High-frequency covering film with high electromagnetic shielding function and preparation method thereof

A technology of electromagnetic shielding and covering film, which is applied in the fields of magnetic/electric field shielding, crosstalk/noise/electromagnetic interference reduction (, electrical components, etc.), and can solve electromagnetic shielding without EMI shielding film, difficult to reach 70dB, complicated problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

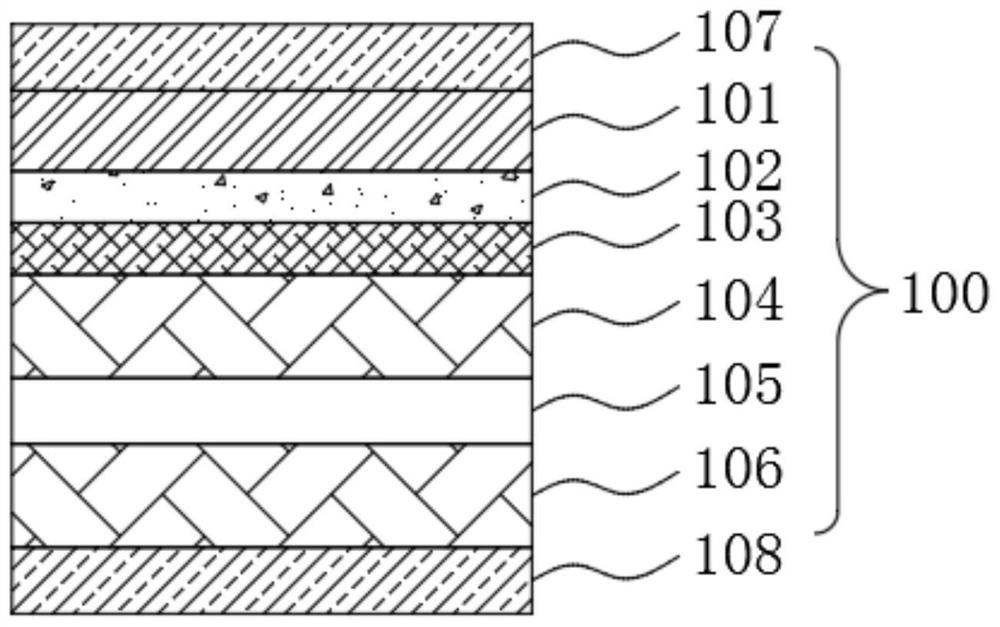

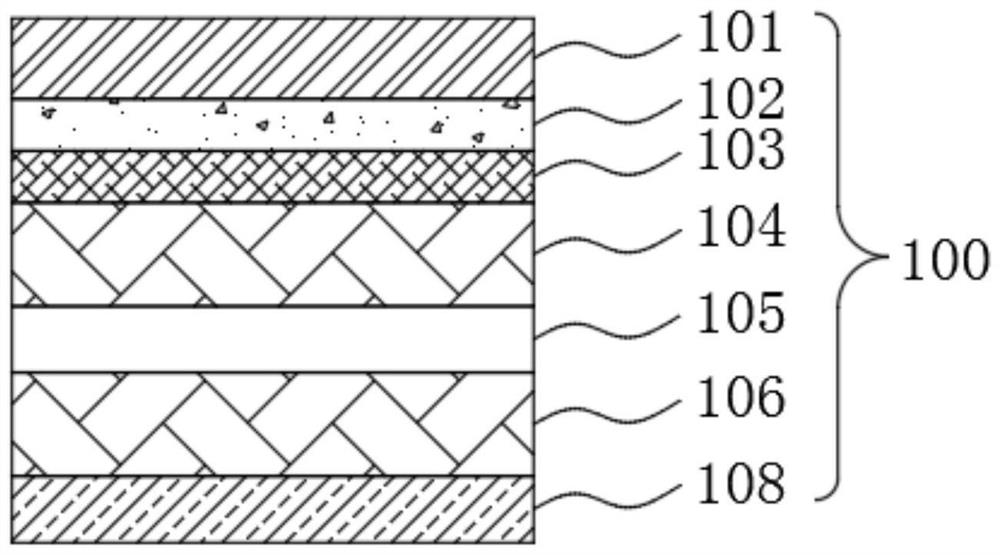

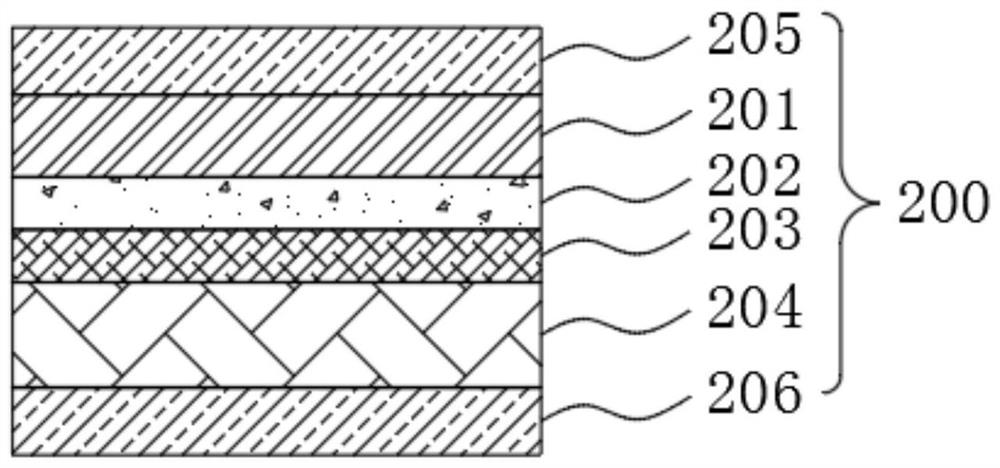

[0060] Embodiment: a kind of high-frequency covering film with high electromagnetic shielding function, such as Figure 1-Figure 2 As shown, it includes an insulating layer 101, an adhesive layer 102, a copper foil layer 103, a first high-frequency adhesive layer 104, a high-frequency insulating layer 105, and a second high-frequency adhesive layer 106 from top to bottom; The following layer is used as a protective layer on the outermost side of the present invention. It is mostly black to cover the circuit design and is beautiful. The release layer on it is not only beneficial to winding, it can also provide stiffness during FPC processing and use, which is beneficial to the process. The release layer, insulation Layers and bonding layers do not affect signal transmission and shielding performance.

[0061] The high-frequency insulating layer is an insulating layer with a dielectric coefficient lower than 4.0 and a dielectric loss lower than 0.015 (@10GHz); the dielectric los...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Total thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com