Multi-component polymer mixing spiral jet device

A technology of mixing screw and jet device, applied in the direction of spray device, liquid spray device, etc., can solve the problems of waste of raw materials, change of spraying position, substandard coating quality, etc., to avoid product loss, reduce impact force, and improve adhesion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

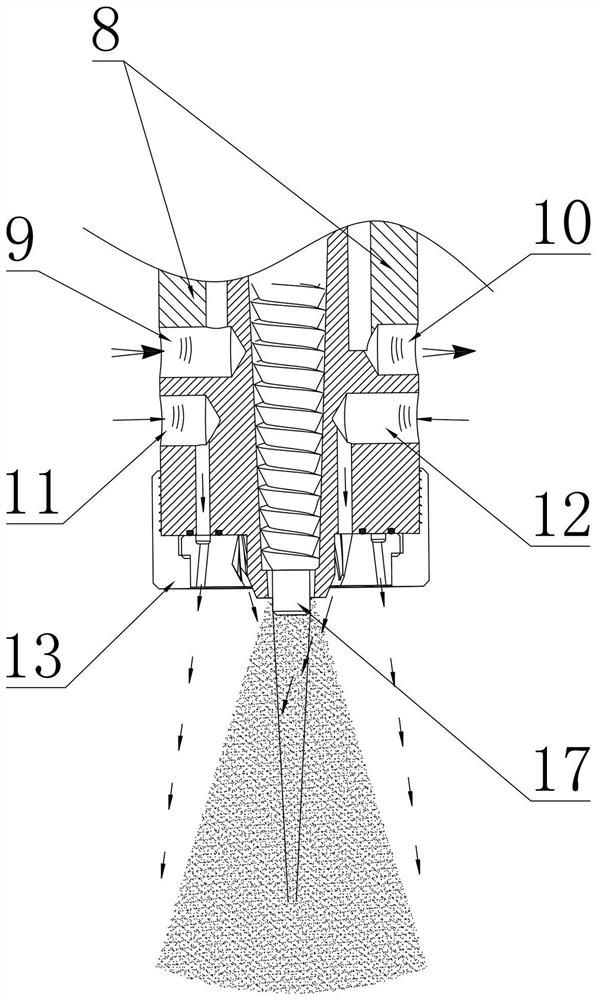

[0036] Example A multi-component polymer mixed spiral jet device

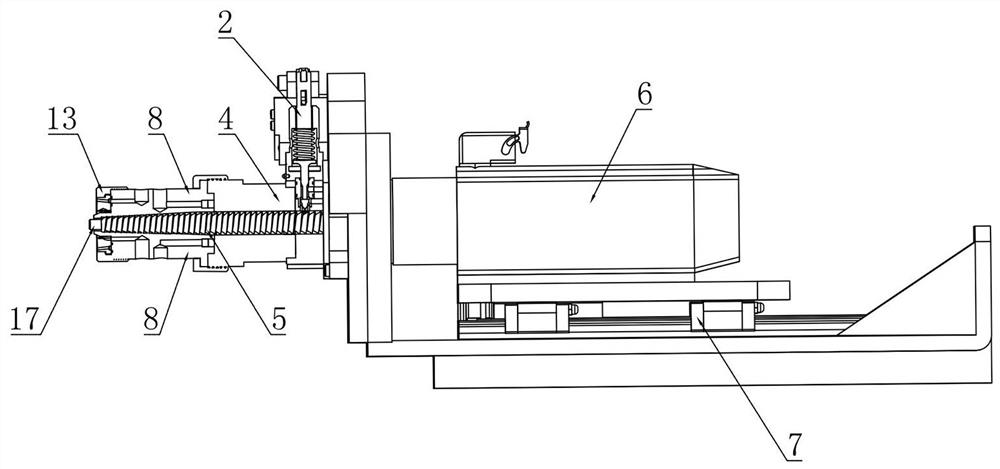

[0037] In this embodiment, after the multi-component polymer is stirred and mixed by the high-speed rotating screw 5, the air is compressed by the helical air jet mechanism 3 at the front end of the screw chamber 4, so that the mixed high-viscosity multi-component polymer can be dispersed in the form of particles Spray to the solid surface in the form of a spiral jet, the jet flow is large, up to 10-30g / s, and the radiation boundary is clear, the atomization is small, and there is no splash.

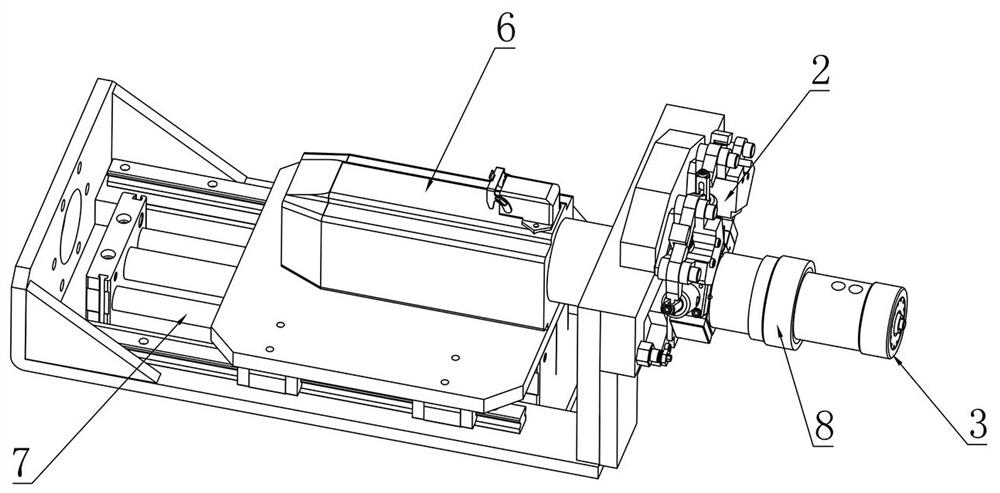

[0038] like figure 1 As shown, this implementation includes a screw mixing mechanism 1 , a feeding mechanism 2 and a helical gas jet mechanism 3 .

[0039] 1. Screw mixing mechanism 1

[0040] The screw mixing mechanism 1 is used for mixing and stirring multi-component polymers to make them fully react to form a high-viscosity mixture. like figure 2 As shown, the screw mixing mechanism 1 includes a screw cavity 4 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com