Patents

Literature

142results about How to "Good shielding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

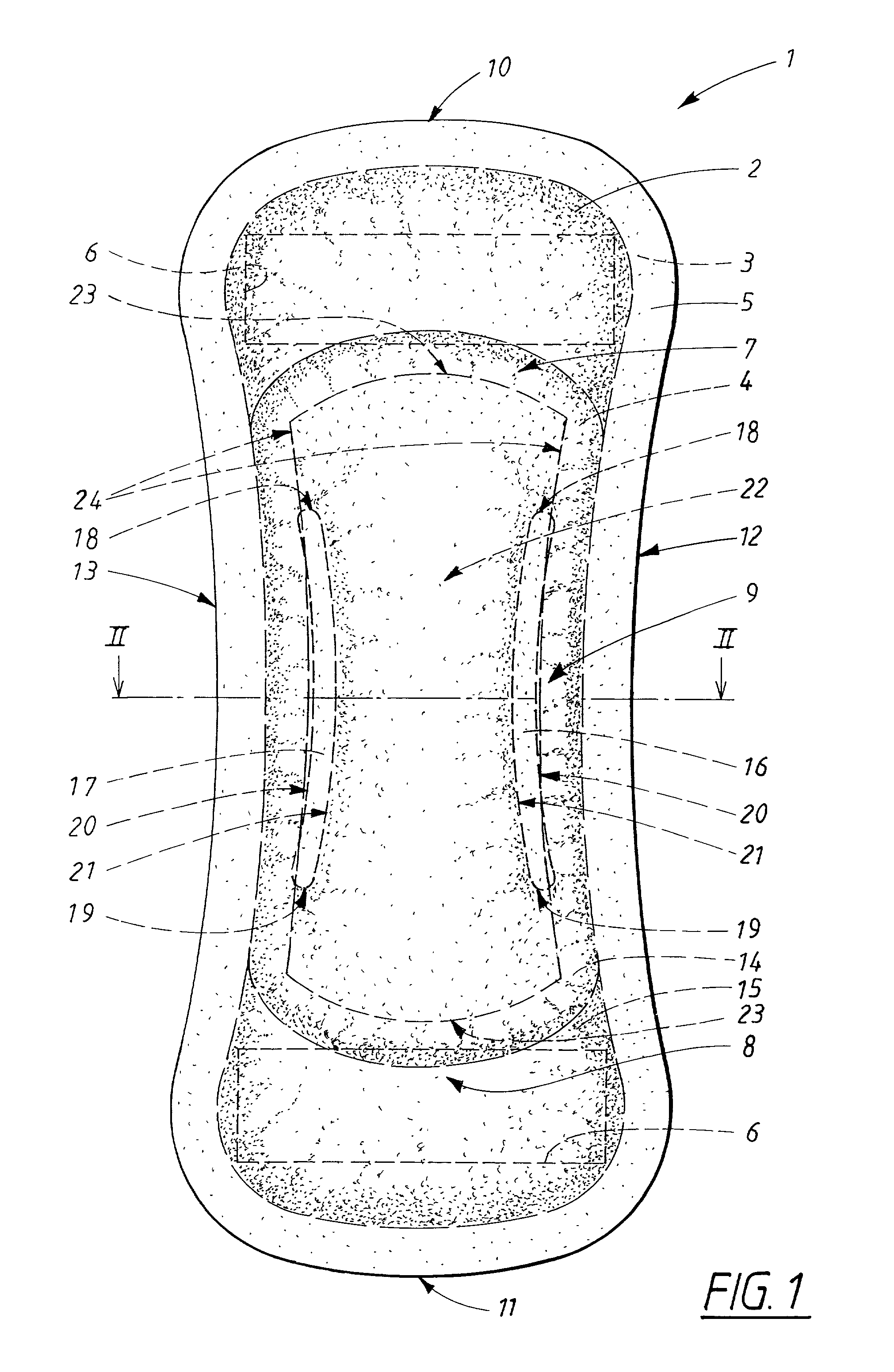

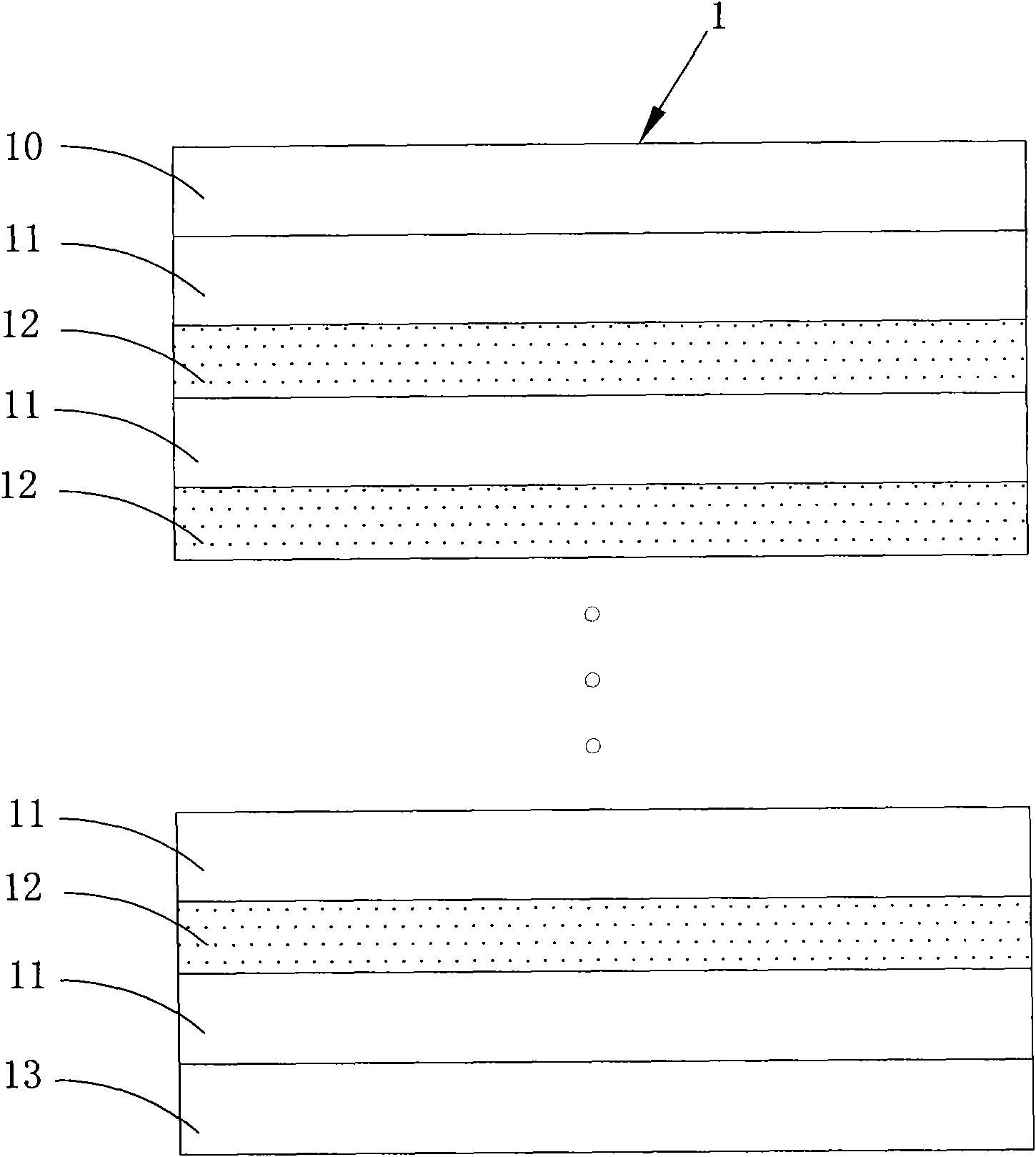

Absorbent product with improved instantaneous liquid adsorption, and improved fit

InactiveUS6605752B2Increases stability and deformation resistancePromote absorptionSanitary towelsBaby linensEngineeringAbsorption layer

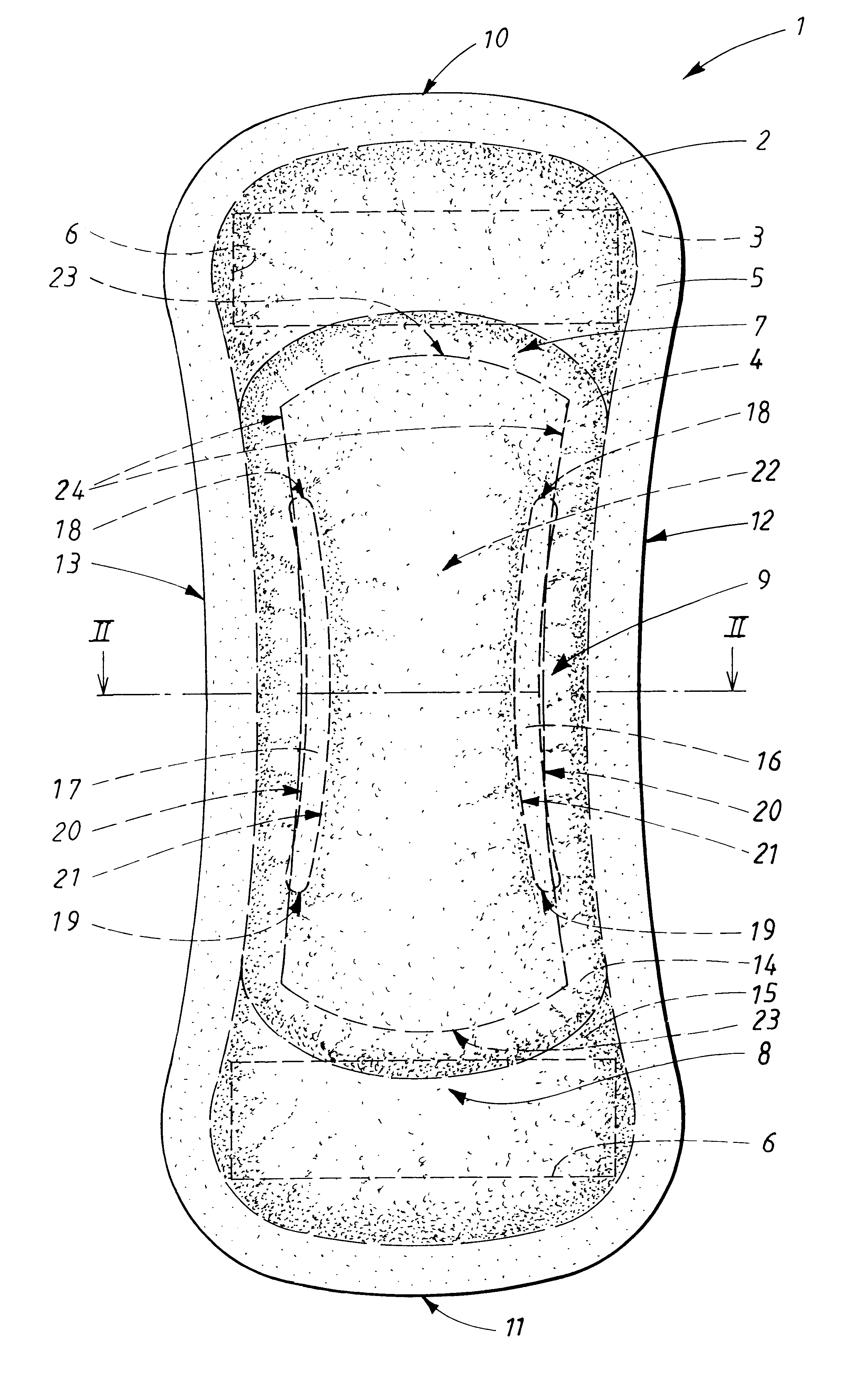

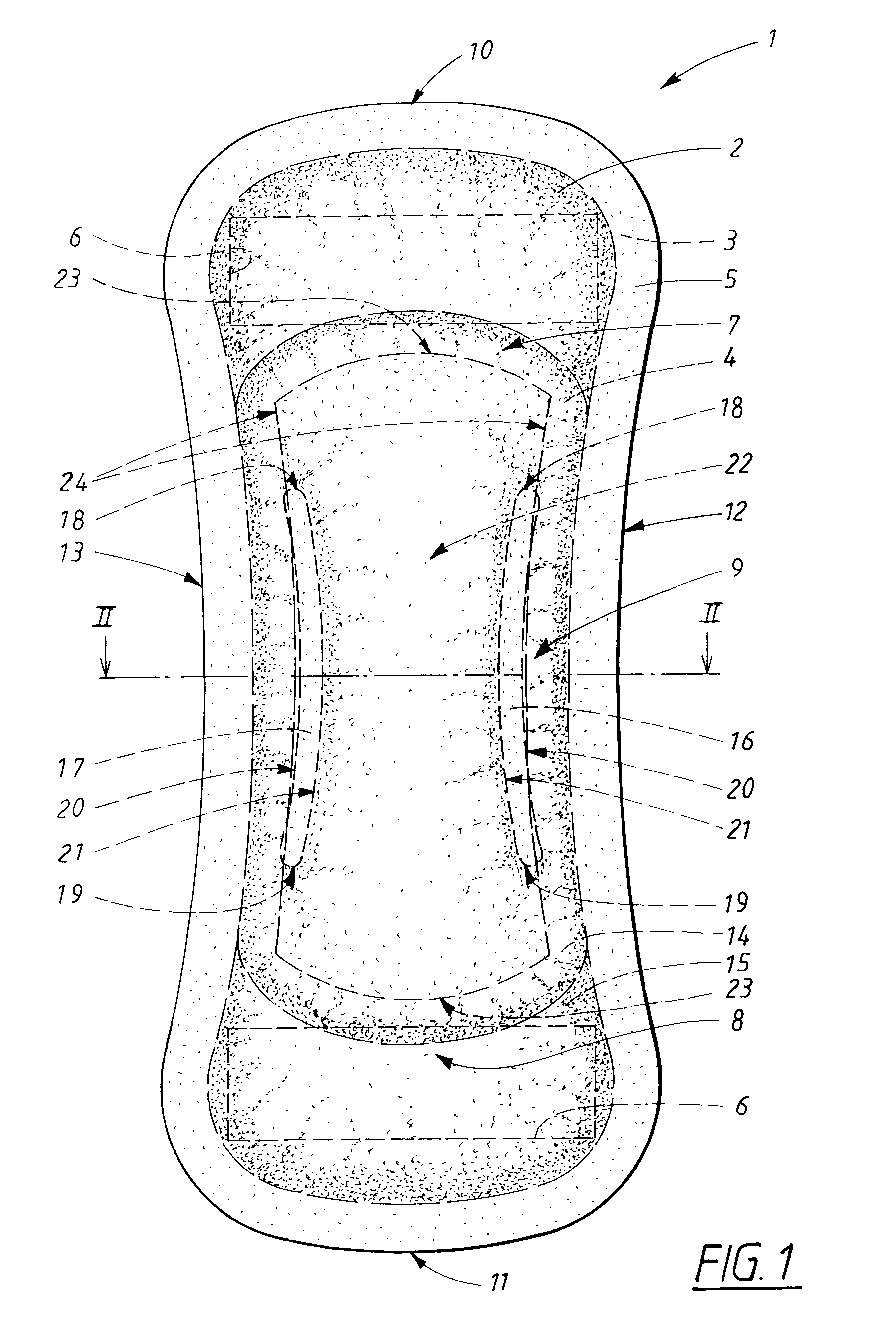

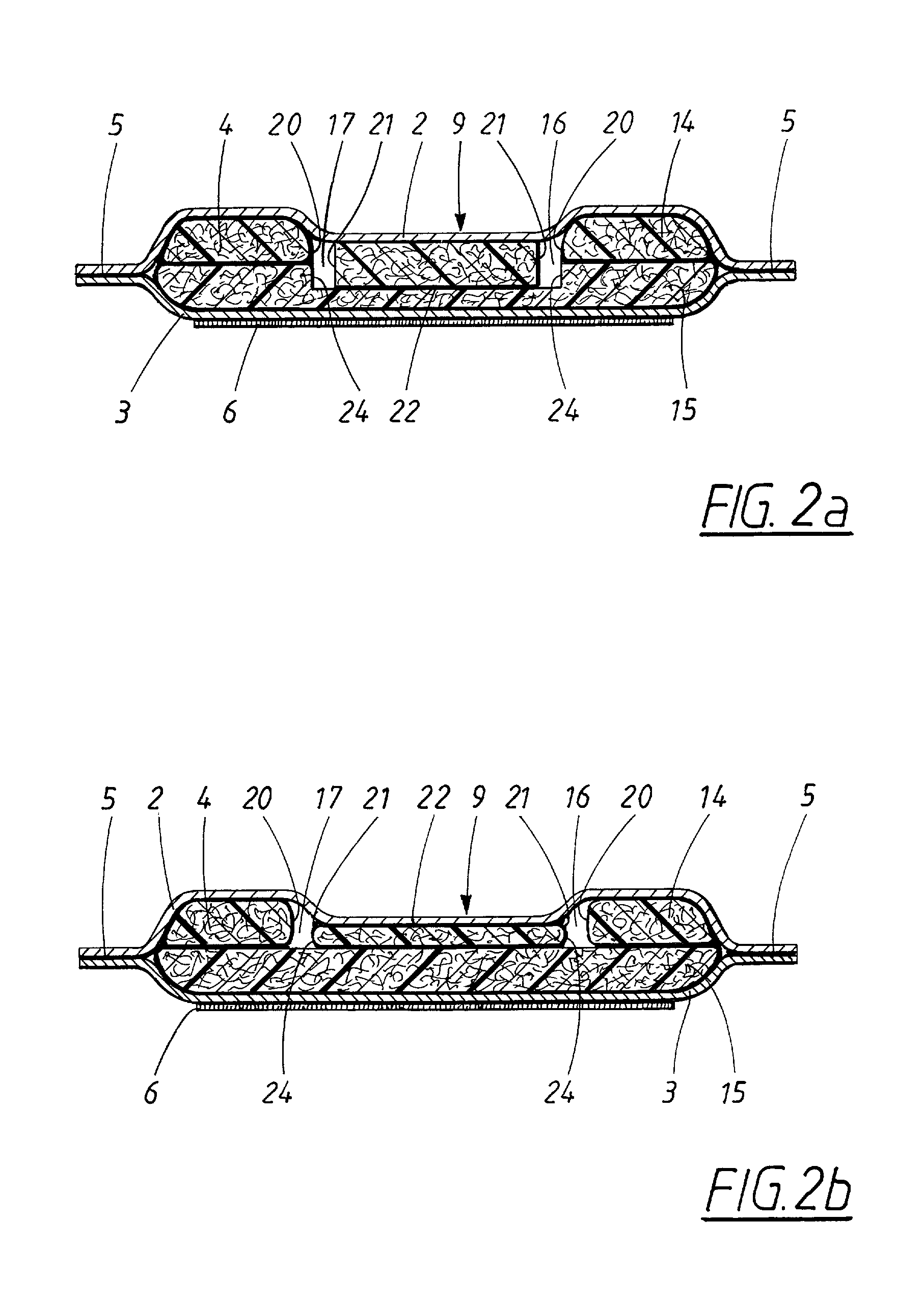

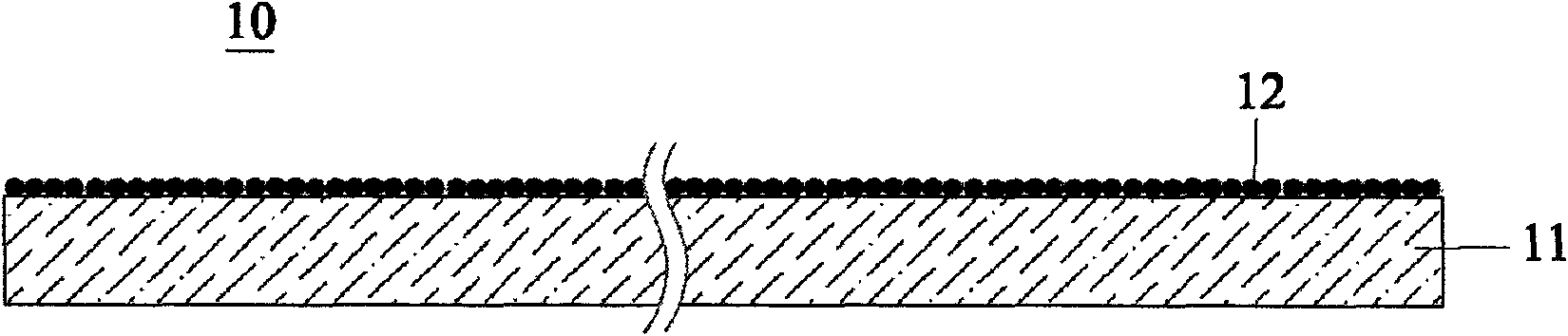

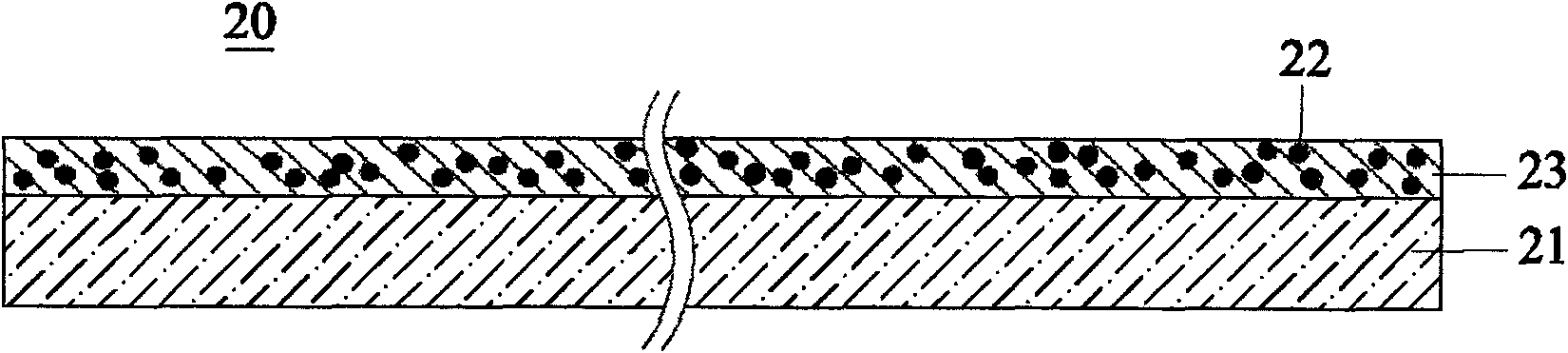

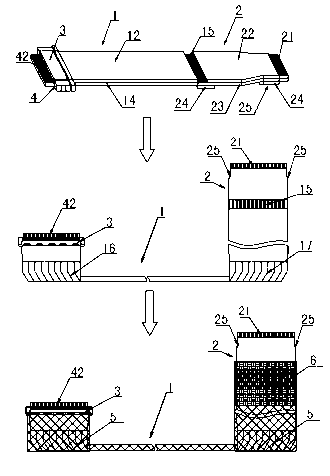

An absorbent product which possesses two longitudinal side edges (12,13), two transverse end edges (10,11), a longitudinal centre line and a transverse centre line, and which comprises a liquid-permeable outer layer (2), a liquid-impermeable backing layer (3) and an absorption core (4) which is located between the outer layer (2) and the backing layer (3), with the absorption core (4) comprising a first and a second absorption layer (14,15), with the first absorption layer (14) being arranged behind the liquid-permeable outer layer (2) and the second absorption layer (15) being arranged between the first absorption layer (14) and the liquid-impermeable backing layer (3), with the first absorption layer (14) having two longitudinal channels (16,17), with each of the channels having an outer edge (20) closest to the corresponding longitudinal side edge (12,13) of the product and an inner edge (21) closest to the longitudinal centre line of the product. The two longitudinal channels (16,17) extend through the whole of the thickness of the first absorption layer (14), and a compressed area (22) is arranged between the longitudinal sides (12,13) of the absorbent product, wherein the distance between the side edges (24) of the compressed area (22) is smaller than or equal to the distance between the outer side edges (20) of the longitudinal channels (16,17).

Owner:ESSITY HYGIENE & HEALTH AB

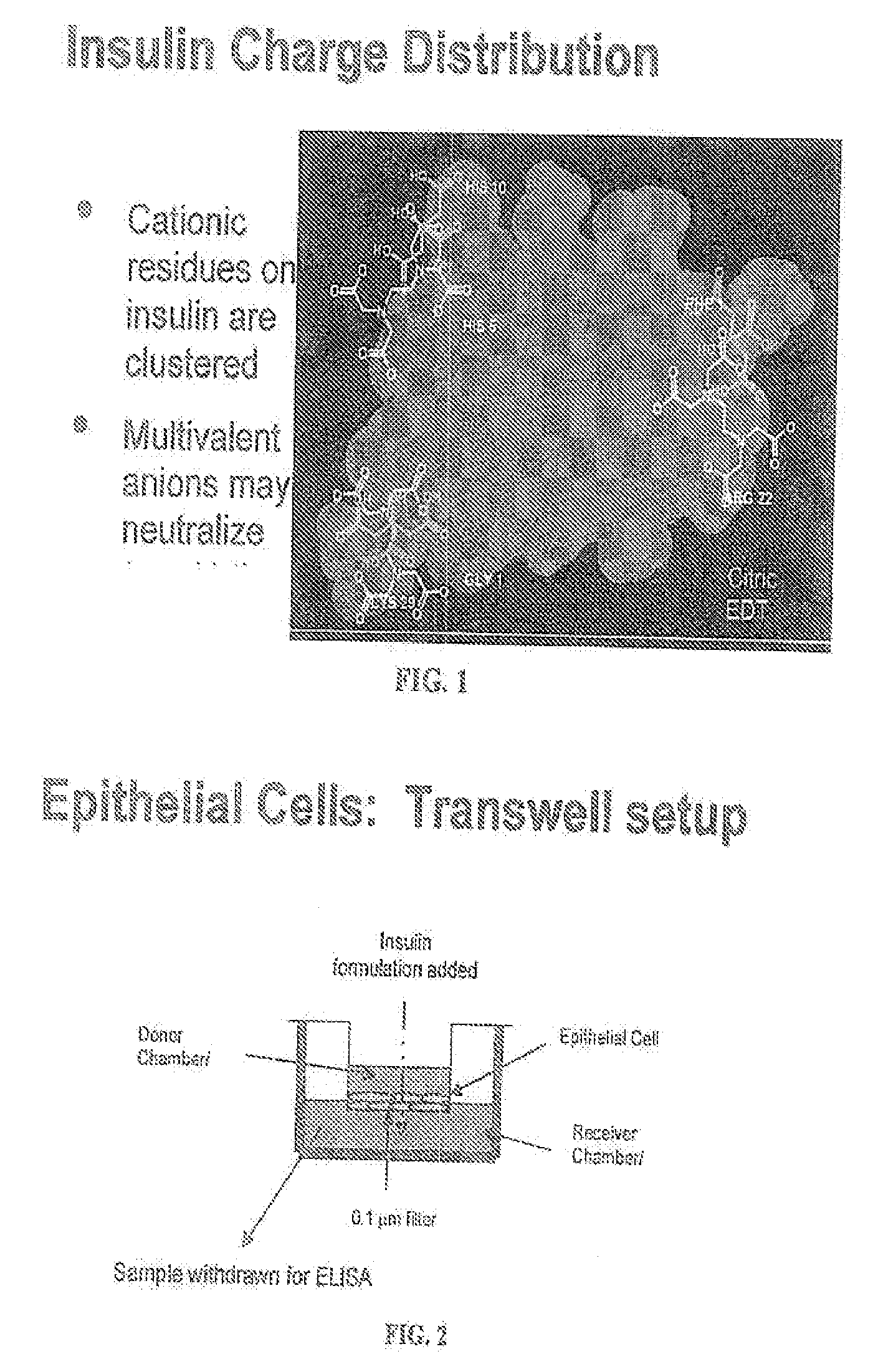

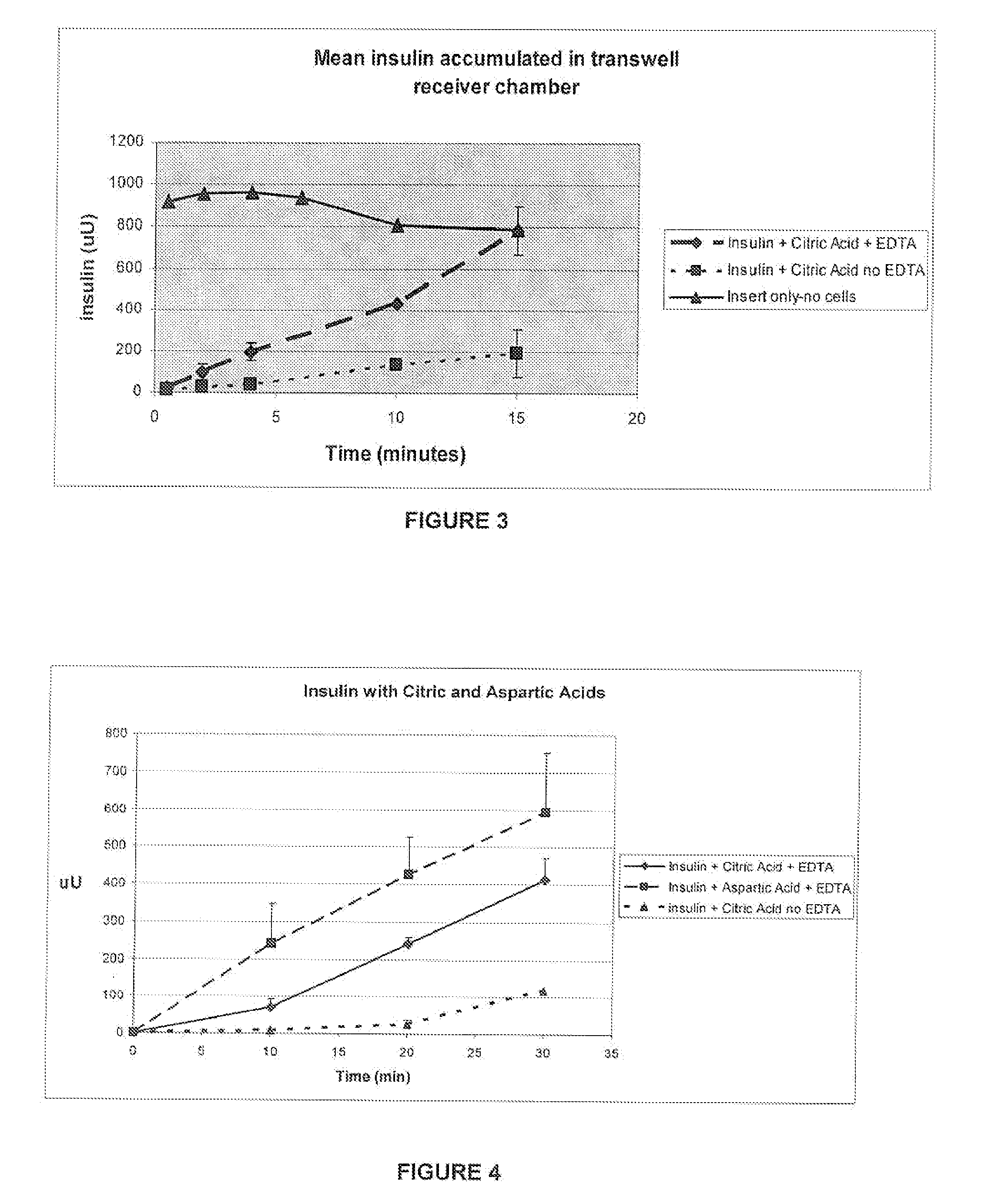

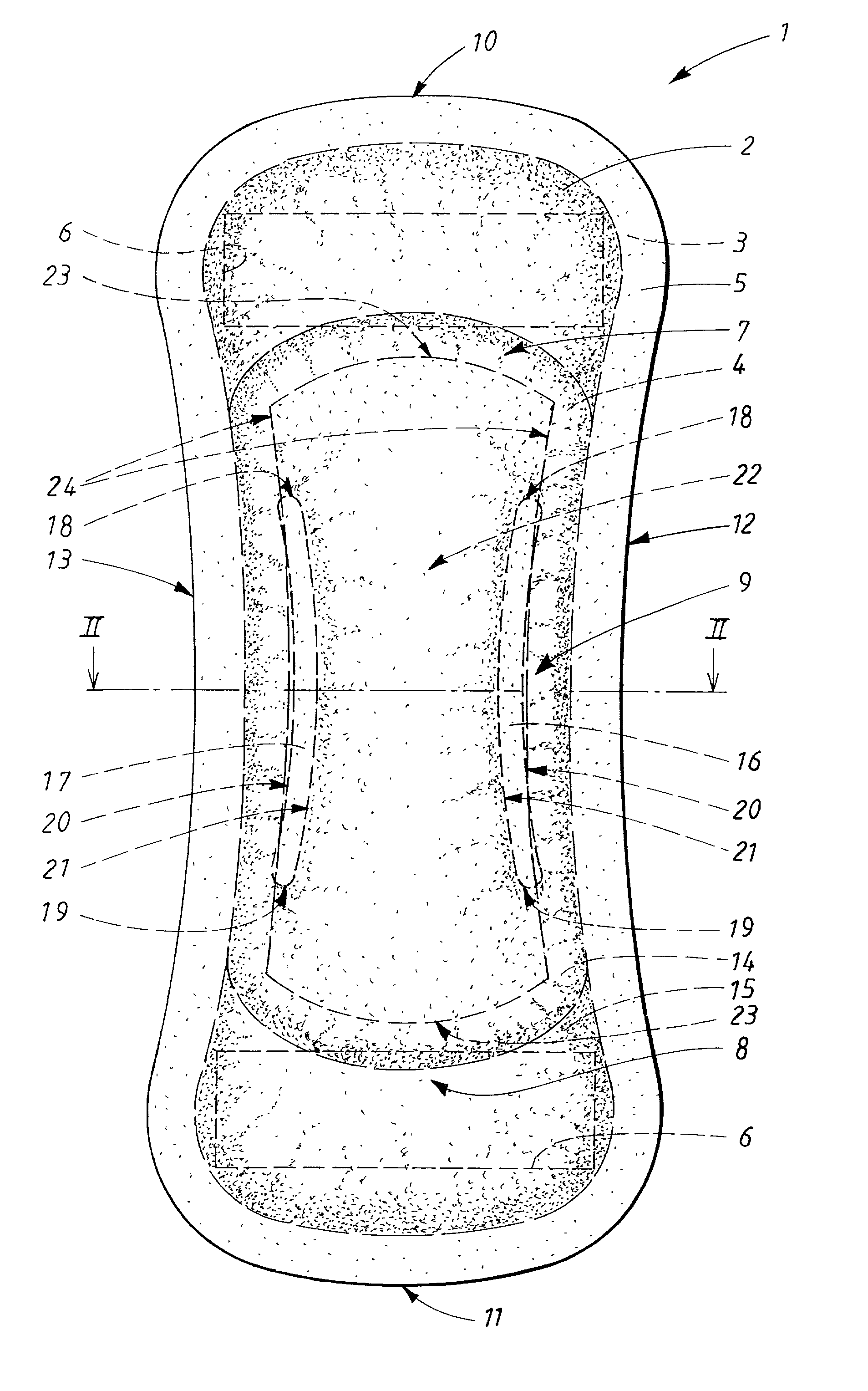

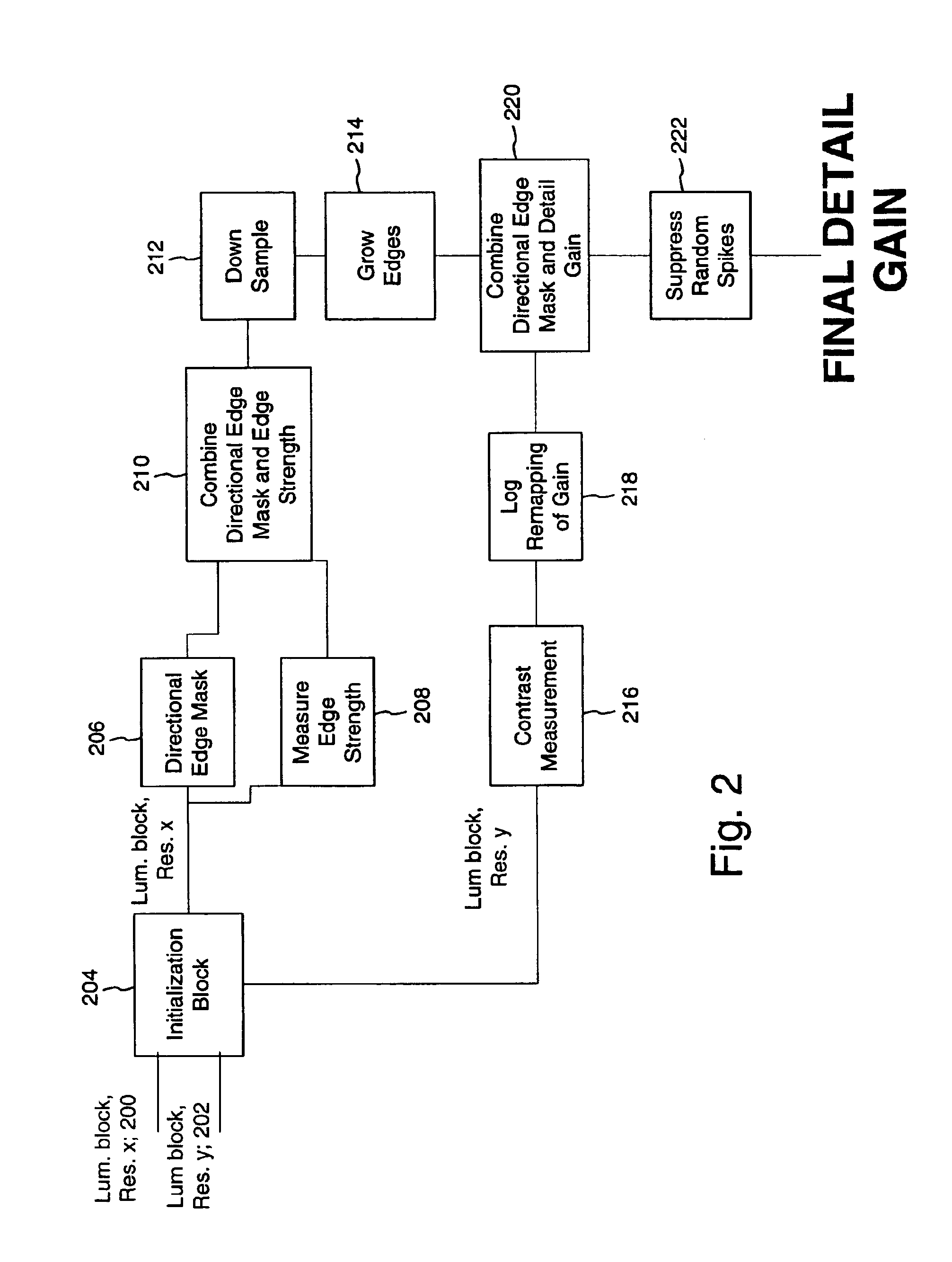

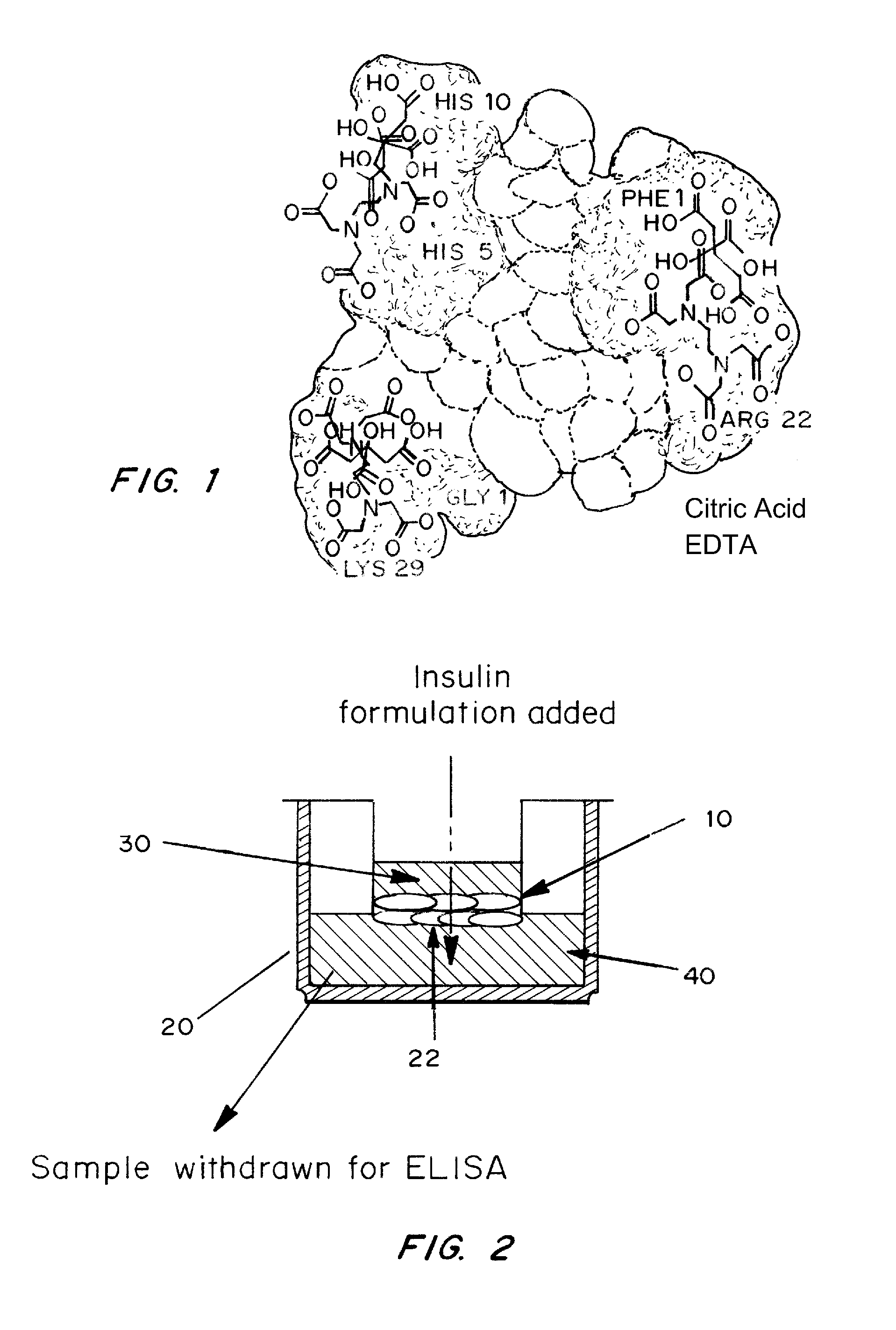

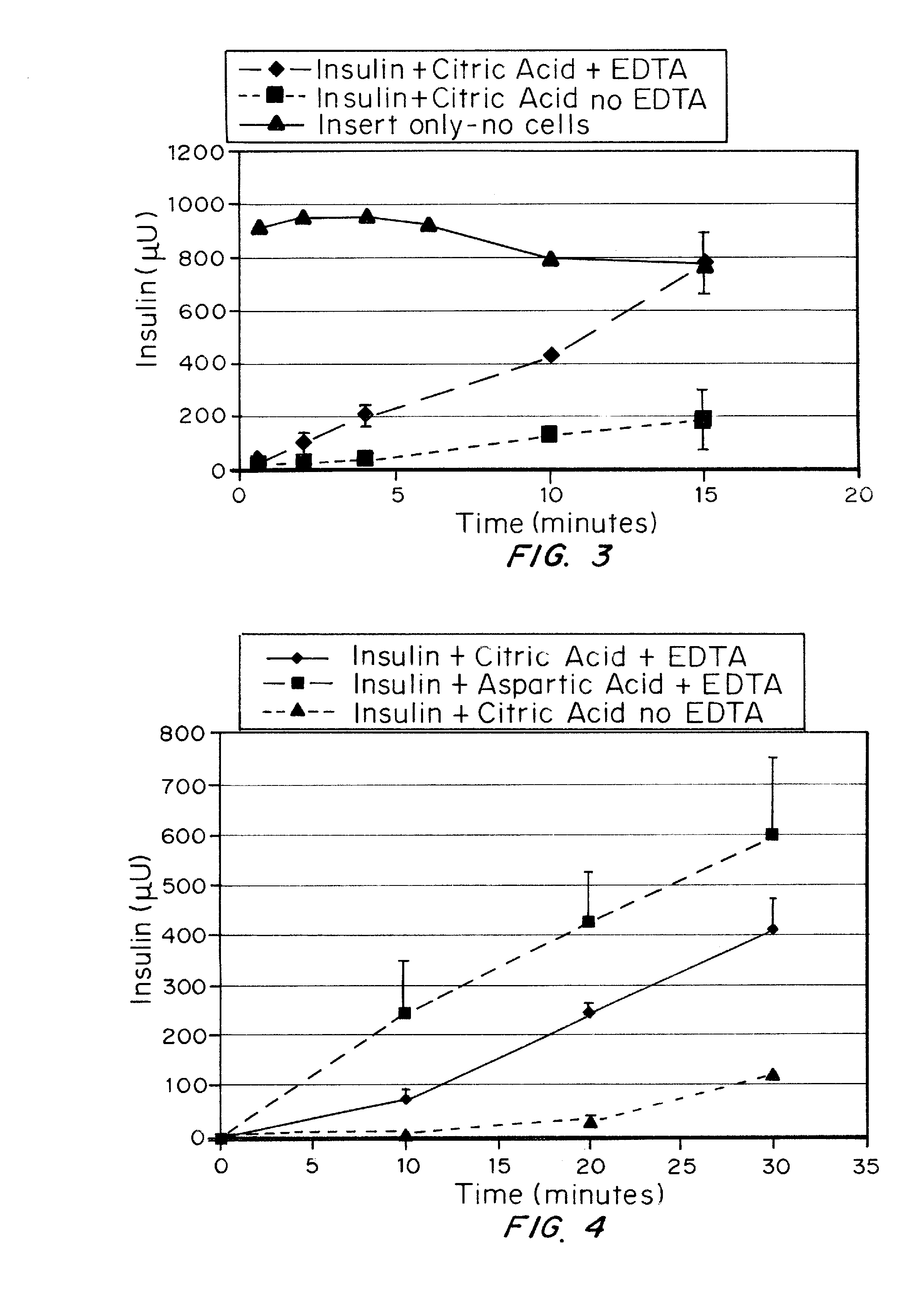

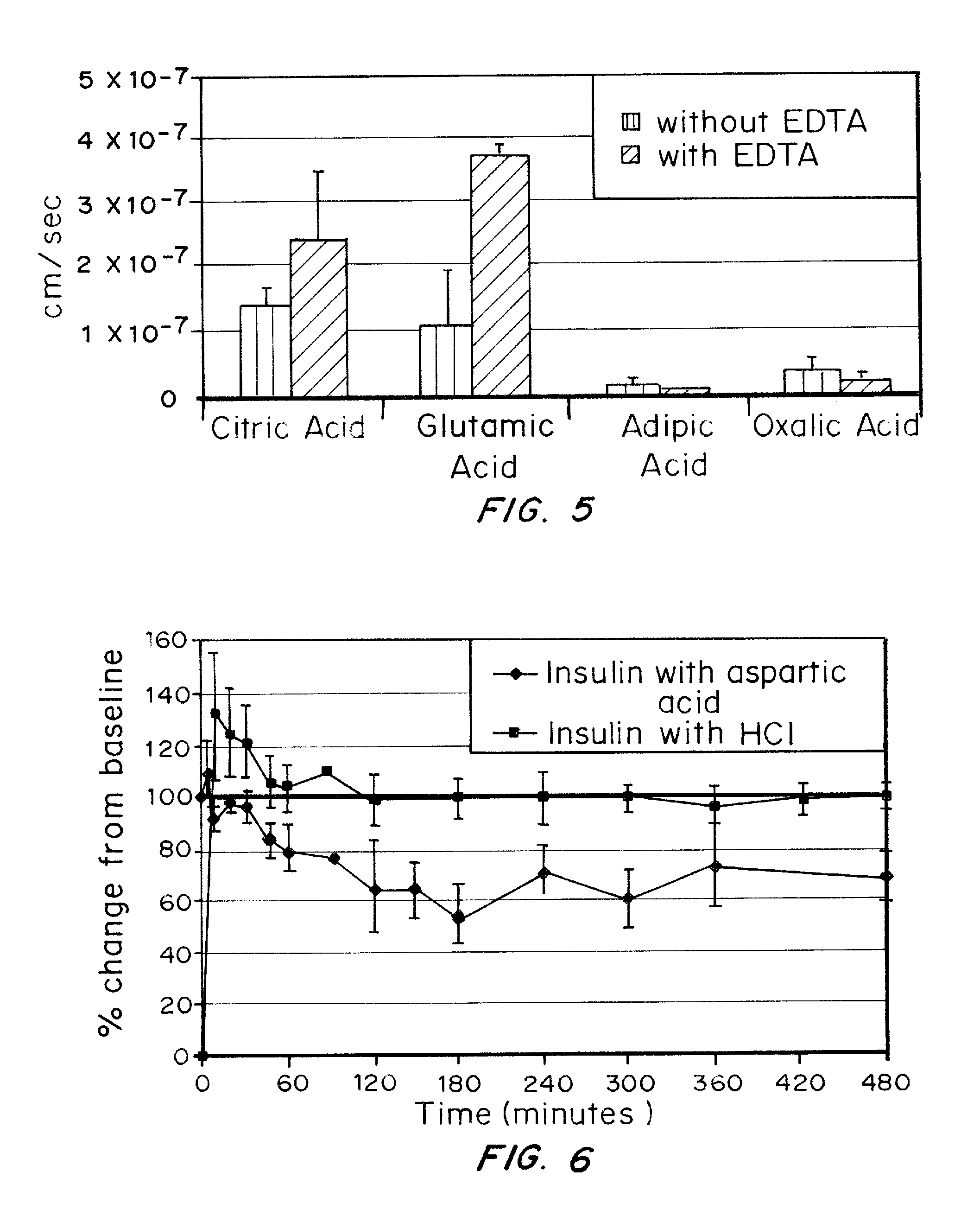

Rapid acting and long acting insulin combination formulations

ActiveUS20080039368A1Increase speedReduce the amount of solutionPeptide/protein ingredientsMetabolism disorderBefore BreakfastIntensive insulinotherapy

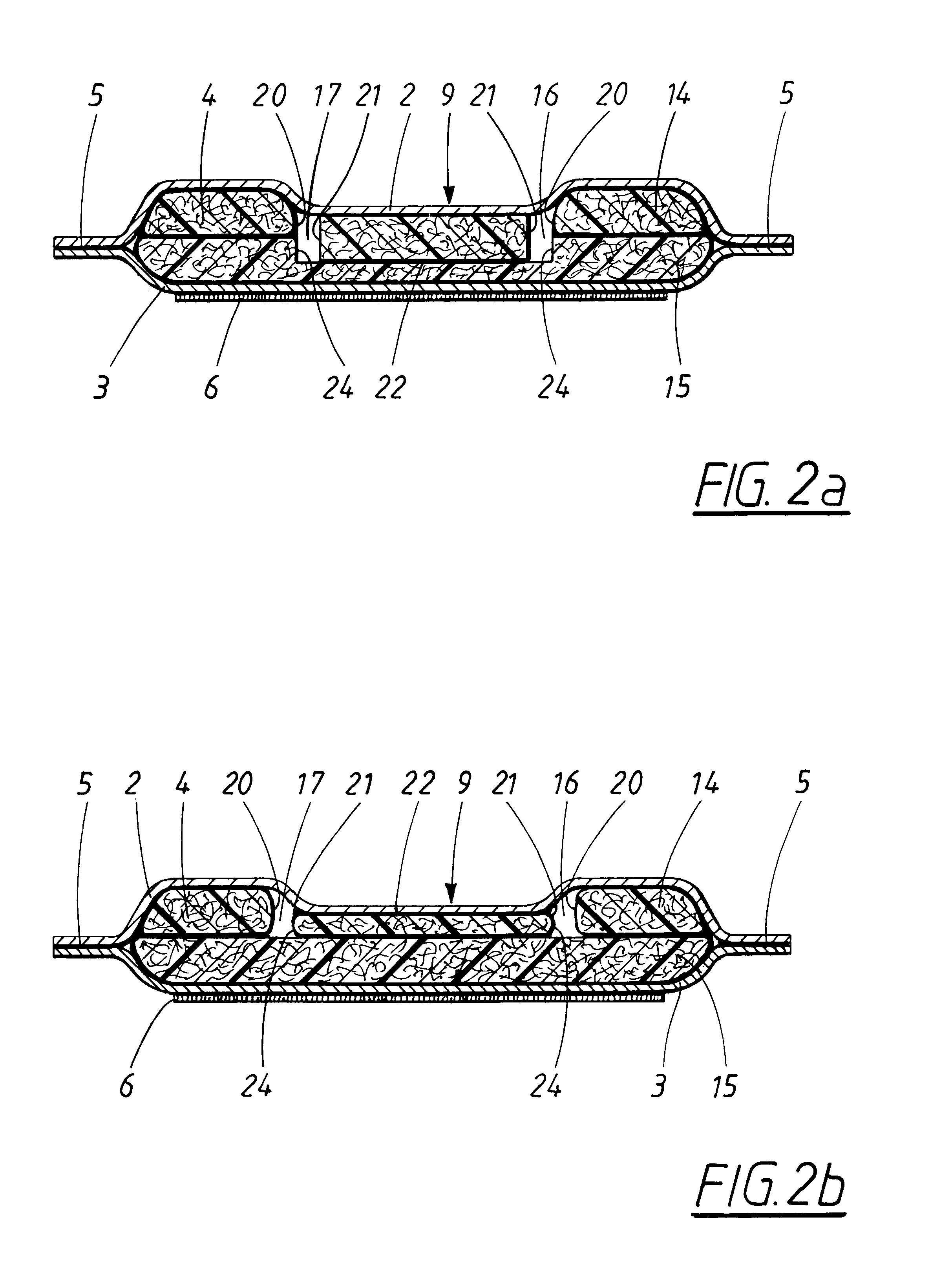

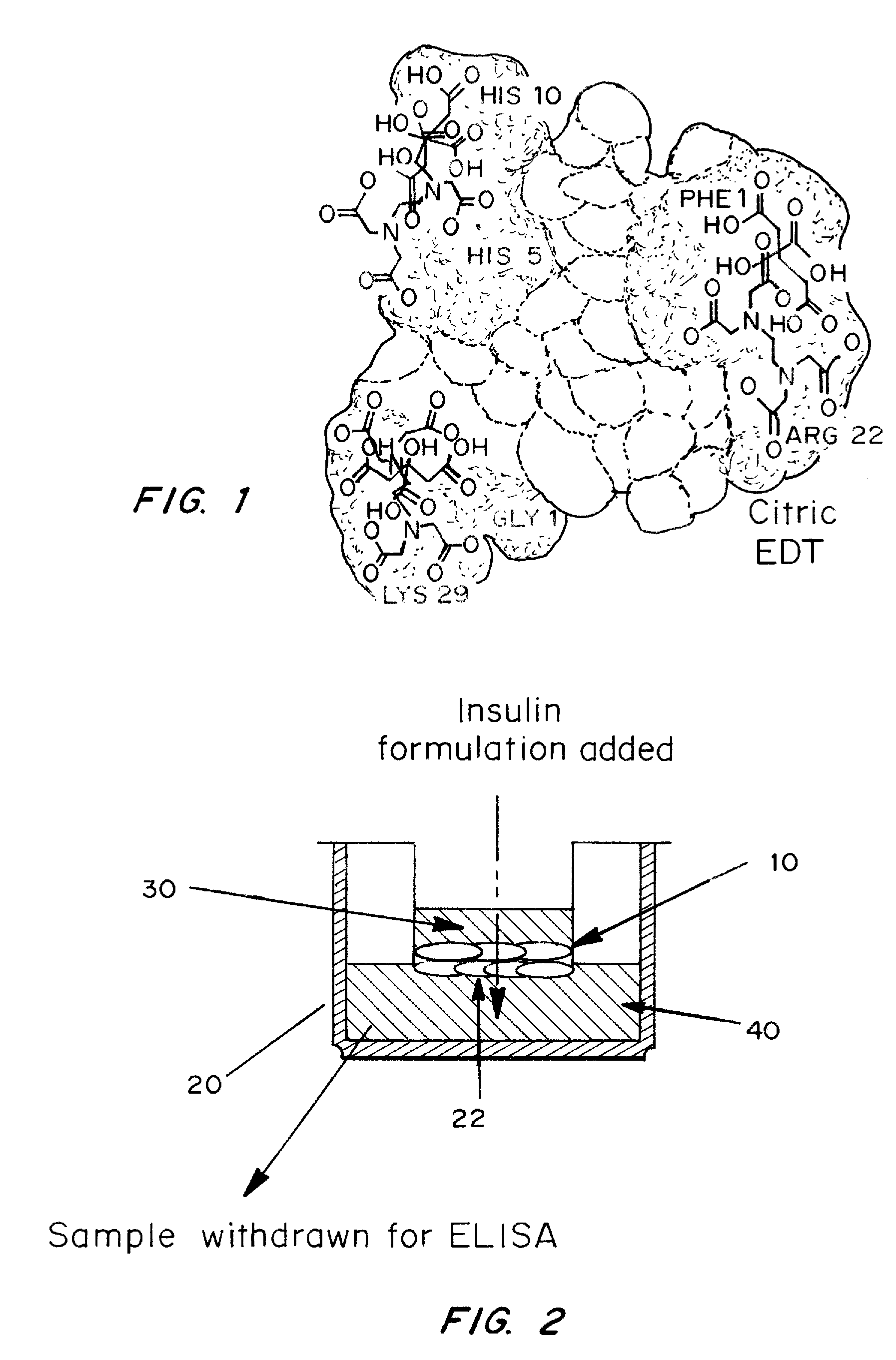

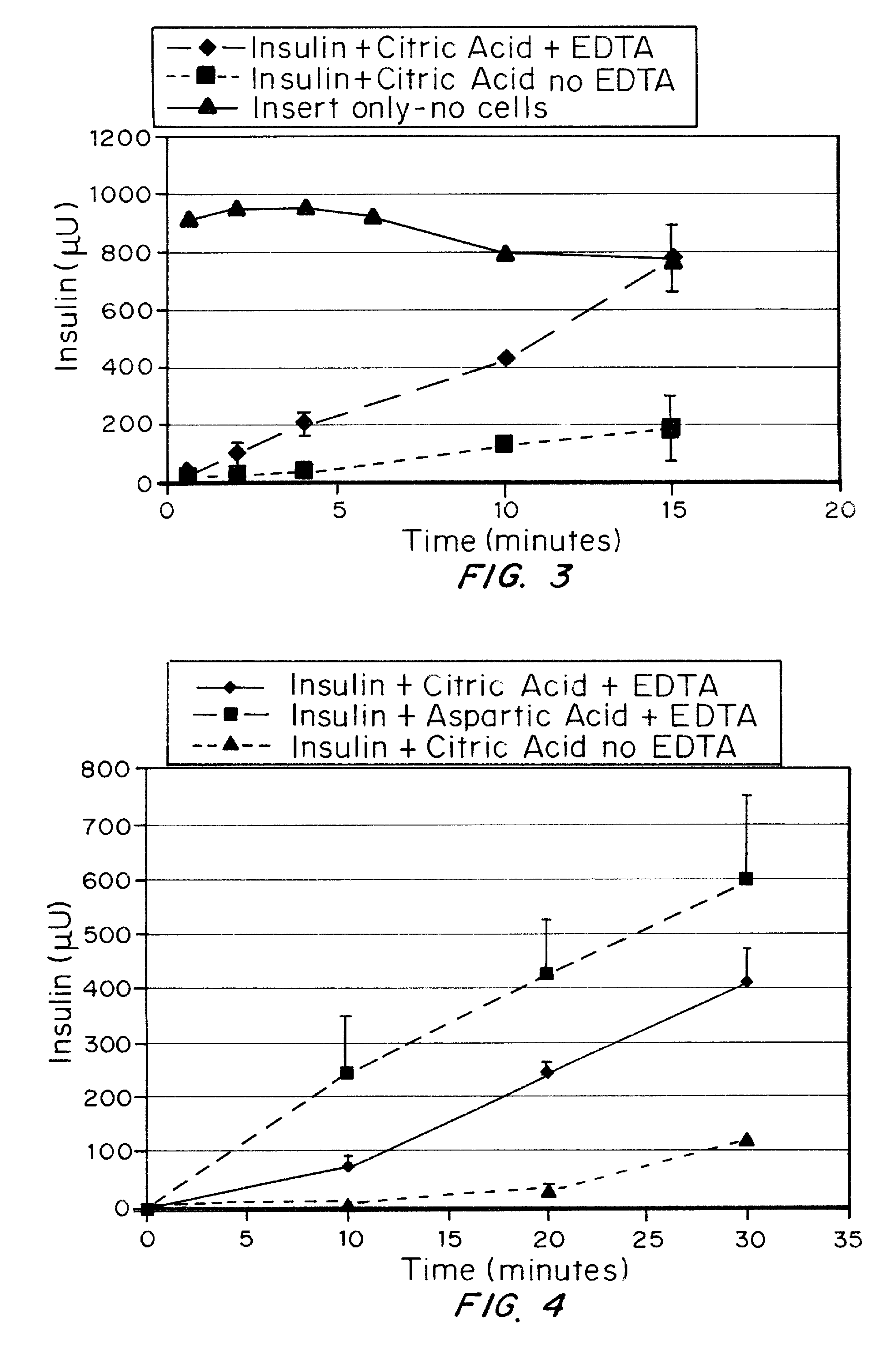

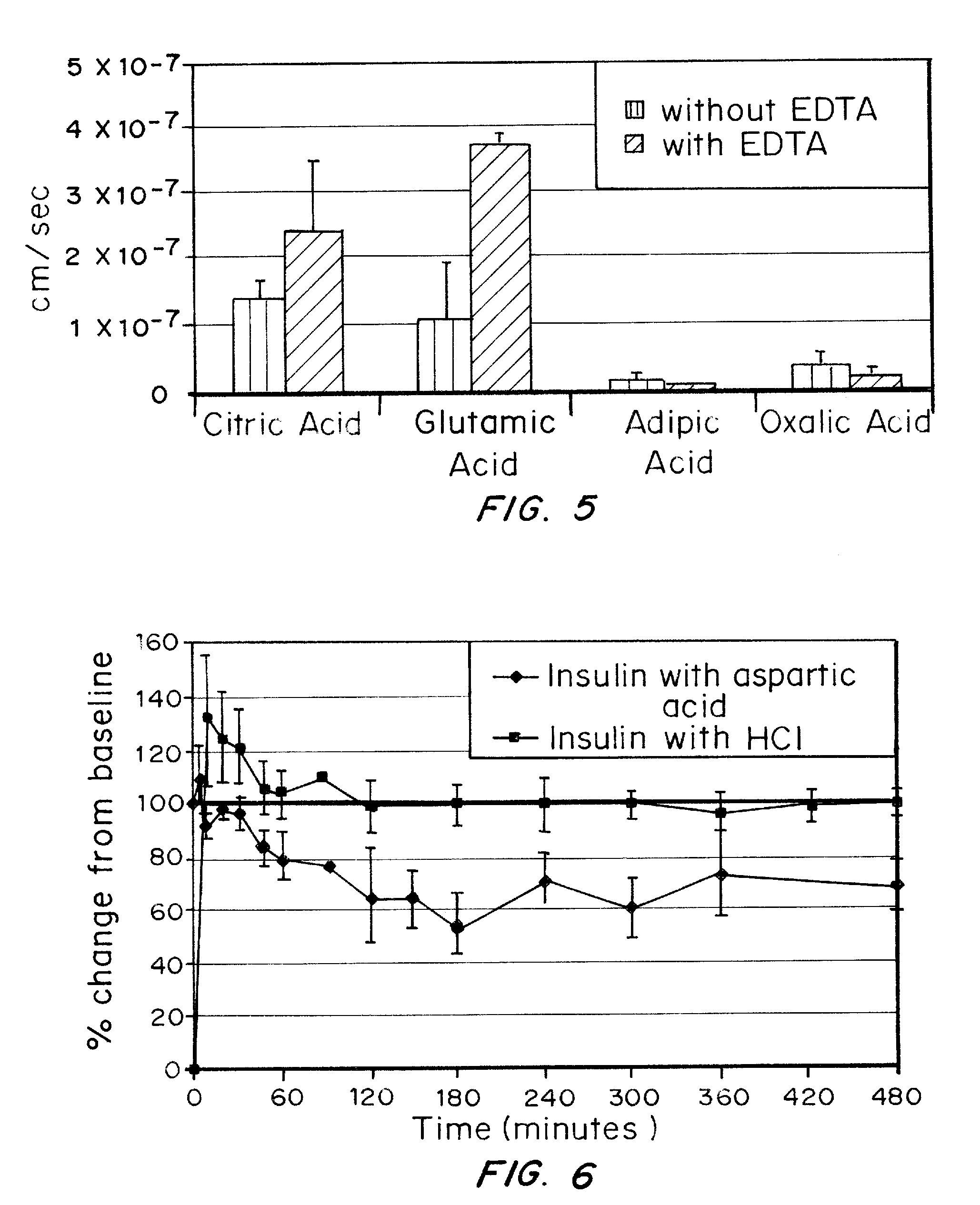

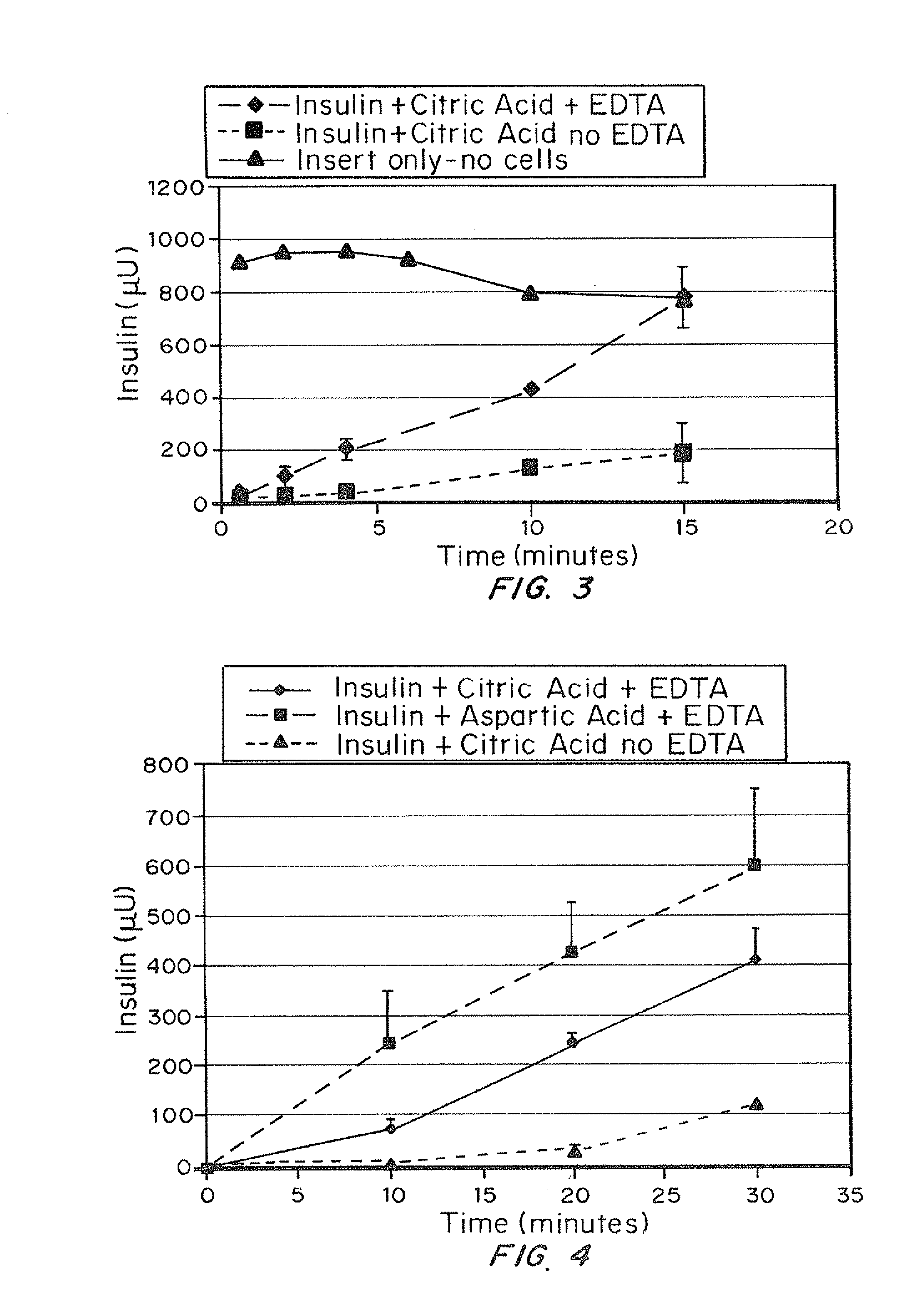

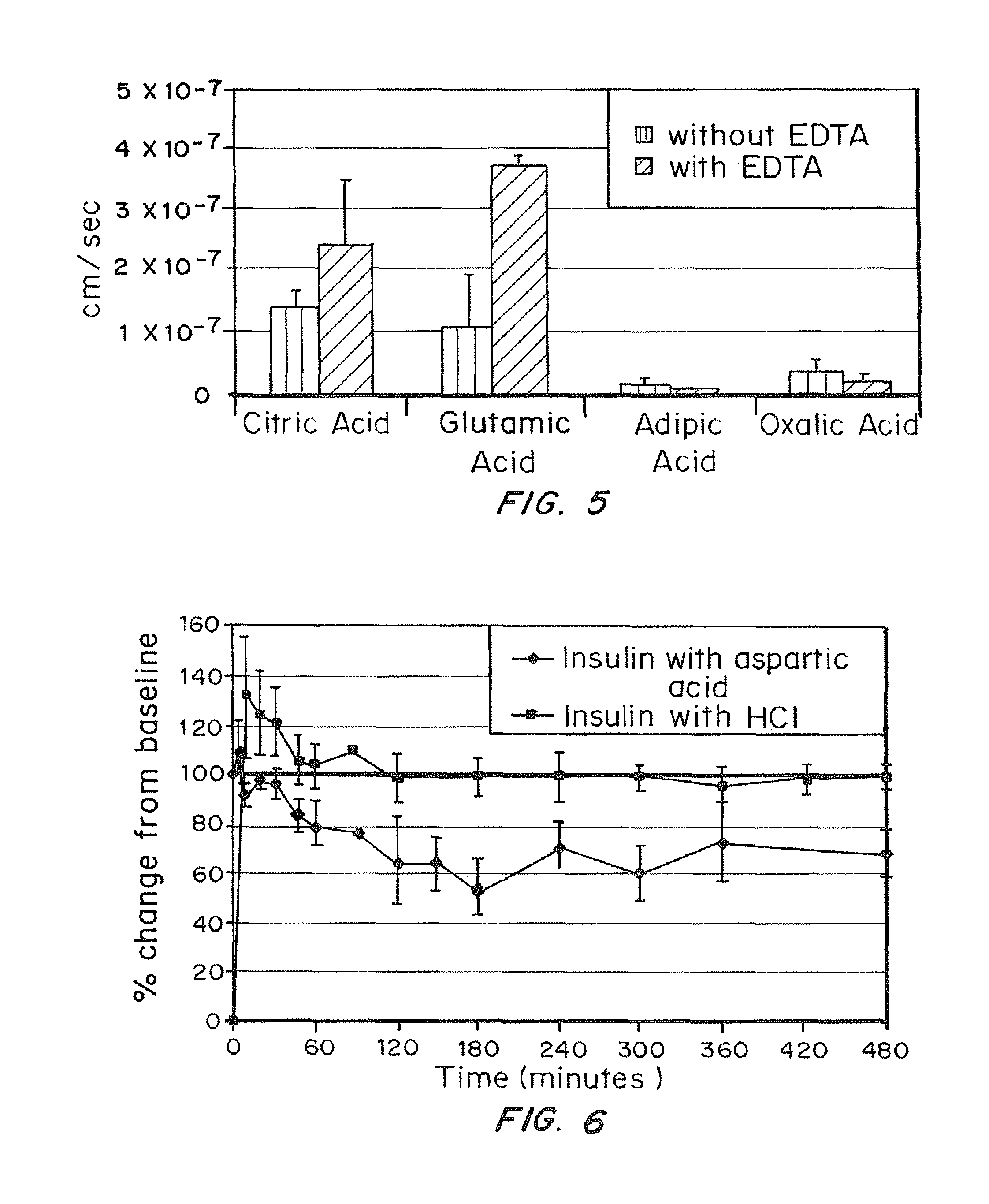

A combined rapid acting-long acting insulin formulation has been developed wherein the pH of the rapid acting insulin is adjusted so that the long acting glargine remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day. Experiments have been performed to demonstrate, the importance of the addition of specific acids to hexameric insulin to enhance speed and amount of absorption and preserve bioactivity following dissociation into the monomeric form by addition of a chelator such as EDTA. As shown by the examples, the preferred acids are aspartic, maleic, succinic, glutamic and citric acid. These are added in addition to a chelator, preferably ethylenediaminetetraacetic acid (EDTA). The results show that the citric acid formulation was more effective at dropping the blood glucose rapidly than the identical rapid acting formulation prepared with HCl in swine. Charge masking by the polyacid appears to be responsible for rapid insulin absorption. EDTA was not effective when used with adipic acid, oxalic acid or HCl at hastening the absorption of insulin. These results confirm the results seen in clinical subjects and patients with diabetes treated with the rapid acting insulin in combination with citric acid and EDTA.

Owner:ELI LILLY & CO

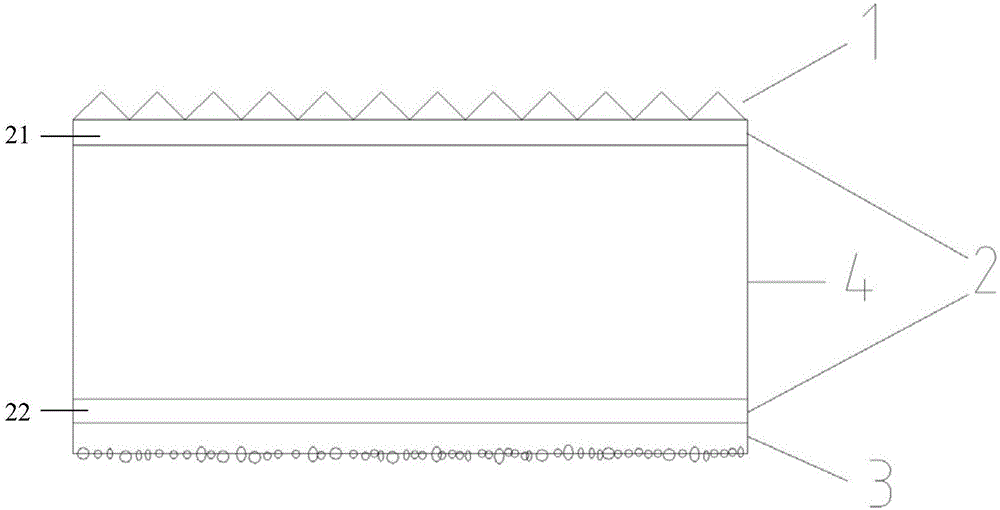

Absorbent product with improved instantaneous liquid absorption, and improved fit

InactiveUS20020052587A1Increase absorption lengthIncrease widthInfusion syringesIntravenous devicesEngineeringAbsorption layer

An absorbent product which possesses two longitudinal side edges (12, 13), two transverse end edges (10, 11), a longitudinal centre line and a transverse centre line, and which comprises a liquid-permeable outer layer (2), a liquid-impermeable backing layer (3) and an absorption core (4) which is located between the outer layer (2) and the backing layer (3), with the absorption core (4) comprising a first and a second absorption layer (14, 15), with the first absorption layer (14) being arranged behind the liquid-permeable outer layer (2) and the second absorption layer (15) being arranged between the first absorption layer (14) and the liquid-impermeable backing layer (3), with the first absorption layer (14) having two longitudinal channels (16, 17), with each of the channels having an outer edge (20) closest to the corresponding longitudinal side edge (12, 13) of the product and an inner edge (21) closest to the longitudinal centre line of the product. The two longitudinal channels (16, 17) extend through the whole of the thickness of the first absorption layer (14), and a compressed area (22) is arranged between the longitudinal sides (12, 13) of the absorbent product, wherein the distance between the side edges (24) of the compressed area (22) is smaller than or equal to the distance between the outer side edges (20) of the longitudinal channels (16, 17).

Owner:ESSITY HYGIENE & HEALTH AB

Rapid acting and long acting insulin combination formulations

ActiveUS7718609B2Increase speedReduce the amount of solutionPeptide/protein ingredientsMetabolism disorderBefore BreakfastIntensive insulinotherapy

A combined rapid acting-long acting insulin formulation has been developed in which the pH of the rapid acting insulin is adjusted so that the long acting glargine remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day.

Owner:ELI LILLY & CO

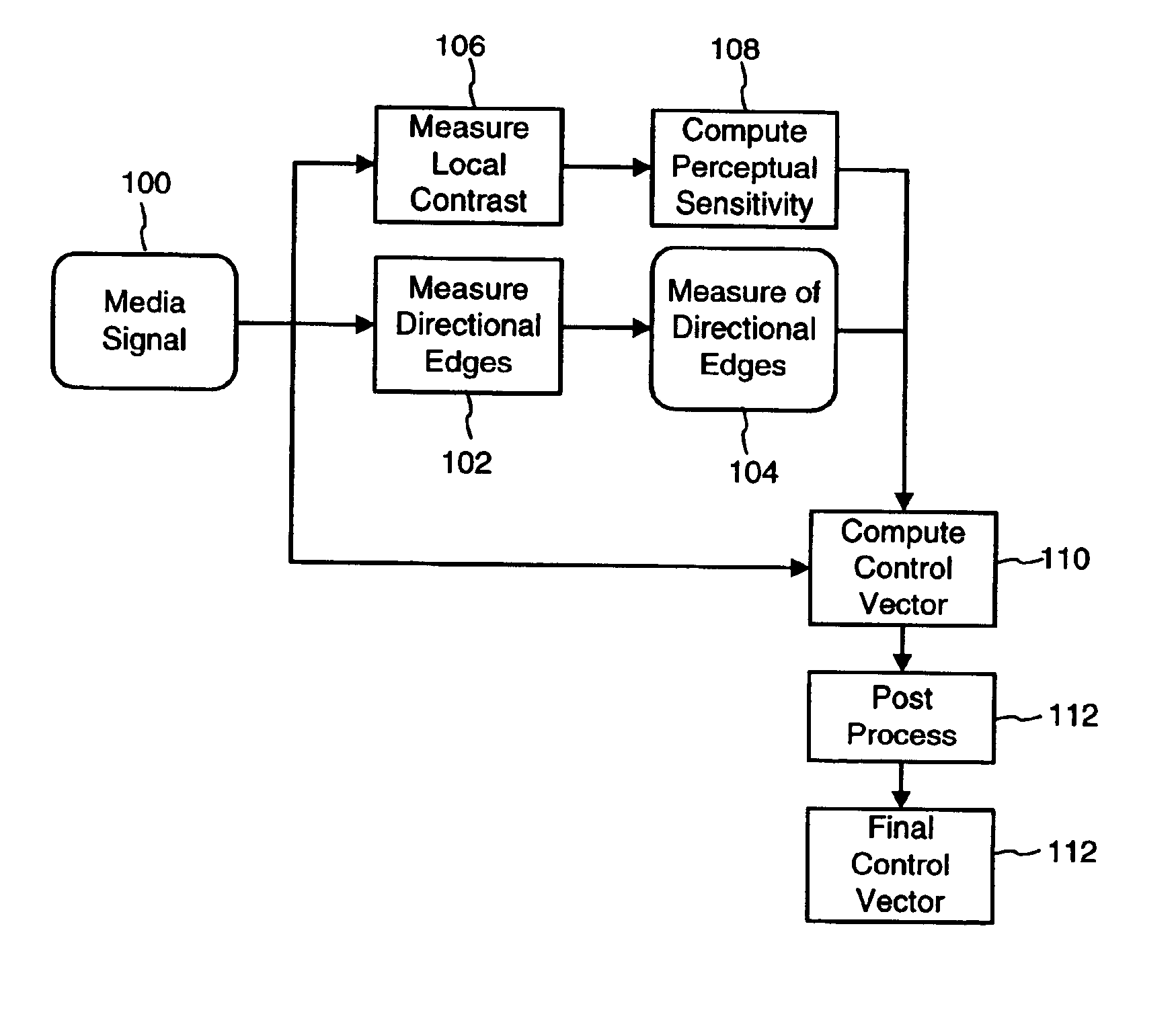

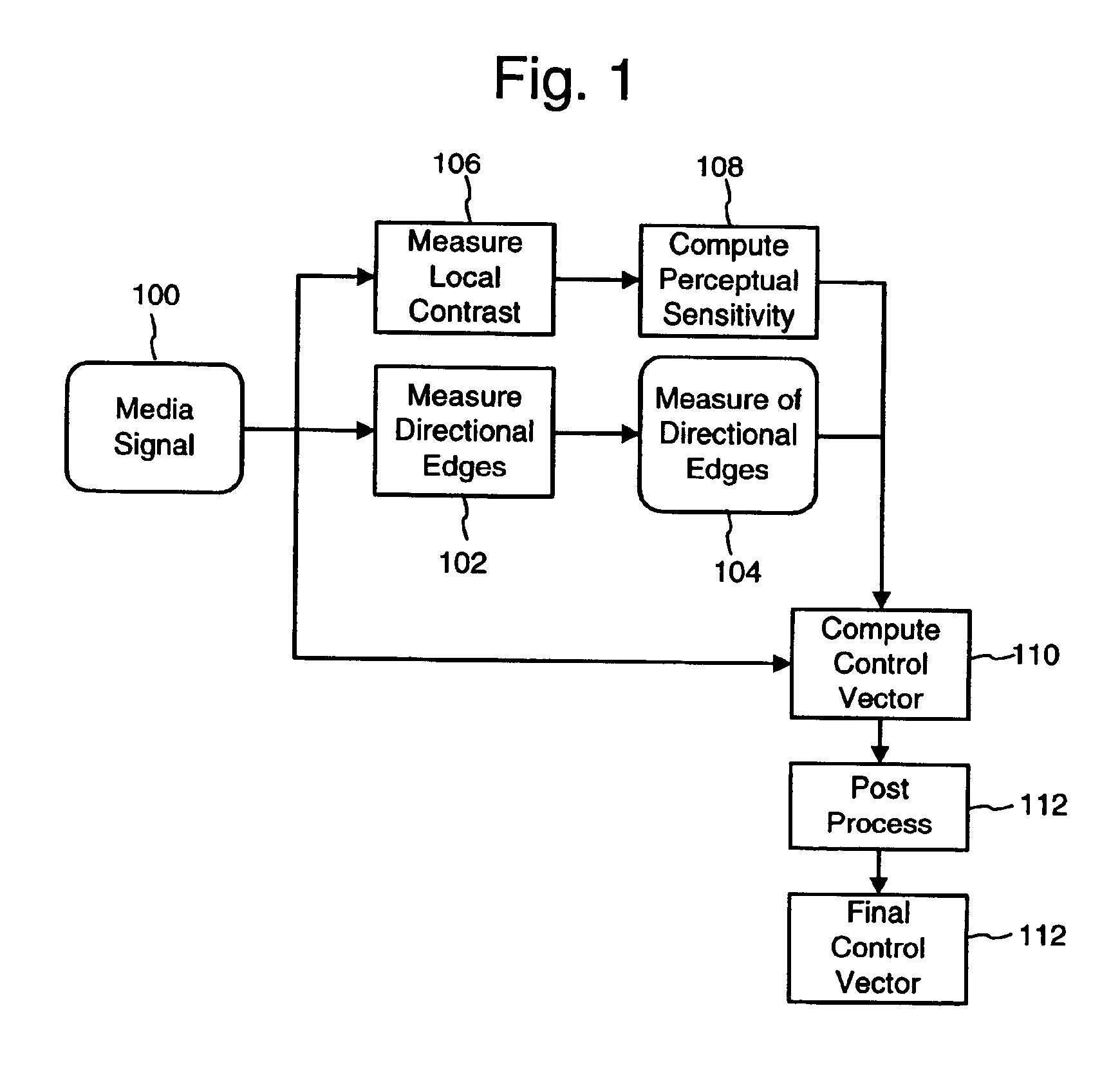

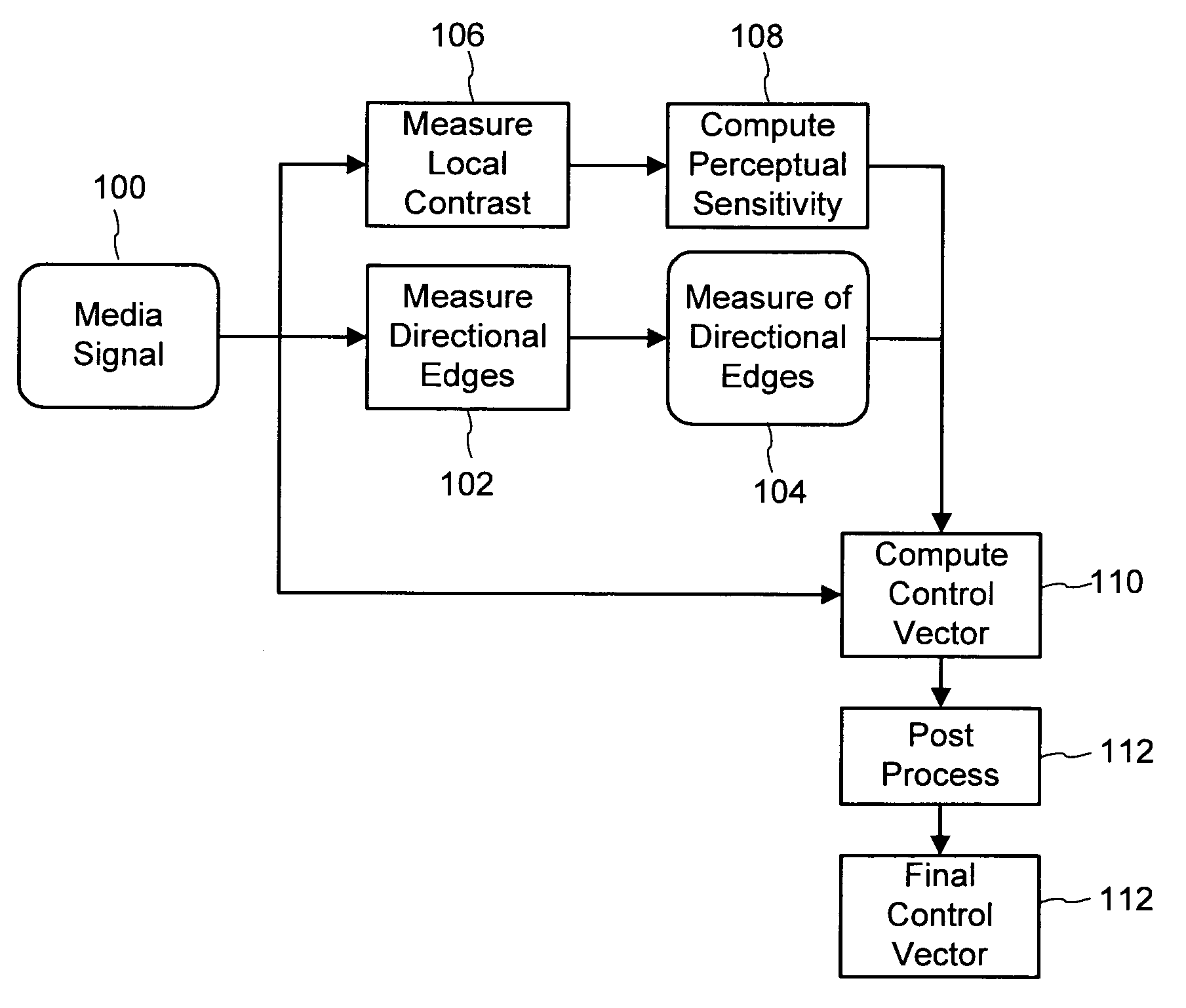

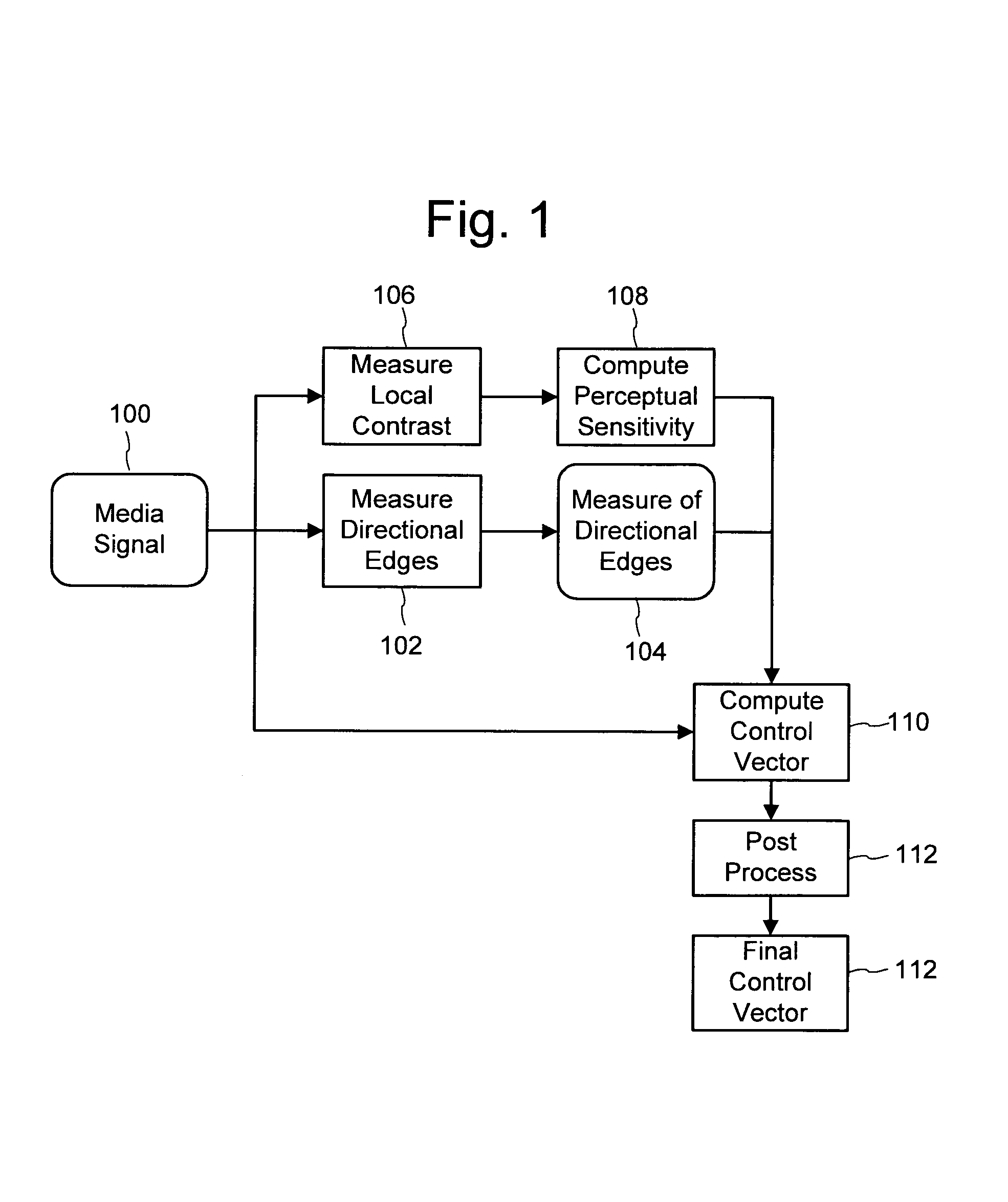

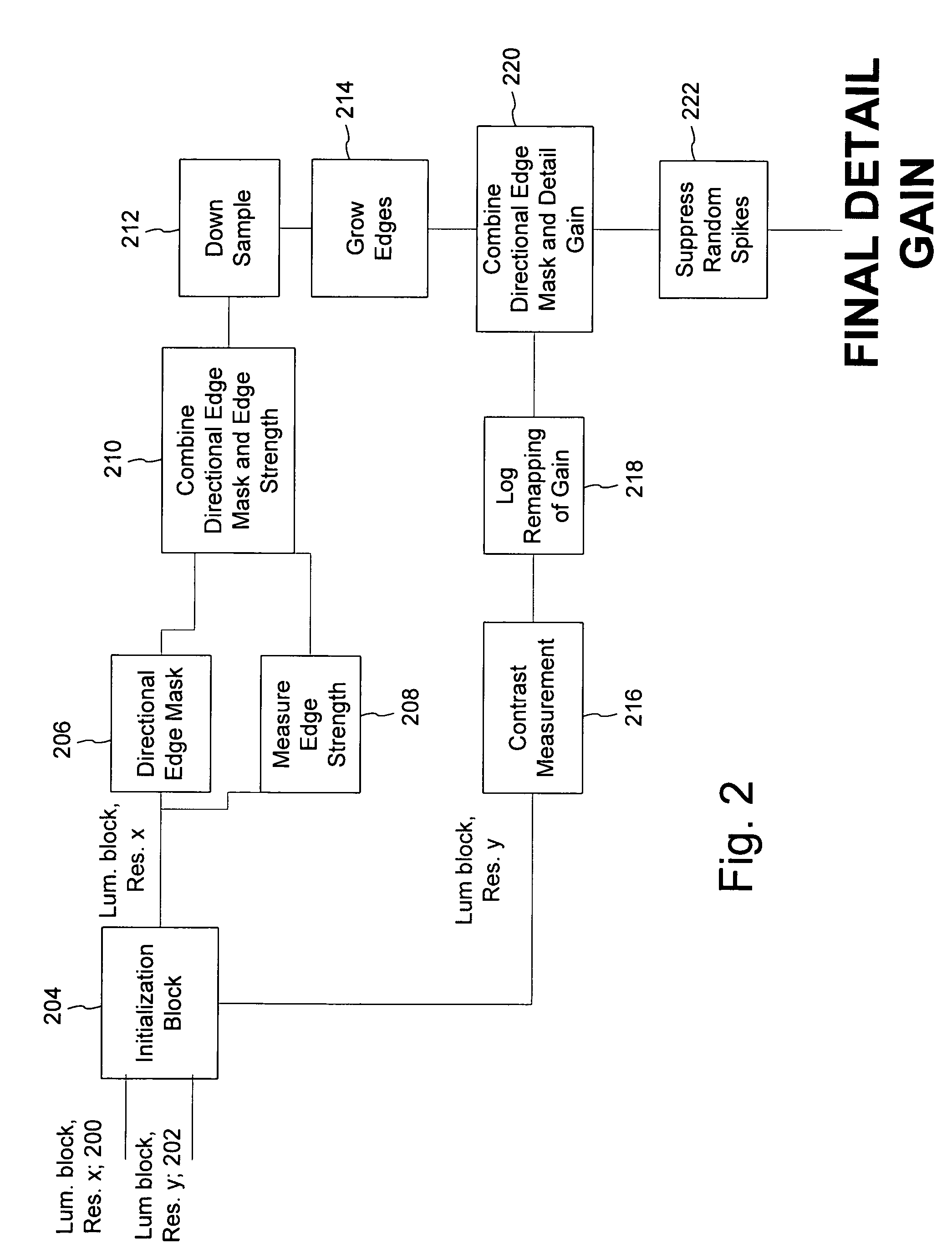

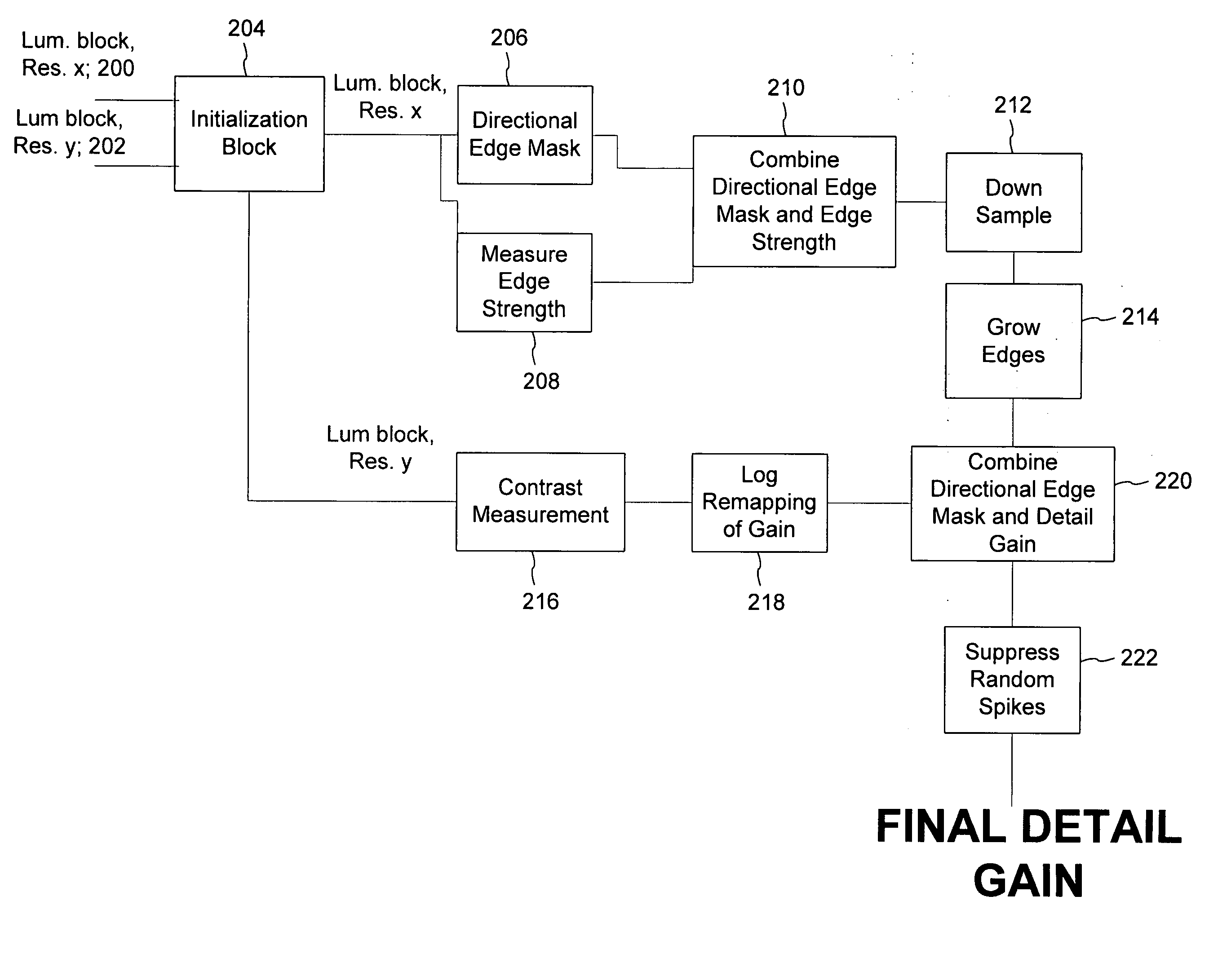

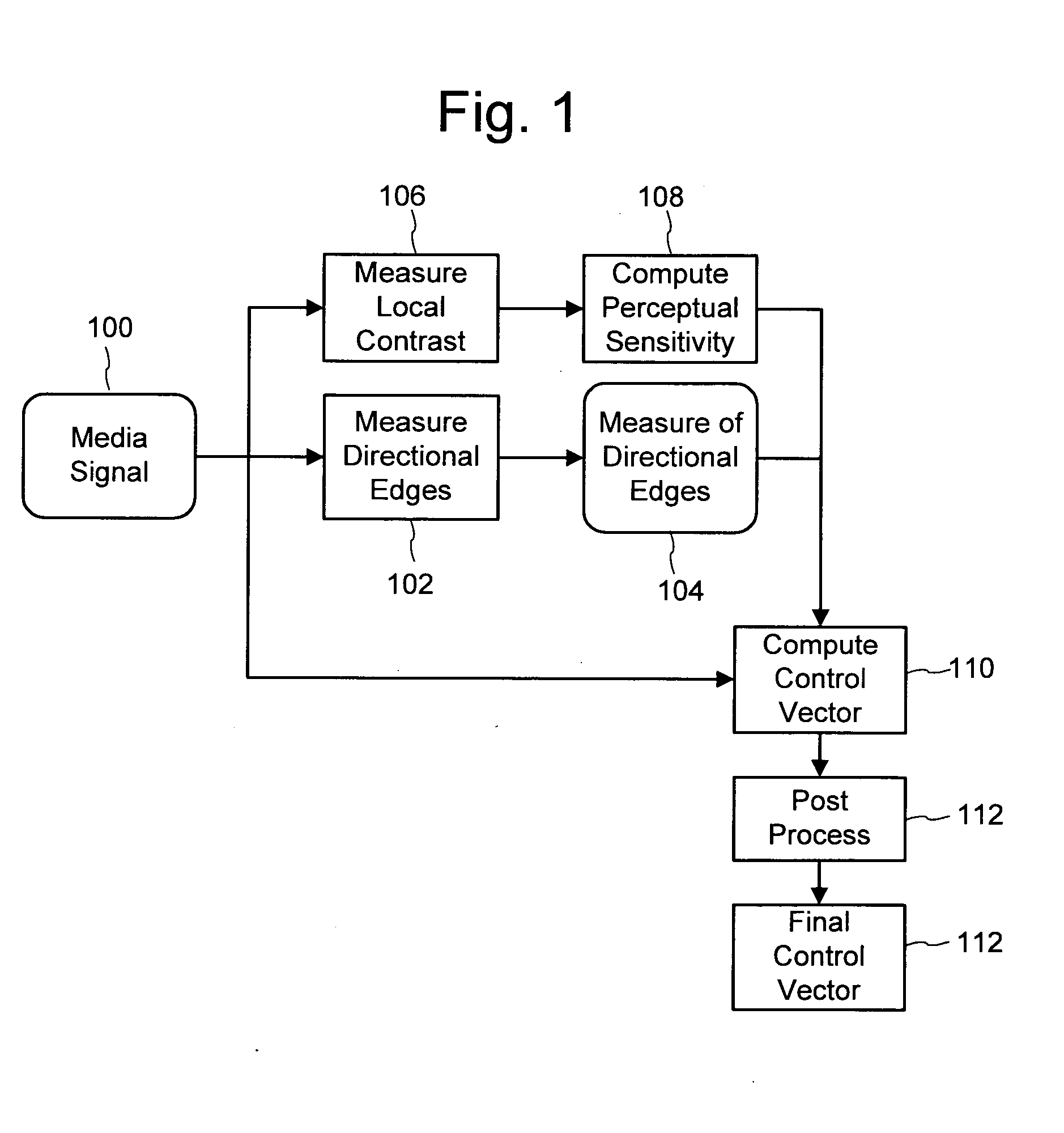

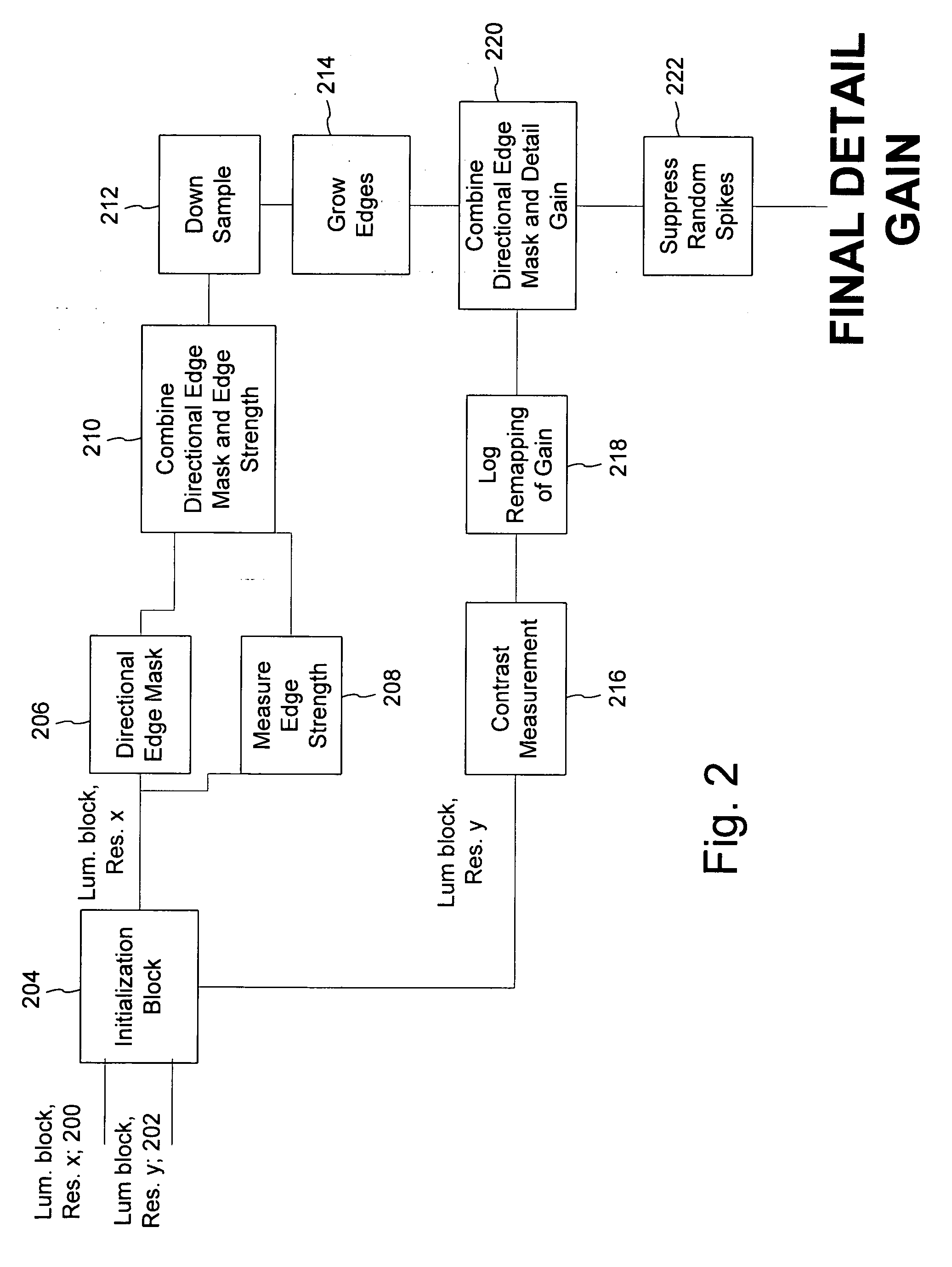

Perceptual modeling of media signals based on local contrast and directional edges

InactiveUS7088844B2Reduce memoryAttenuation bandwidthUser identity/authority verificationCharacter and pattern recognitionData compressionMediaFLO

A perceptual model performs an analysis of a media signal, such as an image or audio signal. The model may be used in media signal processing applications such as digital watermarking and data compression to reduce perceptibility of changes made to code the signal. In one implementation, a method of reducing human perceptibility of visible artifacts attributable to embedding a digital watermark in a media signal is provided. The method determines a contrast measurement for local areas of the media signal; adjusts a contrast measurement for a local area if the contrast measurement is above a predetermined level; and embeds the digital watermark in the local areas in a manner determined at least in part by their respective contrast measurement.

Owner:DIGIMARC CORP

Rapid acting and long acting insulin combination formulations

ActiveUS8084420B2Short durationImprove blood sugar controlPeptide/protein ingredientsMetabolism disorderBefore BreakfastInsulin injection

An injectable formulation containing a rapid acting insulin and a long acting insulin has been developed. The pH of the rapid acting insulin is adjusted so that the long acting insulin, remains soluble when they are mixed together. Preferably, the formulation is administered before breakfast, provides adequate bolus insulin levels to cover the meal and basal insulin for up to 24 hours, and does not produce hypoglycemia after the meal. Lunch and dinner can be covered by two bolus injections of a fast, rapid, or very rapid acting insulin. Alternatively, by adjusting the ratio of rapid to long acting insulin, the long acting insulin may be shortened to a 12 hour formulation, and re-administered to the patient at dinner time, providing a safe and effective basal insulin level until morning. As a result, a patient using intensive insulin therapy should only inject three times a day.

Owner:ELI LILLY & CO

Transparent heat insulation polyvinyl chloride rubberized fabric and preparation method thereof

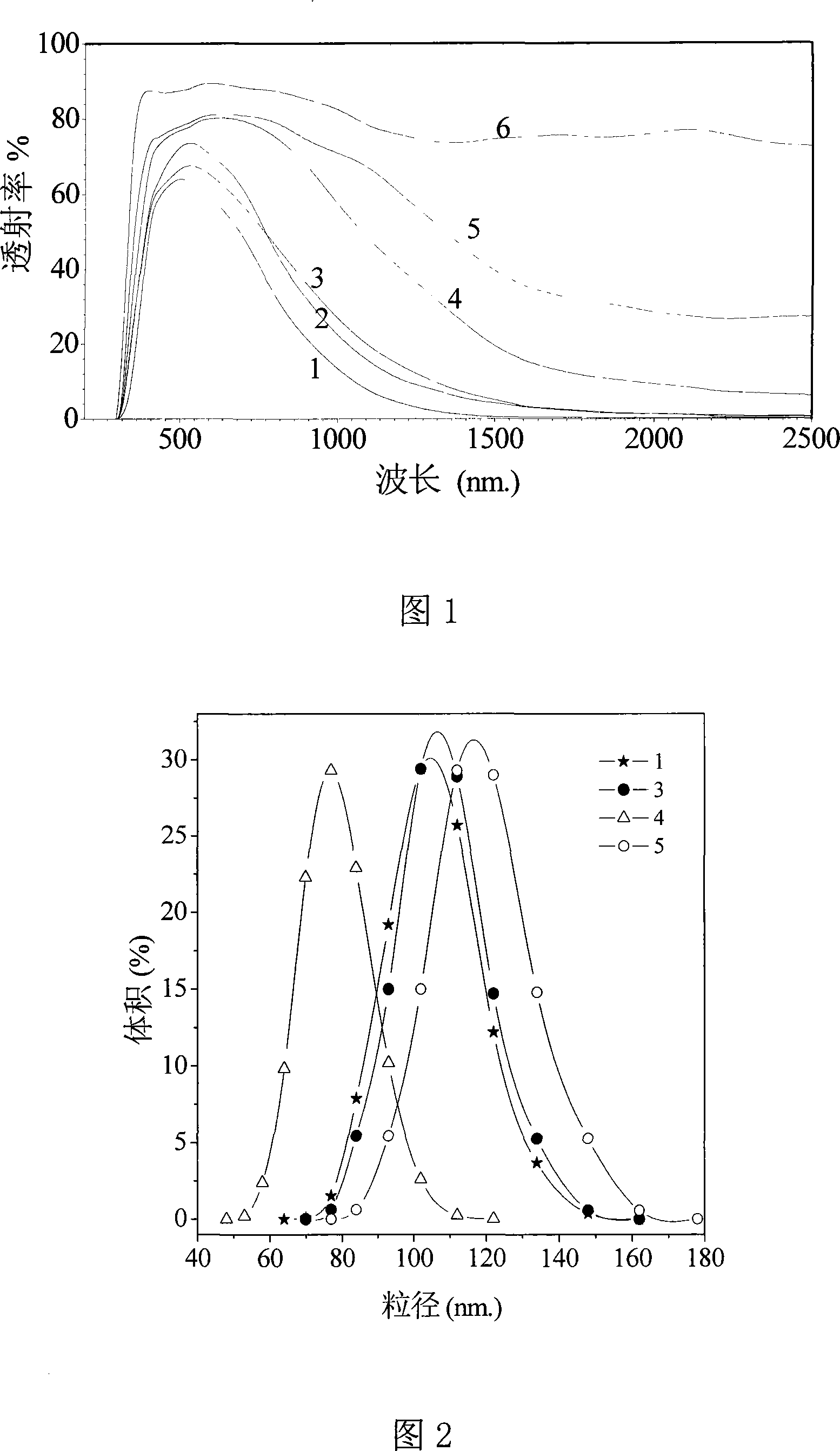

InactiveCN101962516AGood infraredGood UV shielding effectNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer sciencePlasticizer

The invention relates to a transparent heat insulation polyvinyl chloride rubberized fabric prepared in a non-coating processing mode and a preparation method thereof. The prepared rubberized fabric has the infrared and ultraviolet blocking energy-saving effect. The preparation method comprises the following steps of: mixing a heat insulation material and an auxiliary agent for modification and stirring the mixture uniformly, properly dispersing the heat insulation granules, and mixing the dispersed heat insulation granules, polyvinyl chloride resin, plasticizer and auxiliary agent in turn; and directly guiding the rubberized mixture to a rubberized fabric machine for rolling and the like. The rubberized fabric produced by the method has the physical properties of good heat insulation effect, transparency and the like.

Owner:NANYA PLASTICS CORP

Rapid acting and long acting insulin combination formulations

ActiveUS20090137455A1Short durationImprove blood sugar controlPeptide/protein ingredientsMetabolism disorderBefore BreakfastIntensive insulinotherapy

An injectable formulation containing a combination of a rapid acting insulin and a long acting insulin has been developed wherein the pH of the rapid acting insulin is adjusted so that the long acting insulin, e.g. insulin glargine, remains soluble when they are mixed together. In the preferred embodiment, this injectable basal bolus insulin is administered before breakfast, provides adequate bolus insulin levels to cover the meal, does not produce hypoglycemia after the meal and provides adequate basal insulin for up to 24 hours. Lunch and dinner can be covered by two bolus injections of a fast acting, or a rapid acting or a very rapid acting insulin. Alternatively, through adjustment of the ratio of rapid acting insulin to long acting insulin, the long acting insulin may be shortened to a 12 hour formulation. This rapid and long acting blend is re-administered to the patient at dinner time, providing a safe and effective basal insulin level until morning. As a result, a patient using intensive insulin therapy should only inject three, rather than four, times a day.

Owner:ELI LILLY & CO

Perceptual modeling of media signals for data hiding

InactiveUS7483547B2Reduce memoryAttenuation bandwidthUser identity/authority verificationCharacter and pattern recognitionTelecommunicationsSteganography

The present invention relates generally to steganography and data hiding. In one embodiment a method is provided including obtaining a media signal; determining characteristics of the media signal; based at least in part on the characteristics of the media signal, providing a map of the media signal; transforming at least some portions of the media signal into a transform domain; and hiding plural-bit data in at least some portions of the transformed media signal. The map identifies at least one area in the media signal in which hiding of plural-bit data should be avoided or suppressed. At least one of the act of transforming or the act of hiding utilizes the map of the media signal. Other embodiments are also provided.

Owner:DIGIMARC CORP

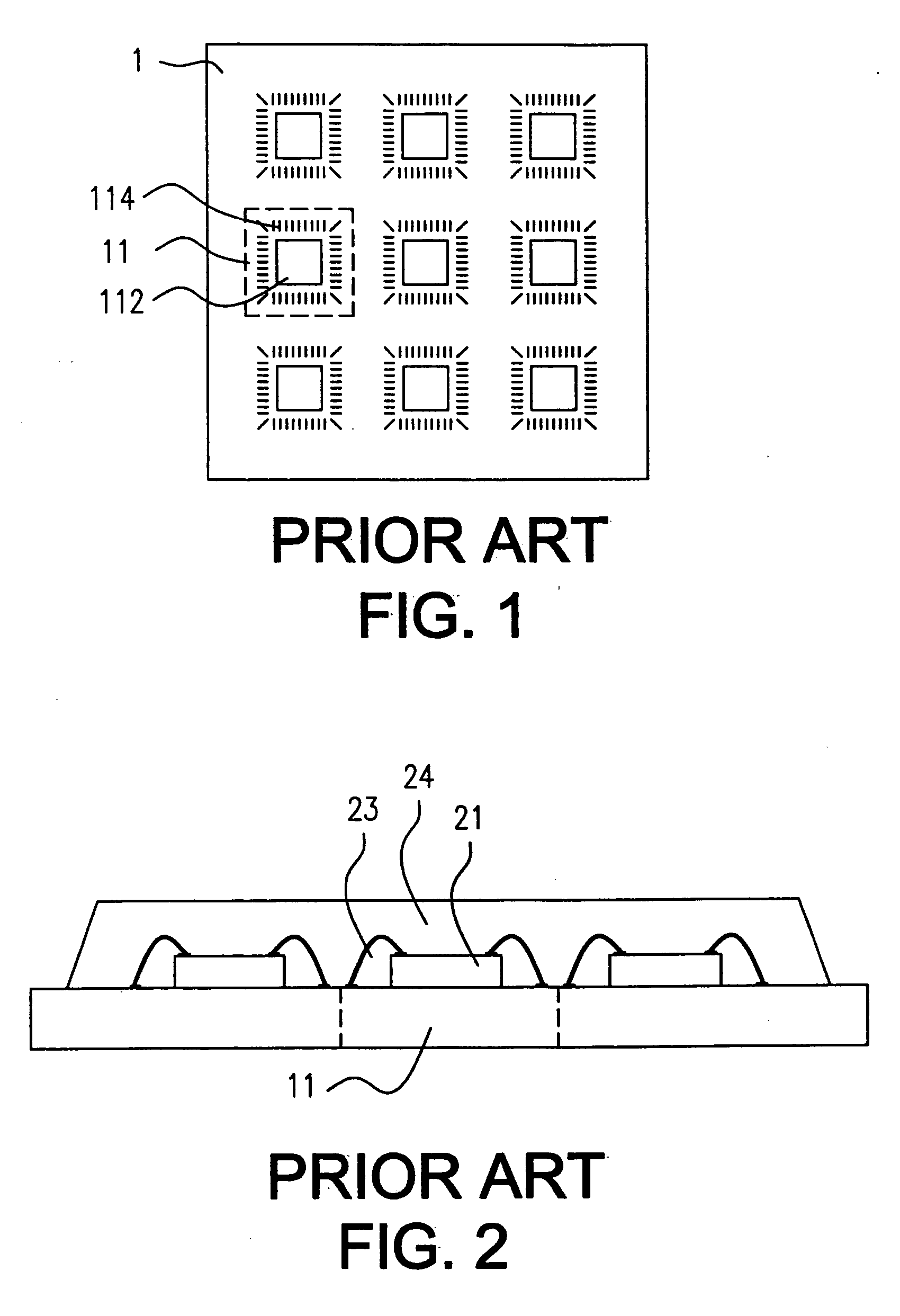

Stiffening plate for printed circuit board

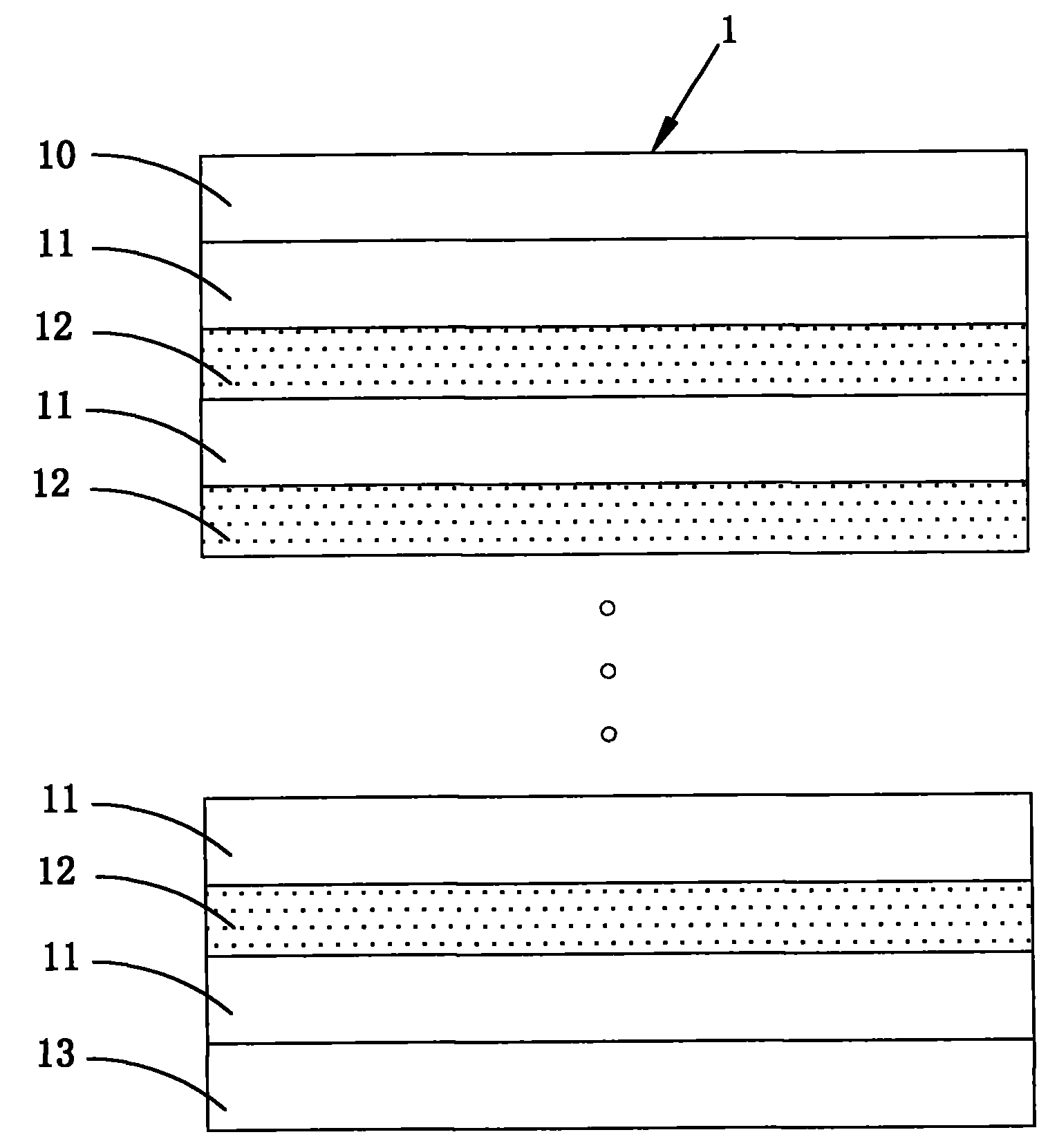

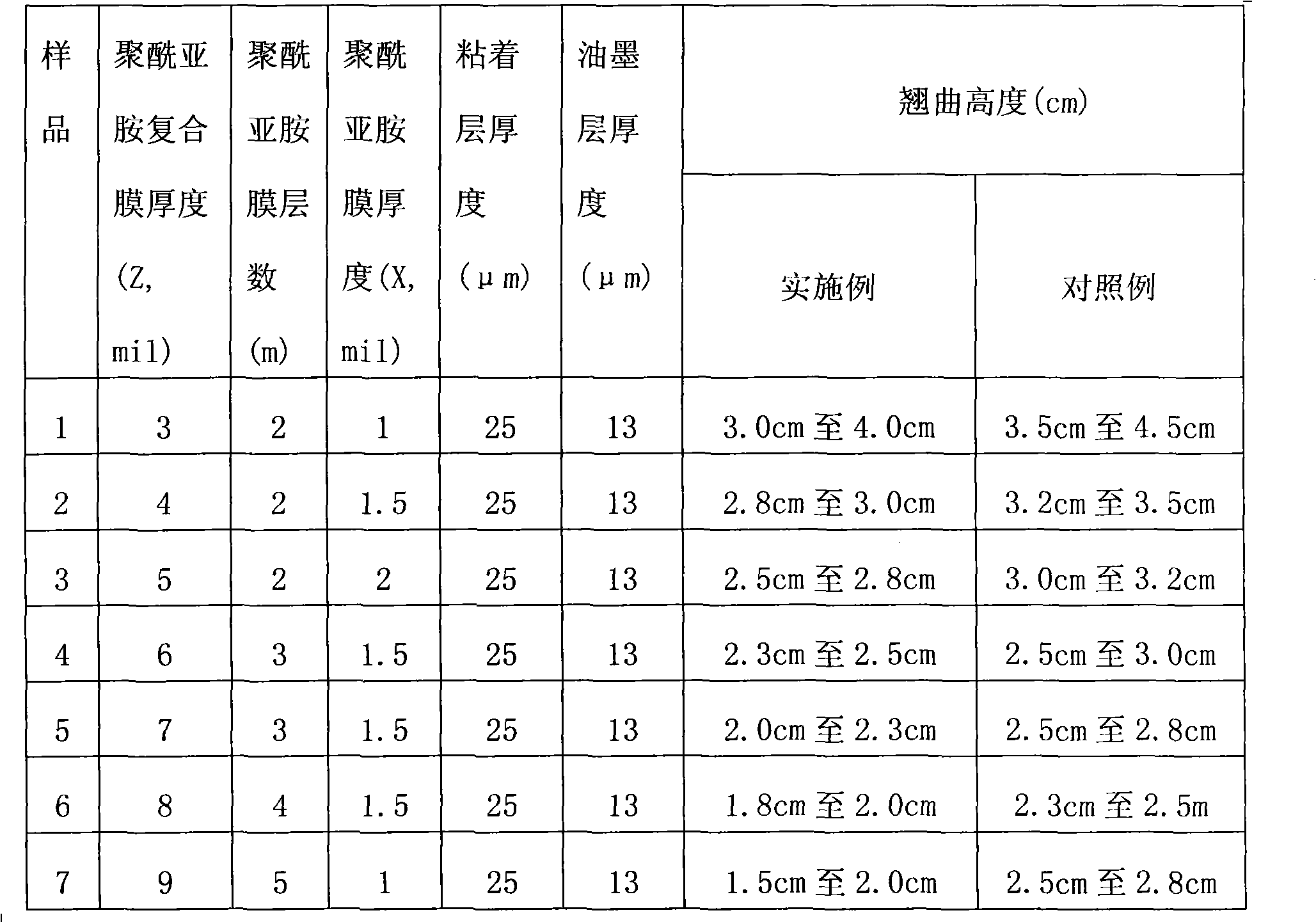

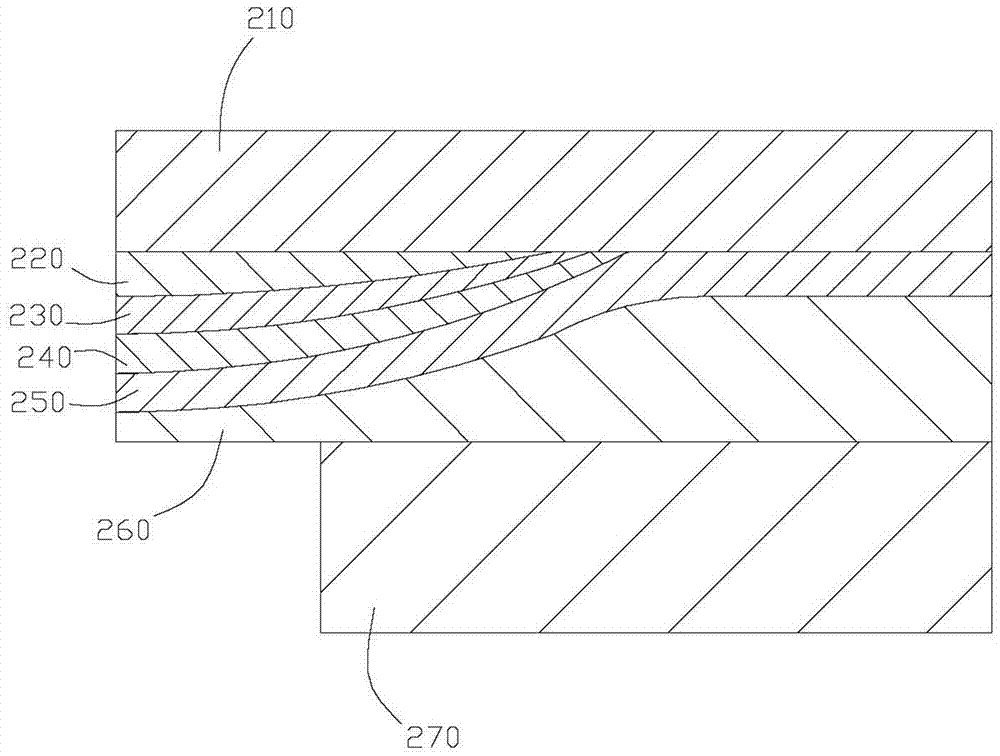

ActiveCN102143646AImprove reflectivityGood shieldingPrinted circuit detailsSynthetic resin layered productsEngineeringPolyimide membrane

The invention discloses a stiffening plate for a printed circuit board, which consists of an ink layer, a polyimide compound membrane and an adhesive layer for sticking the polyimide compound membrane to the printed circuit board. A polyimide compound membrane fixing clamp is arranged between the ink layer and the adhesive layer. The polyimide compound membrane consists of a plurality of polyimide membranes and adhesion agent layers for sticking the adjacent polyimide membranes. The ink layer with specific thickness can lower the warping height of the compound membrane stuck to the circuit board, and contributes to protection of circuit patterns of electronic products. In addition, the ink layer of the stiffing plate comprises developers, wherein white developers can endow the compound membrane with good reflectivity and black developers can improve the shielding effect of circuit patterns, and the ink layer of the stiffing plate also comprises heat radiation powder bodies which can enhance heat radiation.

Owner:KUSN APLUS TEC CORP

Energy-saving heat-insulating environment-protection coating material for glass and producing method thereof

ActiveCN101172778ATo overcome the excessive content of volatile organic solventsOvercome uniformity issuesInfraredAcrylic resin

The invention discloses a coat material for glass effective in energy saving, heat insulation and environment protection. The coat material is characterized in that the invention comprises by weight percent of 10 to 65 percent of improved aquosity urethane resin, 0 to 40 percent of modified aquosity acrylic resin, 2 to 55 percent of nanometer metal oxide aquosity paste, 0 to 70 percent of water, and 0 to 5 percent of auxiliary agent. The production method comprises the steps as follows: modified resin is fixed equably with water, the nanometer metal oxide aquosity paste is added, and finally the auxiliary agent is added to mix. The glass coated with the dope has high permeance rate of visible light, while the ultraviolet and the infrared ray (thermal radiation) have extremely low permeance rate, thereby having the function of high efficiency to obstruct the ultraviolet and the infrared ray. Besides, the invention is an environmental protection product taking water as the solvent, and has simple construction method. The coating membrane can solidify into membrane under the room temperature rapidly. The invention is widely used in the energy conservation and heat insulation for door-window glass of all buildings, vehicles and ships.

Owner:烟台佳隆纳米产业有限公司

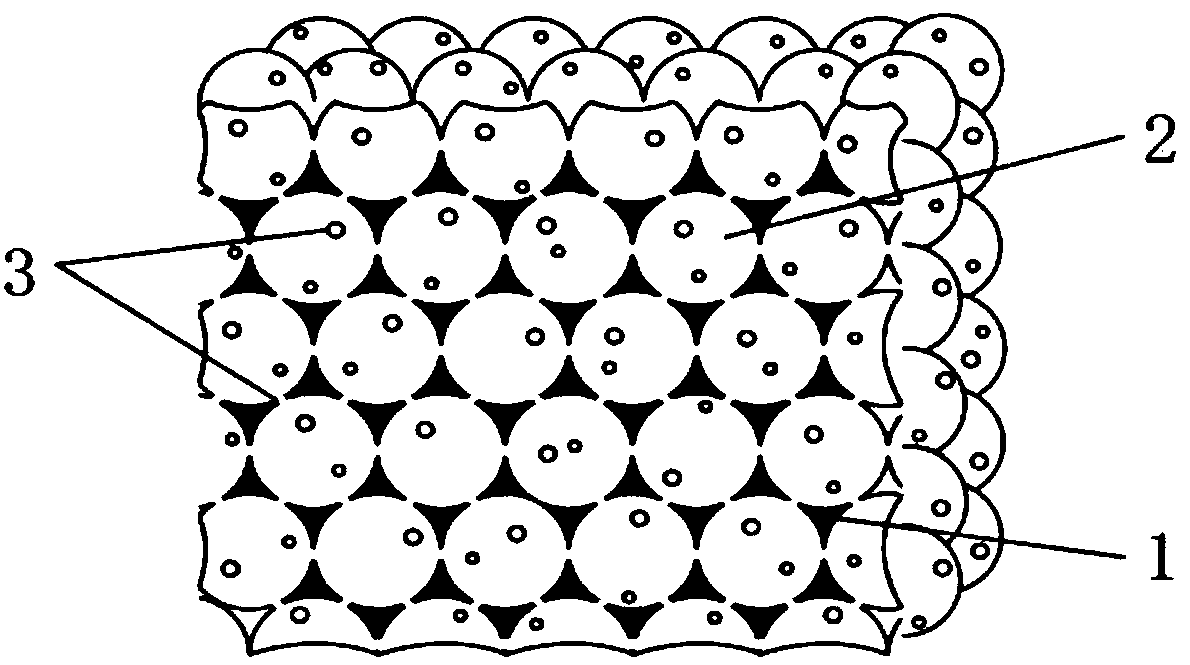

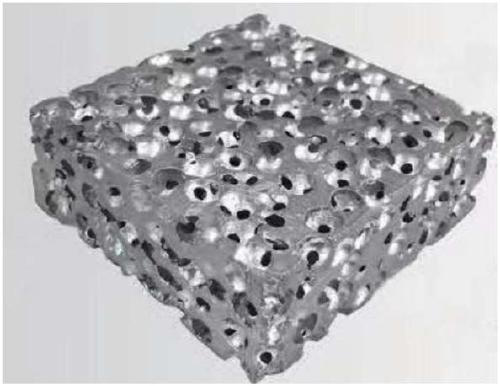

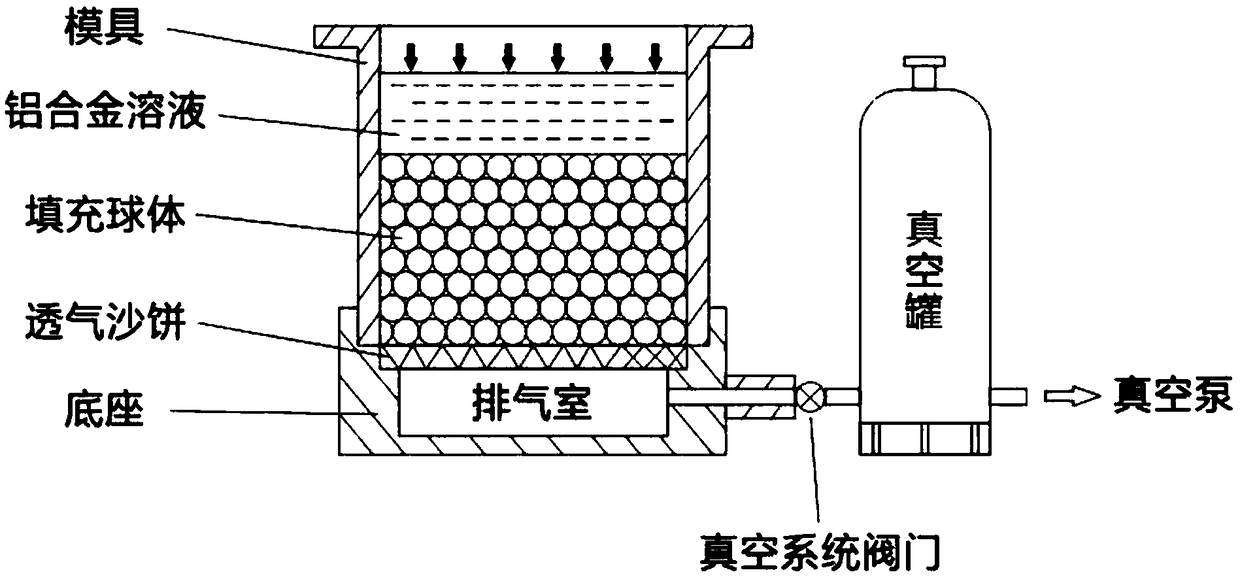

High-performance through hole foamed aluminum material and preparation process thereof

ActiveCN109465426ALarge specific surface areaOvercome energy absorptionProduction lineEnergy absorption

The invention relates to a preparation process of a high-performance through hole foamed aluminum material. The preparation process mainly comprises the steps that prepared transition filling balls are placed into a casting mold, after vibration operation and preheating treatment, the prepared transition filling balls are moved into a negative pressure device, a negative pressure valve is startedto form negative pressure in a mold cavity, molten aluminum alloy molten liquid is cast, and the clearances between the balls are evenly full of the aluminum alloy molten liquid in a penetration manner under the action of negative pressure and heat balance; and after cooling, the mold is demounted, cutting and slicing or modeling processing is carried out, the transition filling balls are clearedaway and removed through production lines of ultrasonic cleaning, high-pressure water cleaning, high-pressure gas cleaning and drying cleaning, three-dimensional through ball-shaped pore cavities aredistributed in an obtained aluminum alloy matrix, and the regular ball-shaped pore cavities are independently and evenly distributed in the matrix, and the ball-shaped pore cavities are connected through through holes. The specific surface area of the matrix is large, and the physical, mechanics and mechanical properties are better on the aspects of damping, energy absorption, sound insulation andnoise reduction, heat insulation, electromagnetic shielding, impacting force resistance, permeability and the like.

Owner:王楷煌

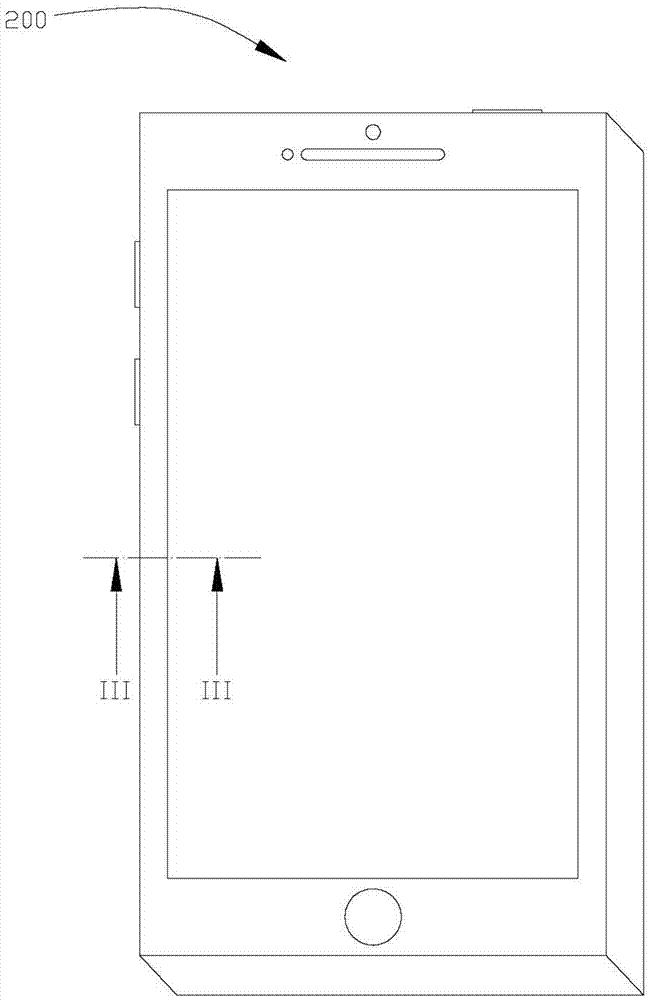

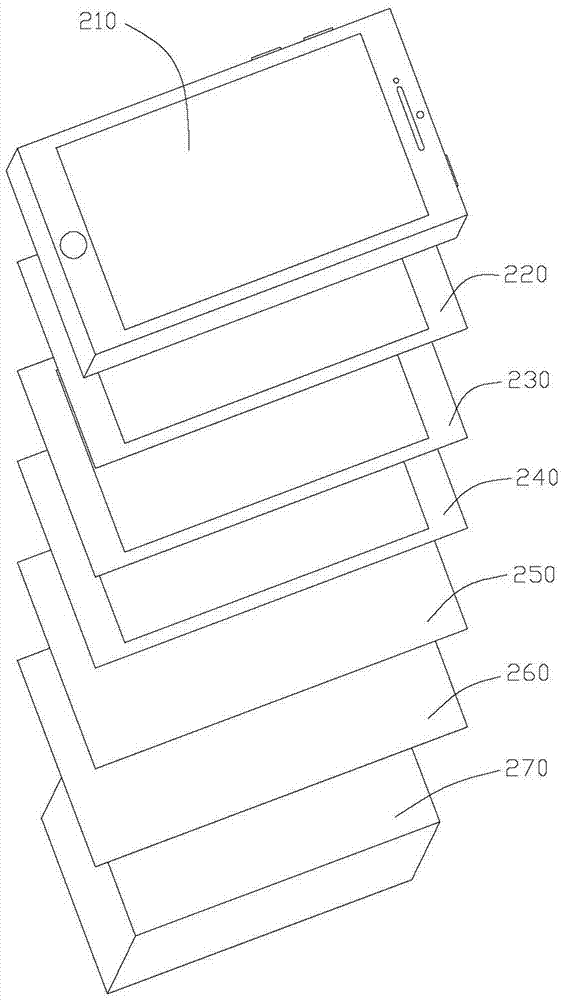

Touch display apparatus

ActiveCN105446527AReduce the differenceReduce the probability of air bubblesInput/output processes for data processingLight absorbanceOxide

The present invention relates to a touch display apparatus. The touch display apparatus is defined to comprise a touch area for displaying an image and receiving a touch operation and a non-touch area surrounding the touch area. The touch display apparatus comprises a cover plate, a display panel, and a decorative layer and a shielding layer that are located between the cover plate and the display panel and are arranged corresponding to the non-touch area. The decorative layer is used for providing a required border color for the touch display apparatus, and the shielding layer is used for shielding electrical signal transmission cabling surrounding the touch display apparatus. The decorative layer is between the cover plate and the shielding layer. The shielding layer is made of metal or metal oxide. According to the touch display apparatus, metal or metal oxide is used as the shielding layer of the touch display apparatus, so that a probability of bubble generation in the touch display apparatus is reduced. In addition, light absorbance of a decorative border can be improved, thereby having a good shielding effect.

Owner:INTERFACE OPTOELECTRONICS SHENZHEN +1

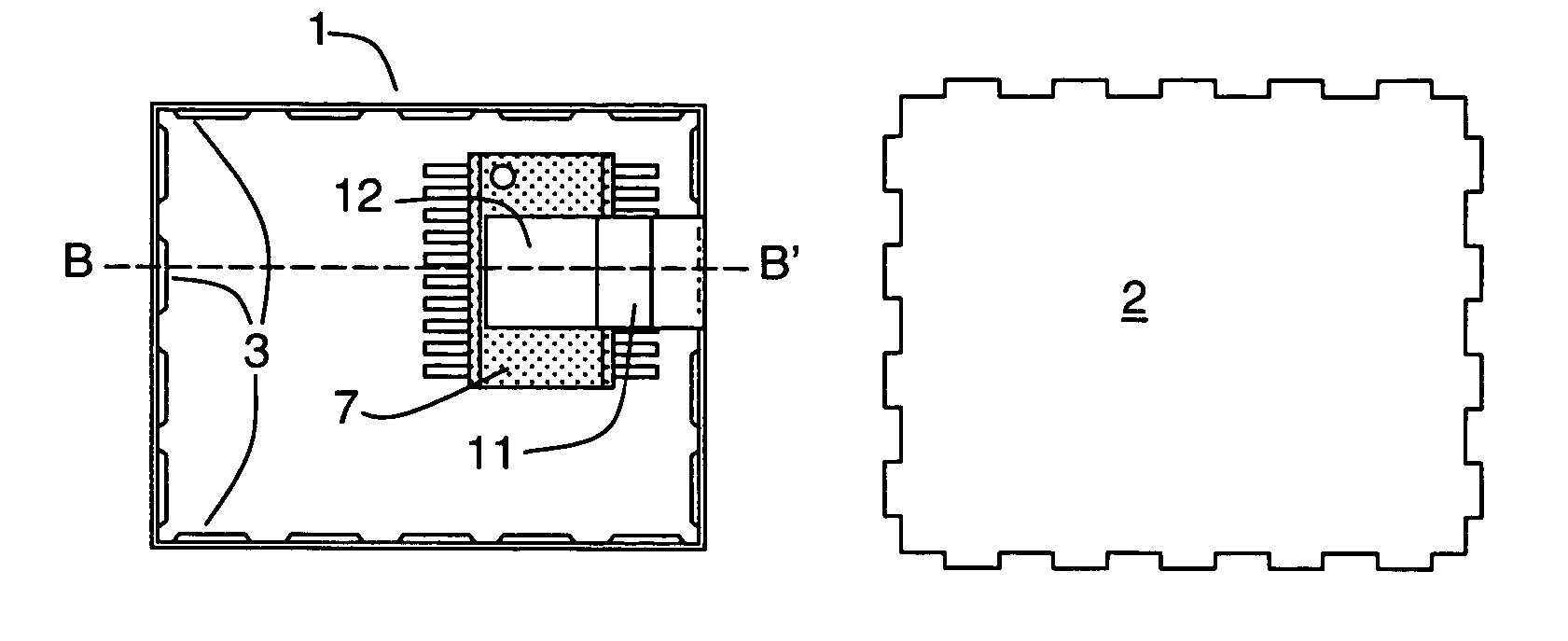

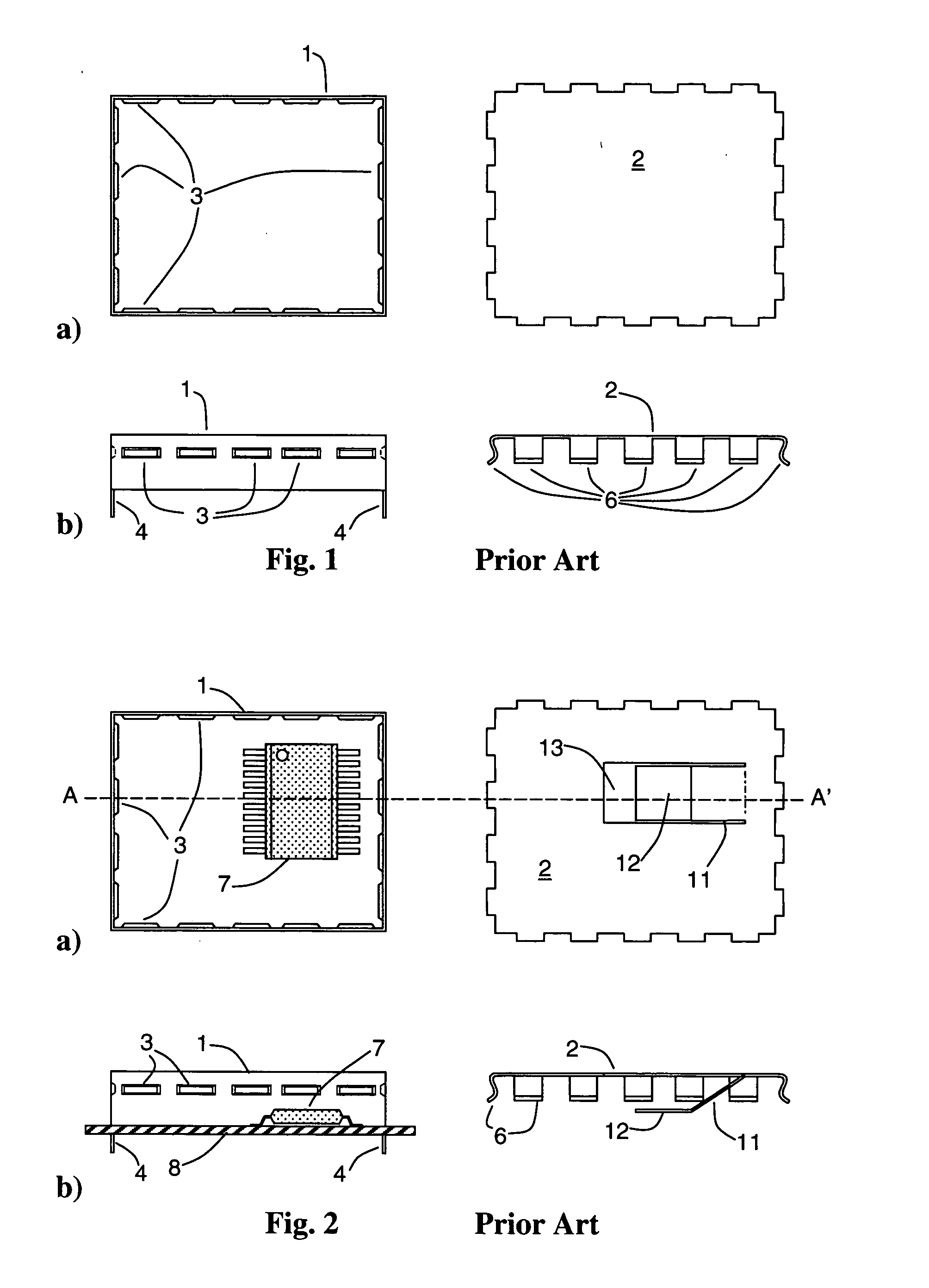

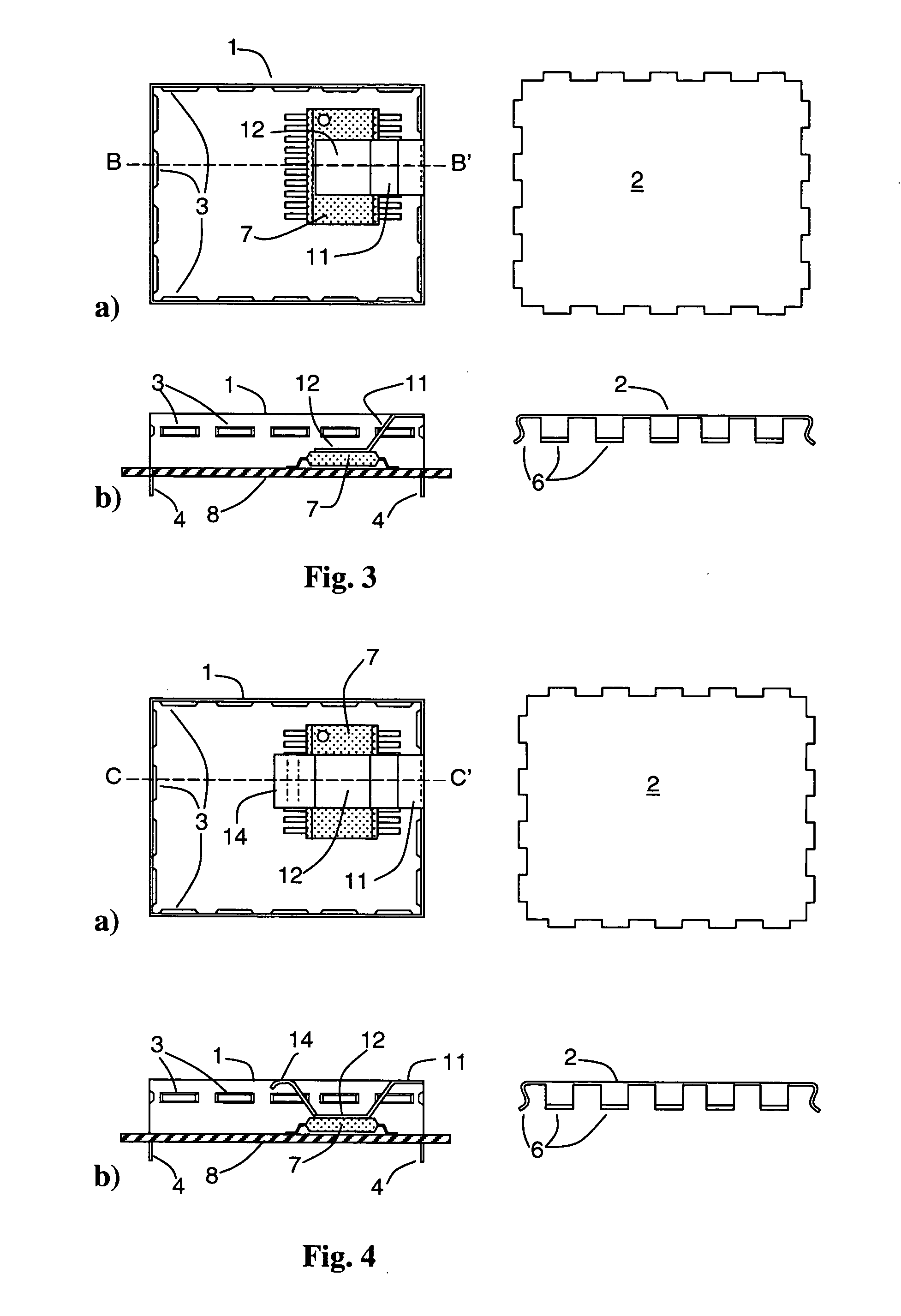

Shield casing with heat sink for electric circuits

InactiveUS20050018411A1Dissipate heatGood shieldingShielding materialsRack/frame constructionEngineeringHeat spreader

A casing for electric circuits is proposed, which shields the circuits from EMI phenomena. The circuit has means for making thermal contact with heat generating components inside the casing, allowing using the casing as a heat sink to dissipate the heat. The casing comprises a frame, a cover and an inwardly projecting element for thermally contacting a heat source within the casing. The inwardly projecting element is designed so as not to cause any openings in the casing. The inwardly projecting element may be an integral part of the frame or the cover and all parts of the casing may advantageously be produced using cut-and-bend procedures.

Owner:THOMSON LICENSING SA

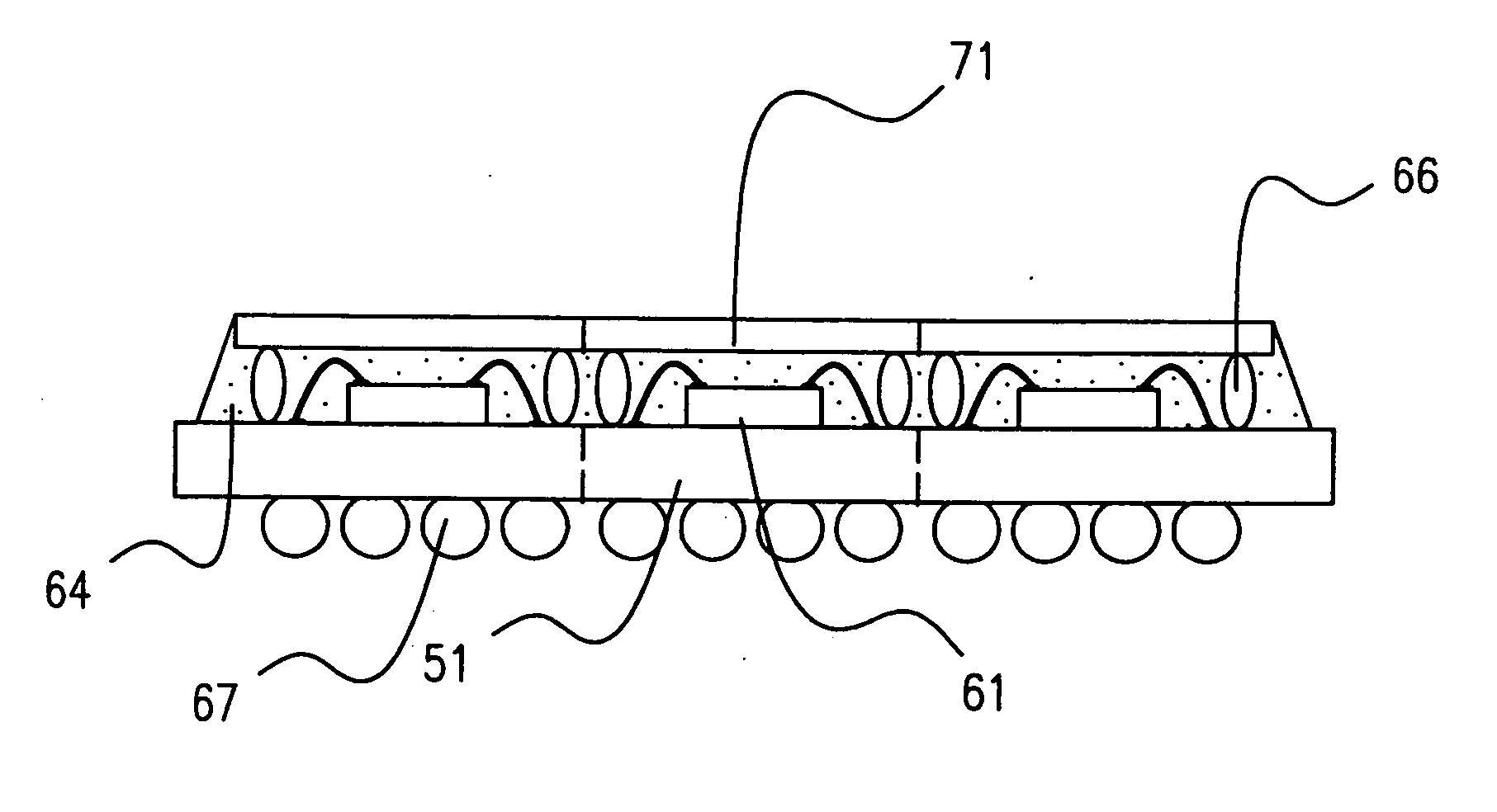

Thermal enhance package and manufacturing method thereof

InactiveUS20060094161A1Upgrade thermal performance and electrical performanceGood shieldingSemiconductor/solid-state device detailsSolid-state devicesGround contactElectrical and Electronics engineering

A thermal enhance package mainly comprises a chip, a substrate unit, a heat spreader unit and a plurality of pellets. The chip is disposed above the substrate unit and electrically connected to the substrate unit, and an encapsulation unit encapsulates the chip, the substrate unit, the heat spreader unit and the pellets. Therein the pellets are formed on the substrate unit and connect the substrate unit and the heat spreader unit. Thus the heat arisen out of the chip can be transmitted to the heat spreader unit not only through the encapsulation unit but also the pellets. Moreover, the substrate unit has at least one grounding contact connecting to one of the pellets so as to provide the thermal enhance package a good shielding. In addition, a method for manufacturing the thermal enhance package is also provided.

Owner:ADVANCED SEMICON ENG INC

Hydrogenated nitrile rubber composition

InactiveCN1612914AGood shieldingImprove heat resistanceEngine sealsCompression machines with non-reversible cyclePolymer scienceNitrile rubber

Owner:EAGLE INDS

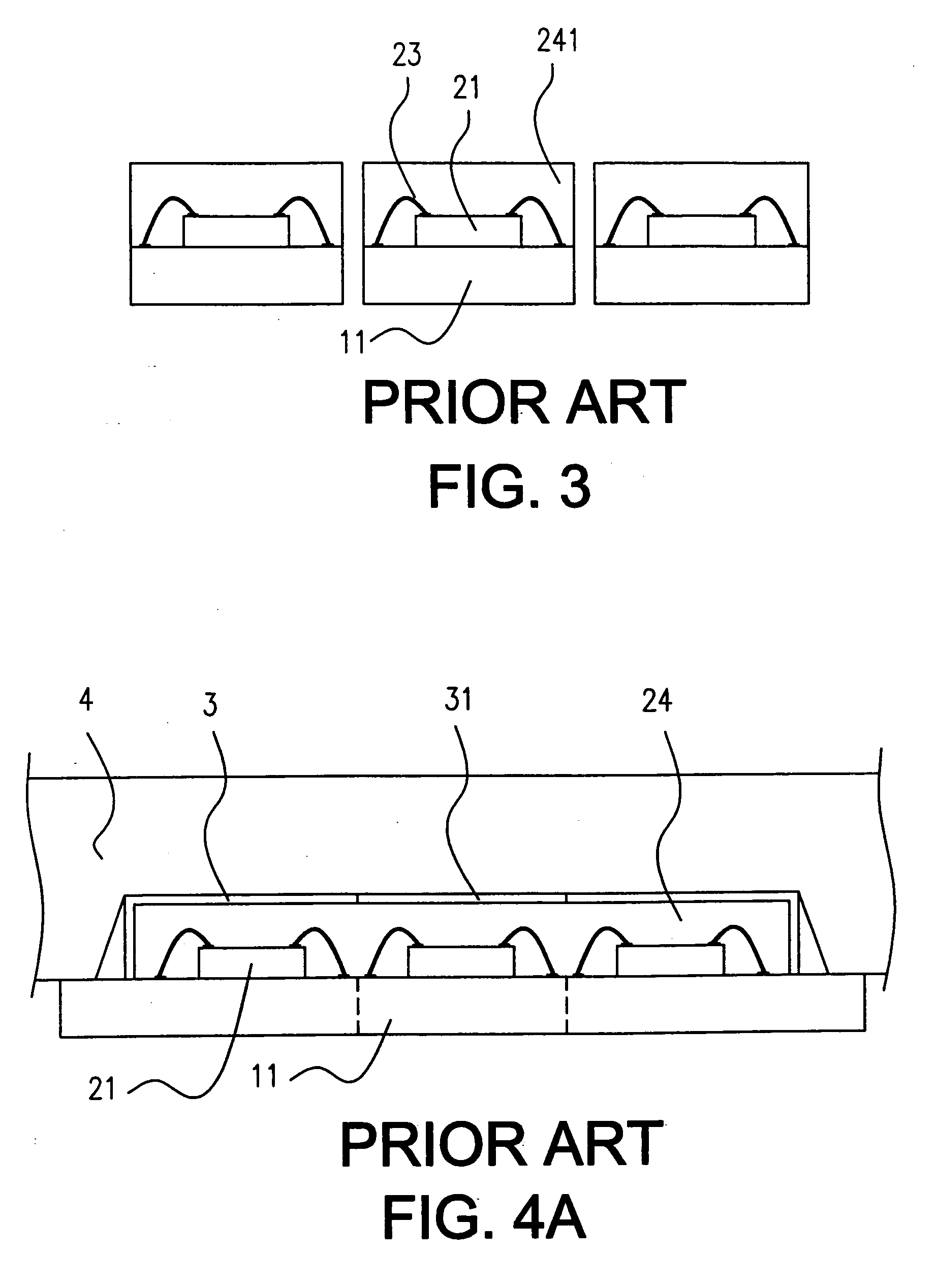

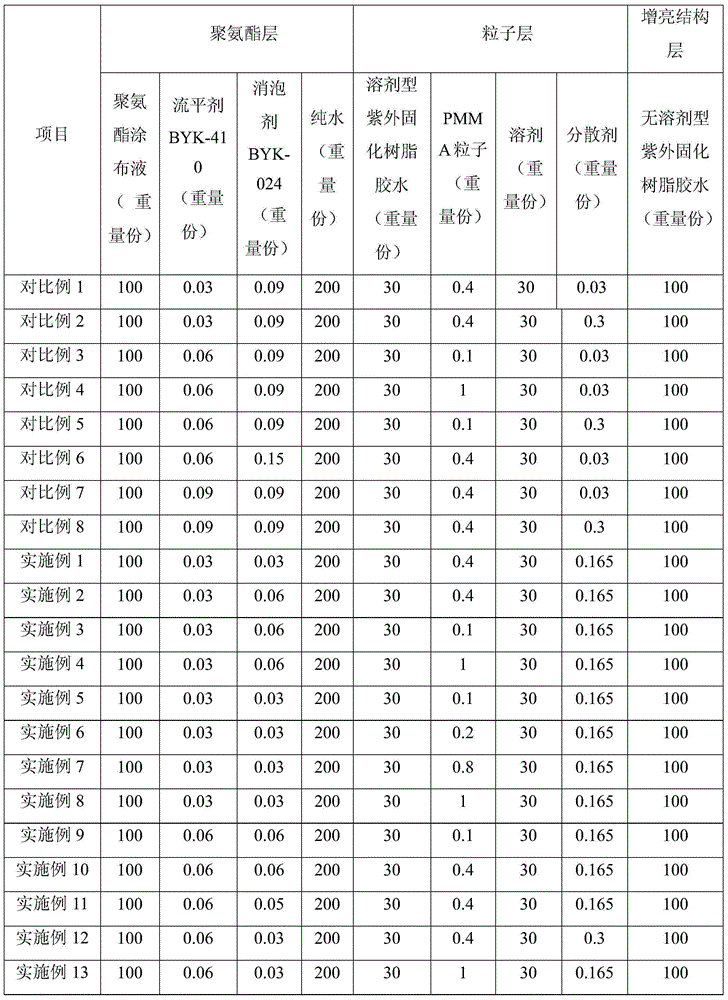

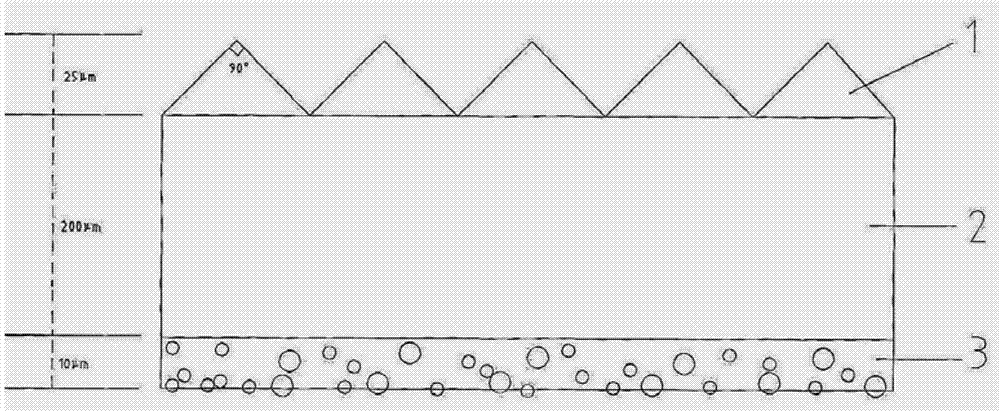

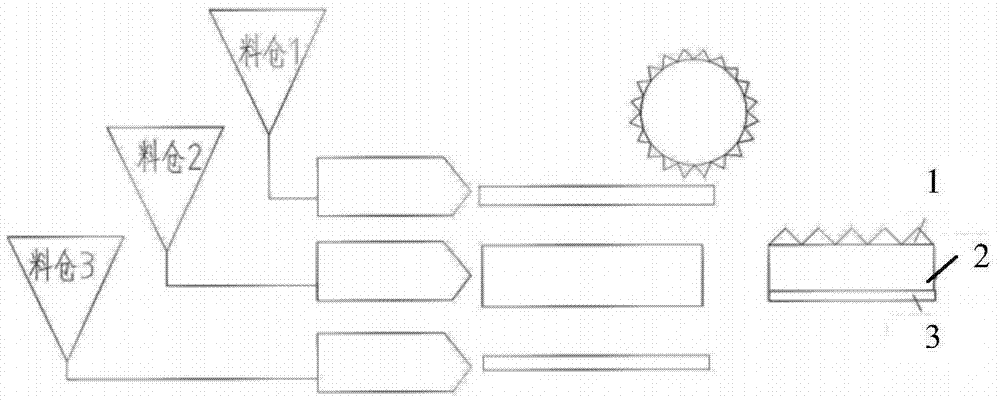

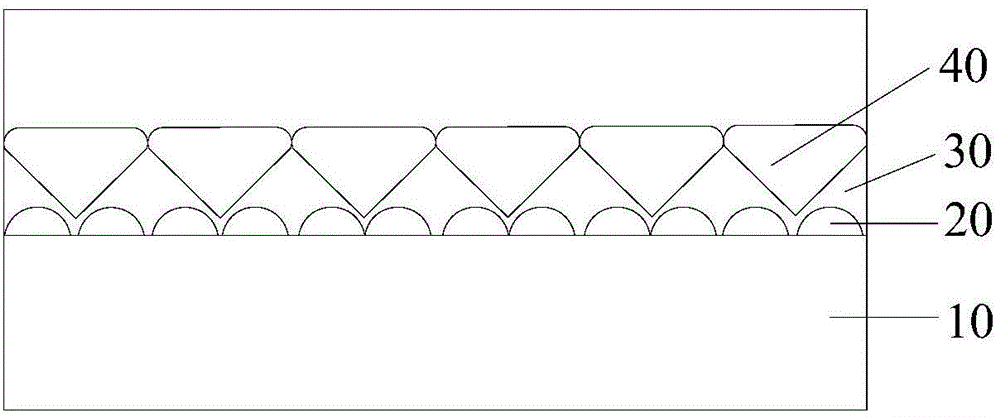

Composite brightness enhancement film and preparation method thereof

ActiveCN105093367AHigh light transmittanceHigh hardnessPrismsSynthetic resin layered productsTransmittanceLiquid-crystal display

The invention relates to a composite brightness enhancement film used by a backlight source in a liquid crystal display, and particularly relates to a composite brightness enhancement film. The invention provides a composite brightness enhancement film and a preparation method thereof in order to solve defects that a small-size display is insufficient in brightness and relatively thick as a whole and that lamp shadow occurs easily. The composite brightness enhancement film sequentially comprises a brightness enhancement structural layer, a first polyurethane layer, a PET layer, a second polyurethane layer and a particle layer, wherein the first polyurethane layer and the second polyurethane layer are collectively referred as a polyurethane layer. The composite brightness enhancement film has high light transmittance, shielding performance and brightness performance, and can effectively solve the defect that the display is serious in energy consumption and insufficient in brightness and has lamp shadow after being applied to a backlight module. In addition, the reverse side of the brightness enhancement film is enabled to have a good adhesion preventing effect, and the thickness of the backlight module is effectively reduced.

Owner:NINGBO CHANGYANG TECH

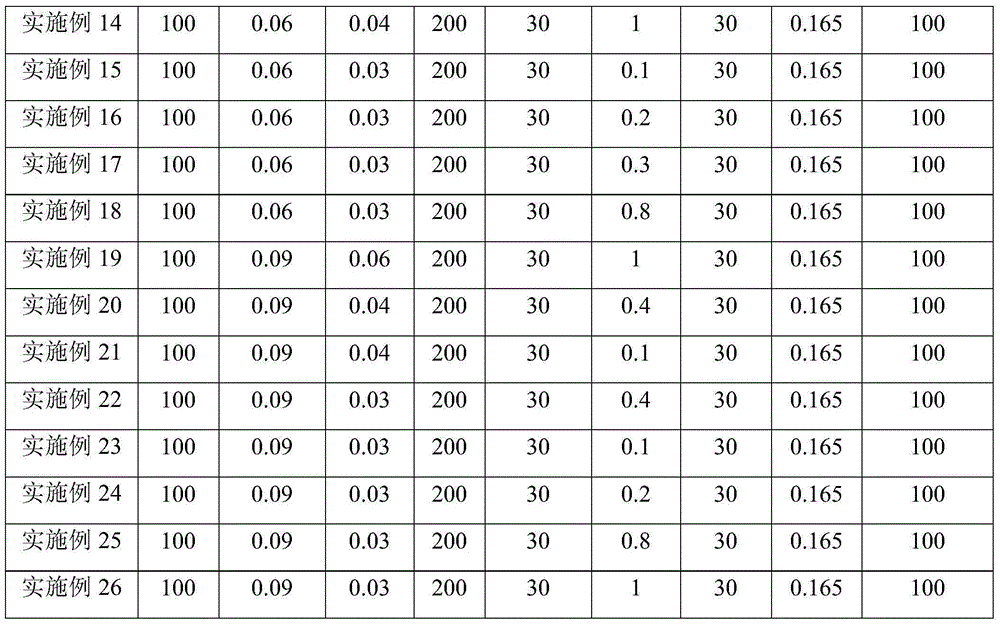

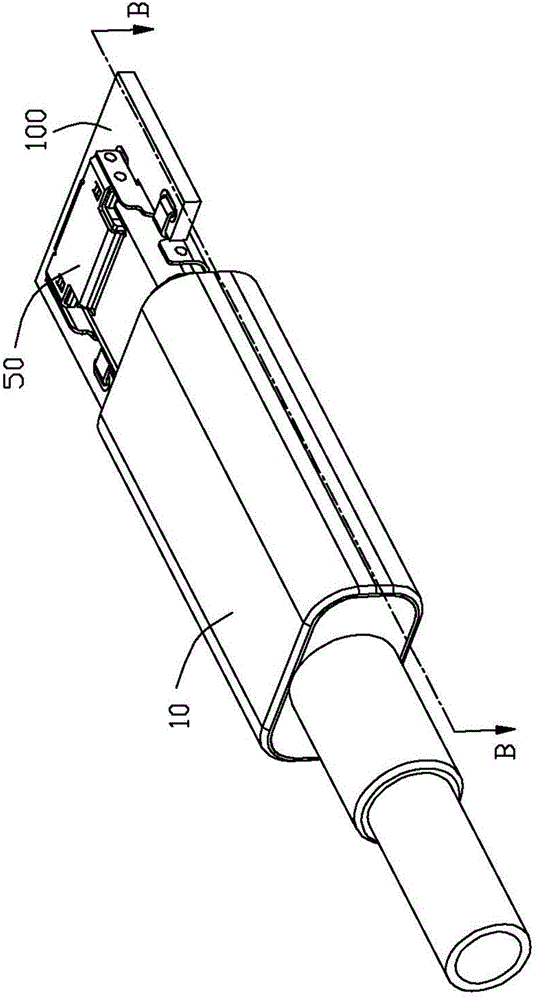

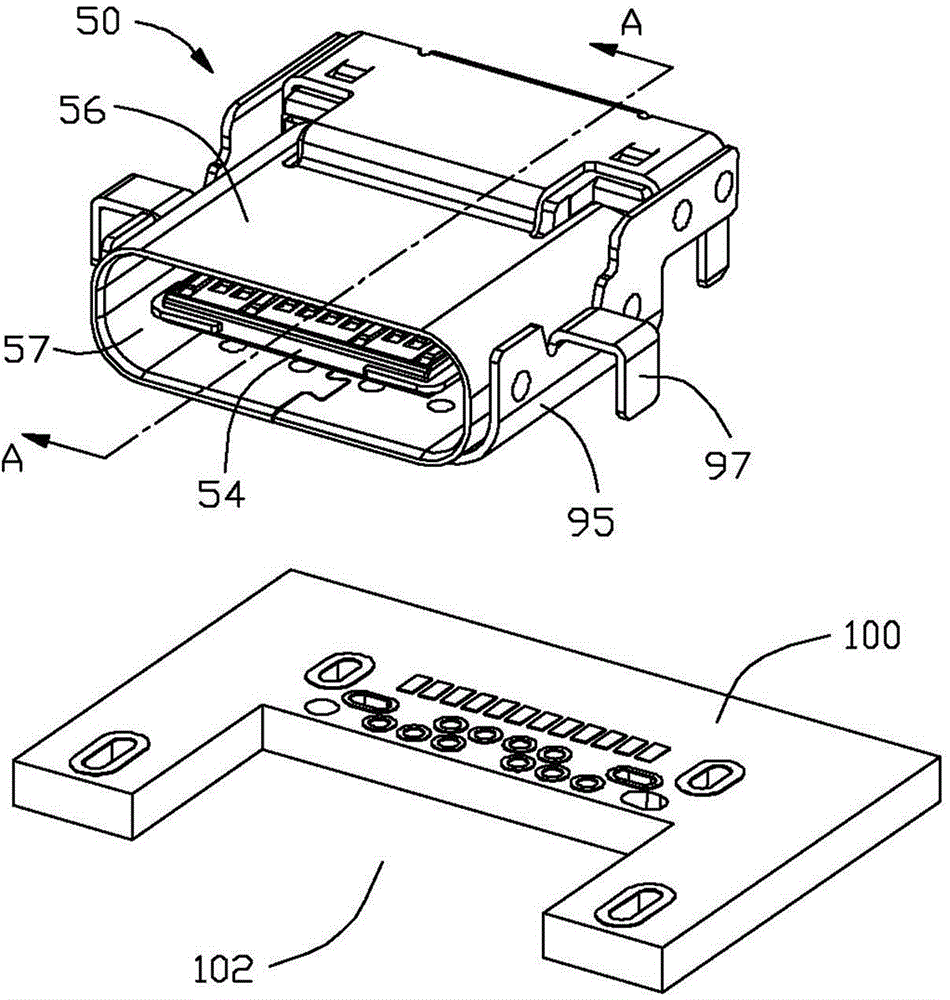

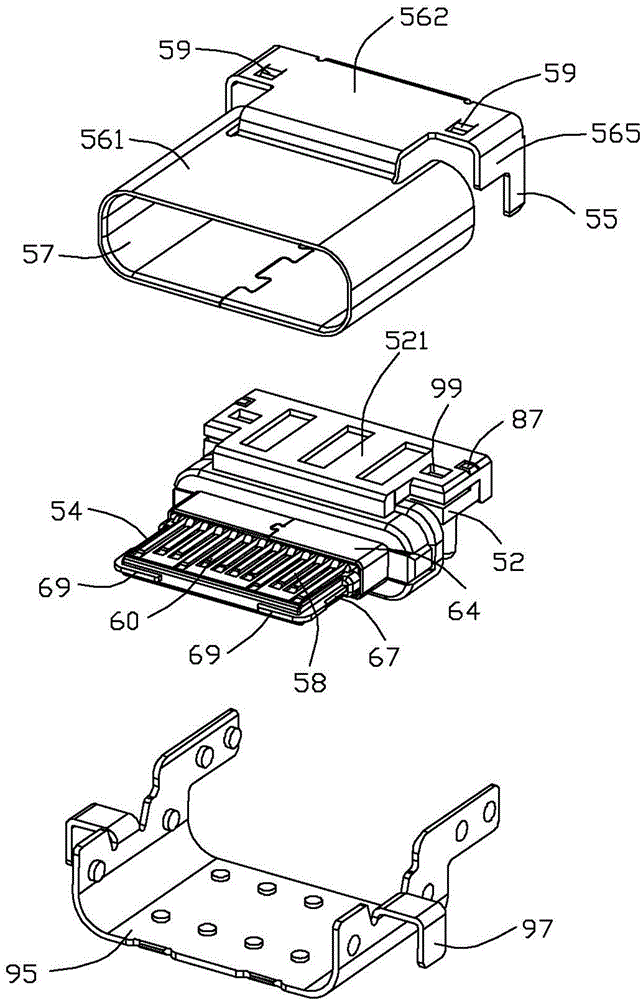

Socket connector

ActiveCN104901060AGood shieldingHigh strengthFixed connectionsCoupling parts mountingElectrical and Electronics engineeringShielding effect

A socket connection includes an insulation body, a terminal, a shielding housing and a metal cover. The insulation body includes a base and a mating tongue plate. The terminal includes a contact part disposed on the mating tongue plate and a pin extending the insulation body. The shielding housing includes a mating part surrounding the mating tongue plate. A mating cavity is formed between the mating part and the mating tongue plate. The metal cover is fixed out of the shielding housing and has first circuit board support pins. The first circuit board support pins are arranged at two sides of the mating part. The mating part of the shielding housing of the socket connector does not have the circuit board support pins, thereby forming the shielding housing approximately closed, thus the whole connector has good shielding effect and better strength.

Owner:FOXCONN (KUNSHAN) COMPUTER CONNECTOR CO LTD

Decorative panel and touch control device

InactiveCN104750297ALess prone to uneven edgesEdge unevenness improvementInput/output processes for data processingComputer science

The utility model provides a decorative panel and a touch control device. The decorative panel comprises a first substrate, a first decorative layer, a second decorative layer and a shading layer. The first substrate is provided with a light-transmitting area and peripheral areas outside the light-transmitting area; the first decorative layer, the second decorative layer and the shading layer are arranged in the peripheral areas of the first substrate. The first decorative layer is disposed between the second decorative layer and the first substrate. The second decorative layer is disposed between the shading layer and the first decorative layer. The first decorative layer, the second decorative layer and the shading layer are respectively provided with a first decorative opening, a second decorative opening and a third decorative opening which are overlapped mutually, and the light-transmitting area is exposed from the first decorative opening, the second decorative opening and the third decorative opening. The orthographic projection of the second decorative opening on the first substrate completely covers the orthographic projection of the first decorative opening on the first substrate. The thickness of the second decorative layer is larger than that of the first decorative layer. The touch control device comprises the decorative panel.

Owner:WINTEK CORP

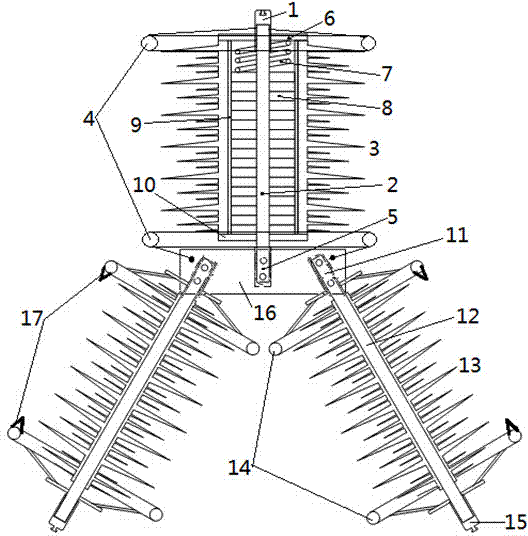

Composite insulator with functions of thunder prevention and icing flashover prevention

ActiveCN104779019APrevent Ice BridgingIncrease creep distanceSuspension/strain insulatorsComposite insulatorsArcing horns

The invention discloses a composite insulator with functions of thunder prevention and icing flashover prevention. The composite insulator comprises a lightning arrester and two sub-insulators, wherein the lightning arrester and the sub-insulators are connected to form an inverted Y-shaped integral structure through a connecting plate fitting, and arcing horns are arranged on the two sub-insulators located at the lower end of the inverted Y-shaped integral structure. The composite insulator can integrate the functions of thunder prevention and icing flashover prevention and is likely to meet the dimensional requirement of an original tower window structure, properties such as windage yaw, thunder prevention and the like of a circuit are not influenced, the insulating property is not influenced after lightning discharge, the insulator is high in insulating strength and long in service life, only one suspension point is required to be arranged on a tower, the installation is simple and convenient, and the tower structure is not required to be changed, so that the investment is saved and the maintenance cost is reduced.

Owner:STATE GRID CORP OF CHINA +2

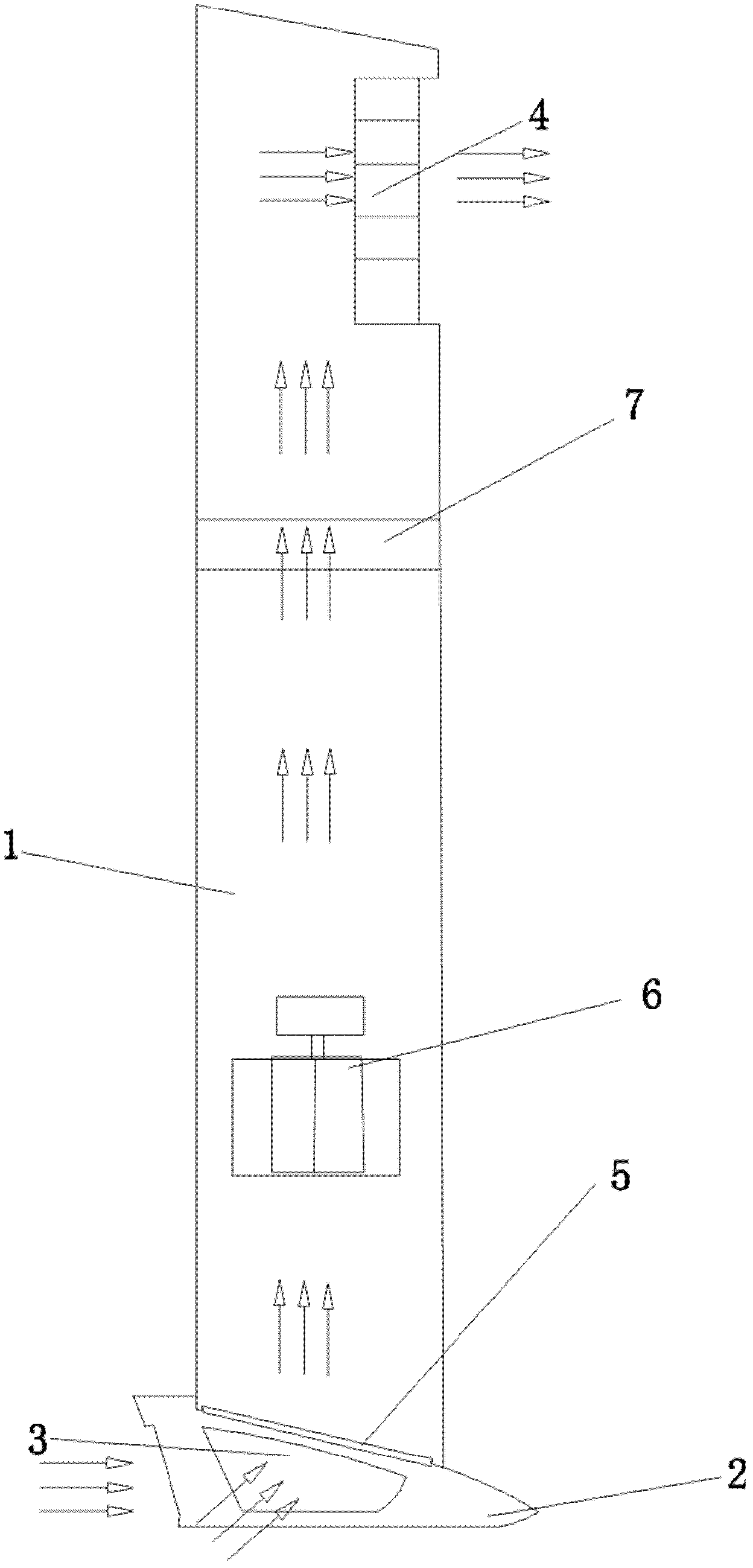

Household packaged air conditioner of bottom air admission structure

InactiveCN102563759AGood shieldingReduce wind noiseLighting and heating apparatusAir conditioning systemsAirflowEngineering

The invention discloses a household packaged air conditioner of a bottom air admission structure, which is characterized in that a wedge-type cavity base (2) is arranged at the bottom of an indoor unit body (1), large-bore bottom air inlets (3) are arranged on the left, on the right and in the rear of the base (2), the base (2) and the inside of the indoor unit body (1) are perpendicularly through to form a bottom air inlet channel, an induced-draft port of a centrifugal fan (6) is perpendicularly arranged downwards in the indoor unit body (1), and air is sucked by the centrifugal fan (6) rotatably driven by a perpendicular rotating shaft and flows into a heat exchanger (7) through an air channel. Inlet airflow enters the air conditioner from the bottom of the air conditioner and constantly flows along the same direction, airflow loss in change of flowing directions is decreased, flowing efficiency is improved, and flowing noise is reduced. In existing front air admission and lateral air admission, flowing directions are greatly changed, flowing loss is high, flowing efficiency is reduced, and airflow flowing noise is high.

Owner:CHINA YANGZI GRP CHUZHOU YANGZI AIR CONDITIONERCO

Plate-like brown pigment

InactiveCN101721317AHas a masking effectHigh glossPigmenting treatmentCosmetic preparationsBrown pigmentTitanic acid

The present invention provides a pigment which uses lepidocrocite type plate-like titanic acid and a cosmetic containing the pigment. Specifically, the invention provides the plate-like brown pigment with a general formula of K3x+yLixTi2-x-yFeyO4 (but 0.2< / =x< / =0.3; 0.05< / =y< / =0.5).

Owner:FUAN KERU +1

Water-based high-temperature-resistant long-acting anticorrosive paint and preparation method thereof

InactiveCN110922855AImprove heat resistanceGood shieldingFireproof paintsAnti-corrosive paintsSilane couplingIsopropylene glycol

The invention discloses a water-based high-temperature-resistant long-acting anticorrosive paint and a preparation method thereof. The water-based high-temperature-resistant long-acting anticorrosivepaint comprises a component A and a component B, wherein the component A is prepared from the following raw materials: film-forming substance water-based novolac epoxy resin, carbon black, an antirustpigment, an extender pigment containing sericite powder, an anti-settling agent, deionized water, an epoxy silane coupling agent and other auxiliaries; the component B is prepared from the followingraw materials: a curing agent and propylene glycol monomethyl ether; and the mass ratio of the component A to the component B is (4-6): 1. The water-based novolac epoxy resin is used as a film-formingsubstance and is matched with the sericite powder, and excellent permeation resistance is provided for the coating by virtue of a scaly structure; and the epoxy silane coupling agent is added to improve the crosslinking degree and compactness of the coating, thereby greatly enhancing the heat resistance, chemical resistance, hardness and wear resistance of the coating and overcoming the defect that the existing water-based paint can not have high temperature resistance and long-acting corrosion resistance simultaneously.

Owner:无锡市太湖防腐材料有限公司

Perceptual modeling of media signals for data hiding

InactiveUS20070183622A1Reduce memoryAttenuation bandwidthUser identity/authority verificationCharacter and pattern recognitionArtificial intelligenceSteganography

The present invention relates generally to steganography and data hiding. In one embodiment a method is provided including obtaining a media signal; determining characteristics of the media signal; based at least in part on the characteristics of the media signal, providing a map of the media signal; transforming at least some portions of the media signal into a transform domain; and hiding plural-bit data in at least some portions of the transformed media signal. The map identifies at least one area in the media signal in which hiding of plural-bit data should be avoided or suppressed. At least one of the act of transforming or the act of hiding utilizes the map of the media signal. Other embodiments are also provided.

Owner:DIGIMARC CORP

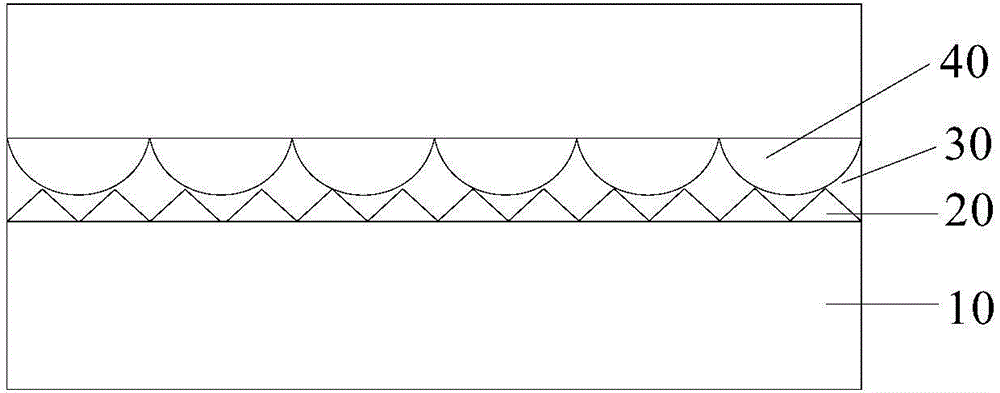

Extruded brightness enhancement film and preparation method thereof

InactiveCN106873059AGood anti-adhesionGood shieldingDiffusing elementsLiquid-crystal displayManufacturing technology

The present invention relates to a brightness enhancement film used by backlight in a liquid crystal display, especially to an extruded brightness enhancement film and a preparation method thereof. In order to solve the problem that the current coating brightness enhancement film is complex in manufacturing technology, the present invention provides an extruded brightness enhancement film and a preparation method thereof. The extruded brightness enhancement film is formed by a brightness enhancement layer, a base film layer and a particle layer in order. The brightness enhancement layer and the particle layer are respectively located at two sides of the base film layer, and the brightness enhancement layer is a three-layer co-extrusion structure. In the preparation process, the brightness enhancement layer, the base film layer and the particle layer are subjected to coextrusion and then curtain coating, a compression roller is employed to roll the brightness enhancement layer to form a brightness enhancement structure, the cooling shaping is performed, and an extruded brightness enhancement film is obtained. The extruded brightness enhancement film has high luminance appearance, and the preparation method of the extruded brightness enhancement film provided by the invention is simple and convenient in technology so as to improve the production efficiency and reduce the production cost.

Owner:NINGBO CHANGYANG TECH

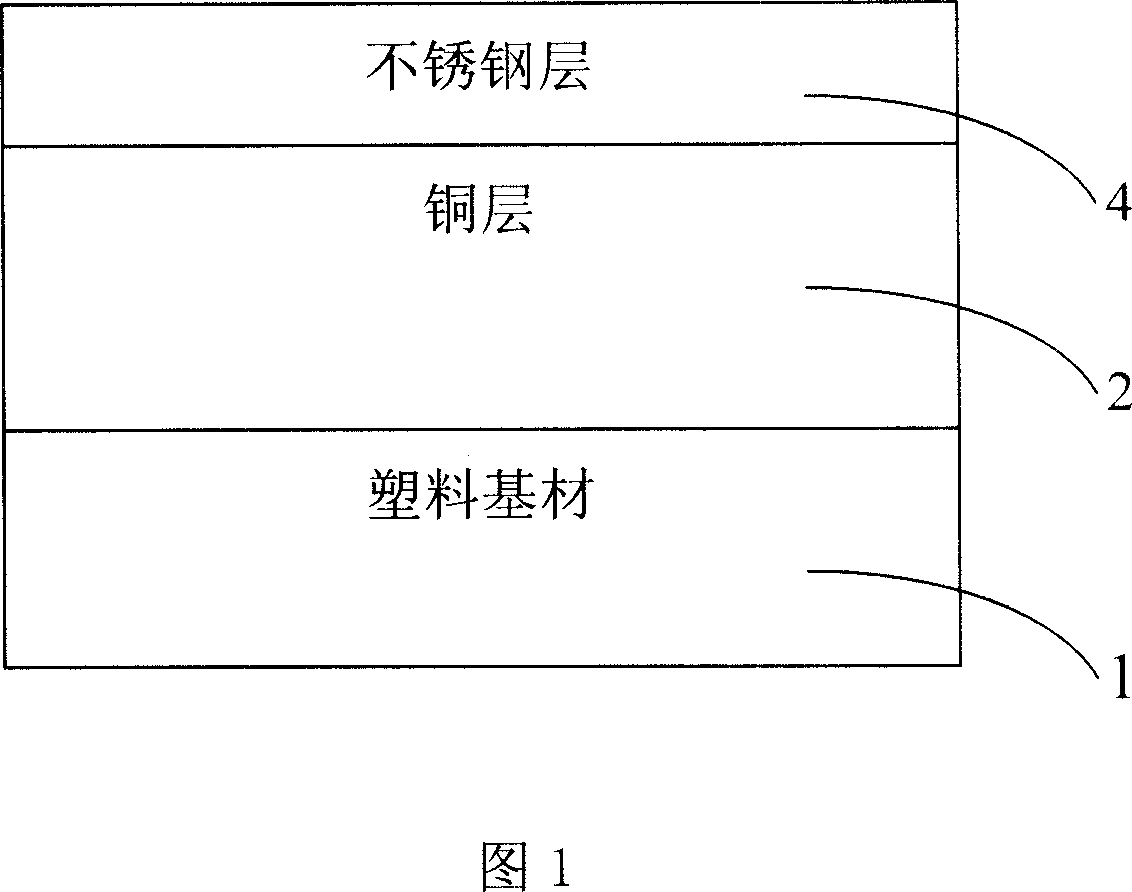

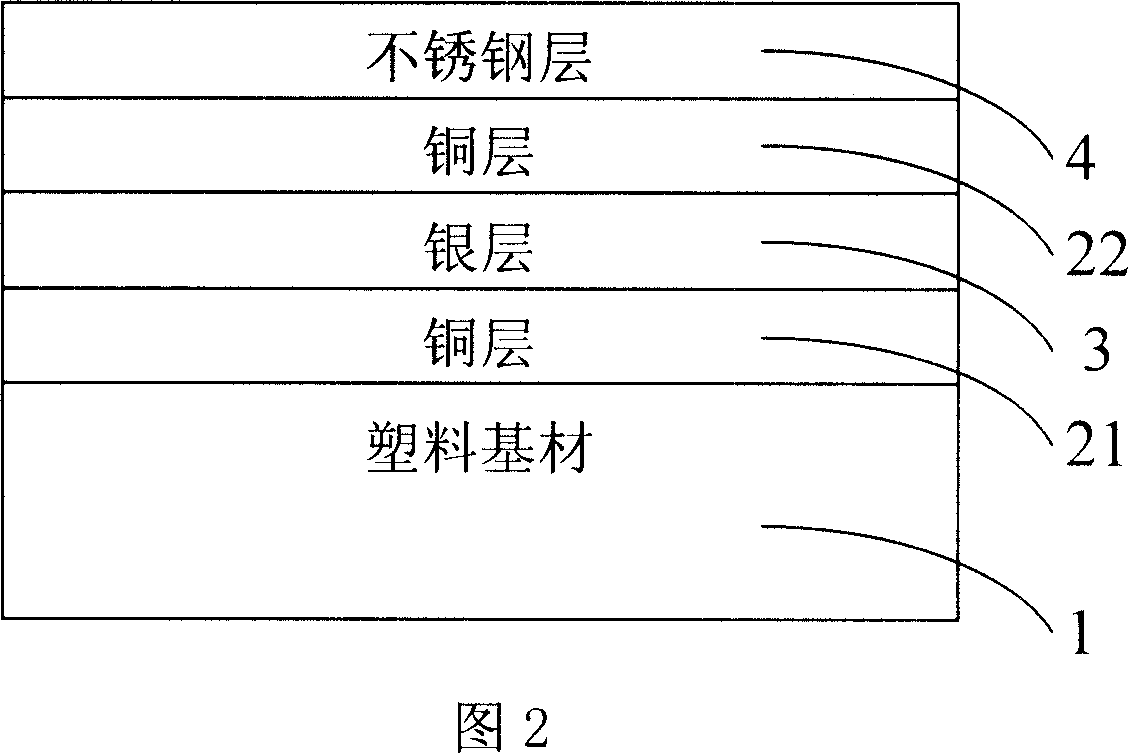

Sputtering coating method for high-shielding thin-film against electromagnetic interference on plastic matrix

InactiveCN1940126ALower Unit ImpedanceImprove anti-electromagnetic interference performanceScreening apparatusVacuum evaporation coatingProduction effectMegasonic cleaning

A kind of sputter method that plating high defilade guarding against electromagnetism disturbance film on the plastic base material, it includes the following steps: Sand blast handle step, gushing in the surface of base material by using the corundum grits; cleaning step, using ultrasonic wash the outside of the base material which has done the sand blast handles; plating step ,plating a layer of cupper film in the surface of the plastic base material with the vacuum sputter method, plating a layer of silver film again, then plating a layer of copper film again to compose of the sandwich plating tier structure that 'copper + silver + copper '. Using the sputtering method in this invention, 'copper + silver + copper ' sandwich plating tier structure is benefit to reducing a unit impedance of the film, strengthening the effect that defending against the interfere of the electromagnetism, it can also form the 'copper / silver / copper / stainless steel ' plating structure at one time in a sputter, whose block effect can reach the efficacy that above 70 dB, it is benefit to improving the production effect.

Owner:MITAC PRECISION TECH CO LTD SHUNDE DISTRICT FOSHAN CITY

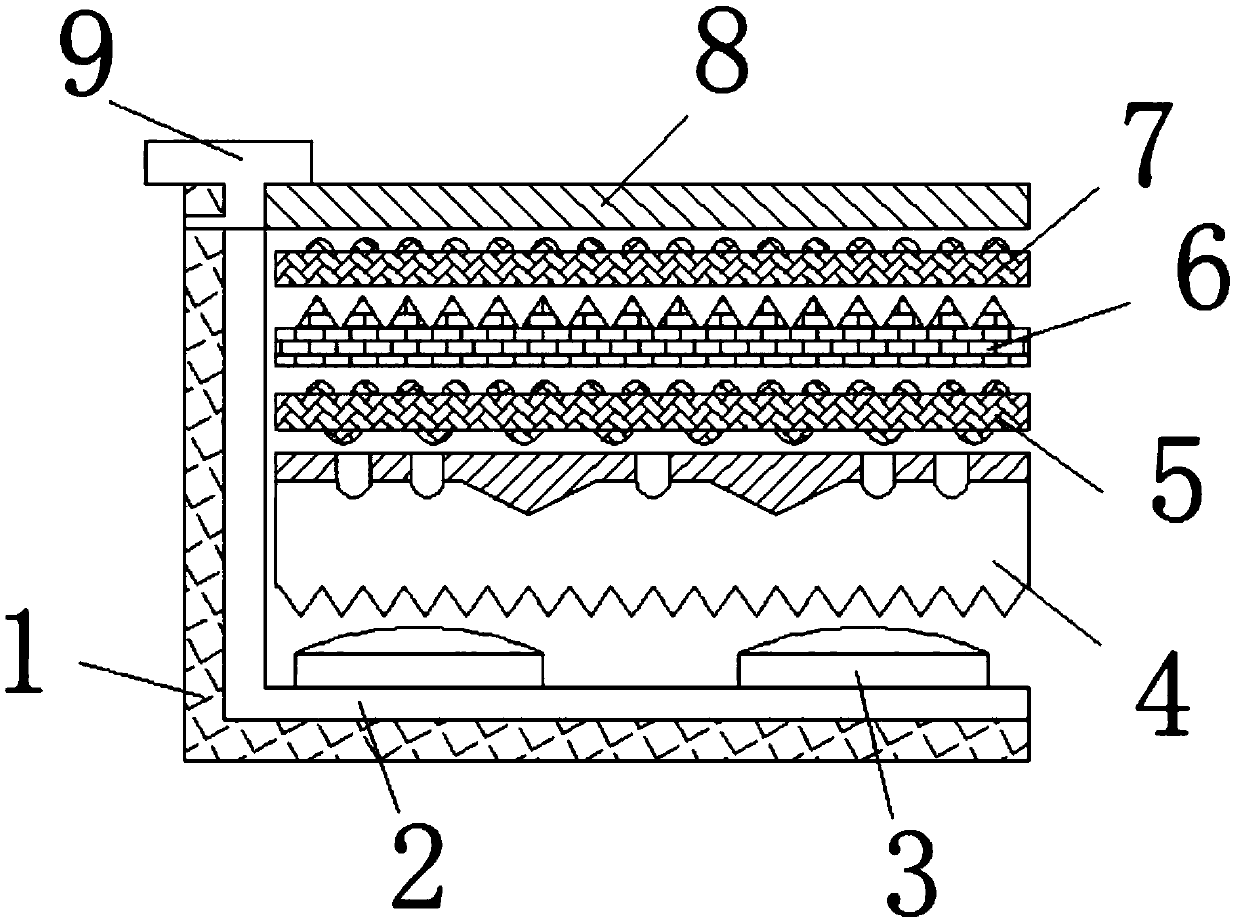

Direct type zero-OD backlight structure with semi-reflecting and semi-transmitting light guide plate

ActiveCN109557719AExcellent shieldingImprove light utilizationOptical light guidesNon-linear opticsTotal thicknessPhysics

The invention discloses a direct type zero-OD backlight structure with a semi-reflecting and semi-transmitting light guide plate. A rectangular groove is formed on the upper end face of a backplane; the inner bottom wall of the rectangular groove is coated with a white reflective layer; an LED light source is fixedly connected to the white reflective layer; the LED light source is fixedly providedwith the semi-reflecting and semi-transmitting light guide plate; a lower diffusion film is fixed to the semi-reflecting and semi-transmitting light guide plate; a prism film is fixed to the lower diffusion film; and an upper diffusion film is fixed to the prism film. According to the direct type zero-OD backlight structure with the semi-reflecting and semi-transmitting light guide plate, the semi-reflecting and semi-transmitting light guide plate is made of PS material, is lower in weight and cost; due to the improvement of the light efficiency and the haze, the films can be correspondinglyreduced, so that the cost can be further reduced; the invention has the advantages of being edge type and thin, and the total thickness is no more than 8 mm; the shielding property is excellent, and the OD approaches 0, so that the utilization rate of light can be increased, light leakage can be avoided, curved display can be achieved, and the development requirement of being thin can be met; andthe invention further has the advantage of being direct type, so that the partition dimming can be realized, and the brightness of the light emitting mode thereof is higher than the edge type.

Owner:合肥泰沃达智能装备有限公司

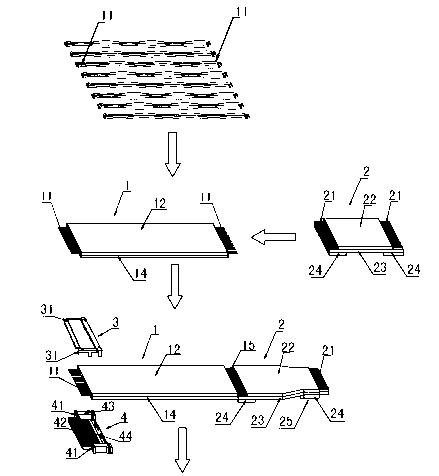

Low voltage differential signaling (LVDS) wire of parallel wire structure and manufacturing method thereof

ActiveCN103107462AReduce consumptionSimple processLine/current collector detailsCoupling device detailsCopper wireEngineering

The invention provides a low voltage differential signaling (LVDS) wire of a parallel wire structure and a manufacturing method of the LVDS wire of the parallel wire structure. The LVDS wire comprises a stranded wire flexible flat cable (FFC), a flat FFC and an electronic connector. The stranded wire FFC comprises a plurality of strands of copper stranded wires, an upper layer insulating film and a lower layer insulating film. Two ends of the copper stranded wire are exposed outside, one exposed end is connected with the flat FFC in a welding mode, and the other exposed end is connected with the electronic connector in a welding mode. The flat FFC comprises a flat copper wire, an upper layer insulating film, a lower layer insulating film and a stiffening plate, wherein the upper layer insulating film and the lower layer insulating film are respectively attached to the flat copper wire in an up-and-down mode. One end of the flat FFC is punched into a buckle structure, and the flat copper wire with the other end being exposed is connected with the plurality of strands of copper stranded wires of the stranded wire FFC in a welding mode. The electronic connector comprises a connector upper cover and a connector body which is connected with the plurality of strands of copper stranded wires of the stranded wire FFC in a welding mode. The connector upper cover and the connector body are buckled. The LVDS wire of the parallel wire structure and the manufacturing method of the LVDS wire of the parallel wire structure have the advantages of being low in cost, high in production efficiency, long in buckling service life, controllable in characteristic impedance, fit for halogen-free requirement, good in shielding performance and the like.

Owner:HESHAN DEREN ELECTRONIC TECH CO LTD

Circular pulling rope type blind

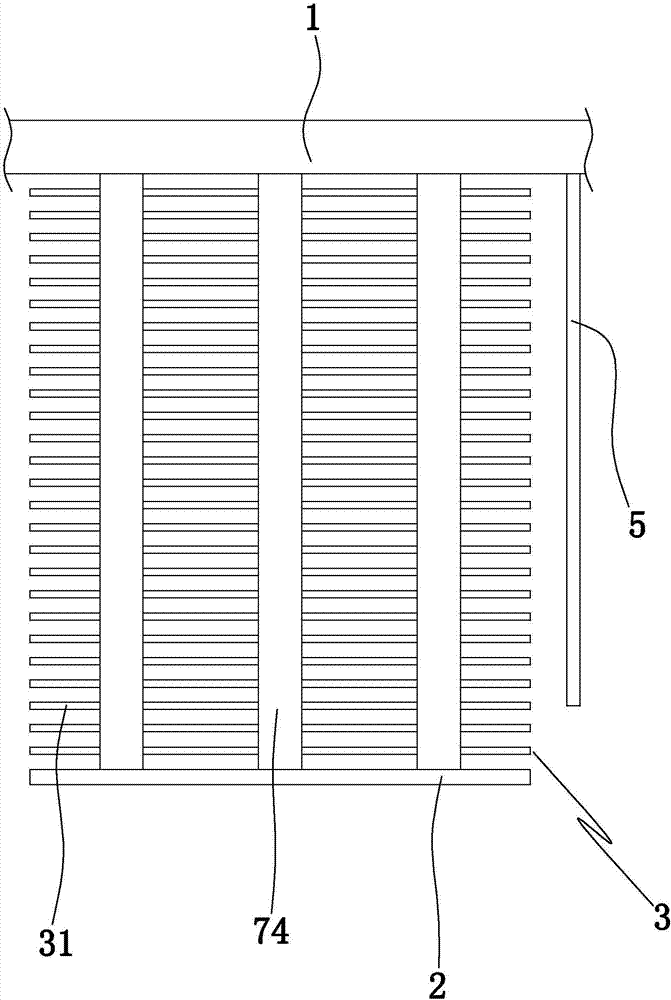

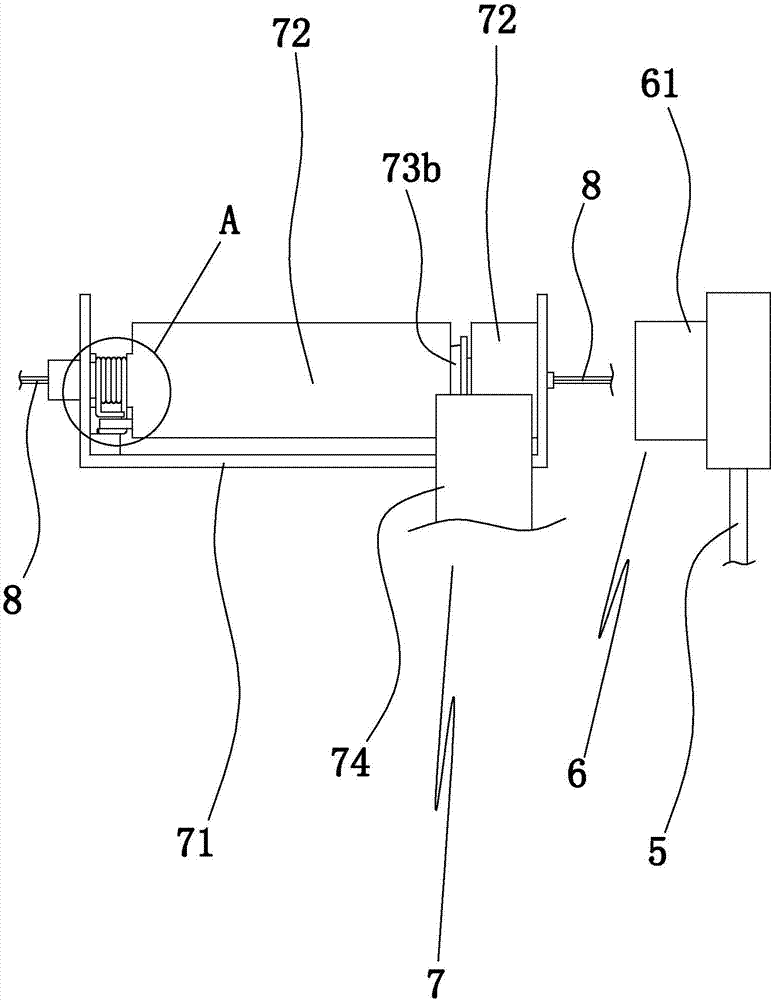

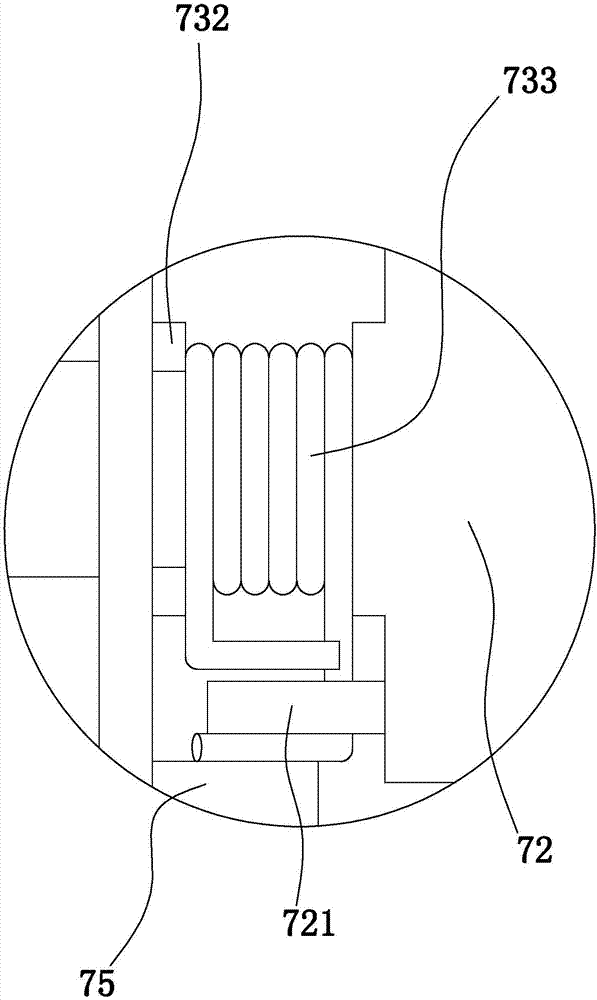

InactiveCN106968583AOpen efficientlyNo intertwiningLight protection screensAgricultural engineeringRolling shutter

Owner:HANGZHOU YOUPU PLASTIC NEW MATERIAL CO LTD

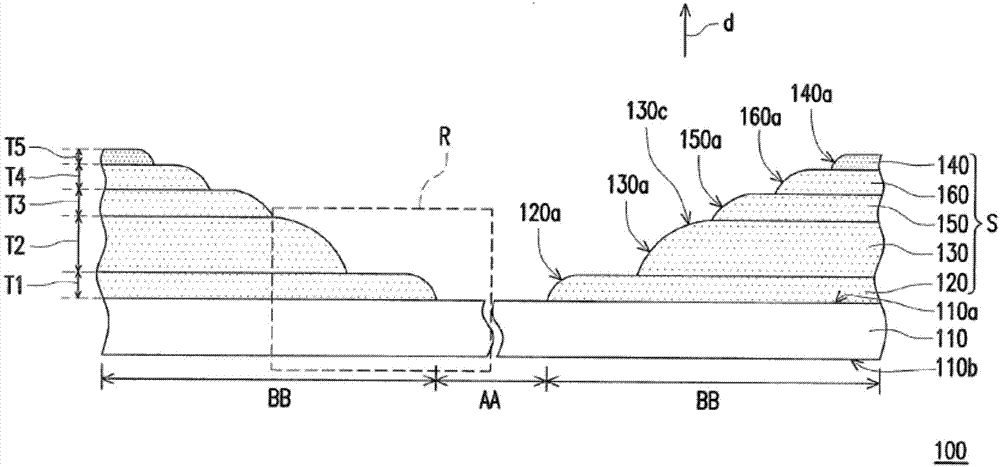

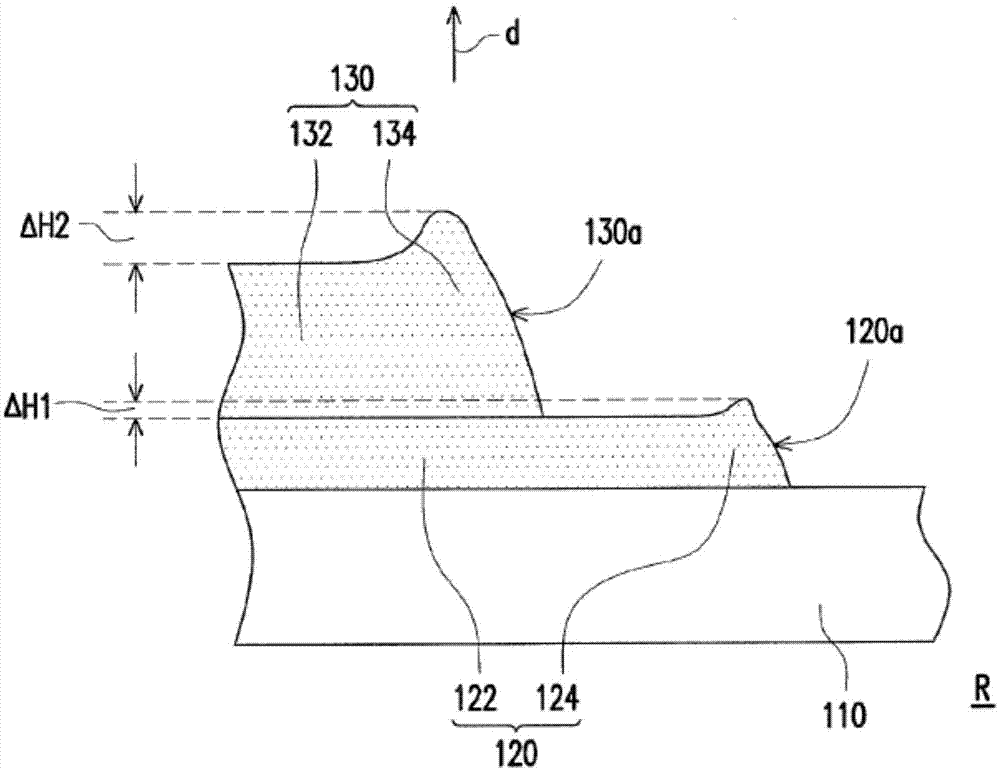

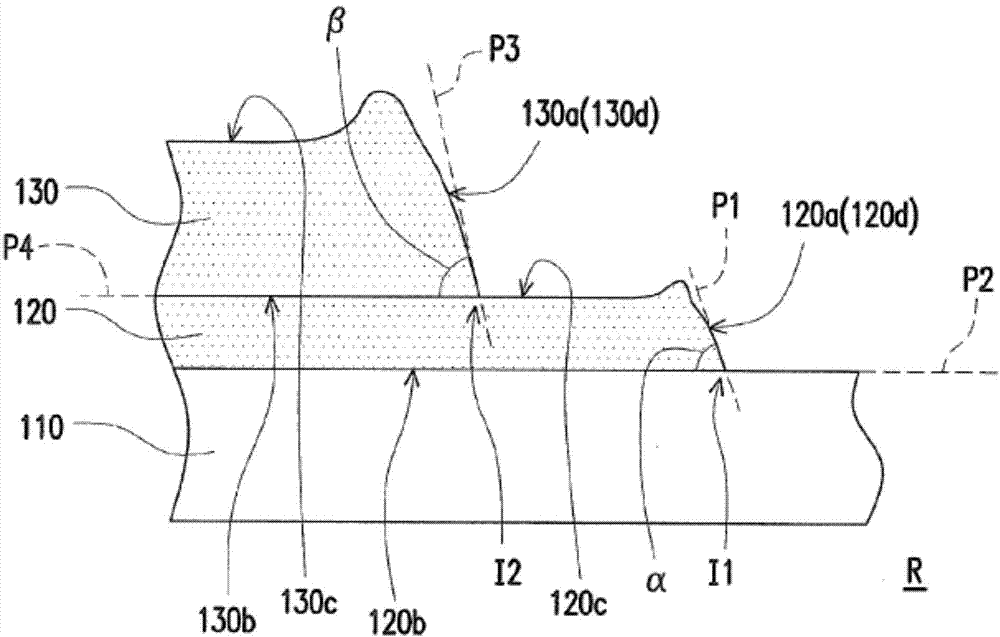

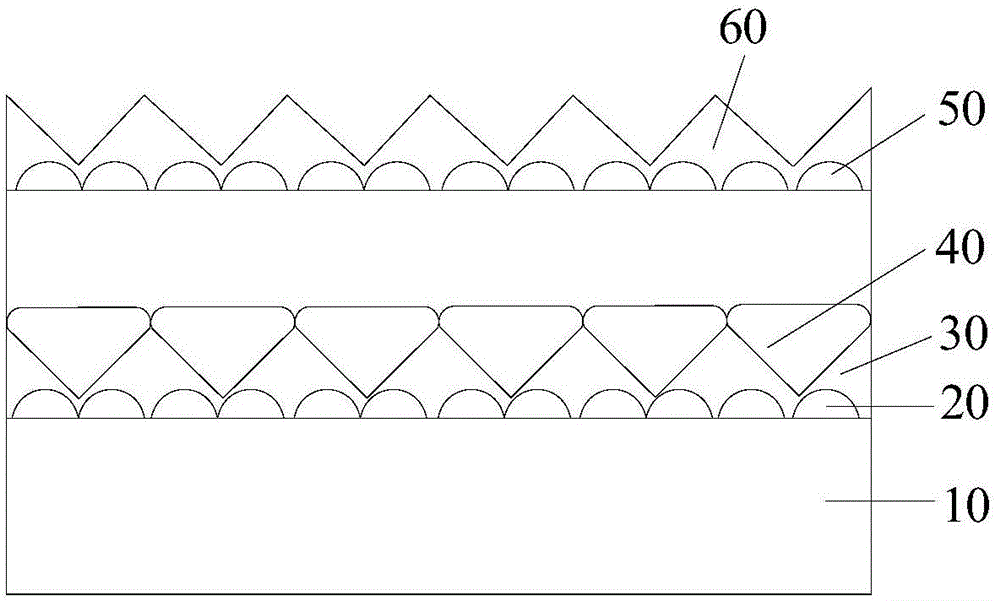

Optical thin film and backlight unit

ActiveCN104950361AGood shieldingReduce adverse phenomenaPrismsDiffusing elementsRefractive indexOptical thin film

The invention provides an optical thin film and a backlight unit. The optical thin film comprises a plurality of stacked transparent material layers, wherein a first composite structure layer is arranged between at least two adjacent transparent material layers and comprises a first bulge structure and a second bulge structure covering the first bulge structure, the first bulge structure comprises a plurality of first bulge parts sequentially arranged in the a direction, the second bulge structure comprises a plurality of second bulge parts sequentially arranged in the a direction, the first bulge parts and the second bulge parts penetrate through the transparent material layers in the b direction, the a direction and the b direction are perpendicular to each other and are parallel to the extending surface of each transparent material layer, each second bulge part covers at least one first bulge part, an air channel is formed by a gap between every two adjacent second bulge parts, and the first bulge structure and the second bulge structure have different refractive indexes. The optical thin film has good shielding performance, and the probability of occurrence of phenomena of moire interference, newton ring and the like is lower.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com