Patents

Literature

34results about How to "Guaranteed carbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-high purity purifying technique for native graphite

The invention discloses a hyper-high purity extracting technology of natural graphite, which comprises the following steps: (1) putting natural graphite in the container to do oxidizing disposal with low-middle carbon content more than 98%; (2) fusing at high temperature; (3) inputting in the metal erosion-proof container; proceeding dealkalization; (4) deacidifying to wash to neutral; (5) proceeding electromagnetic black metal removing disposal in the floating pool; (6) heating in the autoclave from 118 deg, 206 deg and 220 deg separately; (7) using pure water to dispose; (8) dehydrating; (9) drying until the water content is less than 0.1%.

Owner:LUOYANG GUANQI INDAL & TRADE

Method for rectangular continuous casting production of low-carbon low-silicon steel

The invention discloses a method for rectangular continuous casting production of low-carbon low-silicon steel. The method includes the procedures of smelting of a converter, LF refining and rectangular blank continuous casting. In the procedure of smelting of the converter, manganese alloying is performed through low-carbon ferromanganese, and the terminal point carbon content of the converter is controlled to be 0.04 or below; in the steel discharging process, aluminum ingots are adopted for deoxidization; in the LF refining procedure, manganese component adjustment is performed through low-carbon ferromanganese, deoxidization is performed through an aluminum-based deoxidization agent, aluminum component adjustment is performed through an aluminum wire, molten steel calcium treatment is performed through a calcium and ferrum wire, and the soft blow time is not shorter than 10 min before leaving; in the rectangular blank continuous casting procedure, an argon-sealed protective sleeve is adopted for a large pack, integrated tundish is adopted for protective casting, a carbon-free covering agent is added in the initial stage of casting of a continuously-cast first pack, and the superheat degree of tundish molten steel is controlled to be 20-40 DEG C. According to the method, by reasonably controlling the aluminum content of molten steel, continuous casting bubble defects are avoided, it is also avoided that castability of high-aluminum-content molten steel is poor, and cost of a deoxidization agent is reduced.

Owner:TANGSHAN IRON & STEEL GROUP

Smelting method of semisteel

InactiveCN103952507AIncrease water carbon contentIncrease temperatureManufacturing convertersMolten steelSilicon

The invention discloses a smelting method of semisteel, which comprises steps of tapping of semisteel, and smelting in a converter when tapping is completed, wherein the semisteel is subjected to silicon increasing by adding a silicon increasing agent into the steel flow during the tapping process. The method can increase both the carbon content and the temperature of the molten steel at the end point of the converter, reduces the TFe content of converter final slag, thus effectively reduces loss of steel materials, is simple in operation, and strong in practicality, and has good application prospects.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Method for preparing TZM alloy material through spray drying

The invention discloses a method for preparing a TZM alloy material through spray drying. The method comprises the following steps: 1, placing molybdenum powder, titanium hydride powder and zirconium hydride in a mixer, and uniformly mixing to obtain a mixture; 2, dissolving an organic binder in an organic solvent to prepare a solution; 3, adding the mixture to the solution, uniformly stirring to obtain a slurry, and carrying out spray drying of the slurry to obtain alloy powder; 4, compacting the alloy powder to form a pressed compact; and 5, placing the pressed compact in a sintering furnace, heating the sintering furnace under a vacuum condition, carrying out heat insulation when the temperature in the furnace increases to 1500-1850DEG C, letting hydrogen in the sintering furnace, continuously heating to 1950-2200DEG C, and cooling with the furnace to obtain the TZM alloy. The TZM alloy prepared through adopting the method disclosed in the invention has a guaranteed carbon content, has a controlled oxygen content of below 250ppm, and is obviously better than the TZM alloy prepared through a routine powder alloy method.

Owner:JINDUICHENG MOLYBDENUM CO LTD

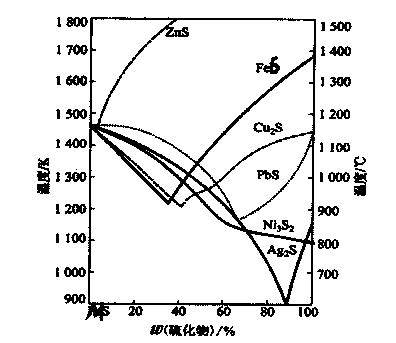

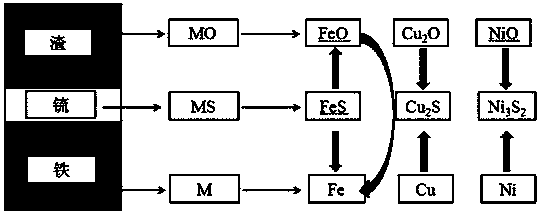

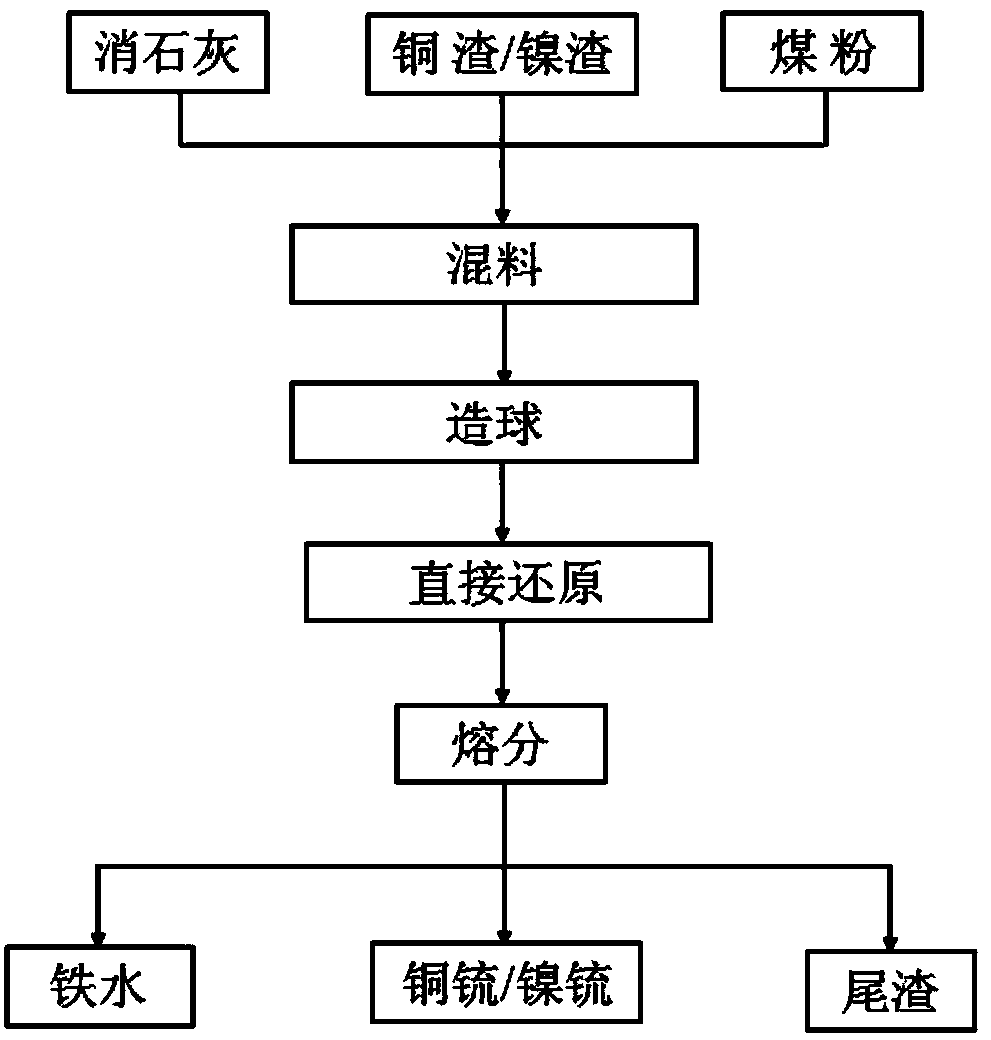

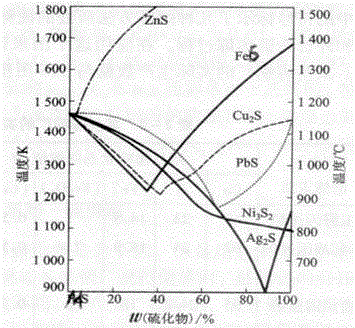

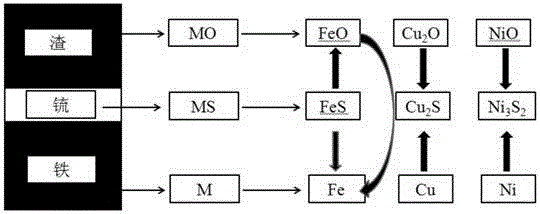

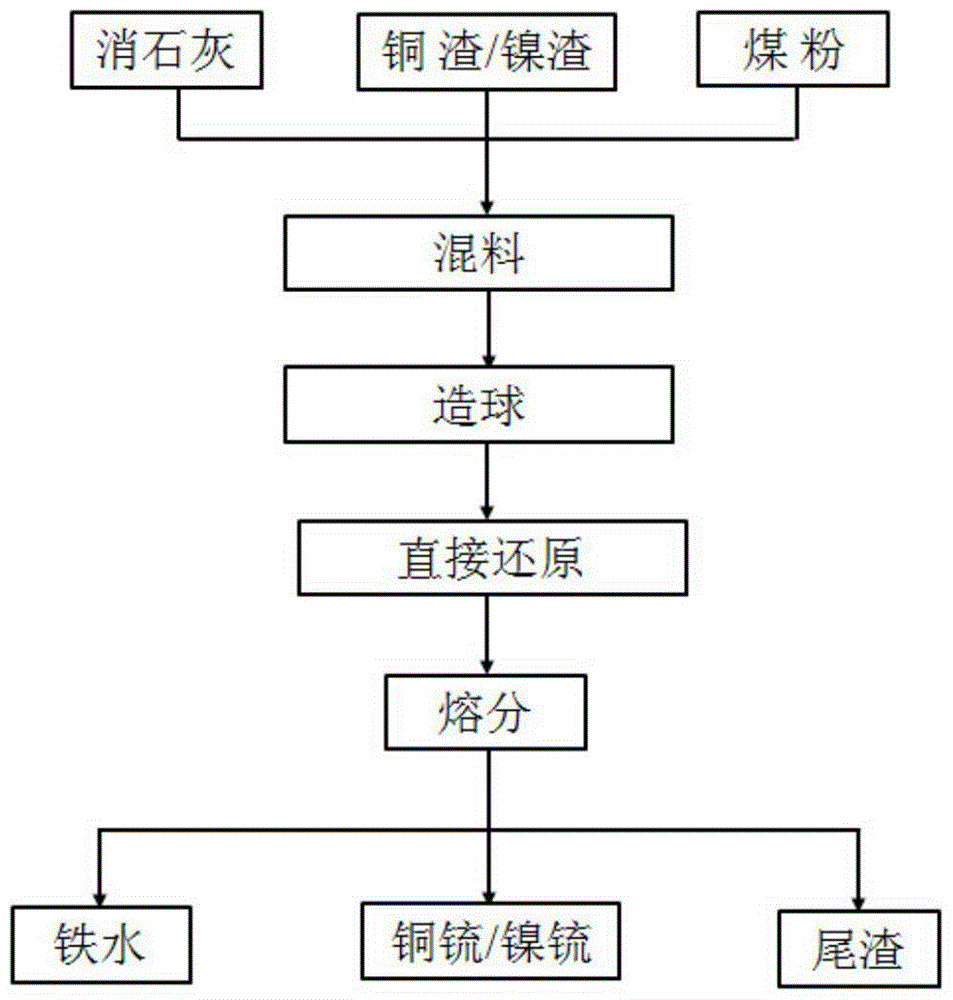

Process for one-step reduction of metallurgical composite slag to obtain molten iron and matte phase

ActiveCN104342560AAchieve separationRealize separation and recoveryProcess efficiency improvementSocial benefitsSlag

The invention discloses a process for one-step reduction of metallurgical composite slag to obtain molten iron and a matte phase, belongs to the technical fields of ferrous metallurgy and non-ferrous metallurgy, and relates to a technology for separating and recovering iron and nonferrous metals of metallurgical composite slag in a reducing melting process. The process comprises the following steps: levigating metallurgical composite slag and then feeding lime and a carbonaceous reducing agent to prepare a carbon-containing pellet; directly restoring the carbon-containing pellet and then achieving slag-matte-iron three-phase layering in a melting furnace; and respectively recovering iron and nonferrous metals. The process is capable of achieving separation of iron and nonferrous metals, and gathering the nonferrous metals into the matte phase to play a comprehensive recovery role in a plurality of metal elements; a serious environment problem is caused by stacking of the metallurgical slag, and great waste of resources is also caused, so that the current situation of utilization of the metallurgical slag is greatly changed by the process; considerable economic benefits and social benefits are generated; and the process has a wide application prospect.

Owner:CENT IRON & STEEL RES INST +1

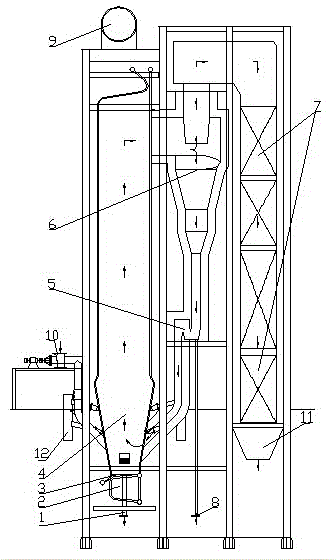

Decarburization method of coal gangue and circulating fluidized bed mineral separating boiler

InactiveCN104100967AHigh thermal efficiencyGuaranteed carbon contentFluidized bed combustionClinker productionEngineeringCalcination

A decarburization method of coal gangue and a circulating fluidized bed mineral separating boiler. The decarburization method comprises the following steps: (1), crushed and dried coal gangue is placed in a fluidized bed combustor of a fluidized bed boiler to be combusted, heat is transferred to the boiler wall by high-temperature flue gas generated by the combustion of the coal gangue, so that the temperature of the boiler furnace is improved to 850 to 950 DEG C, and the coal gangue is combusted completely to be further decarburized; (2), the high-temperature flue gas generated by the combustion of the coal gangue is separated through a cyclone separator, so that vanadium in the coal gangue can be extracted by stage in the form of vanadium pentoxide according to the graded distribution of the furnace pressure of the fluidized bed; the invention further provides the fluidized bed mineral separating boiler. According to the invention, electricity generation, supply of heat, calcination and efficient and integrated mineral separation can be achieved, the coal gangue can be decarburized till 2% of residual carbon, and the heat efficiency of the fluidized bed mineral separating boiler is improved by 5% above.

Owner:HUNAN CHANGHONG BOILER

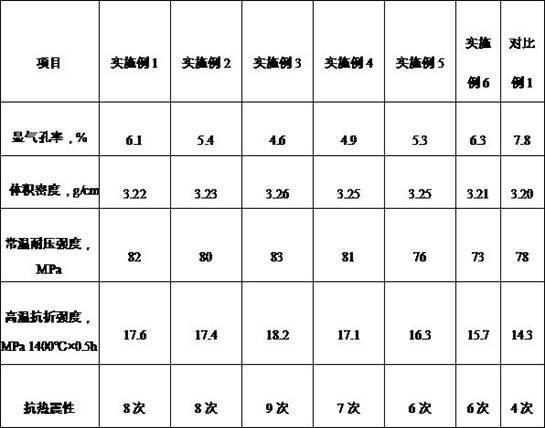

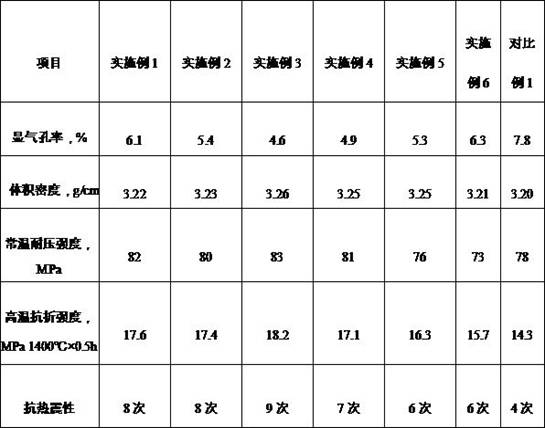

Novel low-carbon aluminum-magnesium spinel carbon brick with high thermal shock resistance and preparation method of novel low-carbon aluminum-magnesium spinel carbon brick

The invention relates to a novel low-carbon aluminum-magnesium spinel carbon brick with high thermal shock resistance and a preparation method of the novel low-carbon aluminum-magnesium spinel carbon brick. The brick comprises 1-90 parts of a corundum spinel carbon reclaimed material, 1-50 parts of corundum particles, 1-40 parts of fused magnesite, 1-40 parts of corundum dedusting powder, 1-8 parts of active alpha-alumina micro powder, 1-10 parts of a spinel-calcium aluminate multiphase material, 0.1-3 parts of metal aluminum powder, 0.1-5 parts of nano carbon black and 1-8 parts of a binding agent. The invention aims to provide a novel high-thermal-shock-resistance low-carbon aluminum-magnesium spinel carbon brick, which solves the problem that in the prior art, materials such as tabular corundum, white corundum, fused magnesite, crystalline flake graphite, spinel micro powder, alumina micro powder and silicon carbide fine powder are used as raw materials; the steel ladle brick is obtained by high-temperature firing, great pollution is caused to the environment, and the raw material cost is high.

Owner:北京利尔高温材料股份有限公司

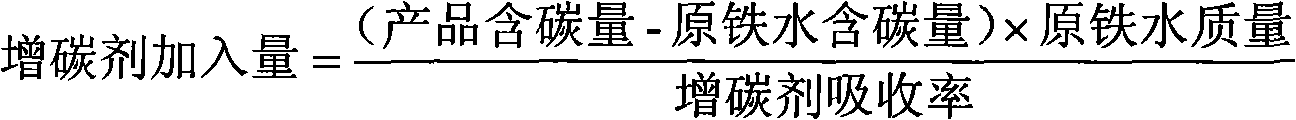

Method for smelting ductile cast iron

InactiveCN101671754AReduce manufacturing costReduce labor intensityProcess efficiency improvementScrapIron filings

The invention discloses a method for smelting ductile cast iron, which comprises the following steps: adding returning iron, scrap iron and scrap steel into a long coil melting furnace layer by layerfor being melted into ductile cast iron base iron, and then adding a recarbonizer, wherein the ingredients are in the following proportion: 35-40 percent of scrap iron or scrap steel and 60-65 percentof returning iron. The scrap steel, the scrap iron and the recarbonizer are used for replacing past pig iron raw materials with higher price, thereby well saving the production cost, facilitating theproduction according to the produced products with different brands and different carbon contents, reducing the labor intensity, ensuring the strict carbon contents of the products, and improving thequality of the products.

Owner:QINGTE GRP

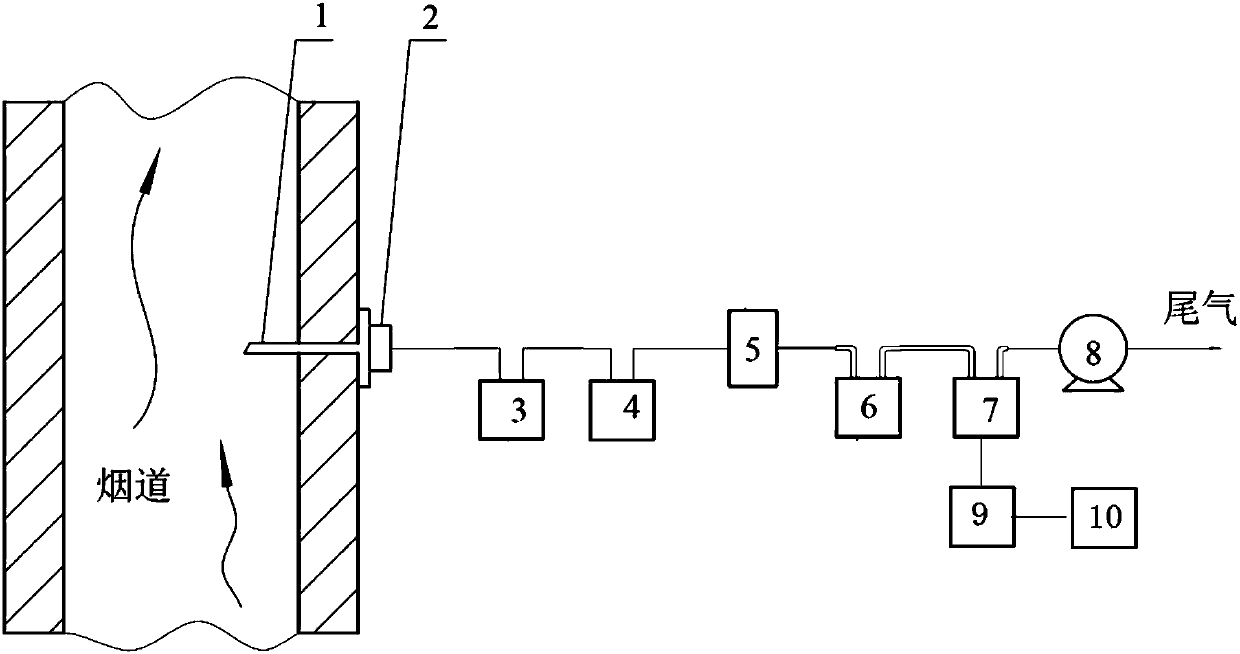

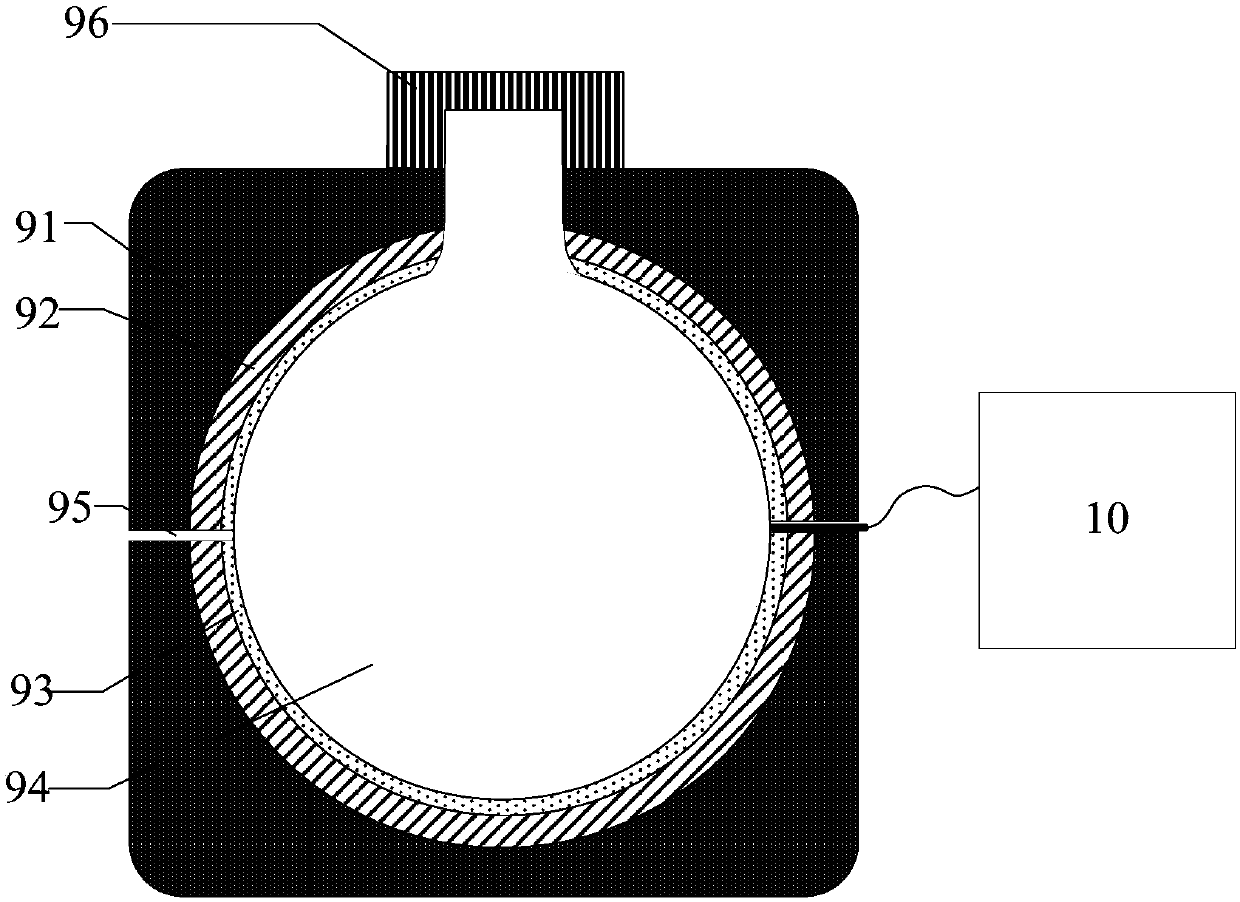

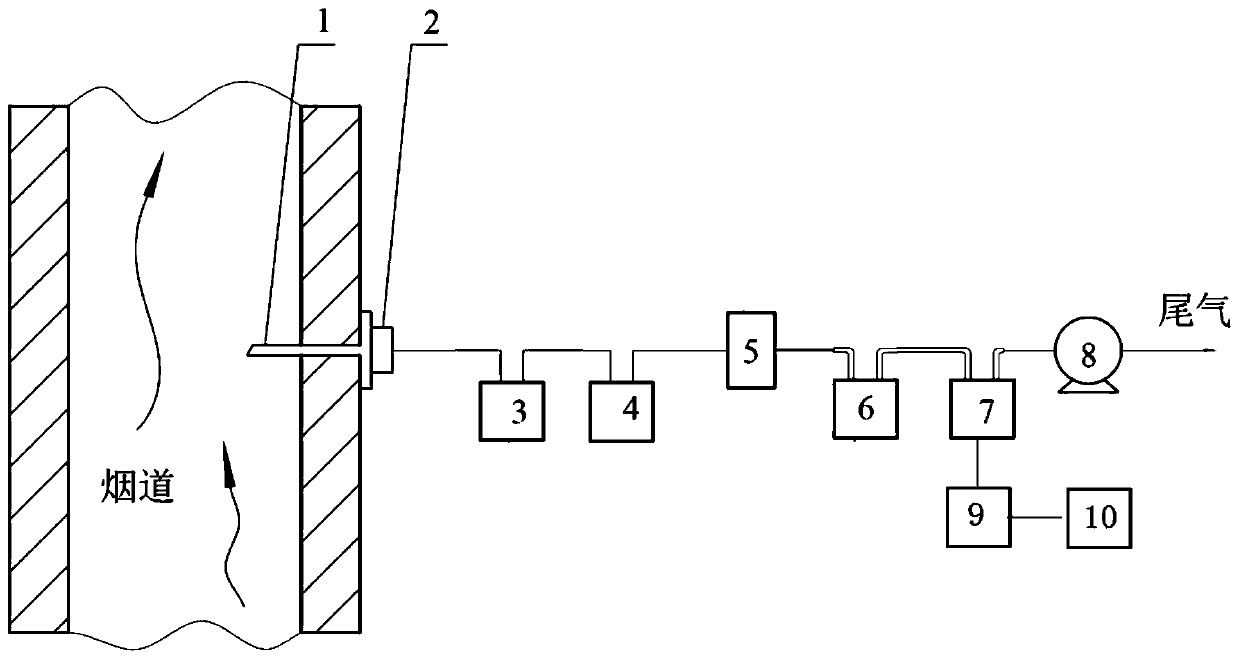

Carbon-14 testing sample bottle and test method, and sampling and sample preparation system for testing mixed combustion ratio of coal-mixed biomass power station

ActiveCN107942368AHigh purityIncreased specializationX/gamma/cosmic radiation measurmentPower stationTest sample

The invention provides a carbon-14 testing sample bottle and test method and a sampling and sample preparation system for a mixed combustion ratio of a coal-mixed biomass power station. The carbon-14testing sample bottle and test method and the sampling and sample preparation system can help overcome lack of effective monitoring means for the mixed combustion of a conventional coal-mixed biomasscombustion power station and monitor a biomass mixed combustion ratio of a coal-mixed biomass combustion power station, and data is provided for biomass mixed combustion monitoring and subsidy-relatedwork. Compared with conventional methods, the carbon-14 testing sample bottle and test method and the sampling and sample preparation system are advantageous in that short detection period can be realized when the biomass mixed combustion ratio is low, accuracy of detection results can be improved, and the coal-mixed biomass combustion power plant is integrated with a mixed combustion ratio monitoring station.

Owner:ZHEJIANG UNIV

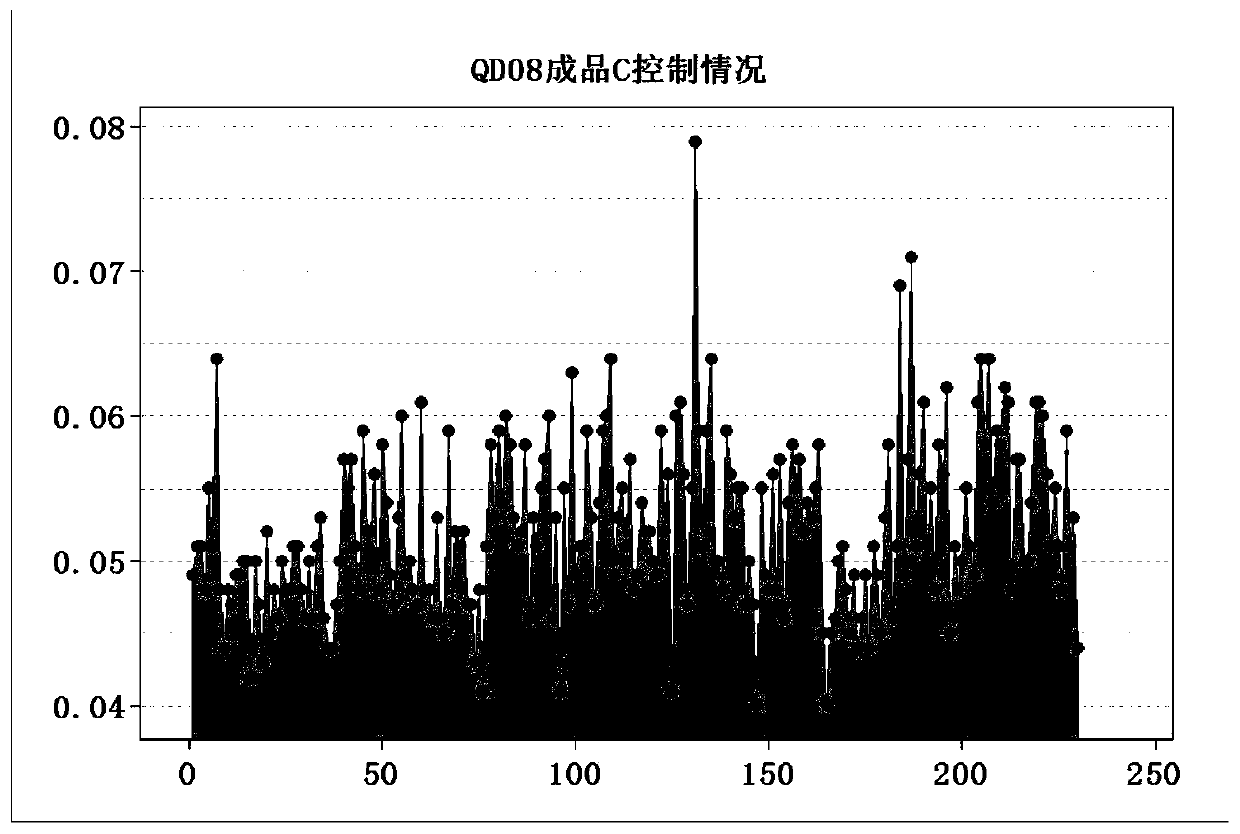

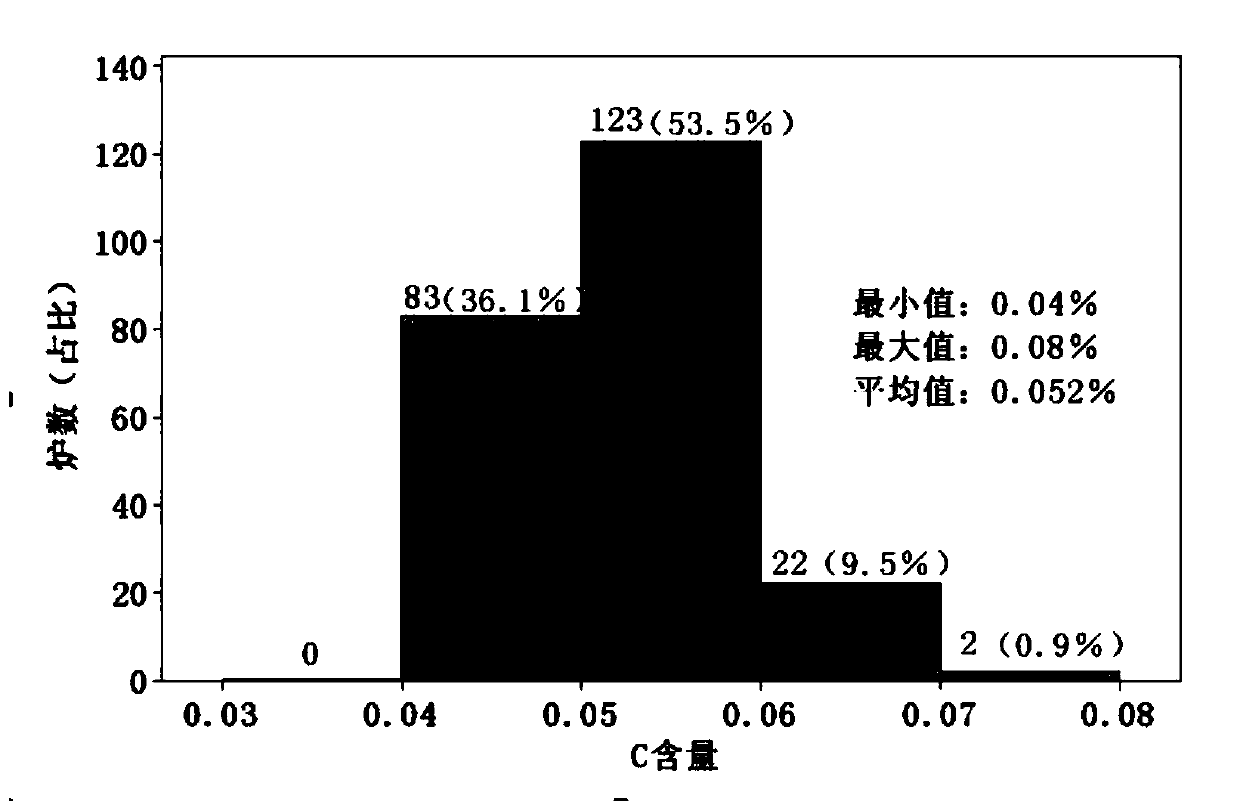

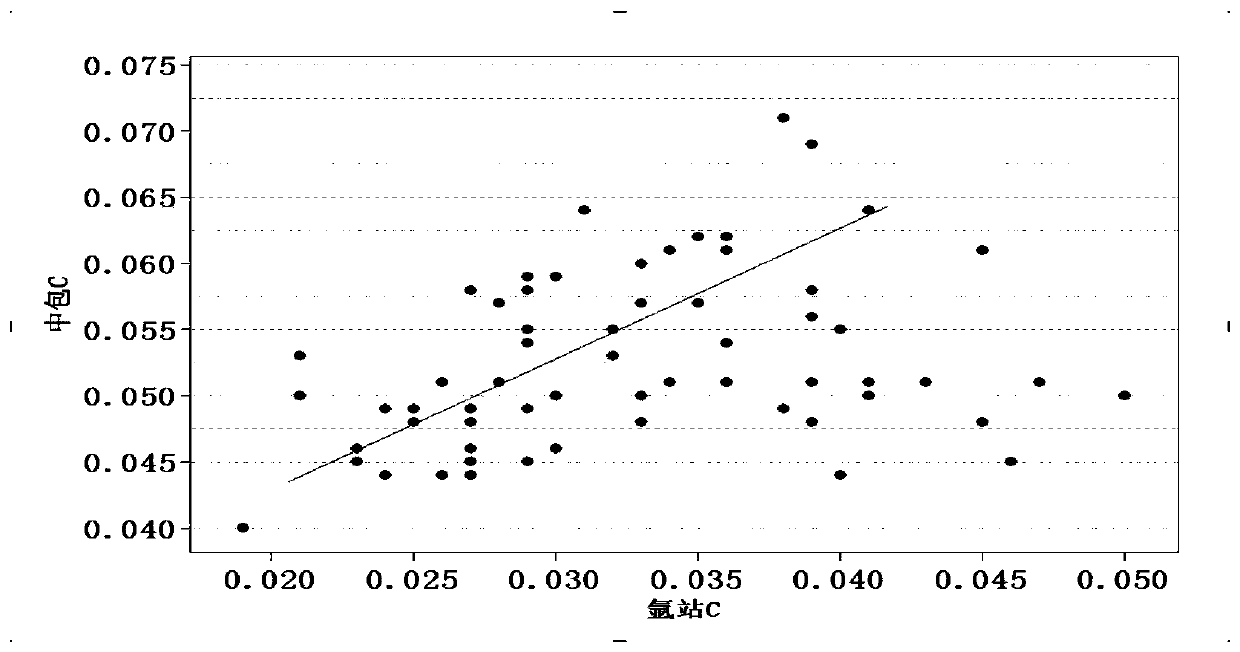

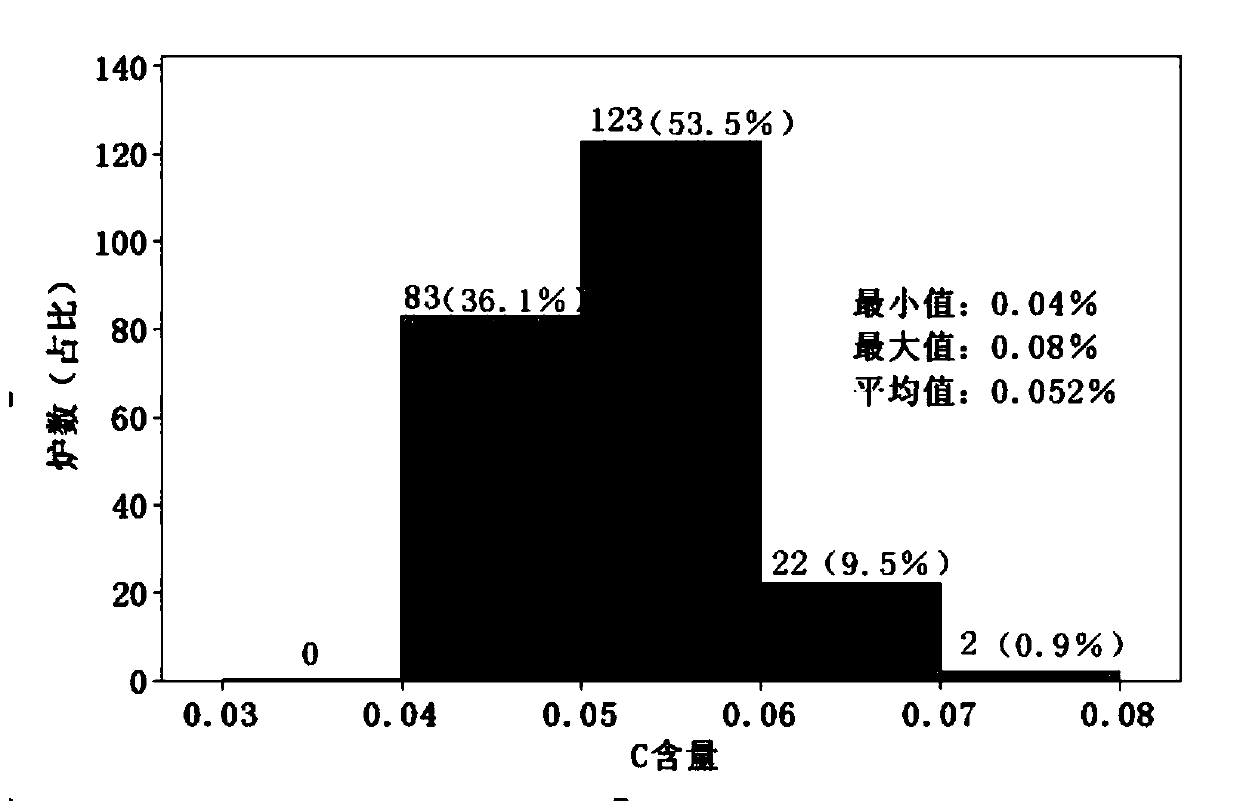

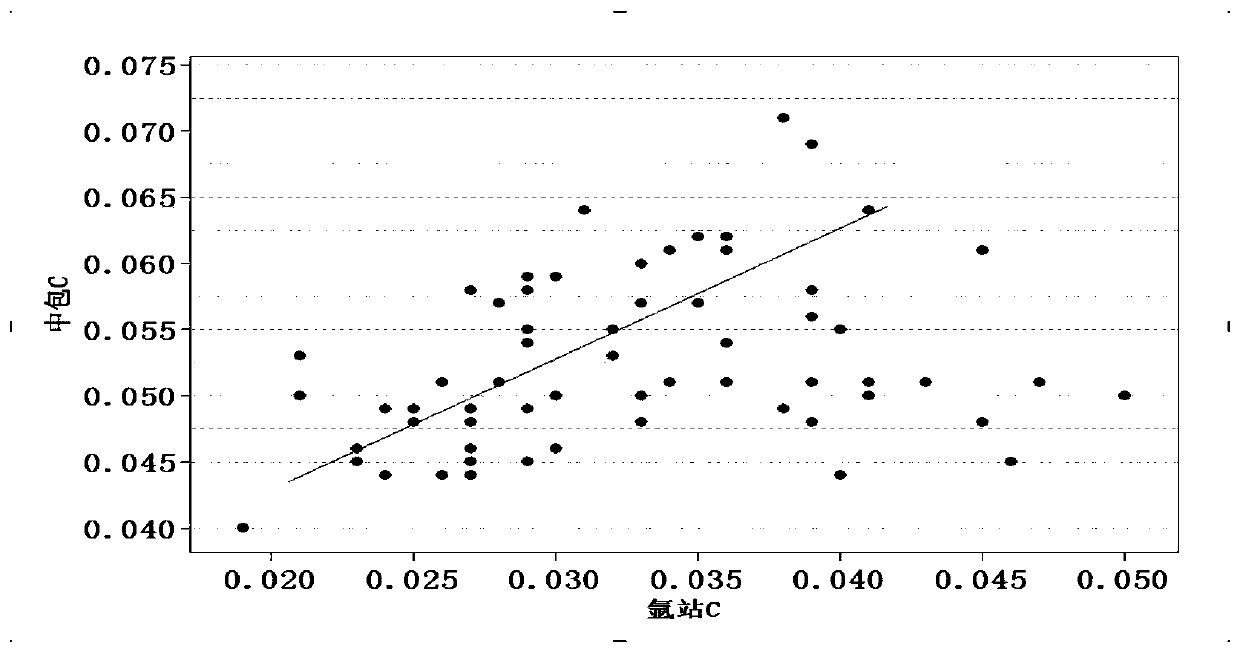

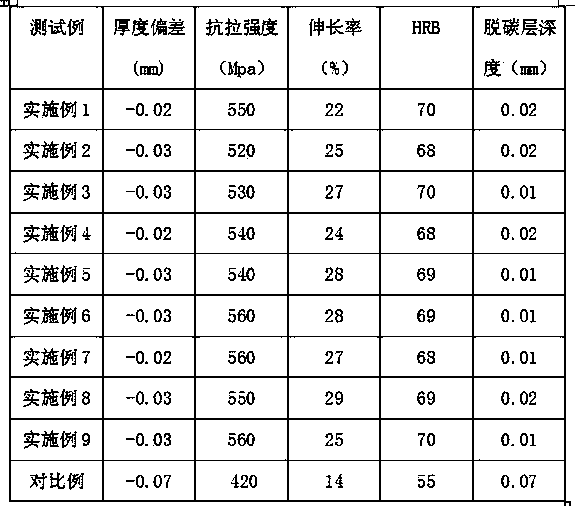

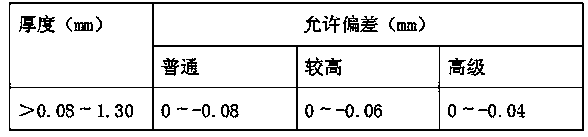

Low-carbon steel carbon content stably-controlled smelting method

ActiveCN110468335AReduce tap carbon contentIncrease tapping temperatureManufacturing convertersSmelting processProcess capability

The invention discloses a low-carbon steel carbon content stably-controlled smelting method. The smelting method includes converter smelting, LF refining and continuous casting. According to the method, by reasonably optimizing process parameters and enhancing process capability control, the carbon content can also be stably controlled within 0.05% without RH vacuum processing, the finished product carbon fluctuation range is small and is controlled at 0.03%-0.05%, the target value hit rate is high, product quality stability is facilitated, and judgement amending or scrapping caused by errantcomponents is reduced. The RH decarburization working procedure is not needed; by means of regulation and cooperation of all step conditions, the carbon steel carbon content is stably controlled at 0.03%-0.05%, and the inclusion content is low; and compared with frequently-used smelting process converter-RH decarburization-LF treatment-continuous casting, operation is easy, the production efficiency is high, and the cost of each ton of steel is effectively reduced.

Owner:ZENITH STEEL GROUP CORP

Micro-carbon, aluminium, manganese, titanium and ferrous alloy for terminal deoxidizing and alloying_of molten steel and preparation method thereof

InactiveCN1908195AEasy to useThe content is easy to control and reach the standardChemical compositionAlloy

the invention discloses a micro-carbon Al-Mn-Ti-Fe alloy and preparing method, which comprises the following parts: 40-60% Al, 2-10% Mn, 1-10% Ti, not more than 0.08% C and Fe. the preparing method comprises the following steps: allocating metal Al, Mn, Ti and optimum waste steel; fusing in the line frequency electric furnace; fusing; deslagging; stewing; casting.

Owner:代腾飞

Ultra-high purity purifying technique for native graphite

The invention discloses a hyper-high purity extracting technology of natural graphite, which comprises the following steps: (1) putting natural graphite in the container to do oxidizing disposal with low-middle carbon content more than 98%; (2) fusing at high temperature; (3) inputting in the metal erosion-proof container; proceeding dealkalization; (4) deacidifying to wash to neutral; (5) proceeding electromagnetic black metal removing disposal in the floating pool; (6) heating in the autoclave from 118 deg, 206 deg and 220 deg separately; (7) using pure water to dispose; (8) dehydrating; (9) drying until the water content is less than 0.1%.

Owner:LUOYANG GUANQI INDAL & TRADE

Activated rubber powder and preparation method thereof

InactiveCN111019208AIncrease the amount addedGuaranteed desulfurization effectBuilding insulationsAsphaltSulfur hydride

The invention discloses an activated rubber powder and a preparation method thereof. The activated rubber powder comprises the following components: a rubber powder, waste engine oil, an essence and astrong resin. The preparation method of the activated rubber powder comprises the following steps: preparing 60-mesh rubber powder by taking waste tires as raw materials; adding waste engine oil, theessence and the strong resin into 60-mesh rubber powder, mixing, putting an obtained mixture into a desulfurization tank, introducing 0.3 Mpa of steam into the desulfurization tank, and releasing pressure and exhausting when the pressure in the desulfurization tank reaches 0.9 Mpa to obtain a modified rubber powder; and cooling the modified rubber powder to below 40 DEG C, screening out caked rubber powder by using a vibrating screen paved with a 20-mesh screen, metering, and packaging to obtain the finished product activated rubber powder. The preparation method is used for solving the problems that the existing common rubber powder has unobvious modification effect on asphalt and can discharge a large amount of carbon dioxide, hydrogen sulfide and other gases in the use process.

Owner:雅安和鑫橡塑有限责任公司

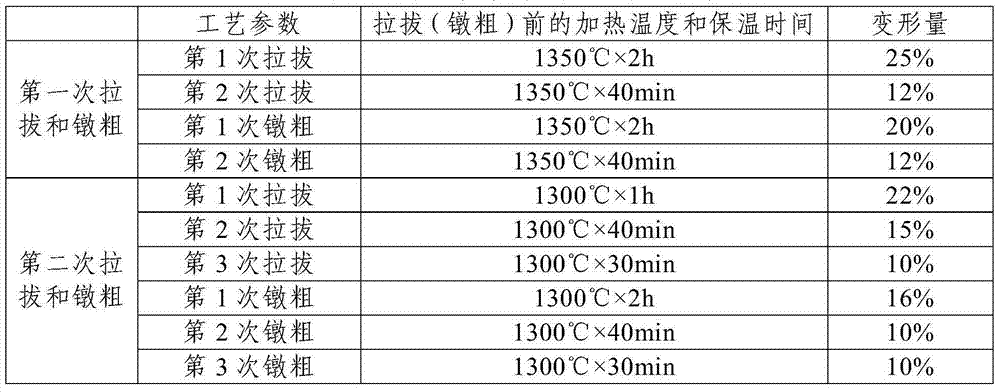

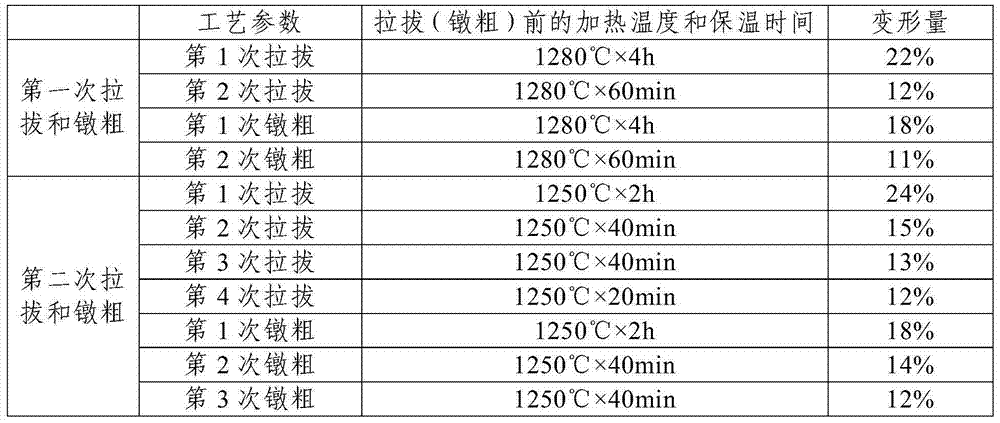

Preparation method of molybdenum alloys for isothermal forging die

The invention discloses a preparation method of molybdenum alloys for an isothermal forging die. The method includes the steps that first, molybdenum powder, additive powder, auxiliary additive powder and carbon powder are placed in a blender mixer to be evenly mixed so that alloy powder can be obtained, wherein the additive powder is titanium carbide and / or zirconium carbide; second, the alloy powder is pressed into pressed compact; third, the pressed compact is placed into a sintering furnace to be sintered, and after the pressed compact is cooled along with the furnace, molybdenum alloy blank is obtained; fourth, multi-pass drawing is conducted on the molybdenum alloy blank, and then multi-pass upsetting is carried out on the drawn molybdenum alloy blank; fifth, annealing treatment is conducted on the upset molybdenum alloy blank, and the molybdenum alloys for the isothermal forging die can be obtained after the molybdenum alloy blank is cooled along with the furnace; or the step four is repeated for one to two times for the upset molybdenum alloy blank, then the annealing treatment is conducted, and the molybdenum alloys for the isothermal forging die can be obtained after the molybdenum alloy blank is cooled along with the furnace. By means of the method, the prepared molybdenum alloys are even in structure and good in performance, and the molybdenum alloys are obviously superior to molybdenum alloys of the same kind prepared through an existing conventional method.

Owner:JINDUICHENG MOLYBDENUM CO LTD

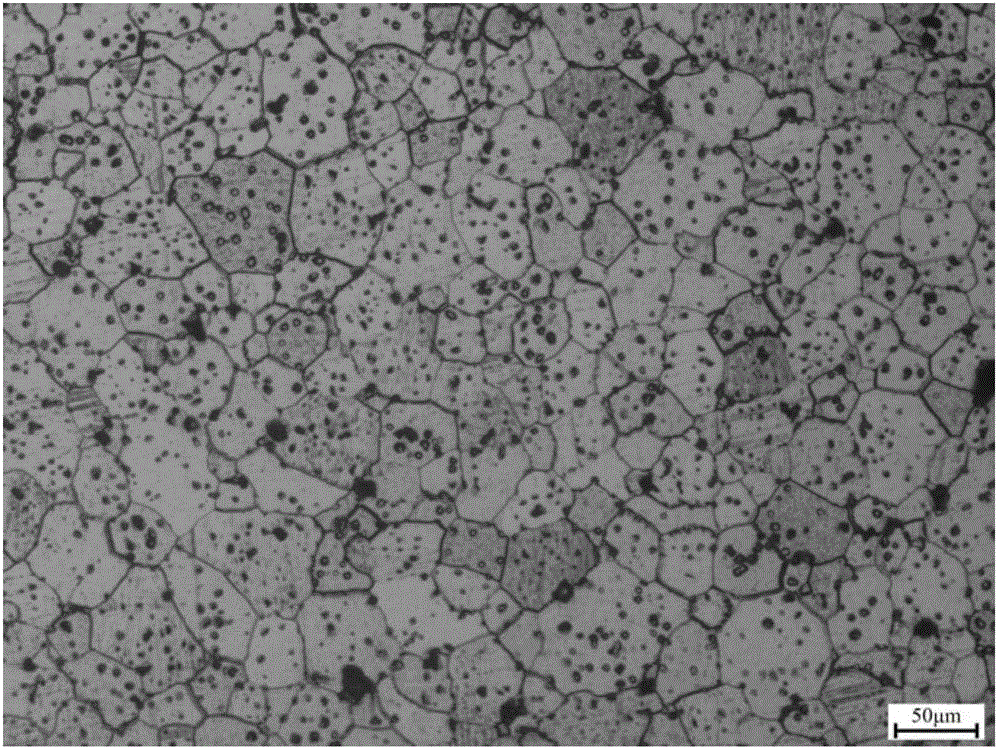

Wear-resistant high-toughness steel material and preparation method thereof

ActiveCN113005371AImprove toughnessImprove anti-wear performanceMetal-working apparatusMolten steelSodium silicate

The invention relates to a wear-resistant high-toughness steel material and a preparation method thereof, and belongs to the technical field of special steel material preparation. According to the wear-resistant high-toughness steel material and the preparation method thereof, firstly, the toughness and mechanical strength of the steel material are preliminarily enhanced through a special molten steel formula, and then a tungsten carbide material with interlayer sliding anti-friction performance is prepared by using expanded graphite as a template and is used as an anti-wear filler, so that the wear resistance and toughness of the steel material are improved; and in addition, sodium silicate and hydrochloric acid are used for further modifying the surface of the wear-resistant material, the wear resistance and toughness of the steel material are further improved through modification, and the wear-resistant high-toughness steel material and the preparation method thereof have wide application prospects.

Owner:常州亿富泰特钢有限公司

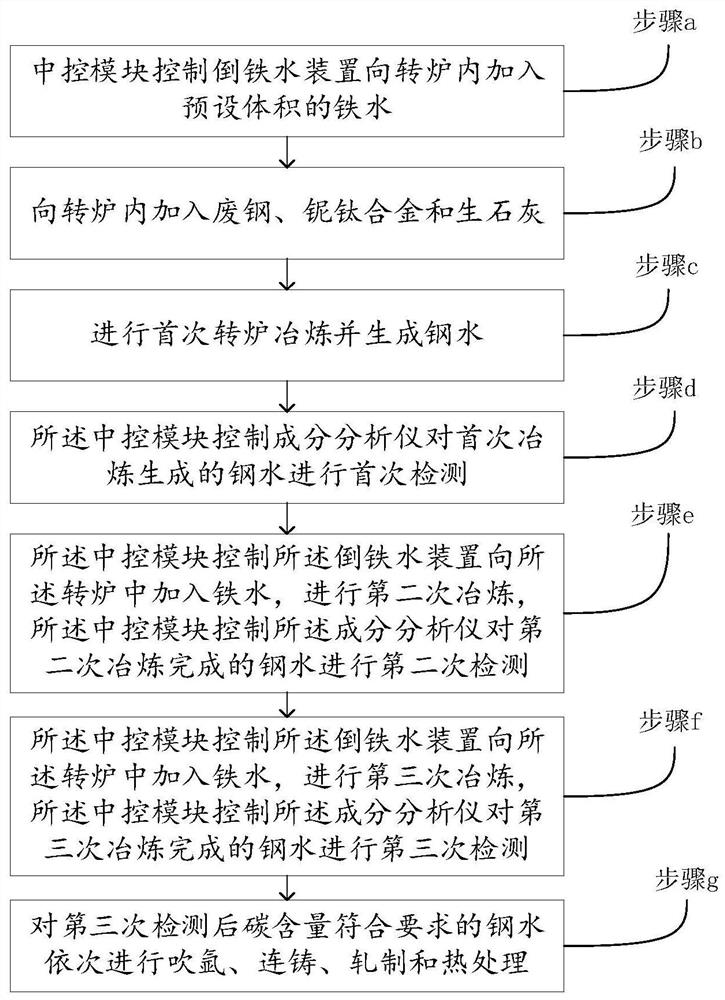

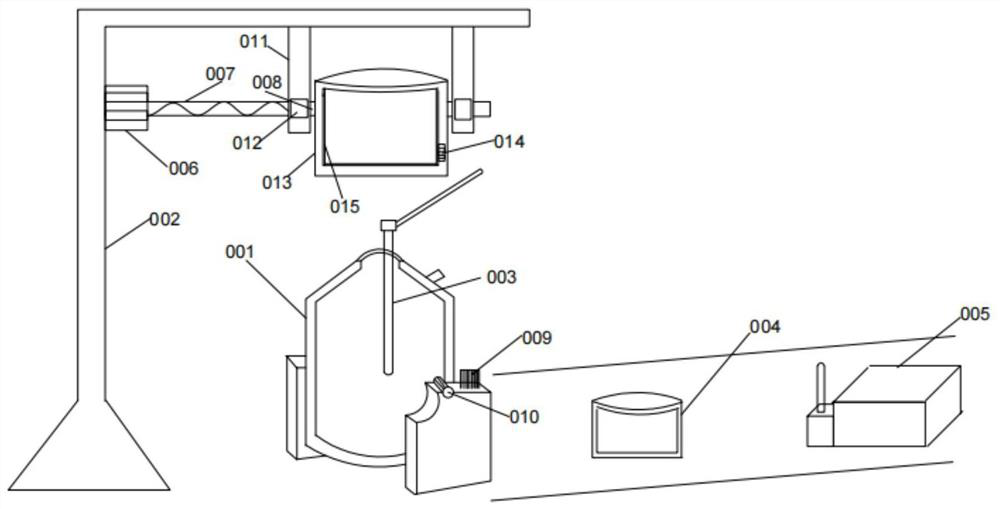

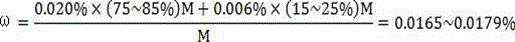

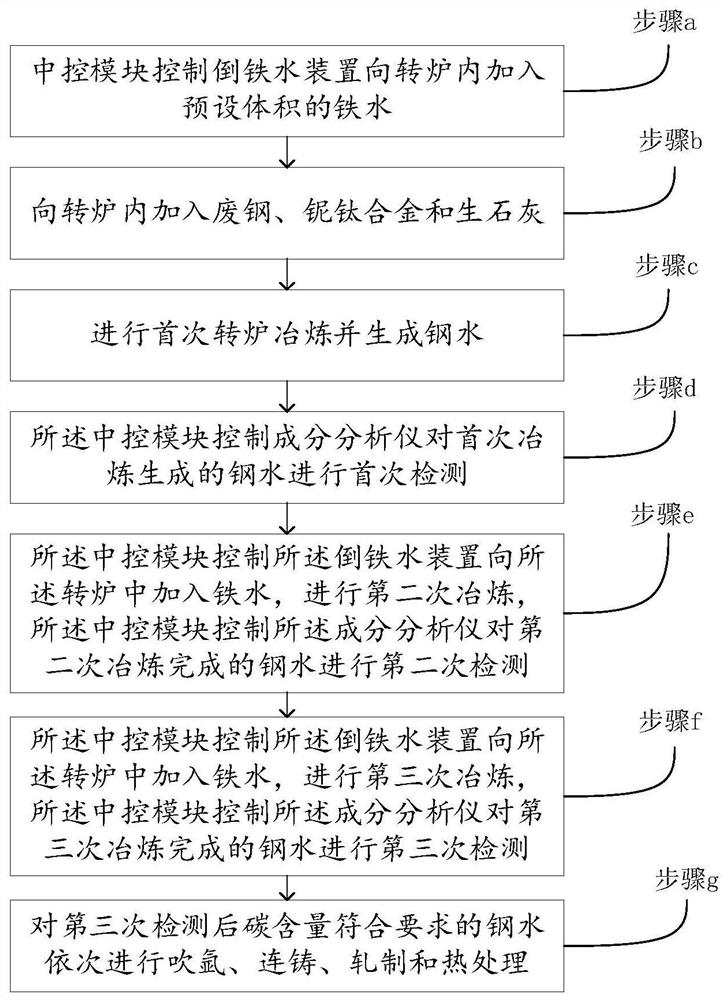

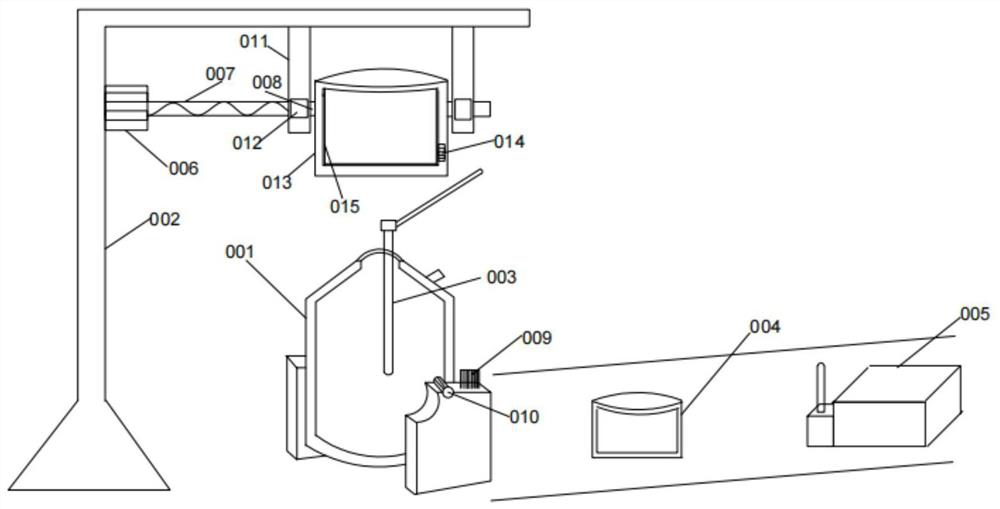

Preparation method of HRB500E niobium-containing titanium alloy deformed steel bar

ActiveCN113106188AQuality assuranceGuaranteed accuracyManufacturing convertersProcess efficiency improvementAlloy steelTitanium alloy

The invention relates to a preparation method of an HRB500E niobium-containing titanium alloy deformed steel bar, and relates to the technical field of alloy steel. The preparation method comprises the following steps: step a, controlling, by a central control module, a molten iron pouring device to add a preset volume of molten iron into a converter; step b, adding waste steel, a niobium-titanium alloy and quick lime into the converter; step c, carrying out first-time converter smelting to generate molten steel; step d, carrying out first detection on the molten steel generated by the first smelting; step e, adding the molten iron into the converter, carrying out secondary smelting, and carrying out secondary detection on molten steel obtained after secondary smelting is completed; step f, controlling, by the central control module, the molten iron pouring device to add the molten iron into the converter for third-time smelting, and detecting the molten steel obtained after third-time smelting for the third time; and step g, carrying out argon blowing, continuous casting, rolling and heat treatment sequentially on the molten steel with the carbon content meeting the requirement after third-time detection. According to the method, the quality of the produced deformed steel bar is effectively improved.

Owner:福建三宝钢铁有限公司

Method for smelting primary steel making liquid for high-alloy steel casting

InactiveCN105087861AControl Phosphorus ContentGuaranteed carbon contentProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

A method for smelting primary steel making liquid for a high-alloy steel casting includes the following steps that a preset amount of low-phosphorous slag-free molten steel of the last time is reserved in an electric arc furnace, and high-alloy returns are added into the electric arc furnace; high-alloy returns in an electric melting furnace are conveyed to the electric arc furnace, a power supply is cut off after 70%-80% of the high-alloy returns are melted, then high-alloy returns are added again, power is supplied, an oxygen blowing pipe extends into the furnace after the high-alloy returns become red and molten steel appears when the furnace is inclined, and oxygen is blown towards the high-alloy returns exposed out of the molten steel to complete cutting; large high-alloy return blocks are prevented from being attached to the wall of the electric arc furnace, and the large high-alloy return blocks exposed outside the molten steel are cut and smashed, fall into the molten steel and are quickly molten. After the content of phosphorus in the molten steel meets the preset technical requirements, an aluminum block, CaSi grains and aluminum grains are inserted into the molten steel, and sample analysis is carried out after 15 min; when the mass fraction of Al accounts for 0.03%-0.06% of the total mass of the molten steel and added reduction agents, steel is output.

Owner:KOCEL STEEL

Manufacturing process of round pipe steel of chain

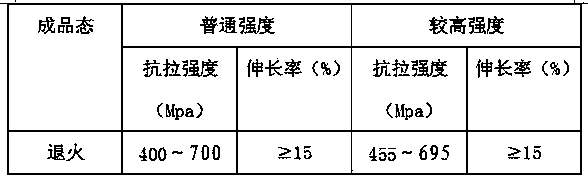

InactiveCN102886651AImprove mechanical propertiesAvoid deformationFurnace typesMetallic material coating processesNitrogenUltimate tensile strength

The invention relates to a manufacturing process of steel of a chain, in particular to a manufacturing process of round pipe steel of a chain, belonging to the processing industry of steels. The manufacturing process of the round pipe steel of the chain comprises orderly processing a belt material by the following steps in sequence: de-rusting, rolling, annealing, acid cleaning, phosphating, washing with clear water, saponifying, flattening and coiling to form round pipe, wherein the rolling is four continuous rolling or five continuous rolling; the annealing is divided into three steps: the first step is heating insulating treatment, wherein the rolled belt material is fed into an annealing furnace to be heated, nitrogen is fed in the annealing furnace when the annealing furnace is heated to 450-500 DEG C, the temperature is kept for 5-7 hours after the heating temperature reaches 670-700 DEG C; the second step is furnace cooling, and the belt material treated by the heating insulating treatment is cooled to be 300-400 DEG C in the annealing furnace. The manufacturing process of the round pipe steel of the chain is simple in process and low in cost; the manufactured steel plate for the round pipe of the chain is high in strength, corrosion resistant and high in precision.

Owner:ZHEJIANG ANJI LUYAO METAL PRODS

Steelmaking method through medium-frequency electric furnaces

InactiveCN105525057AImprove power utilizationSignificant power savingProcess efficiency improvementElectric furnaceSteelmakingElectricity

The invention provides a steelmaking method through medium-frequency electric furnaces. According to the steelmaking method, the electric furnace A and the electric furnace B both controlled by a medium-frequency cabinet are involved, raw material is proportioned according to the requirement, the proportioned steel material is equally distributed to the electric furnace A and the electric furnace B, the steel material in the electric furnace A is smelted at 100% power, after the set time is up, molten iron in the electric furnace A is covered with thermal insulation agents for thermal preservation, a power source of the electric furnace A is cut off through a control cabinet, then the steel material in the electric furnace B is smelted at 100% power, and tapping is carried out after the temperature in the electric furnace A and the temperature in the electric furnace B reach the set tapping temperature. When the temperature in the electric furnace A reaches the set tapping temperature earlier than the temperature in the electric furnace B, tapping is firstly carried out for the electric furnace A, and the electric furnace B is covered with the thermal insulation agents for thermal preservation. The steelmaking method is simple and convenient, the quality of produced products is stable, the electric furnaces do not need to be transformed, the utilization rate of the electric energy is high, the electricity is obviously saved, the production efficiency is improved, and the input-outputratio is high.

Owner:TIANJIN ZHONGDA PRECISION MACHINERY

A smelting method for stable control of carbon content in low carbon steel

ActiveCN110468335BReduce tap carbon contentIncrease tapping temperatureManufacturing convertersSmelting processProcess engineering

Owner:ZENITH STEEL GROUP CORP CO LTD

Manufacturing process of round pipe steel of chain

InactiveCN102886651BImprove mechanical propertiesAvoid deformationFurnace typesMetallic material coating processesSheet steelNitrogen

Owner:ZHEJIANG ANJI LUYAO METAL PRODS

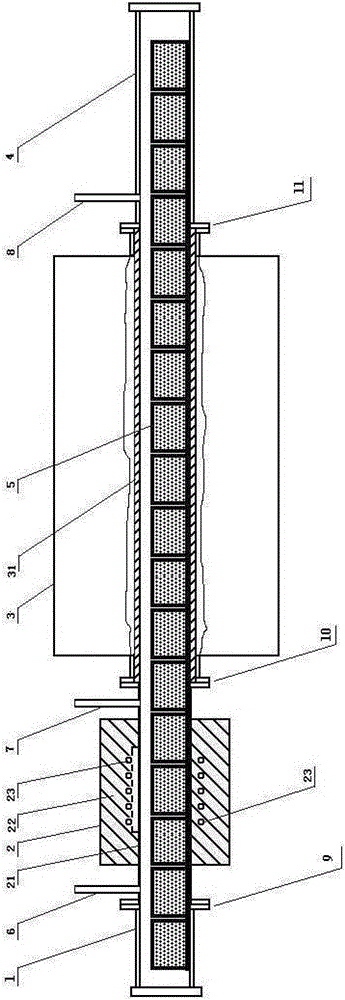

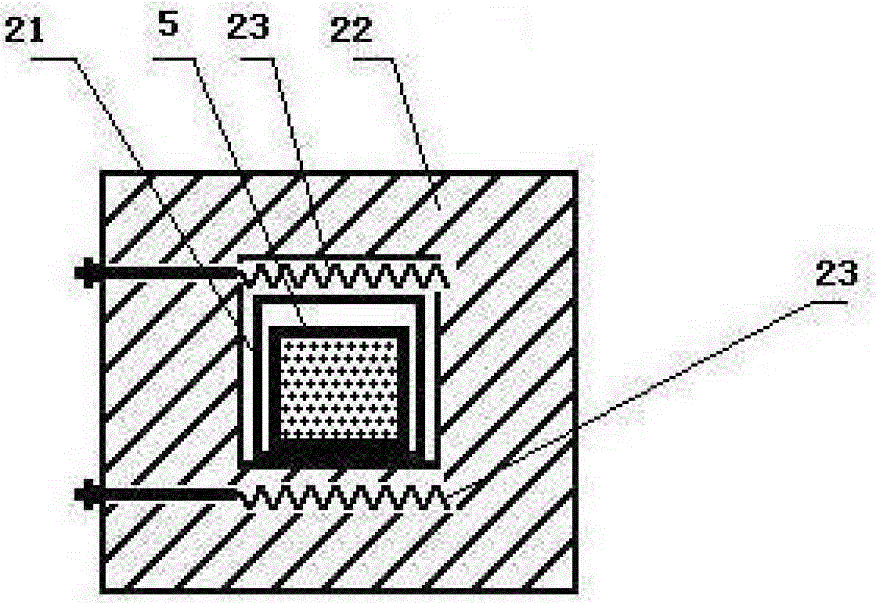

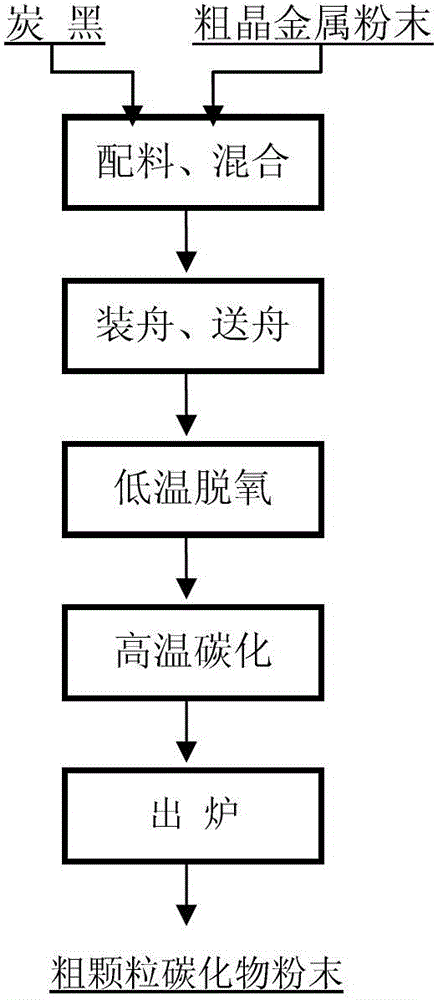

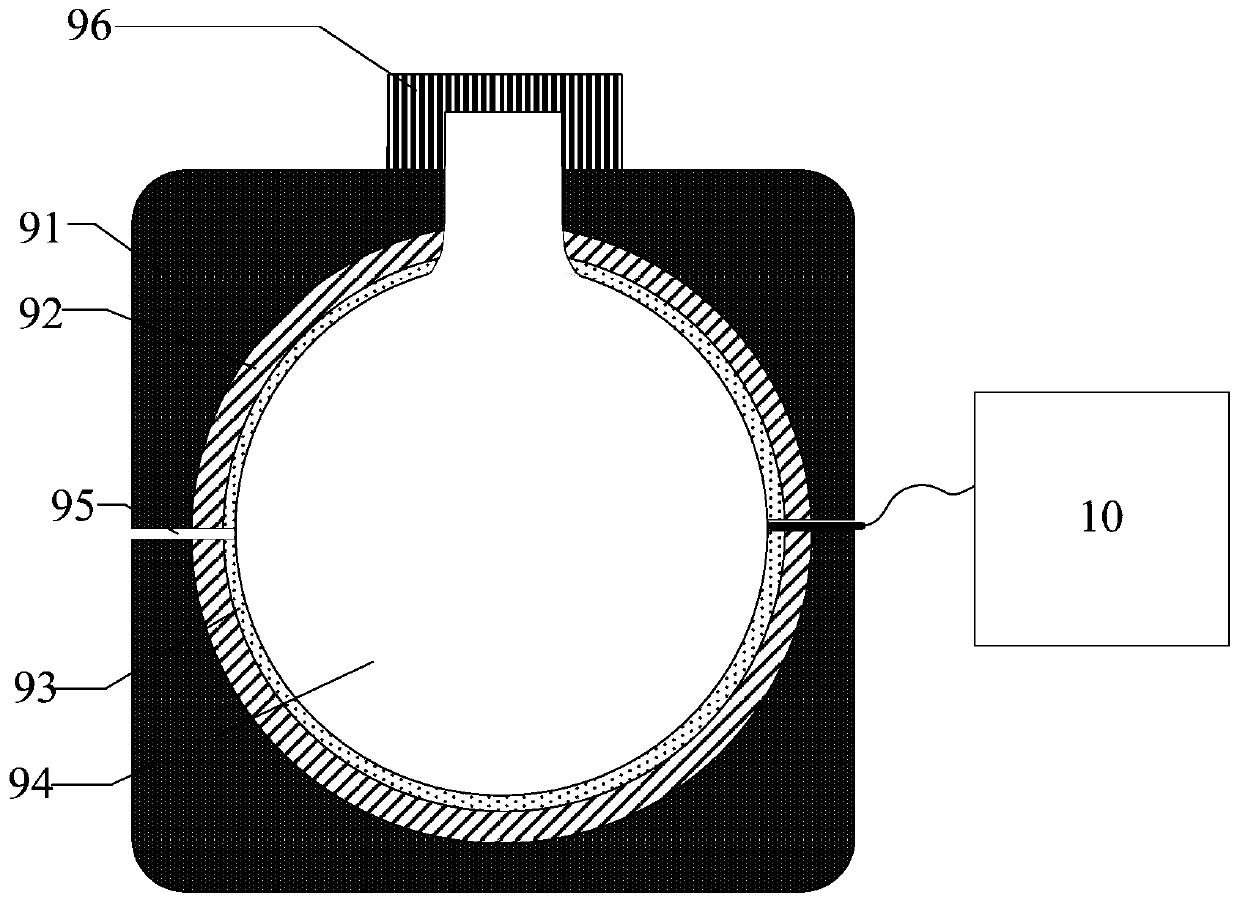

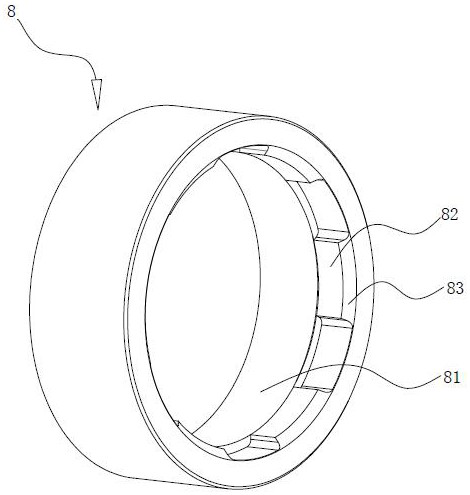

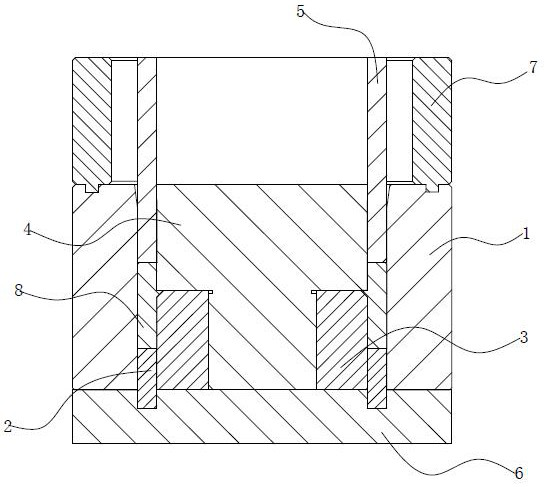

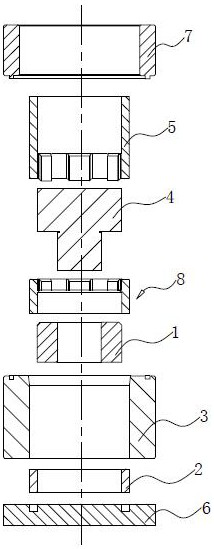

Continuous high-temperature carbonization furnace and method for continuously producing coarse-grained carbide powder

ActiveCN103033044BExtend furnace repair periodGuaranteed carbon contentFurnace typesTungsten/molybdenum carbideCarbideWorking temperature

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

A composite briquette binder

ActiveCN110747029BGood connection effectImprove joint stabilitySolid fuelsWaste based fuelLactobacillusBriquette

The invention discloses a composite shaped coal binder, which belongs to the field of shaped coal. The present invention uses lithium-based grease, sodium-based bentonite, sodium aluminosilicate, etc. as raw materials to prepare briquette binder A, wherein lithium-based grease has good anti-fretting wear performance, and the added hydrogen-containing silicone oil may also provide hydrophobic At the same time, it can help improve the bonding stability of the blend, improve the binding effect on coal powder particles, and stably improve the thermal efficiency and molding effect of briquettes; fish skin, rice straw, Lactobacillus bulgaricus, etc. Co-fermentation uses microbial metabolism to destroy fish skin and straw tissue to obtain colloids and sugars, while ensuring cohesiveness and increasing carbon content. The invention solves the problems of high ash content, low carbon content and poor structural stability in the briquette prepared by the conventional briquette binder.

Owner:曲阳县建硕型煤有限公司

A kind of preparation method of hrb500e niobium-titanium alloy rebar

ActiveCN113106188BQuality assuranceGuaranteed accuracyManufacturing convertersProcess efficiency improvementMolten steelRebar

The invention relates to a preparation method of HRB500E niobium-titanium alloy threaded steel, and relates to the technical field of alloy steel. Add scrap steel, niobium-titanium alloy and quicklime; step c, carry out first converter smelting and generate molten steel; step d, first detect the molten steel generated by first smelting; step e, add molten iron to the converter, and carry out second smelting, The molten steel that has been smelted for the second time is detected for the second time; in step f, the central control module controls the molten iron pouring device to add molten iron to the converter, and the third smelting is performed. Carry out the third detection; step g, sequentially perform argon blowing, continuous casting, rolling and heat treatment on the molten steel whose carbon content meets the requirements after the third detection. The method of the invention effectively improves the quality of the rebar produced.

Owner:福建三宝钢铁有限公司

A kind of preparation method of tzm alloy material

The invention discloses a preparation method of a TZM alloy material, which comprises following steps: 1. putting molybdenum powder, additive powder, auxiliary additive powder and carbon powder in a blender mixer for uniform mixing to obtain alloy powder; 2. fabricating the alloy powder into a compact; 3. putting the compact into a sintering furnace, heating the sintering furnace under a vacuum condition, conducting heat preservation for 3-5 h when the temperature in the furnace is heated to 1,500 DEG C to 1,850 DEG C, inletting hydrogen into the sintering furnace, increasing the temperature continuously to 1,950 DEG C to 2,200 DEG C, conducting insulated sintering for 5-10 h and then obtaining the TZM alloy material through furnace cooling. In the invention, a carbide strengthening phase is directly added in the alloy powder to decrease losses of carbon elements in the alloy sintering. Meanwhile, the invention adopt a method of combining the vacuum sintering with the hydrogen sintering to control the change tendency of alloy elements during the alloy sintering, further realizing the reduction of oxygen content which can be controlled under 250 ppm.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A kind of low-carbon aluminum-magnesium spinel carbon brick with high thermal shock resistance and preparation method thereof

Owner:北京利尔高温材料股份有限公司

A process for obtaining molten iron and matte phase by one-step reduction of metallurgical composite slag

ActiveCN104342560BGuaranteed carbon contentTo achieve the purpose of comprehensive recyclingProcess efficiency improvementSocial benefitsNonferrous metal

The invention discloses a process for one-step reduction of metallurgical composite slag to obtain molten iron and a matte phase, belongs to the technical fields of ferrous metallurgy and non-ferrous metallurgy, and relates to a technology for separating and recovering iron and nonferrous metals of metallurgical composite slag in a reducing melting process. The process comprises the following steps: levigating metallurgical composite slag and then feeding lime and a carbonaceous reducing agent to prepare a carbon-containing pellet; directly restoring the carbon-containing pellet and then achieving slag-matte-iron three-phase layering in a melting furnace; and respectively recovering iron and nonferrous metals. The process is capable of achieving separation of iron and nonferrous metals, and gathering the nonferrous metals into the matte phase to play a comprehensive recovery role in a plurality of metal elements; a serious environment problem is caused by stacking of the metallurgical slag, and great waste of resources is also caused, so that the current situation of utilization of the metallurgical slag is greatly changed by the process; considerable economic benefits and social benefits are generated; and the process has a wide application prospect.

Owner:CENT IRON & STEEL RES INST +1

Carbon-14 test sample bottle, test method, and sampling and sample preparation system suitable for testing the mixing ratio of coal-blended biomass power plants

ActiveCN107942368BHigh purityIncreased specializationX/gamma/cosmic radiation measurmentPower stationTest sample

The invention provides a carbon-14 testing sample bottle and test method and a sampling and sample preparation system for a mixed combustion ratio of a coal-mixed biomass power station. The carbon-14testing sample bottle and test method and the sampling and sample preparation system can help overcome lack of effective monitoring means for the mixed combustion of a conventional coal-mixed biomasscombustion power station and monitor a biomass mixed combustion ratio of a coal-mixed biomass combustion power station, and data is provided for biomass mixed combustion monitoring and subsidy-relatedwork. Compared with conventional methods, the carbon-14 testing sample bottle and test method and the sampling and sample preparation system are advantageous in that short detection period can be realized when the biomass mixed combustion ratio is low, accuracy of detection results can be improved, and the coal-mixed biomass combustion power plant is integrated with a mixed combustion ratio monitoring station.

Owner:ZHEJIANG UNIV

A powder metallurgy moving ring and its preparation method

ActiveCN112676567BHigh strengthImprove anti-corrosion performanceCompression moldingTemperature control

The application discloses a powder metallurgy moving ring. The powder metallurgy material composition of the powder metallurgy moving ring is 0.4-0.6% of cobalt powder, 7.3%-8.5% of nickel powder, and the balance is tungsten carbide powder. The powder metallurgy moving ring provided by the application has good hot red hardness, no obvious change in performance under high temperature conditions, and good wear resistance. This application also discloses a method for preparing powder metallurgy moving rings, including mixing materials, ball milling, drying, adding molding agents, compression molding, sintering and other processes. By increasing the amount of molding agents in the mixed materials after ball milling, the A good molding effect is achieved, and the molding performance is improved, and the molding agent is removed by adopting multi-stage temperature control in the subsequent vacuum sintering process, which not only ensures the molding performance, but also removes the molding agent to avoid It affects the product properties after sintering.

Owner:宁波新宇硬质合金密封有限公司

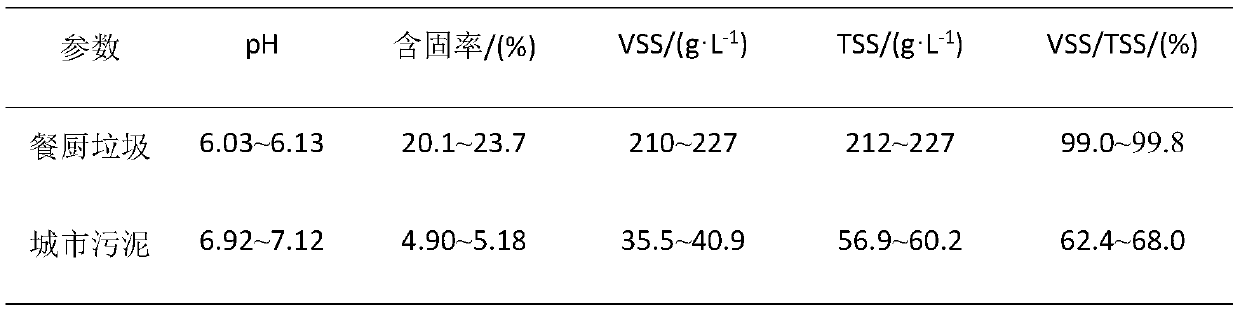

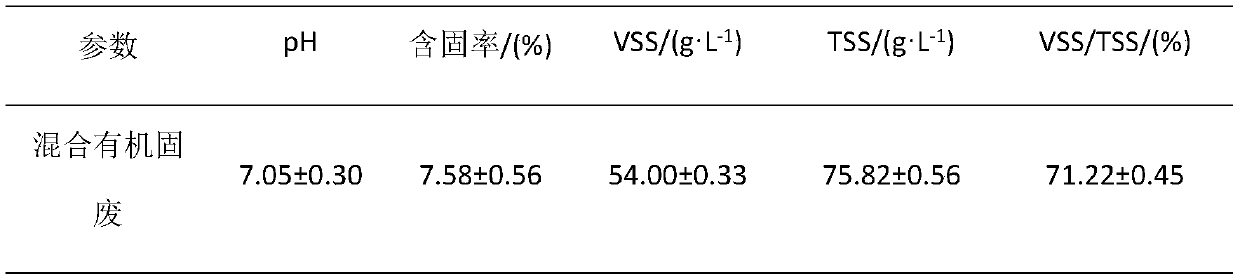

Process for accelerating organic solid waste to generate hydrogen by iron-containing sludge

ActiveCN111268643AGuaranteed carbon contentEasy to handleWaste based fuelHydrogen productionResource recoverySludge

The invention provides a process for accelerating organic solid waste to generate hydrogen by iron-containing sludge, which relates to the technical field of organic solid waste treatment and comprises the following steps of: crushing and acidifying kitchen waste to obtain hydrogen-producing kitchen waste; carrying out alkaline hydrolysis treatment on the municipal sludge to obtain hydrogen production municipal sludge; mixing the hydrogen production kitchen waste, the hydrogen production municipal sludge and the hydrogen production inoculation liquid to obtain mixed solid waste; and adding themixed solid waste into an anaerobic hydrogen production reactor, adding iron-containing sludge, and carrying out anaerobic hydrogen production reaction at 35-65 DEG C to obtain hydrogen and a mixture. The invention provides a process for accelerating organic solid waste to generate hydrogen by iron-containing sludge. By organically combining the three solid wastes, namely the kitchen waste, the municipal sludge and the iron-containing sludge, the problem of environmental pollution caused by the kitchen waste and the municipal sludge is solved; meanwhile, the solid wastes are subjected to resource recovery, so that the method is green and environment-friendly and has a good application prospect.

Owner:JIANGSU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com