Device and method for removing low molecular substances in casting PBX slurry

A molecular substance and slurry technology, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of reduced safety performance of charges, low liquid phase content, air bubbles, etc., to improve the internal quality and safety performance of charges, The effect of avoiding bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

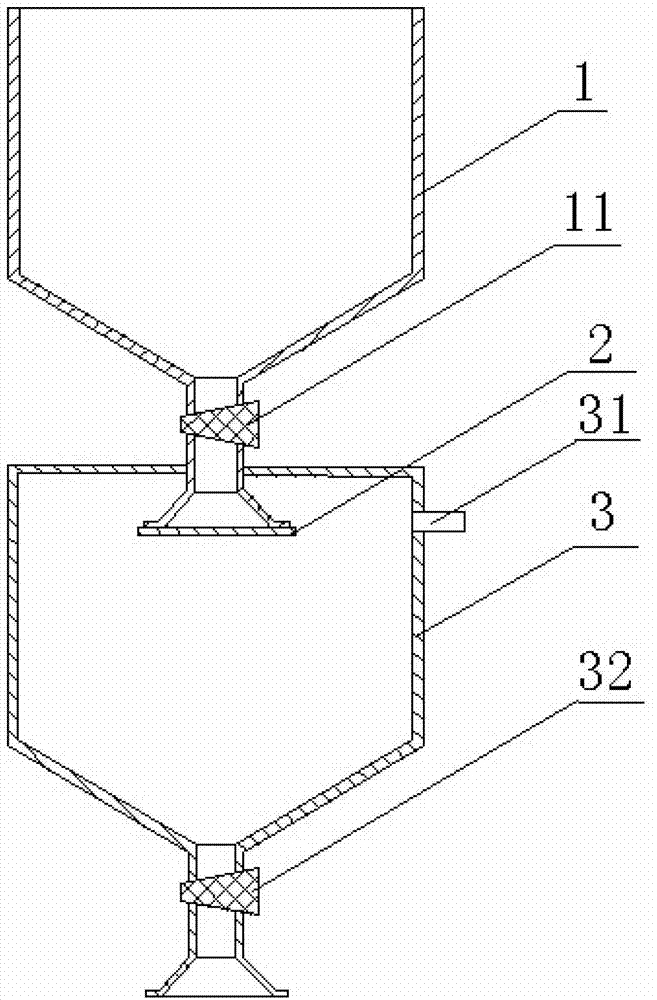

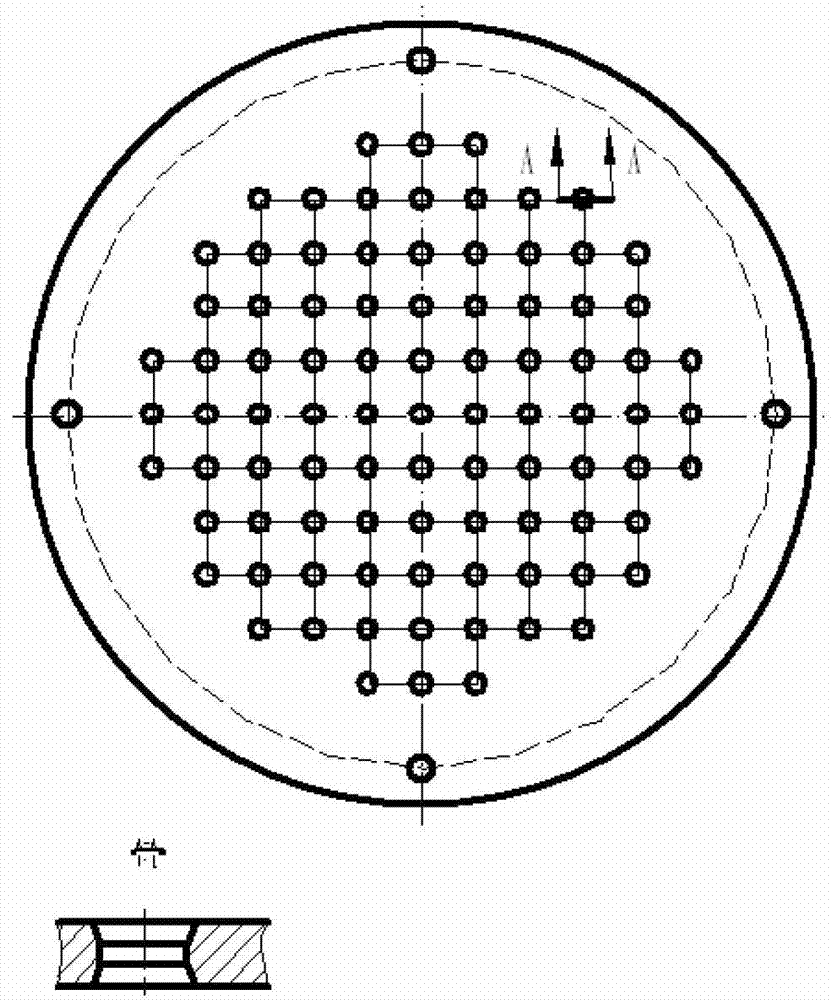

[0023] A device for removing low-molecular-weight substances in pouring PBX slurry, such as figure 1 As shown, the device includes a storage hopper 1, a distribution tray 2 and a receiving hopper 3, wherein the storage hopper 1 and the receiving hopper 3 are sealed up and down as a whole, and the distribution tray 2 is sealed and connected to the end face of the discharge port of the storage hopper 1. , the distribution holes with a diameter of 5-8mm are distributed on the distribution plate 2, such as figure 2 shown. A plug valve 11 is installed on the neck of the discharge port of the storage hopper 1, a nozzle 31 connected to the vacuum device is installed on the side of the hopper 3, and a plug valve 32 is installed on the neck of the discharge port. When the two plug valves 11 and 32 are closed at the same time, the hopper is connected 3 becomes a confined space.

[0024] Further, the connection between the storage hopper 1 and the receiving hopper 3, and the material ...

Embodiment 2

[0035] A device for removing low-molecular-weight substances in pouring PBX slurry, such as figure 1 As shown, the device includes a storage hopper 1, a distribution tray 2 and a receiving hopper 3, wherein the storage hopper 1 and the receiving hopper 3 are sealed up and down as a whole, and the distribution tray 2 is sealed and connected to the end face of the discharge port of the storage hopper 1. , the distribution holes with diameters ranging from 3.5-5mm are distributed on the distribution plate 2, such as figure 2 shown. A plug valve 11 is installed on the neck of the discharge port of the storage hopper 1, a nozzle 31 connected to the vacuum device is installed on the side of the hopper 3, and a plug valve 32 is installed on the neck of the discharge port. When the two plug valves 11 and 32 are closed at the same time, the hopper is connected 3 becomes a confined space.

[0036] Further, the connection between the storage hopper 1 and the receiving hopper 3, and th...

Embodiment 3

[0047] A device for removing low-molecular-weight substances in pouring PBX slurry, such as figure 1 As shown, the device includes a storage hopper 1, a distribution tray 2 and a receiving hopper 3, wherein the storage hopper 1 and the receiving hopper 3 are sealed up and down as a whole, and the distribution tray 2 is sealed and connected to the end face of the discharge port of the storage hopper 1. , the distribution holes on the distribution plate 2 with a diameter of 2-4mm, such as figure 2 shown. A plug valve 11 is installed on the neck of the discharge port of the storage hopper 1, a vacuum device 31 is connected to the side of the receiving hopper 3, and a plug valve 32 is installed on the neck of the discharge port. When the two plug valves 11 and 32 are closed at the same time, the receiving hopper 3 becomes a closed space.

[0048] Further, the connection between the storage hopper 1 and the receiving hopper 3, and the material distribution tray 2 and the storage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com