Vacuum autoclave used for motorcycle helmet production and motorcycle helmet forming process

A vacuum autoclave and autoclave technology, which is applied in the field of helmet production, can solve the problems affecting the impact resistance effect of helmets, internal structure tearing, overall cracks, etc., so as to ensure the fault tolerance rate, operation safety, and impact resistance strength. , the effect of saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

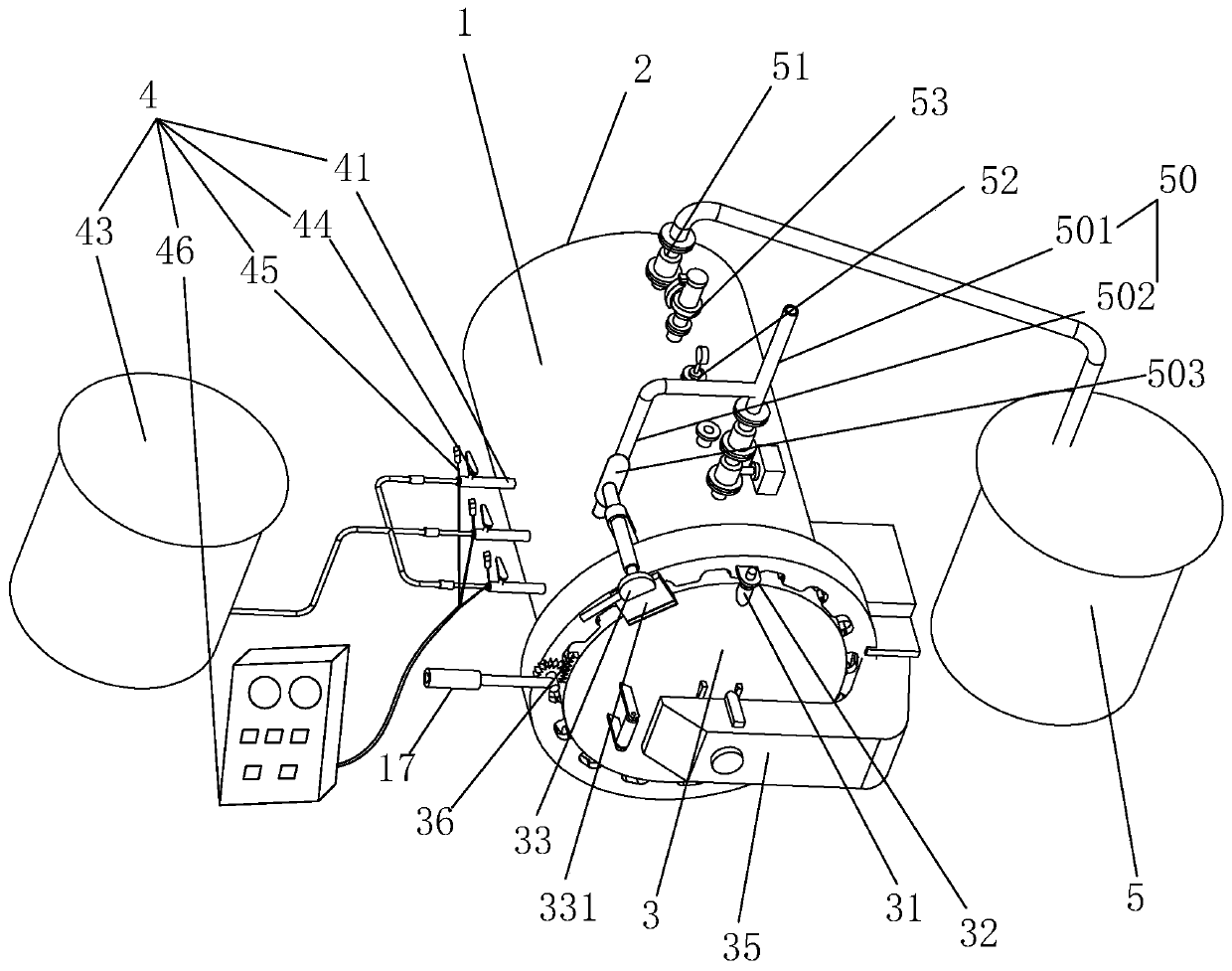

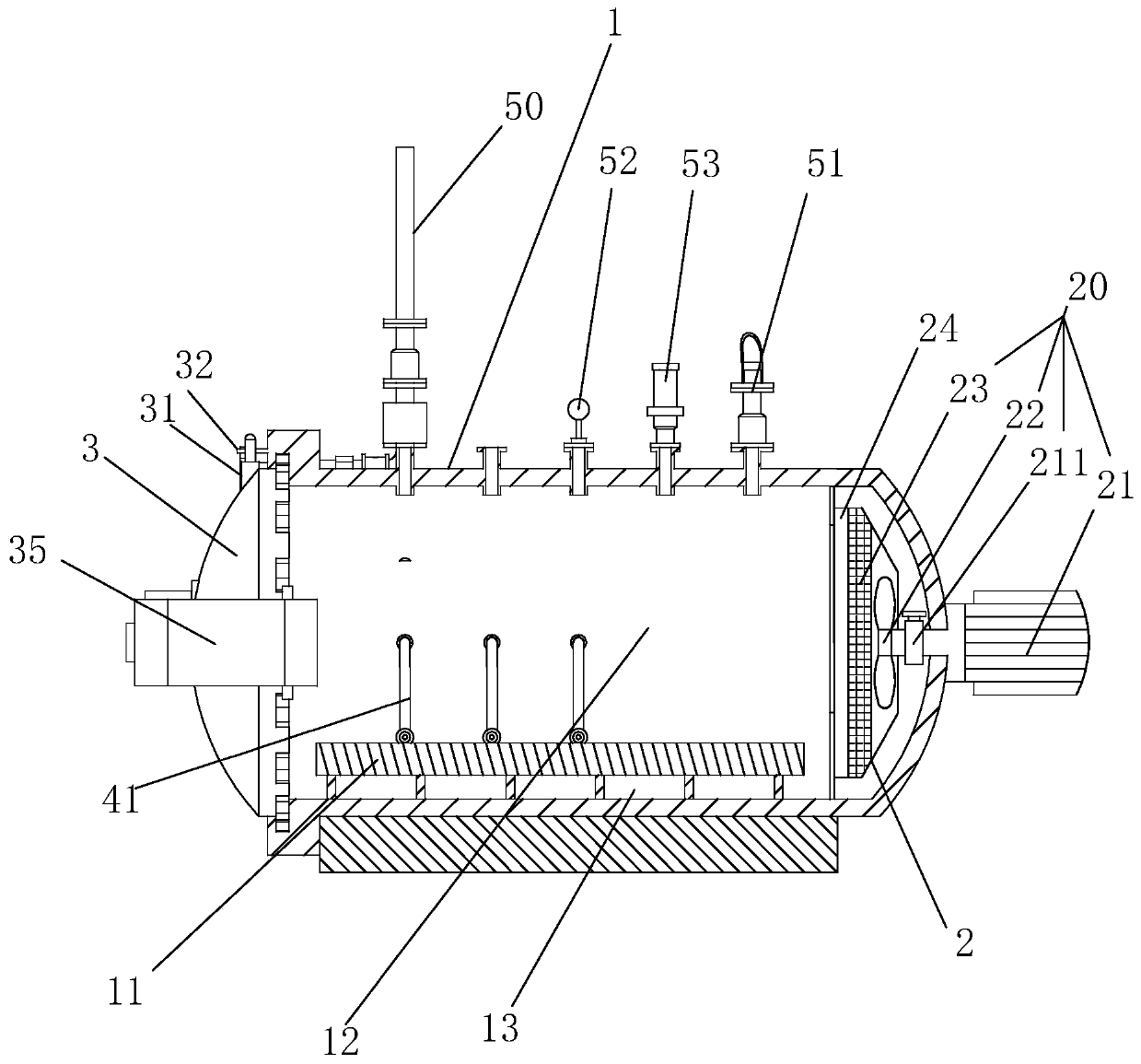

[0039] refer to figure 1 , is a vacuum autoclave disclosed in the present invention for the production of motorcycle helmets, comprising an autoclave body 1 and a molding device 10, one end of the autoclave body 1 is fixedly connected with a closure 2; the closure 2 is provided with Heating device 20 (label image 3 ); the other end of the autoclave body 1 is connected with a tank door 3; the autoclave body 1 is connected with a vacuum device 4 communicating with the molding device 10; Device 50 , pressure gauge 52 , safety valve 53 and air intake pipe 51 ; air intake pipe 51 communicates with air intake device 5 .

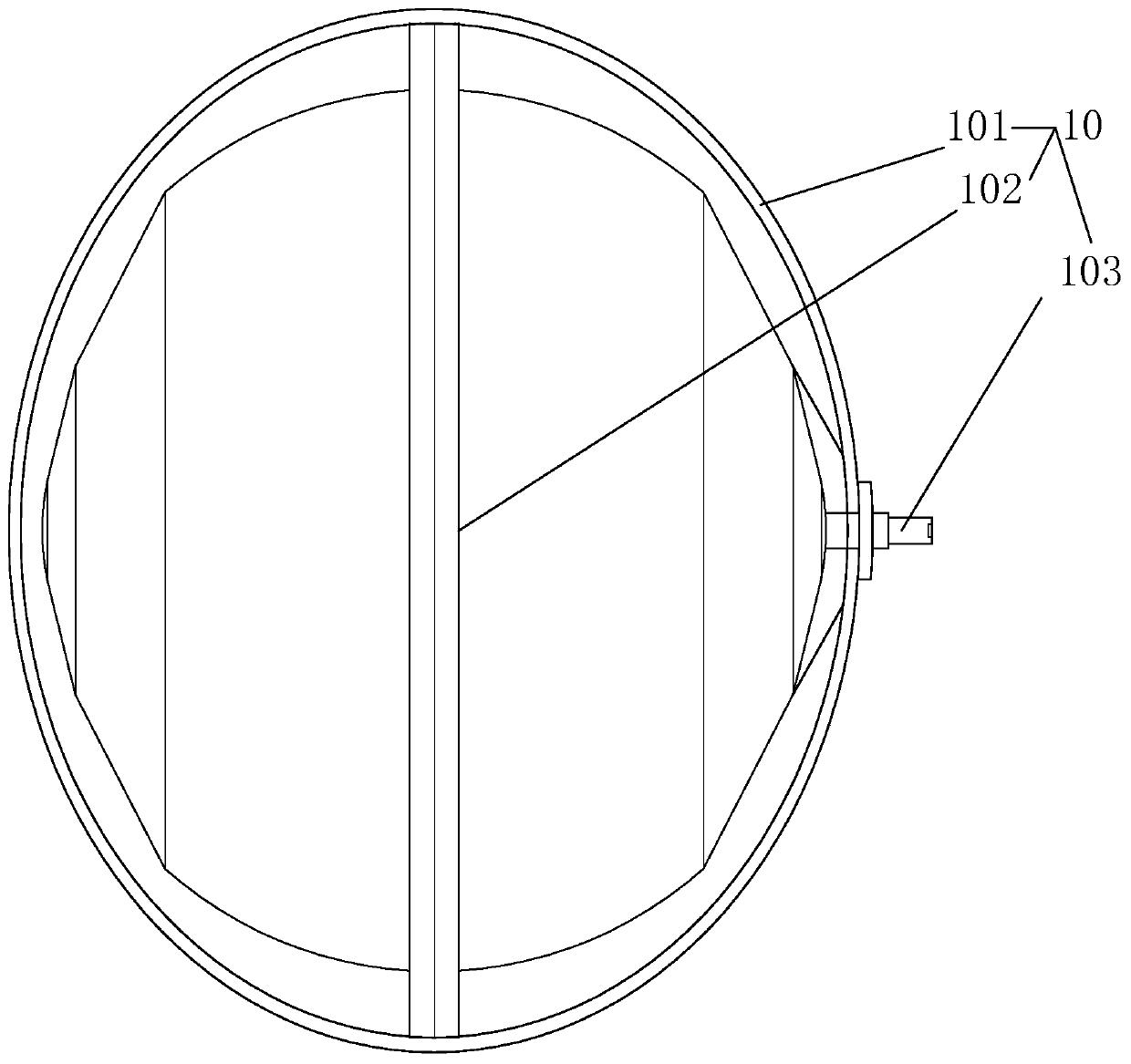

[0040] refer to figure 2 and image 3 , the forming device 10 includes a vacuum bag 101, preferably a PE bag. A forming mold 102 is arranged inside the vacuum bag 101 ; The vacuum device 4 includes a plurality of connection pipes 41 fixedly connected to the outer wall of the autoclave body 1; one end of the connection pipes 41 communicates with a vacuum tub...

Embodiment 2

[0047] Step 1. Preliminary operation of the forming device 10: the inner wall of the forming mold 102 is attached with composite materials and auxiliary materials; and then the inner and outer surfaces of the forming mold 102 are covered with high-temperature vacuum diversion cotton, and then put into the vacuum bag 101.

[0048] Step 2, vacuuming operation: first put the molding device 10 into the autoclave body 1 and at the same time confirm that the gas storage tank 43 is in a normal working state; then connect the joint 103 with the vacuum tube 42; finally open the control valve 44 to start vacuuming, Finally, observe the indication of the air pressure display device 46. If the indication of the vacuum degree is abnormal, close the corresponding control valve 44, and judge that the quality of the outer casing in the forming mold 102 is not up to standard.

[0049] Step 3, thermosetting molding: turn on the electric heater 23 and simultaneously turn on the driving motor 21 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com