Oscillating device of locating clip in copper-aluminum composite busbar gating system

A copper-aluminum composite row and casting system technology, applied in the field of oscillating devices, can solve problems such as inconsistent density of aluminum materials, affect product quality, and uneven lattice, so as to increase metal ductility, avoid bubble defects, and uniform lattice Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

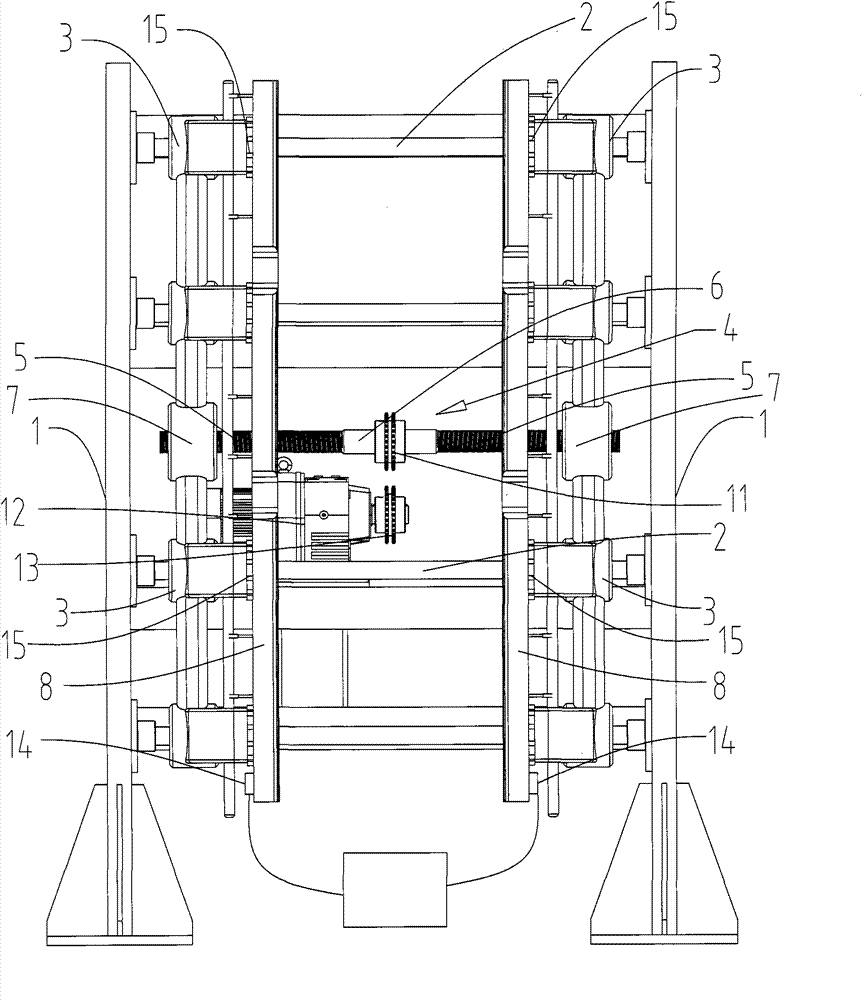

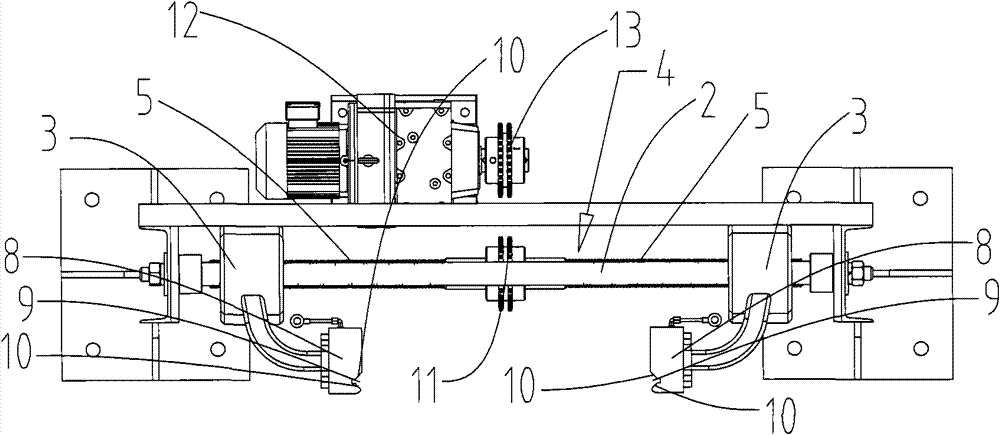

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

[0012] see Figure 1-2 As shown, the positioning clip in the copper-aluminum composite row casting system includes a pair of supporting uprights 1, a guide post 2 arranged laterally between the pair of supporting uprights 1, and can be slidably sleeved along the length direction of the guide post 2. A pair of guide sleeves 3 on the guide post 2, a screw rod 4 arranged horizontally, a pair of nuts 7 that can be used for opening and closing movement matched with the screw rod 4, a pair of clamping blocks 8, and a motor 12, the clamping block 8 is a long strip shape, extending along the length direction of the support pole 1, so that the pair of clamping blocks 8 can clamp the copper-aluminum composite row from top to bottom. figure 1 Among them, there are four guide posts 2, and the four guide posts 2 are arranged at intervals along the length direction of the support p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com