Preparation method of flexible insulating plate, obtained flexible insulating plate, flexible laminated plate and preparation method and application thereof

A technology for insulating boards and laminates, applied in the field of flexible laminates and their preparation, preparation of flexible insulating boards, and flexible insulating boards, can solve problems such as difficult film formation, high dielectric loss, and complicated processes, and achieve The effect of reducing the difficulty of impregnation, low dielectric loss, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a method for preparing a flexible insulating board, which includes the following process:

[0027] Step S1: Prepare the glue solution of the first fluororesin, immerse the ultra-thin fiber layer with a thickness of 8 μm-25 μm in the glue solution of the first fluororesin, and cure for the first time to obtain a prepreg.

[0028] The ultra-thin fiber layer improves the problem of low fluororesin content due to impregnation difficulties caused by too thick glass fibers in the prior art, avoids glass fiber lines on the surface when it is pressed into CCL, and improves the softness of the insulating board, enabling The insulating board can be applied to a flexible insulating board.

[0029] In a preferred embodiment, the ultra-thin fiber layer is a fiber fabric woven from one or more of glass fibers, quartz fibers and organic fibers. Among them, the ultra-thin fiber layer made of glass fiber can be D-type, S-type, E-type or NE-type electronic glass ...

Embodiment 1

[0064] A flexible laminate 1 was prepared.

[0065] 1) Prepare the first fluororesin glue solution, the first fluororesin glue solution is PTFE resin glue solution, and its solid content is 60%.

[0066] 2) Take an ultra-thin fiber layer (E-type electronic glass fiber cloth) with a thickness of 13 μm, immerse the ultra-thin fiber layer in the first fluororesin glue, and then enter it into an oven for curing through a roller. The curing temperature is 70°C and the drying time is 5 minutes. , remove the water to obtain a prepreg.

[0067] 3) Prepare the second fluororesin glue, the second fluororesin glue is the same as the first fluororesin glue, apply it to both sides of the prepreg by coating, and then enter the oven for curing. The temperature is 70°C, the drying time is 5 minutes, and the water is removed to obtain a semi-finished product.

[0068] 4) Repeat step 3) three times.

[0069] 5) The product obtained in step 4) is transferred to an oven for heat treatment. The...

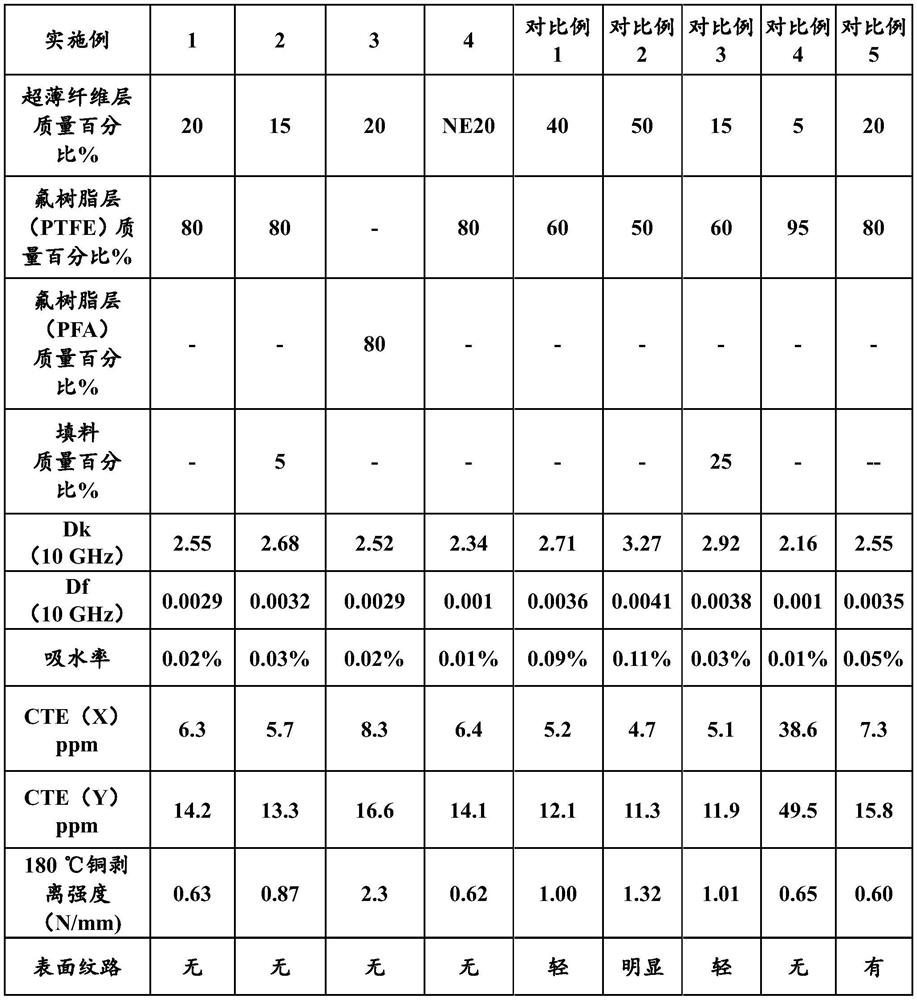

experiment example 1

[0075] Measure the dielectric constant Dk, dielectric loss coefficient Df, CTE (X), CTE (Y), water absorption, 180 ℃ copper peeling strength and observation surface of the flexible laminates obtained in Examples 1-4 and Comparative Examples 1-5 Whether there is fiberglass texture.

[0076] 1) Measurement method of dielectric constant Dk and dielectric loss coefficient Df

[0077] Based on the JISC2565 test standard, the Dk and Df of the sample were tested using the ADMS01Nc series dielectric constant tester TM mode resonator of the Japanese AET company, and the average value was taken for multiple measurements of the same sample.

[0078] 2) Measurement method of CTE(X) and CTE(Y)

[0079] Based on the standard of IPC TM-6502.4.24.3, the CTE value of each insulating board was measured under the measurement conditions of 25°C to 288°C using TA Q400 equipment of TA Instrument.

[0080] CTE(X) is the coefficient of thermal expansion of the flexible insulating board in the trans...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com