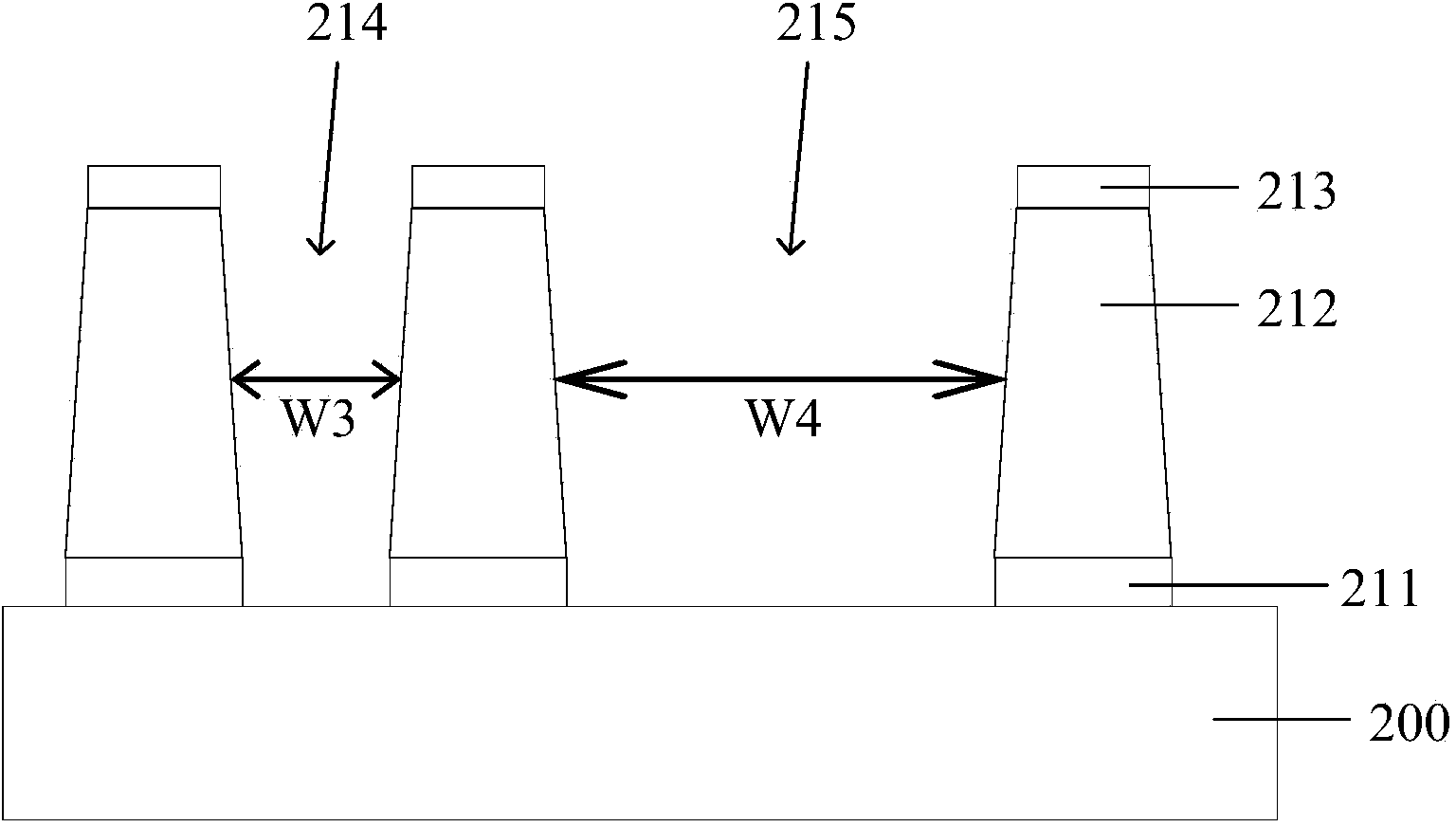

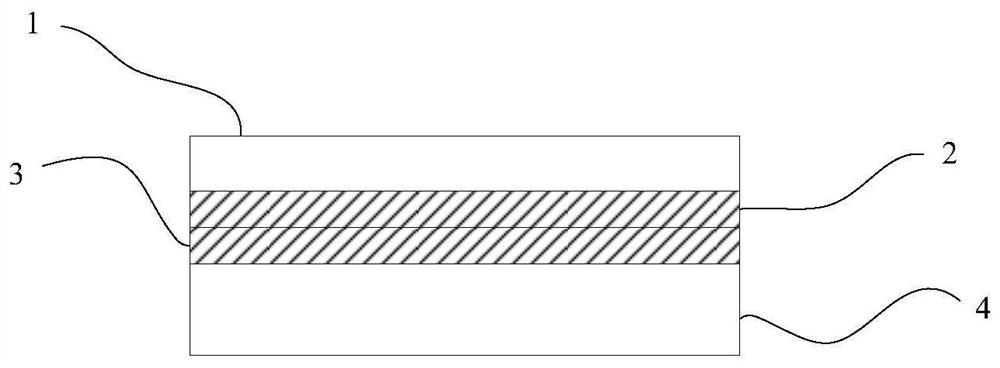

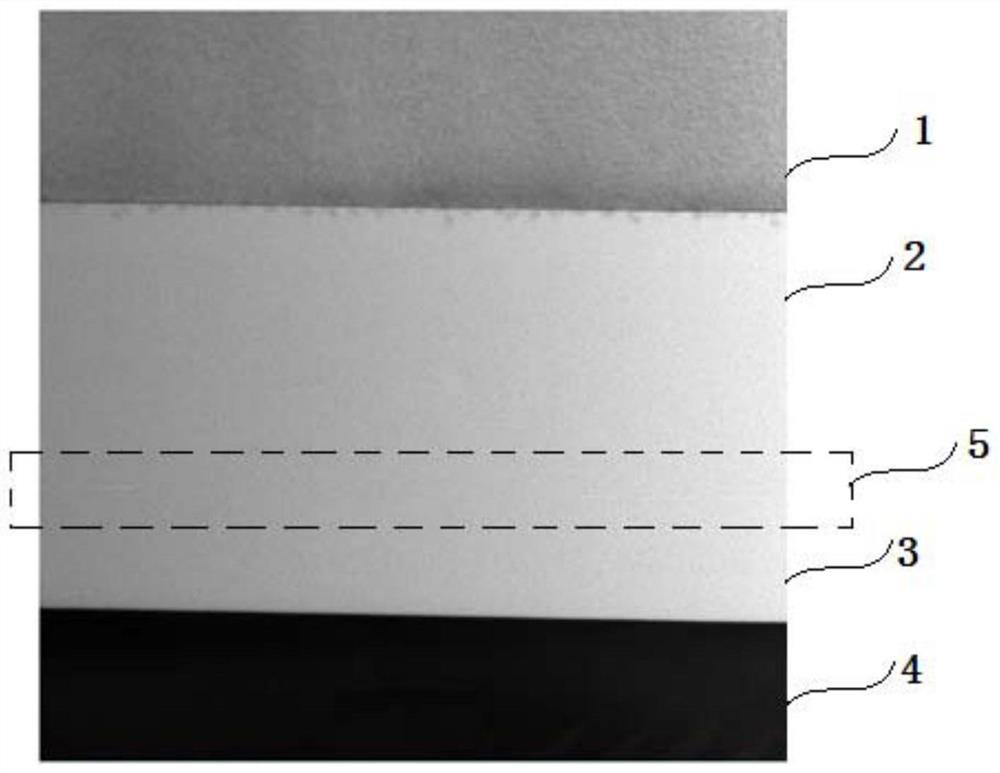

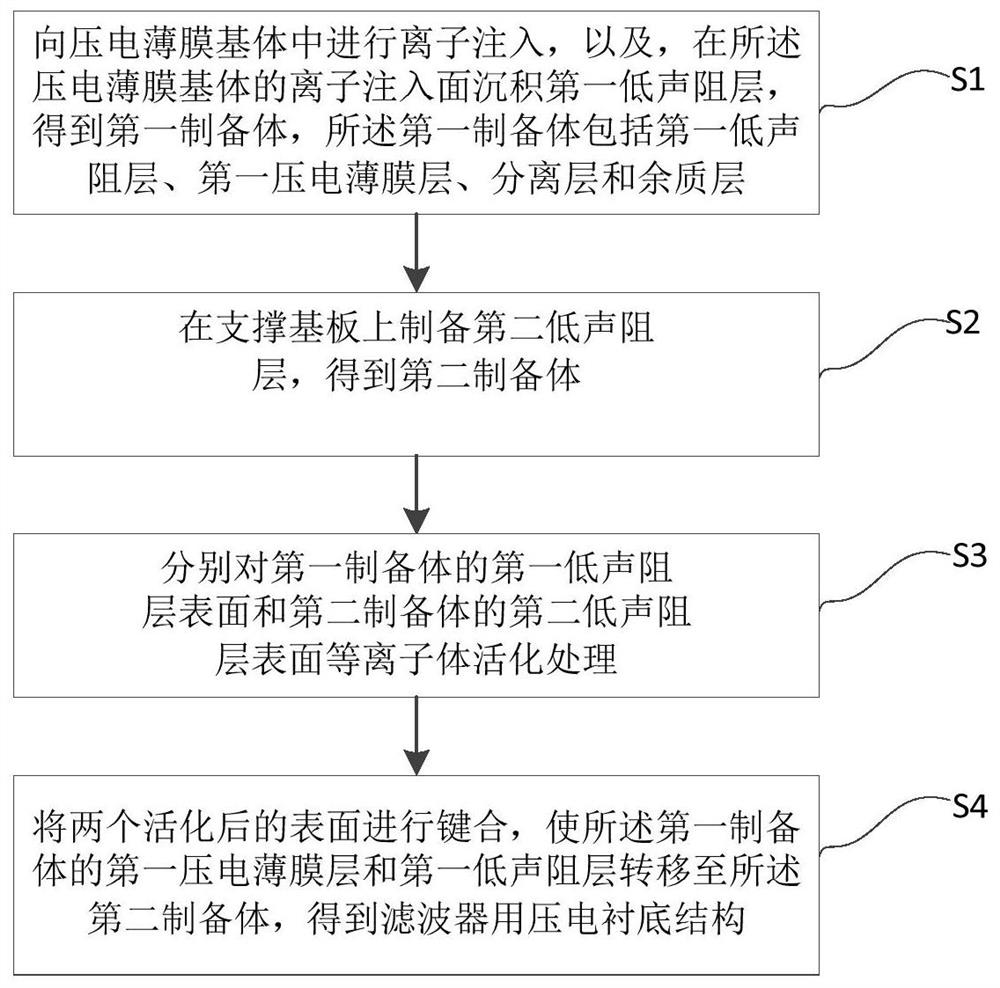

Piezoelectric substrate structure for filter and preparation method thereof

ActiveCN113922778AImprove adsorption capacityAvoid Bubble DefectsImpedence networksWater vaporRadio frequency signal

The embodiment of the invention discloses a piezoelectric substrate structure for a filter and a preparation method thereof, the piezoelectric substrate structure comprises a piezoelectric substrate, a first low acoustic resistance layer, a second low acoustic resistance layer and a support substrate which are stacked in sequence, and the surfaces of the first low acoustic resistance layer and the second low acoustic resistance layer are bonded after plasma activation. Water molecules between the first low-acoustic-resistance layer and the second low-acoustic-resistance layer can be diffused into the first low-acoustic-resistance layer and the second low-acoustic-resistance layer, so that the defect that the piezoelectric substrate generates bubbles due to the generation of water vapor is avoided; in addition, the existence of the first low-acoustic-resistance layer can effectively block proton exchange between H in water molecules between the first low-acoustic-resistance layer and the second low-acoustic-resistance layer and Li in the piezoelectric substrate, so that the original piezoelectric property of the piezoelectric substrate is ensured; moreover, since no water film exists between the piezoelectric substrate and the first low-acoustic-resistance layer, compared with the prior art, the acoustic resistance effect of the first low-acoustic-resistance layer and the second low-acoustic-resistance layer can be improved, and the radio-frequency signal loss of the surface acoustic wave filter can be reduced.

Owner:JINAN JINGZHENG ELECTRONICS

Pretreatment method for silylation and silylation method comprising same

ActiveCN102915908BAvoid resist pattern peelingPrevent peelingSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusPretreatment methodNitrogen

Owner:SEMICON MFG INT (SHANGHAI) CORP

Spiral jet polyurethane upper-connected shoemaking device and preparation process thereof

The invention discloses a spiral jet polyurethane upper-connected shoemaking device. The device comprises a base, a bottom die device, a left side die and a right side die and further comprises a spiral jet device used for spraying raw materials. The invention further discloses a multi-component polymer mixed spiral jet flow shoemaking preparation process. The process comprises the steps: a bottom die moves to the outer portions of the left side die and the right side die; a plurality of polymer raw materials are added into a feeding mechanism of the spiral jet flow device and sprayed to the shoe sole in a spiral airflow mode, and a jet flow layer used for combining the shoe upper and the shoe sole is formed; and the left mold and the right mold press the shoe last to be combined with the bottom mold, and the polymer jet flow layer sprayed on the shoe sole expands and enters the shoe upper and the shoe sole in a diffusion and permeation mode, so that the shoe upper and the shoe sole can be combined. The bottom die can be conveniently and rapidly replaced and cleaned, the spiral jet flow device can conveniently spray raw materials on the bottom die, widened special shoes and boots can be produced, the jet flow amount is large, the edge track of a formed jet flow conical surface is clear, and the device is suitable for production of all the shoes and boots.

Owner:JIHUA 3514 LEATHER & FOOTWARE

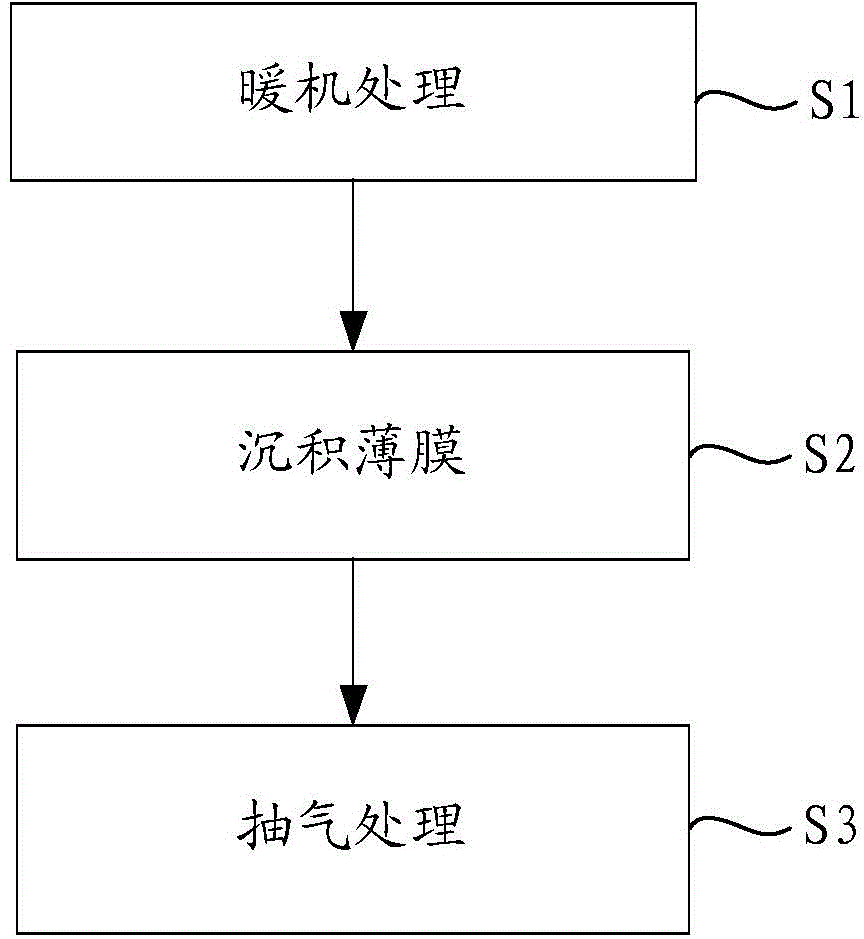

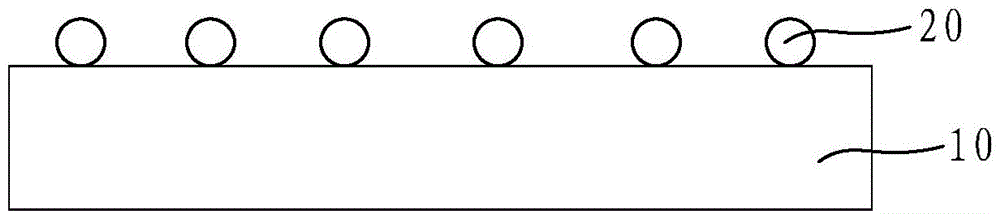

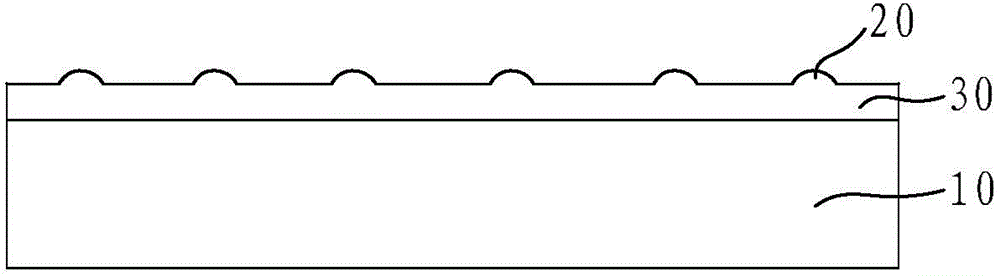

Method of depositing films

The invention discloses a method of depositing films. The method comprises the following steps: performing film depositing on a semiconductor wafer, pre-treating the surface of the semiconductor wafer to remove carbon polymer particles remained on the surface of the semiconductor wafer, and then performing film deposition. The method of depositing films can be used for preventing formation of bubbly defects as the carbon polymer particles are covered below the films by virtue of the film deposition.

Owner:SEMICON MFG INT (SHANGHAI) CORP

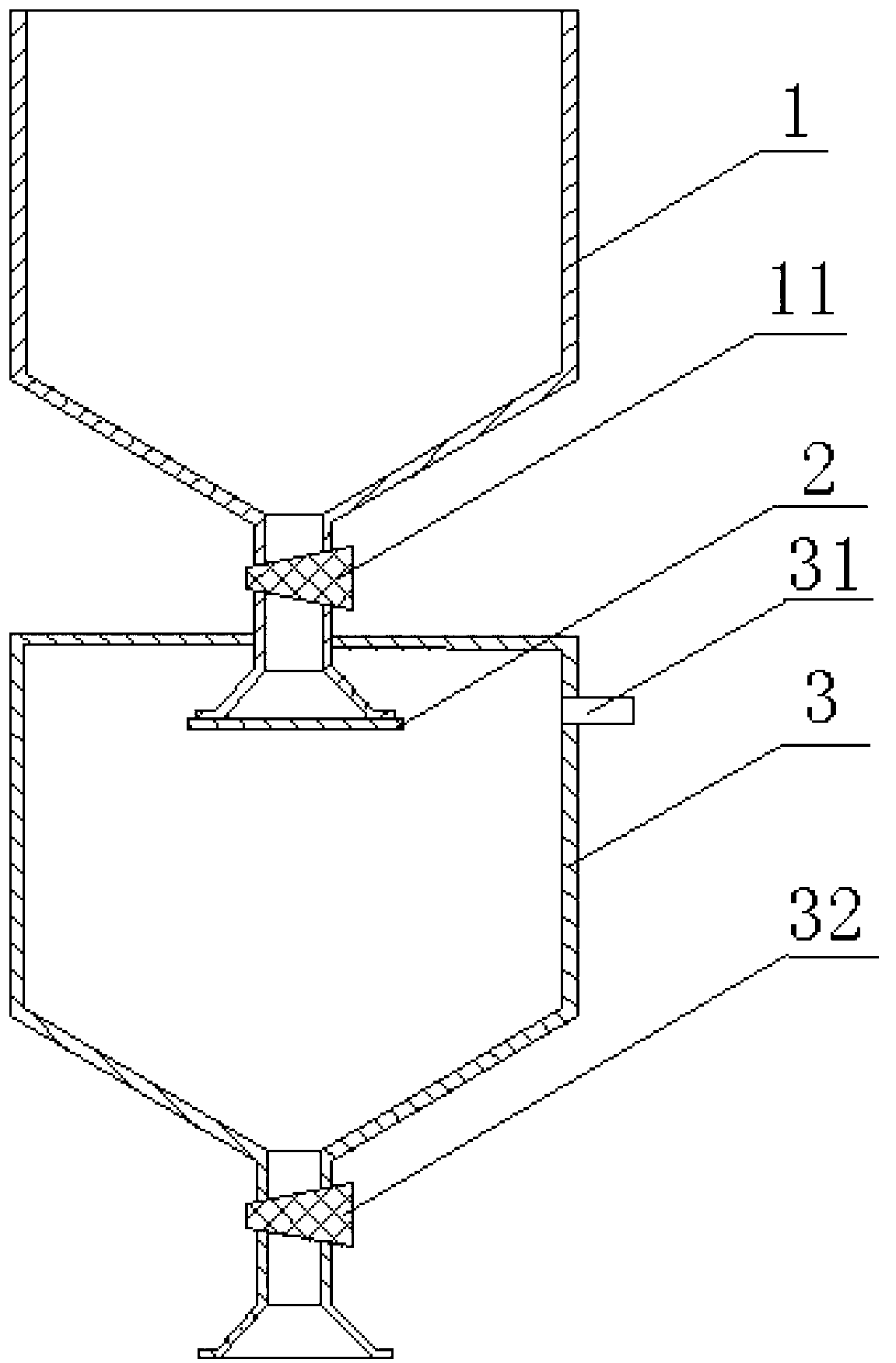

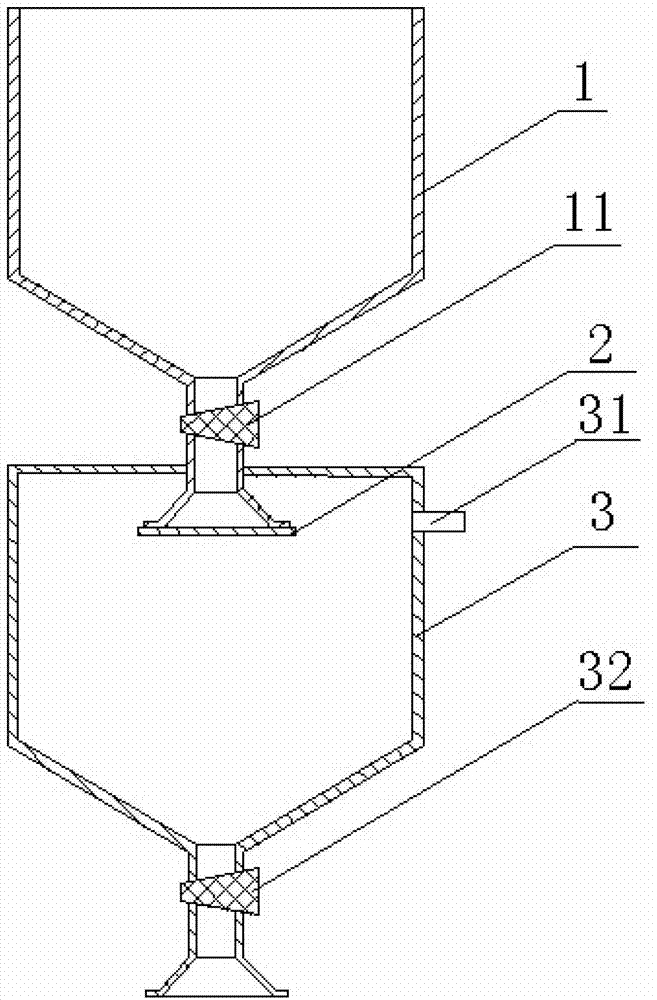

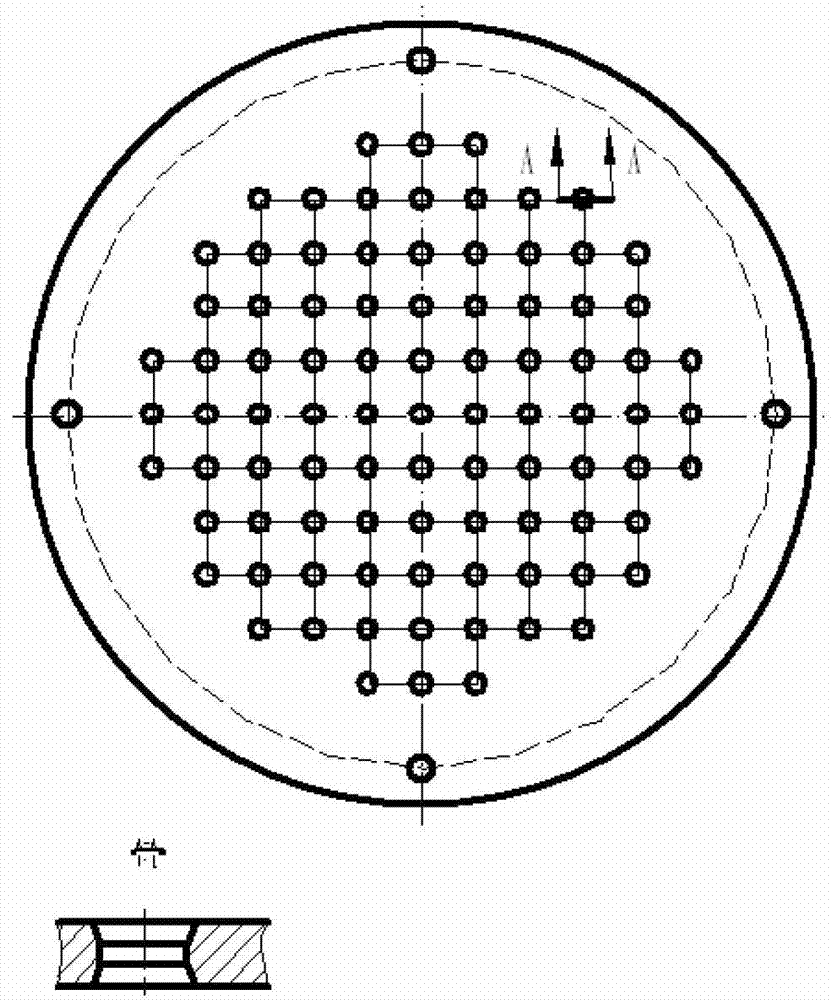

Device and method for removing low molecular substances in casting PBX slurry

ActiveCN103058799AAvoid Bubble DefectsQuality improvementExplosive working-up apparatusVacuum extractorSlurry

The invention discloses a device for removing low molecular substances in casting PBX slurry. The device comprises a storage hopper, a distribution tray and a receiving hopper, wherein the storage hopper and the receiving hopper are connected into an integral body in an up-and-down sealing mode; the distribution tray is connected and sealed in a discharge port end surface of the storage hopper; distribution holes with diameters of 2-8mm are distributed in the distribution tray; the neck of the discharge port of the storage hopper is provided with a plug valve; the side surface of the receiving hopper is connected with a vacuum extractor, and the neck of the discharge port is provided with a plug valve; and when the two plug valves are closed simultaneously, the receiving hopper can become a closed space. The invention also discloses a method for removing low molecular substances in casting PBX slurry by using the device. The invention can be used for successfully removing air, styrene and other low molecular substances in the casting PBX slurry, and avoid the defects of bubbles in the slurry, thereby enhancing the internal quality and safety performance of the casting PBX slurry. The invention has wide application prospects in conventional warhead PBX slurry.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

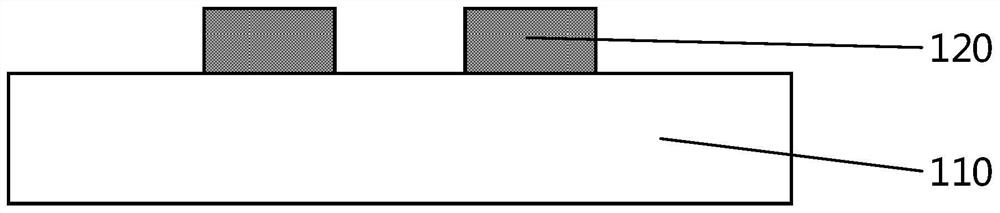

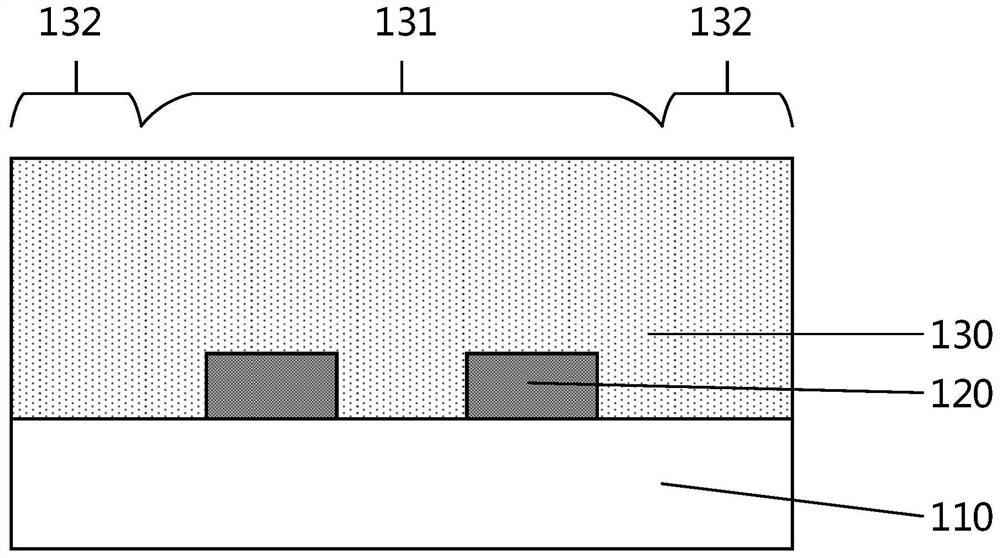

Interconnect structure and method of forming the same

ActiveCN103871964BReduce thicknessReduce stack thicknessSemiconductor/solid-state device detailsSolid-state devicesEngineeringPartial filling

The invention relates to an interconnecting wire structure and a forming method thereof. A semiconductor substrate is provided; the forming method of the interconnecting wire structure comprises the steps of forming multiple independent interconnecting wires on the semiconductor substrate, wherein grooves are formed between adjacent interconnecting wires; forming a first interlayer dielectric layer to cover the interconnecting wires, and filling a groove in part of the first interlayer dielectric layer until an opening is formed; forming a second interlayer dielectric layer to cover the first interlayer dielectric layer, wherein the opening is sealed by the second interlayer dielectric layer to form an air gap; flattening the second interlayer dielectric layer. The interconnecting wire structure formed by the forming method is improved in quality, and the forming method is simple in process and low in process cost.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Device and method for removing low molecular substances in casting PBX slurry

ActiveCN103058799BAvoid Bubble DefectsQuality improvementExplosive working-up apparatusVacuum extractorEngineering

The invention discloses a device for removing low molecular substances in casting PBX slurry. The device comprises a storage hopper, a distribution tray and a receiving hopper, wherein the storage hopper and the receiving hopper are connected into an integral body in an up-and-down sealing mode; the distribution tray is connected and sealed in a discharge port end surface of the storage hopper; distribution holes with diameters of 2-8mm are distributed in the distribution tray; the neck of the discharge port of the storage hopper is provided with a plug valve; the side surface of the receiving hopper is connected with a vacuum extractor, and the neck of the discharge port is provided with a plug valve; and when the two plug valves are closed simultaneously, the receiving hopper can become a closed space. The invention also discloses a method for removing low molecular substances in casting PBX slurry by using the device. The invention can be used for successfully removing air, styrene and other low molecular substances in the casting PBX slurry, and avoid the defects of bubbles in the slurry, thereby enhancing the internal quality and safety performance of the casting PBX slurry. The invention has wide application prospects in conventional warhead PBX slurry.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Preparation method of heat-conducting insulating coating layer for electric floor heating sheet

The invention discloses a preparation method of a heat-conducting insulating coating layer for an electric floor heating sheet. The preparation method comprises the following steps: mixing a water-borne epoxy resin matrix and nanoscale heat-conducting particles to prepare an insulating heat-conducting coating, then coating the surface of a polypropylene base heating sheet subjected to plasma surface treatment with the insulating heat-conducting coating through a spraying process, and drying and curing to obtain an insulating coating layer; the insulating coating layer not only plays an insulating role, but also has excellent heat dissipation performance. On the premise of ensuring the safe use of the polypropylene base heating sheet, the heat dissipation effect is improved.

Owner:摩特卡(杭州)进出口贸易有限公司

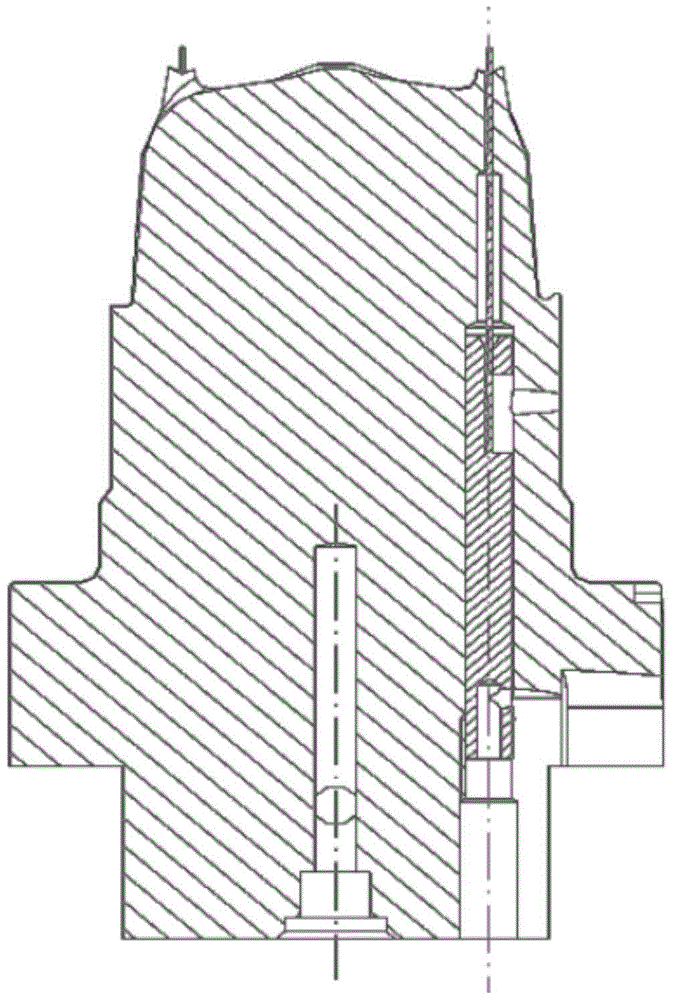

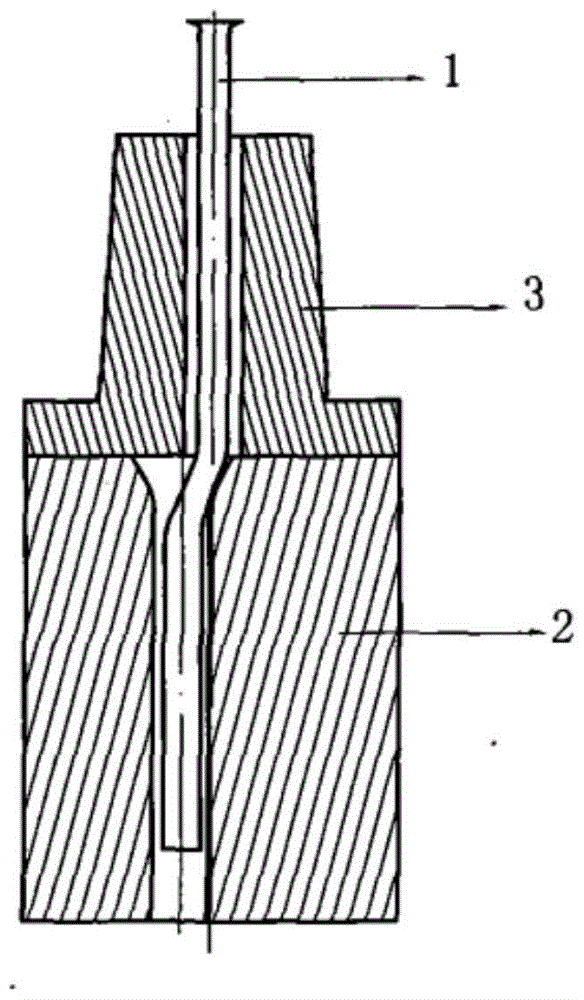

A piston casting mold support and piston casting method

The invention discloses a piston casting mould support. The piston casting mould support comprises a rod body, a rod body supporting structure and a supporting and fixing plate, wherein the rod body is fixed in the rod body supporting structure; the rod body supporting structure is nested in the supporting and fixing plate; and a gas passage which is communicated with the atmosphere is arranged on the inner part of the rod body supporting structure. Compared with the prior art, the problem that casting air bubble defect is caused as the piston casting mould support in the prior art cannot remove gas emitted by salt cores is solved. Furthermore, the invention also provides a piston casting method.

Owner:湖南江滨机器(集团)有限责任公司

Multi-component polymer mixing spiral jet device

The invention discloses a multi-component polymer mixing spiral jet device. The device comprises a screw mixing mechanism, a feeding mechanism and a spiral gas path jet mechanism, wherein, the spiral gas path jet mechanism comprises a beam gas path, a spiral gas path and a spiral jet flow plate arranged at a discharge port of the screw mixing mechanism; the spiral jet flow plate comprises a nozzle arranged in the center and a plurality of beam gas path holes which are circumferentially distributed by taking the nozzle as the circle center and are in communication with the beam gas path; a plurality of spiral gas path holes communicating with the spiral gas path are annularly distributed in the inner side wall of the nozzle and are converged to a port of the nozzle. According to the multi-component polymer mixing spiral jet device, the mixed multi-component polymer can be sprayed to the solid surface in a particle spiral jet flow mode, the jet flow amount is large and can reach 10g / s-30 g / s, the edge track of the formed jet flow conical surface is clean, the atomization splashing and particle reflection conditions cannot be generated, it can be guaranteed that the jet area is clean and tidy, and the device is suitable for being used when the solid surface is sprayed with a high-viscosity polymer coating.

Owner:JIHUA 3514 LEATHER & FOOTWARE +1

A Method for Reducing Bubble Defects in Slabs of Cr-Containing Steels

The invention relates to a method for reducing a bubble defect of a slab Cr-containing steel grade casting blank. Argon gas in a tundish is operated at a small flow rate, the argon gas flow rate of astopper rod in the tundish is less than or equal to 2.0 NL / min, and the argon gas flow rate of an upper nozzle is less than or equal to 2.0 NL / min; in the casting process, the minimum single-flow steel passing is not less than 2.4 tons / min; when the slab width is less than or equal to 1500 mm, three-hole immersive nozzle is used for continuous casting, the inclination angle of the holes in both sides is at 15 degrees, and the area ratio of vertical hole steel passing to the total steel passing is 5-18%; when the slab width is larger than 1500 mm and is small than or equal to 2200 mm, a two-hole immersive nozzle without vertical holes are used for continuous casting, and the inclination angle of the nozzle of water in the two holes are at 20 degrees; the superheat degree of molten steel ofthe tundish is not less than 12 DEG C; and the distance from the top edge of a discharge hole of the immersive nozzle to the liquid level of the molten steel in a crystallizer is 100-160 mm. Accordingto the method, the bubble defect generated by steel grades containing Cr more than or equal to 0.15% is avoided, and the defect of edge portion "peeling"-like formed by bubble exposure rolling elongation in the casting blank rolling process is eliminated. The product quality of the steel grade is improved.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com