Method for smelting ductile cast iron

A technology of nodular cast iron and iron filings, applied in the field of foundry, can solve the problems of loss, waste of resources, and shutdown of foundry enterprises, and achieve the effects of saving production costs, reducing labor intensity, and improving quality

Inactive Publication Date: 2010-03-17

QINGTE GRP

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most of the enterprises producing ductile iron in the foundry industry still use the traditional batching method of pig iron + returned iron + scrap steel, which has high production costs and is greatly restricted by the quality, supply and price of raw materials. Facing losses, suspension of production, or even bankruptcy

After the casting is processed, a large amount of iron filings cannot be recycled and digested, and they are sold as scraps at a low price, resulting in a large waste of resources and increased costs

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

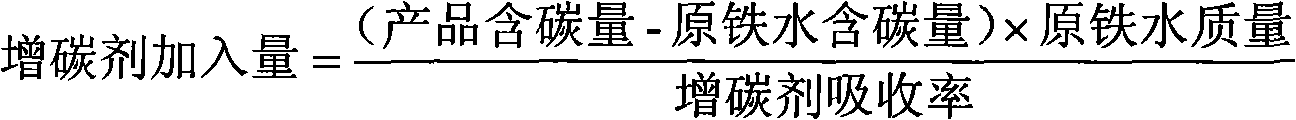

[0011] Embodiment: to produce the nodular cast iron that carbon content is 3.8%, the former molten iron that smelting obtains is through testing, and carbon content is 3.6%, promptly departs from product standard carbon content difference 0.2%, calculates with former molten iron quality 10 tons, 20Kg of carburizer needs to be added, and the absorption rate of carburizer is 80%, so 25Kg of carburizer needs to be added.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for smelting ductile cast iron, which comprises the following steps: adding returning iron, scrap iron and scrap steel into a long coil melting furnace layer by layerfor being melted into ductile cast iron base iron, and then adding a recarbonizer, wherein the ingredients are in the following proportion: 35-40 percent of scrap iron or scrap steel and 60-65 percentof returning iron. The scrap steel, the scrap iron and the recarbonizer are used for replacing past pig iron raw materials with higher price, thereby well saving the production cost, facilitating theproduction according to the produced products with different brands and different carbon contents, reducing the labor intensity, ensuring the strict carbon contents of the products, and improving thequality of the products.

Description

technical field [0001] The invention relates to a casting process, in particular to a ductile iron smelting method, which belongs to the field of casting. Background technique [0002] At present, most of the enterprises producing ductile iron in the foundry industry still use the traditional batching method of pig iron + returned iron + scrap steel, which has high production costs and is greatly restricted by the quality, supply and price of raw materials. Facing losses, suspension of production, or even bankruptcy. After the castings are processed, a large amount of iron filings cannot be recycled and digested, and they are sold as scraps at a low price, resulting in a large waste of resources and increased costs. Contents of the invention [0003] Aiming at the deficiencies of the existing technology, the technical problem to be solved by the present invention is to provide a ductile iron smelting method, which can save production costs and increase output by changing ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C1/10

CPCY02P10/20

Inventor 纪爱师纪建奕吴清建江志兴咸丰大

Owner QINGTE GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com