Process for accelerating organic solid waste to generate hydrogen by iron-containing sludge

A technology of organic solids and sludge, applied in biological sludge treatment, hydrogen production and other directions, can solve the problems of high oil content, large amount of kitchen waste, high cost, etc., to improve the rate of hydrogen production and realize resource utilization The effect of utilization, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The present embodiment provides the operation process of the start-up phase of the iron-containing sludge accelerated organic solid waste hydrogen production process:

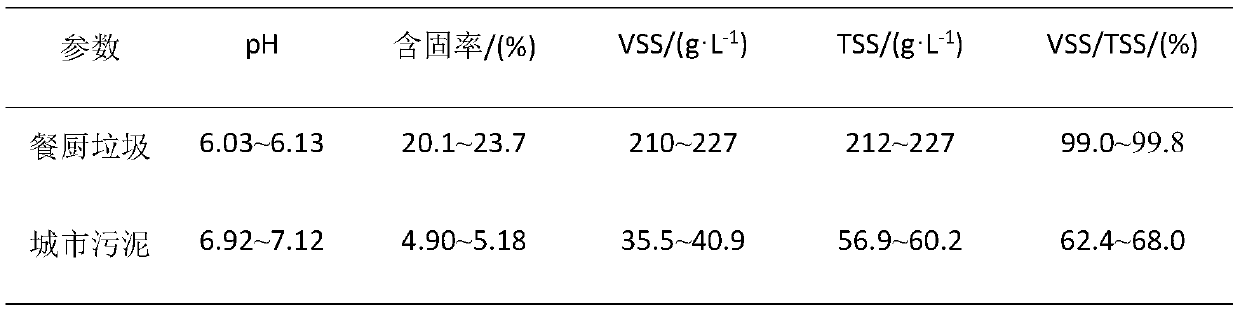

[0046] S1: Take 50 tons of kitchen waste, crush it with a solid content of 20.1-23.7%, and carry out acidification treatment at 50°C for 2±0.5h to obtain hydrogen-producing kitchen waste (the weight is basically the same as that of the kitchen waste);

[0047] S2: Take 178 tons of municipal sludge (solid content 4.90-5.18%) after gravity concentration of the sewage treatment plant, add caustic soda, and carry out an alkaline hydrolysis reaction under the condition of pH 13 for 1 ± 0.5 h to obtain municipal sludge for hydrogen production (weight Basically the same as municipal sludge);

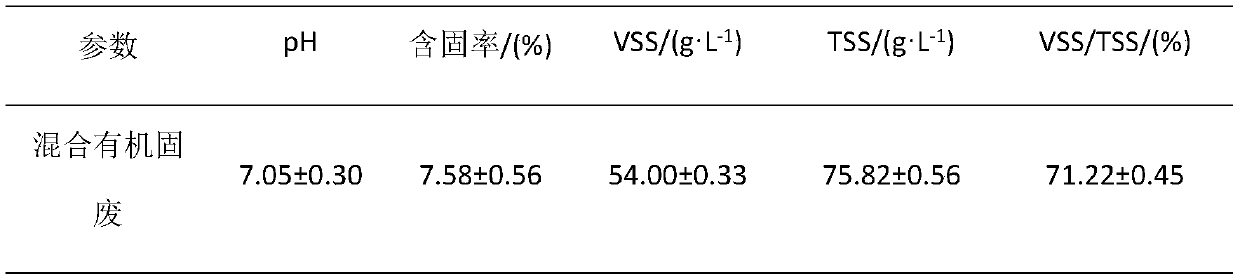

[0048] S3: At the initial start-up, the anaerobic sludge (solid content 1%) taken from the anaerobic tank of the sewage treatment plant is concentrated and then thermally hydrolyzed at 80°C to obtain the hydrolyzed anaero...

Embodiment 2

[0056] In step S4 of this embodiment, the inoculum for hydrogen production is the dehydrated liquid obtained by centrifuging the mixture in the anaerobic hydrogen production reactor after the hydrogen production reaction is completed, and then 50 tons of kitchen waste for hydrogen production, 178 tons of municipal sludge for hydrogen production, 16.7 Tons of dehydration liquid are mixed evenly to obtain mixed solid waste. Add 8.3 tons of iron-containing sludge (solid content 30%). Among them, the composition of iron-containing sludge is calculated by mass percentage, including Fe 35%, Ca 30%; the sum of the content of Mn, Ni, Cr, and Mg is 2%; the sum of the content of Na, Al, Cu, and Zn is 1%. Below; other components are O, S, P, Si.

[0057] The rest are the same as in Example 1.

[0058] In this example, the cumulative gas production in 2 days is 848.3 m 3 , the total hydrogen production is 407.7m 3 ; The daily gas production and hydrogen production peaked at the 20th h...

Embodiment 3

[0061] In step S4 of this embodiment, the amount of kitchen waste added for hydrogen production is 110 tons, which is mixed with 110 tons of municipal sludge for hydrogen production and 55 tons of dehydrated liquid after reaction to obtain mixed solid waste.

[0062] In this example, except for the added iron-containing sludge, which is calculated by mass percentage, it contains 35% Fe and 30% Ca; the sum of the contents of Mn, Ni, Cr, and Mg is 2%; the sum of the contents of Na, Al, Cu, and Zn is 2%. The sum is less than 1%; the other components are O, S, P, Si; the dosage of iron-containing sludge is 9.35 tons.

[0063] Others are the same as in the second embodiment.

[0064] In this example, the cumulative gas production in 2 days is 1102m 3 , the total hydrogen production is 668m 3 ; The daily gas production and hydrogen production peaked at the 20th hour, respectively 649 m 3 and 454m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com