A Method for Reducing Bubble Defects in Slabs of Cr-Containing Steels

A technology for steel types and slabs, which is applied in the field of reducing bubble defects in slabs of Cr-containing steel types, can solve problems such as defects in hot-rolled materials, and achieve the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1 produces the operation control method of slab SS400Cr (width=1280mm):

[0027] 1) The argon gas in the tundish is operated at a small flow rate. The argon gas flow rate of the tundish stopper rod is controlled at 1.2NL / min, and the argon gas flow rate at the upper nozzle is controlled at 1.0NL / min.

[0028] 2) The cross-section is 170*1280mm, the casting speed is 1.9m / min, and the single-flow steel volume is controlled at 3.24 tons / min.

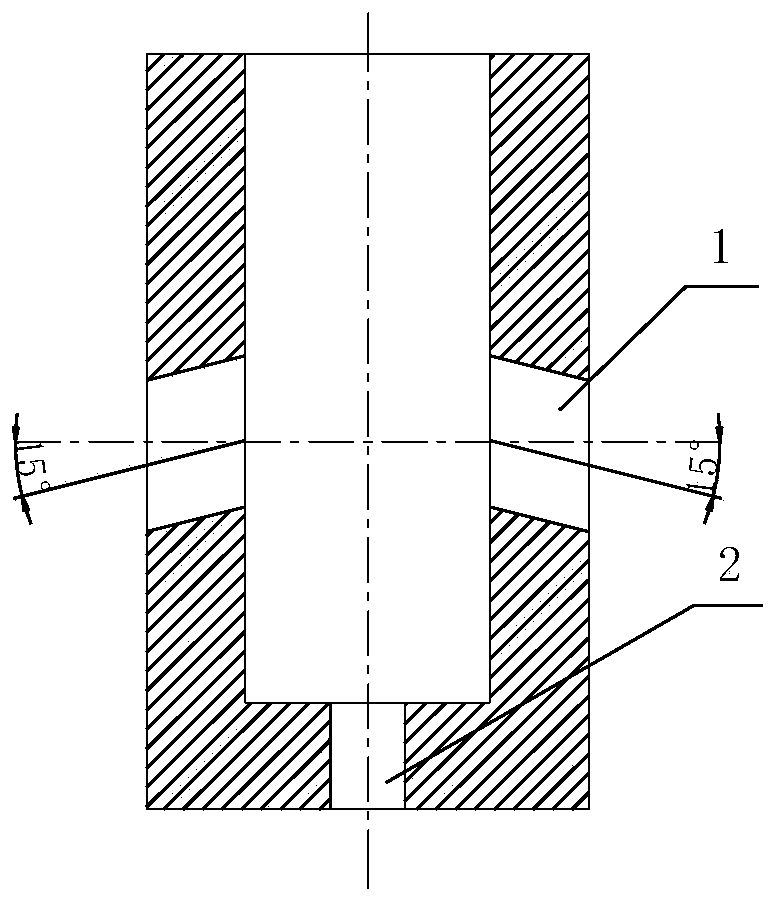

[0029] 3) Three-hole submerged nozzles are used, the inclination angle of the nozzles on both sides is 15°, and the ratio of the vertical hole steel area to the total steel area is 10% (see attached figure 1 ).

[0030] 4) The superheat of the molten steel in the tundish is not less than 18°C, and the target superheat is 23°C.

[0031] 5) The distance from the upper edge of the outlet hole of the submerged nozzle to the molten steel surface of the mold is 120-140mm.

Embodiment 2

[0032] Embodiment 2 produces the operation control method of slab A36-Cr (width=1700mm):

[0033] 1) The argon gas in the tundish is operated at a small flow rate. The argon gas flow rate of the tundish stopper rod is controlled at 1.5NL / min, and the argon gas flow rate at the upper nozzle is controlled at 1.2NL / min.

[0034] 2) The cross-section is 170*1700mm, the casting speed is 1.5m / min, and the single-flow steel volume is controlled at 3.40 tons / min.

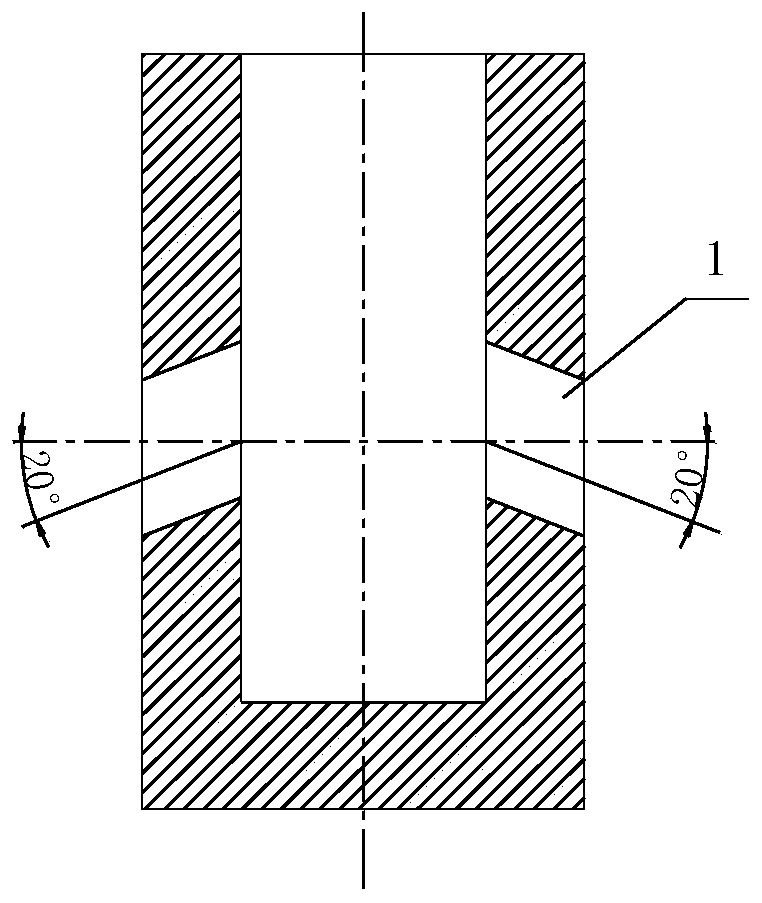

[0035] 3) Use two-hole submerged nozzles, no vertical holes, and the inclination angle of the nozzles on both sides is 20° (see attached figure 2 ).

[0036] 4) The superheat of molten steel in the tundish is not less than 20°C, and the target superheat is 25°C.

[0037] 5) The distance from the upper edge of the outlet hole of the submerged nozzle to the molten steel surface of the mold is 130-150mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com