Spiral jet polyurethane upper-connected shoemaking device and preparation process thereof

A polyurethane and spiral technology, which is applied in the field of shoemaking, can solve the problems of small space for installing the bottom mold, large occupied space, and high requirements on process parameters, etc., and achieve quick and convenient replacement or cleaning of the bottom mold, less space occupied, and temperature control precise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

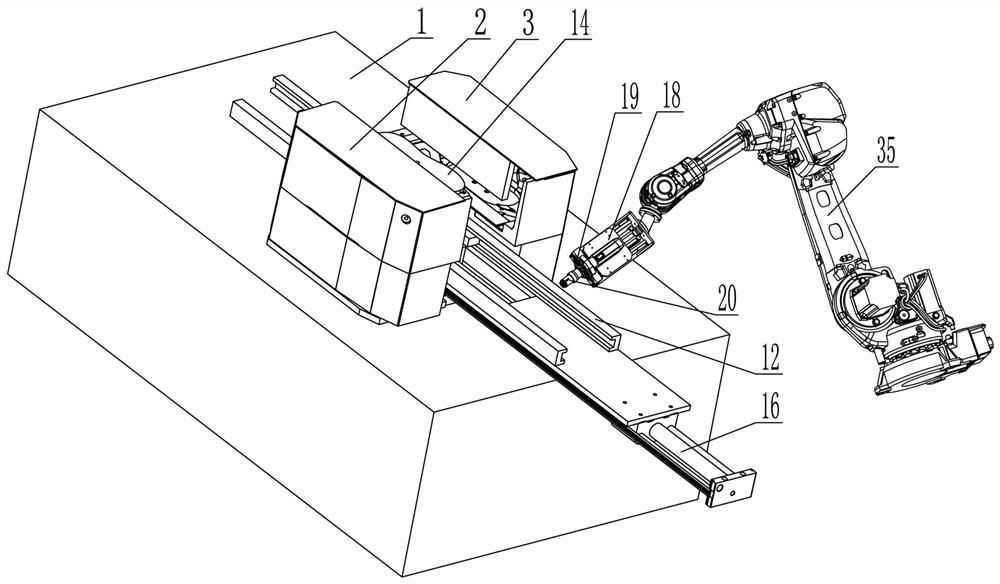

[0050] Example 1 Helical Jet Polyurethane Upper Shoemaking Device

[0051] Example figure 1 As shown, a spiral jet polyurethane shoe-making device with uppers includes a base, a bottom mold device arranged on the base, a left mold 2 and a right mold 3 arranged on the base for matching with the bottom mold device, and also includes Spiral jet device for spraying material into the sole of a shoe. The bottom mold device is used to place the shoe sole, the spiral jet device is used to spray the upper and sole bonded raw materials on the shoe sole, the left mold 2 and the right mold 3 are used to inject the shoe upper on the last, and are connected with the bottom The molding device closes the mold and glues the upper and the sole together.

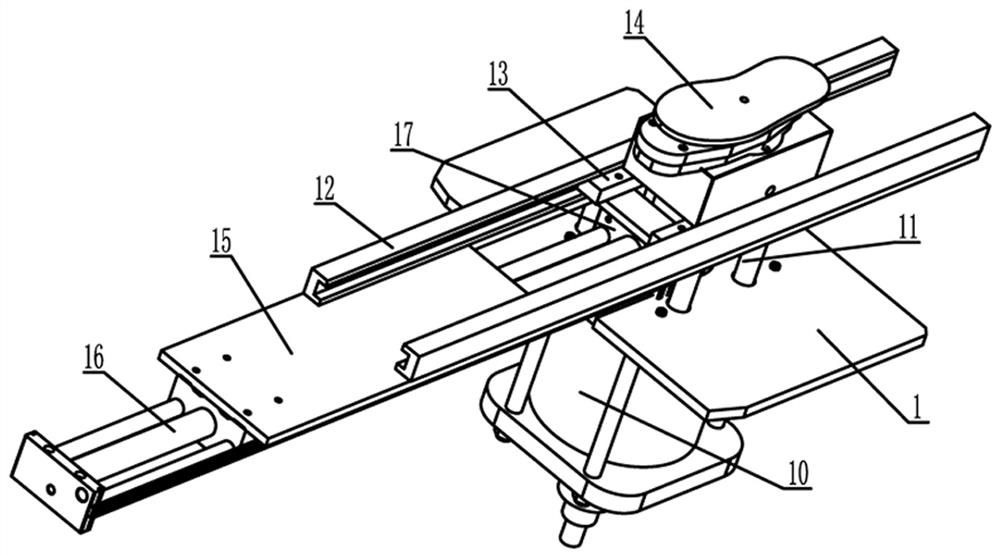

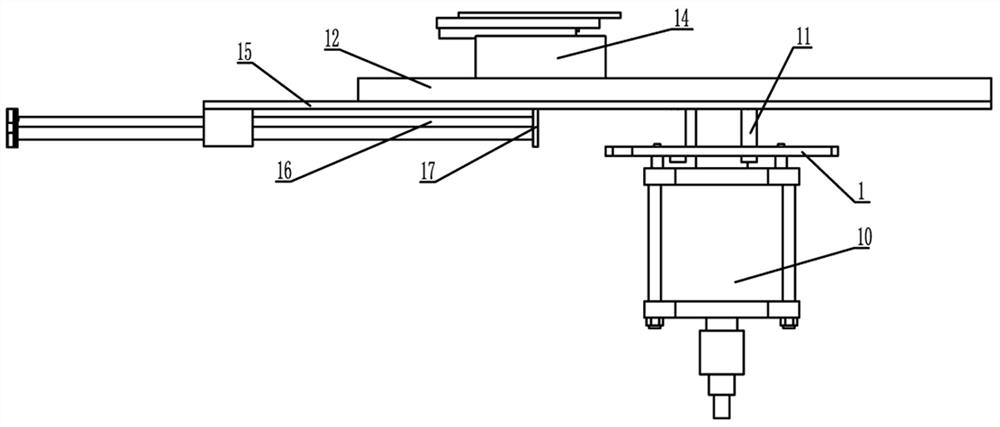

[0052] 1. Bottom mold device

[0053] Such as Figure 2-4 As shown, the bottom mold device includes a base 1 and a lifting device fixed on the base 1, the lifting device is a lifting cylinder 10, and the base 1 is provided with a through h...

Embodiment 2

[0078] Example 2 Preparation process of helical jet polyurethane shoemaking with uppers

[0079] A preparation process for making shoes with spiral jet polyurethane uppers. The process of combining soles and uppers by using the above-mentioned spiral jet polyurethane upper shoemaking device is as follows:

[0080] Start the rodless cylinder 16 of bottom mold device, make the bottom mold 14 that placed sole move to the outside of left side mold 2 and right side mold 3, facilitate spiral jet device to spray multi-component polymer on sole.

[0081] Add a variety of polymer raw materials into the feeding mechanism 19 of the spiral jet device, and mix them through the screw mixing mechanism 18 to form a multi-component polymer. Through the nozzle, the various polymer raw materials are sprayed onto the soles in the form of spiral air flow , forming a fluidic layer for the combination of the upper and the sole. When using a nozzle to spray multi-component polymers, the density of t...

Embodiment 3-7

[0084] Example 3-7 Preparation process of spiral jet polyurethane shoemaking with uppers

[0085] The preparation process of this embodiment is identical with embodiment 2, and difference is, the parameter in the preparation process, and concrete parameter is as table 1:

[0086]Table 1 Preparation process parameter table

[0087]

[0088] Using the preparation process of Examples 2-7 to make shoes has a high degree of automation, saves a lot of manual operations, simplifies the molding process, avoids glue polluting the environment, and has high production quality and high production efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com