Manufacturing process of round pipe steel of chain

A manufacturing process and round pipe technology, applied in the manufacturing process of chain round steel pipes, can solve the problems of low surface friction, deformation and burrs, and high cost, and achieve the effects of improving comprehensive mechanical properties, reducing friction coefficient, and enhancing lubrication effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

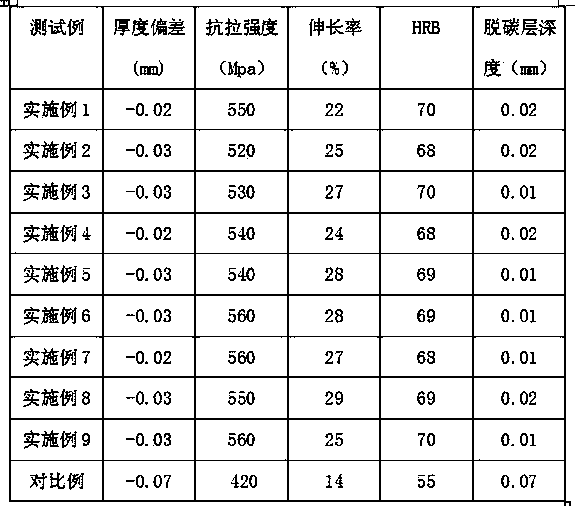

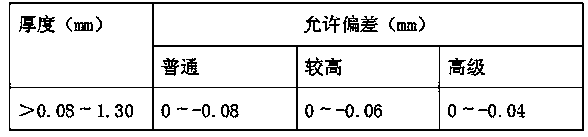

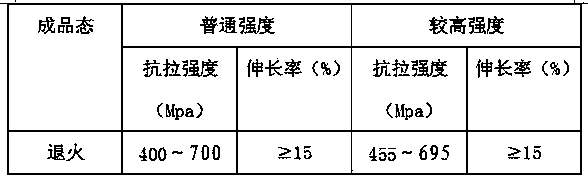

Examples

Embodiment 1

[0028] The first step is to put the strip with a raw material thickness of about 6.00mm and a width of about 6.00mm into the H 2 SO 4 Rust removal treatment is carried out in the solution to remove the rust on the surface to ensure the quality requirements in the rolling process, and the treatment time is 5 minutes. The second step is to carry out the four-rolling cold rolling process. After the first rolling, the thickness of the strip is about 2.40mm and the width is about 10.90mm. After the second rolling, the thickness of the strip is about 1.45mm and the width is about 11.35mm. After the third rolling, the thickness of the strip is about 1.12mm and the width is about 11.50mm. After the fourth rolling, the thickness of the strip is about 0.95mm and the width is about 11.66mm. rolling oil. The third step is to anneal the strip after rolling. Before the annealing treatment, put the strip into the annealing furnace, and then gradually increase the furnace temperature to 670...

Embodiment 2

[0030] Same as Example 1, the difference is that the thickness of the raw material strip is about 8.00mm, and the width is about 8.00mm; the thickness of the strip after the first rolling during the four continuous rolling is about 5.12mm, and the width is about 11.70mm After the second rolling, the thickness of the strip is about 2.21mm, and the width is about 12.22mm. After the third rolling, the thickness of the strip is about 1.50mm, and the width is about 12.52mm. After the fourth rolling, the thickness of the strip is It is about 0.96mm and the width is about 12.66mm.

Embodiment 3

[0032] Same as Example 1, the difference is that the thickness of the raw material strip is about 10.00mm, and the width is about 10.00mm; the cold rolling process is five continuous rolling, and the thickness of the strip after the first rolling of the five continuous rolling is about It is 2.80mm and the width is about 13.50mm. After the second rolling, the strip thickness is about 2.00mm and the width is about 14.10mm. After the third rolling, the strip thickness is about 1.50mm and the width is about 14.20. After the fourth rolling, the thickness of the strip is about 1.21 mm, and the width is about 14.55 mm. After the fifth rolling, the thickness of the strip is about 1.00 mm, and the width is about 14.65 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com