A kind of low-carbon aluminum-magnesium spinel carbon brick with high thermal shock resistance and preparation method thereof

A technology of magnesium spinel and thermal shock resistance, applied in the field of refractory, can solve the problems of environmental pollution and high cost of raw materials, achieve the effects of improving impact resistance and corrosion resistance, improving thermal shock stability, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

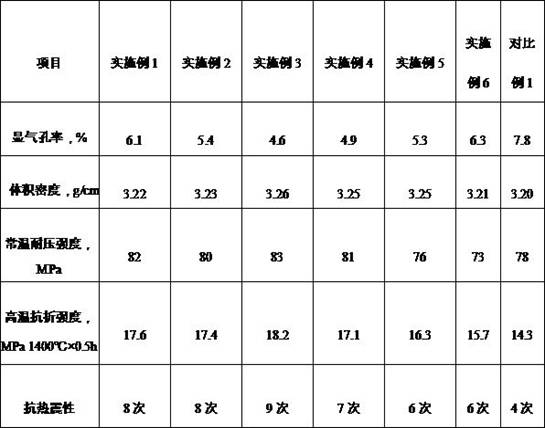

Examples

Embodiment 1

[0053] Preparation of Sample 1:

[0054] In parts by weight, it includes 15 parts of corundum spinel carbon regenerated material, 35 parts of corundum particles, 20 parts of fused magnesia, 22 parts of corundum dust removal powder, 2.5 parts of activated α-alumina micropowder, spinel-aluminic acid 3 parts of calcium composite material, 0.5 parts of metal aluminum powder, 2 parts of nano-carbon black, phenolic resin as binder, and 2.7 parts of phenolic resin.

[0055] Among them, 5 parts of corundum spinel carbon recycled materials with a particle size of 3-5mm, 5 parts of corundum spinel carbon recycled materials with a particle size of 1-3mm, and corundum spinel carbon recycled materials with a particle size of 0-1mm 5 copies;

[0056] 15 parts of corundum particles with a particle size of 3-5 mm, 15 parts of corundum particles with a particle size of 1-3 mm, and 5 parts of corundum particles with a particle size of 0.074-1 mm;

[0057] 5 parts of fused magnesia with a part...

Embodiment 2

[0067] Preparation of sample 2:

[0068] In parts by weight, it includes 27 parts of corundum spinel carbon regenerated material, 24 parts of corundum particles, 20 parts of fused magnesia, 21 parts of corundum dust removal powder, 3 parts of activated α-alumina micropowder, spinel-aluminic acid 2.5 parts of calcium composite material, 1 part of metal aluminum powder, 1.5 parts of nano-carbon black, phenolic resin as binder, and 2.8 parts of phenolic resin.

[0069] Among them, 10 parts of corundum spinel carbon recycled materials with a particle size of 3-5mm, 10 parts of corundum spinel carbon recycled materials with a particle size of 1-3mm, and corundum spinel carbon recycled materials with a particle size of 0-1mm 7 copies;

[0070] 10 parts of corundum particles with a particle size of 3-5 mm, 10 parts of corundum particles with a particle size of 1-3 mm, and 4 parts of corundum particles with a particle size of 0.074-1 mm;

[0071] 5 parts of fused magnesia with a par...

Embodiment 3

[0079] Preparation of sample 3:

[0080] In parts by weight, it includes 40 parts of corundum spinel carbon regenerated material, 17.5 parts of corundum particles, 13.5 parts of fused magnesia, 21 parts of corundum dust removal powder, 3 parts of activated α-alumina micropowder, and spinel-aluminic acid 2.5 parts of calcium composite material, 1 part of metal aluminum powder, 1.5 parts of nano-carbon black, phenolic resin as binder, and 2.9 parts of phenolic resin.

[0081] Among them, 15 parts of corundum spinel carbon recycled materials with a particle size of 3-5mm, 15 parts of corundum spinel carbon recycled materials with a particle size of 1-3mm, and corundum spinel carbon recycled materials with a particle size of 0-1mm 10 copies;

[0082] 10 parts of corundum particles with a particle size of 3-5mm, 5 parts of corundum particles with a particle size of 1-3mm, and 2.5 parts of corundum particles with a particle size of 0.074-1mm;

[0083] 3.5 parts of fused magnesia w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com