Carbon-14 testing sample bottle and test method, and sampling and sample preparation system for testing mixed combustion ratio of coal-mixed biomass power station

A sample bottle and sample chamber technology, applied in the detection field, can solve problems such as the lack of effective monitoring methods for co-combustion, and achieve the effects of improving competitiveness, increasing specialization, and saving time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

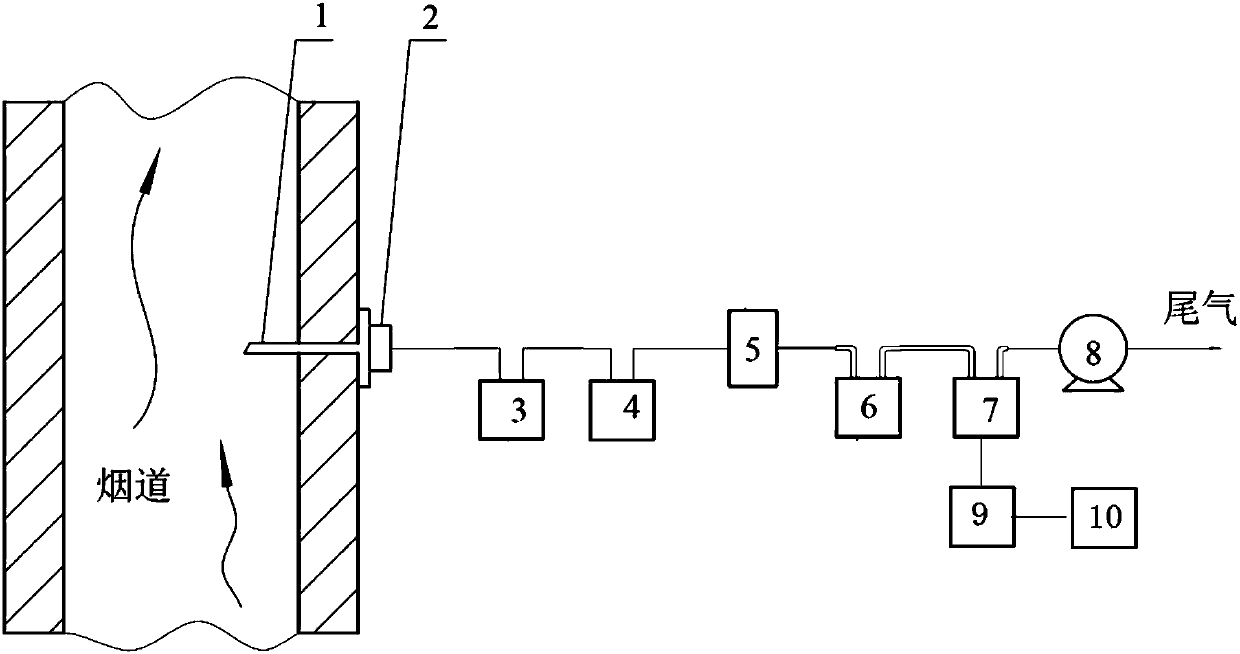

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings.

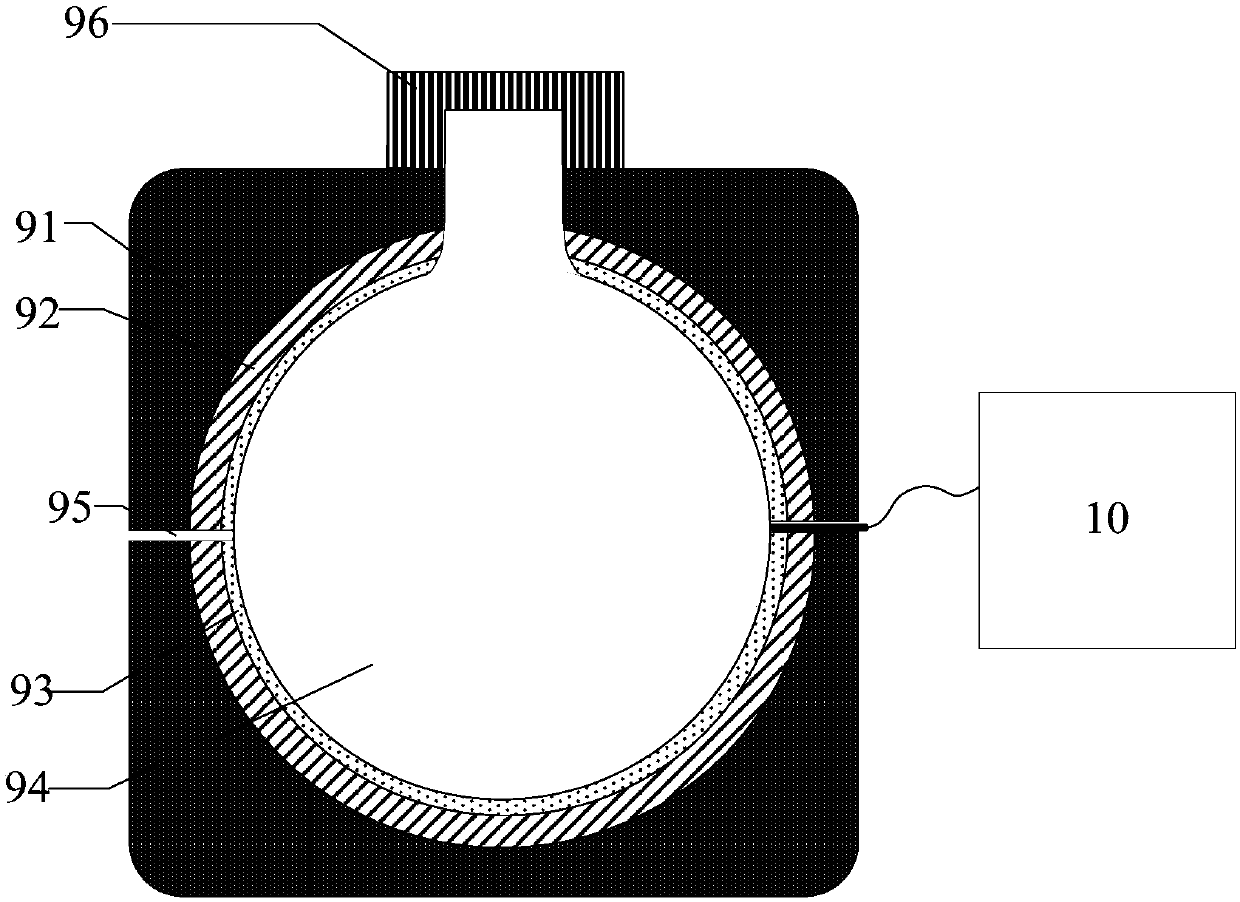

[0021] Such as figure 2 As shown, a sample bottle suitable for testing carbon-14 in pressurized carbon dioxide, the pressure-bearing shell 91 of the sample bottle is made of metal material, and has a spherical or cylindrical transparent sample chamber 94 inside; the transparent sample chamber 94 The outer wall is coated with a layer of diffuse reflection material 93, and an insulating material 92 is filled between the transparent sample chamber 94 and the pressure-bearing shell 91; the bottle wall of the sample bottle is provided with an optical fiber channel 95, and the optical fiber channel 95 is connected from the pressure-bearing shell 91 extends to the outer wall of the transparent sample chamber 94 and does not communicate with the inner cavity of the transparent sample chamber 94 . As common knowledge in the art, the sample bottle also has a sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com