TPE insulating material

An insulating material, TPE technology, applied in insulators, organic insulators, organic liquid insulators, etc., can solve problems such as poor fluidity, poor material fluidity, and lower performance indicators of finished TPE materials to improve dispersion uniformity and extrusion flow. the effect of avoiding air bubble defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

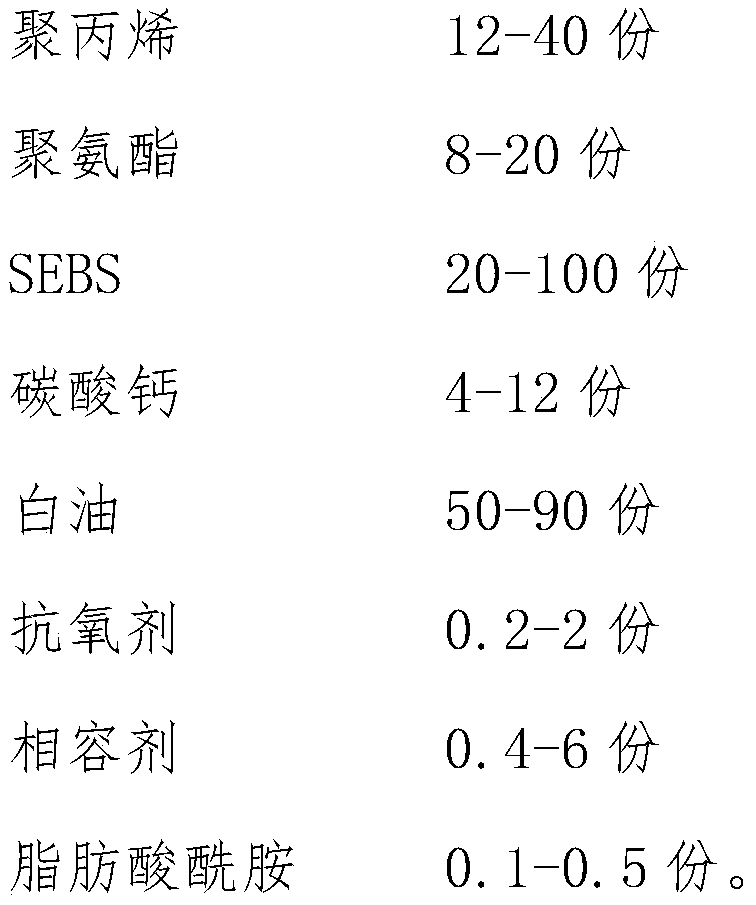

Image

Examples

Embodiment 1

[0024] 12 parts polypropylene

[0025] Polyurethane 20 parts

[0026] SEBS 60 parts

[0027] Calcium carbonate 12 parts

[0028] 90 parts white oil

[0029] Antioxidant 2 parts

[0030] Compatibilizer 4 parts

[0031] Fatty acid amide 0.1 parts

[0032] Add the above materials into a kneader and mix (the kneading temperature in the kneader is 100°C, and the kneading time is 10min) to obtain a premix, which is then sent into a twin-screw extruder for mastication (the mastication of the twin-screw extruder The processing temperature is 190°C, the screw speed is 300r / min), and the TPE insulating material is obtained after pelletizing.

[0033] The extrusion fluidity of the TPE material obtained in this example is good, the material releases smoothly, the fillers and colorants are uniformly and continuously dispersed in the masterbatch, and there is no color difference; the components in the TPE material are evenly dispersed, easy to plasticize, and the processing temperatur...

Embodiment 2

[0035] 30 parts polypropylene

[0036] Polyurethane 8 parts

[0037] SEBS 80 copies

[0038] 4 parts calcium carbonate

[0039] 80 parts white oil

[0040] Antioxidant 1 part

[0041] Compatibilizer 1 part

[0042] Fatty acid amides 0.5 parts.

[0043] Add the above materials into a kneader and mix (the kneading temperature in the kneader is 100°C, and the kneading time is 10min) to obtain a premix, which is then sent into a twin-screw extruder for mastication (the mastication of the twin-screw extruder The processing temperature is 190°C, the screw speed is 300r / min), and the TPE insulating material is obtained after pelletizing.

[0044] The extrusion fluidity of the TPE material obtained in this example is good, the material releases smoothly, the fillers and colorants are uniformly and continuously dispersed in the masterbatch, and there is no color difference; the components in the TPE material are evenly dispersed, easy to plasticize, and the processing temperature...

Embodiment 3

[0046] Polypropylene 40 parts

[0047] Polyurethane 15 parts

[0048] SEBS 100 copies

[0049] Calcium carbonate 8 parts

[0050] White oil 50 parts

[0051] Antioxidant 0.3 parts

[0052] 6 parts of compatibilizer

[0053] Fatty acid amides 0.3 part.

[0054] Add the above materials into a kneader and mix (the kneading temperature in the kneader is 100°C, and the kneading time is 10min) to obtain a premix, which is then sent into a twin-screw extruder for mastication (the mastication of the twin-screw extruder The processing temperature is 190°C, the screw speed is 300r / min), and the TPE insulating material is obtained after pelletizing.

[0055] The extrusion fluidity of the TPE material obtained in this example is good, the material releases smoothly, the fillers and colorants are uniformly and continuously dispersed in the masterbatch, and there is no color difference; the components in the TPE material are evenly dispersed, easy to plasticize, and the processing tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com