Composite brightness enhancement film and preparation method thereof

A brightening film and polyurethane layer technology, applied in chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problems of insufficient brightness of small-sized displays, easy lamp shadows, and overall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

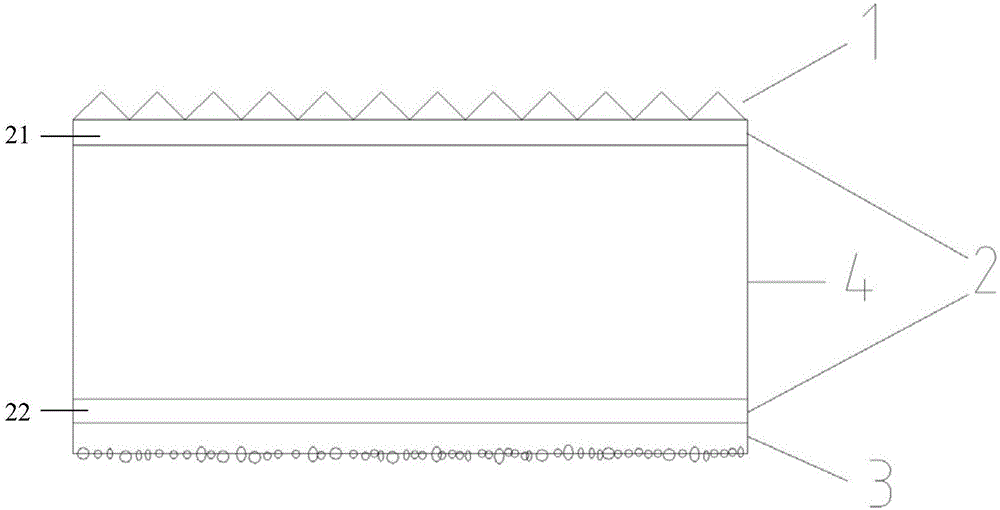

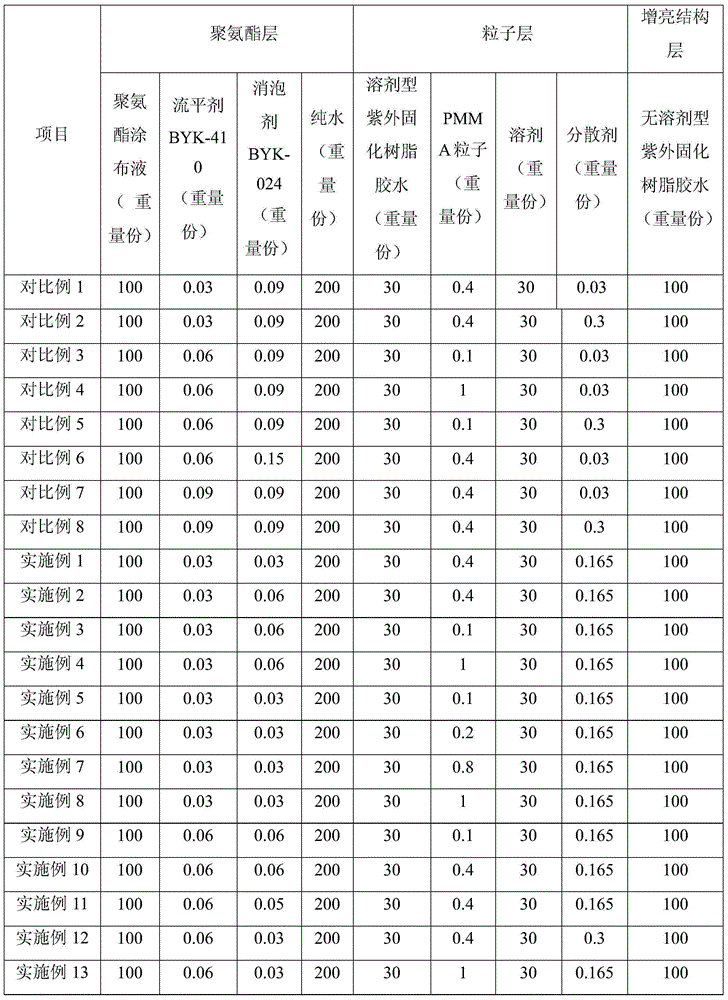

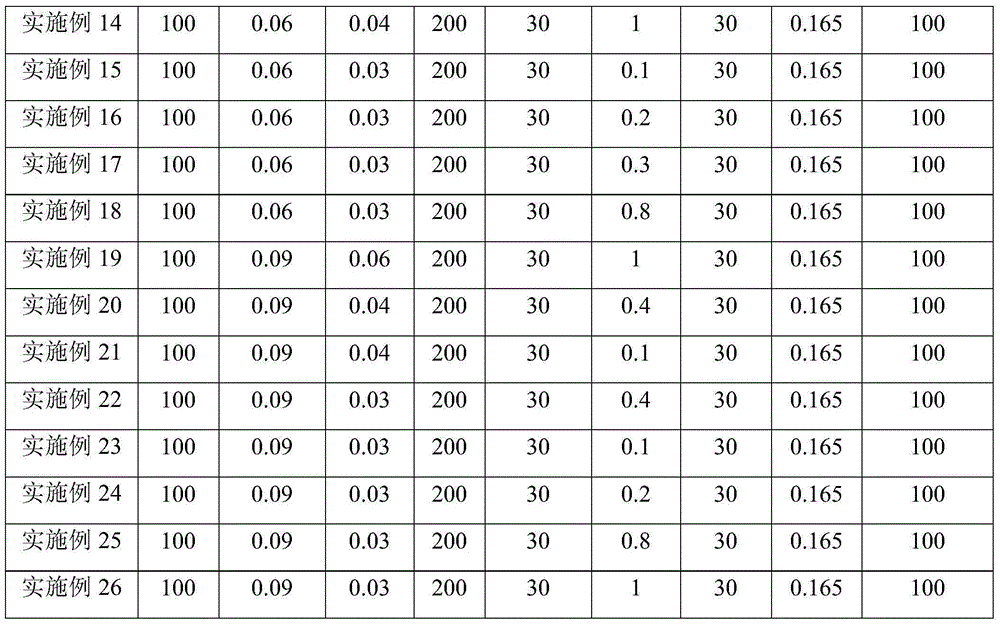

[0065] The composite brightness-enhancing film provided by the present invention comprises 100 parts of polyurethane coating liquid, 0.03 part of polydimethylsiloxane type leveling agent BYK-410, 0.03 part of defoamer BYK-024, 200 parts of pure water 30 parts of solvent-based UV-curable resin glue, 30 parts of solvent, 0.4 parts of PMMA particles, 0.165 parts of dispersant, After mixing evenly with a stirrer, apply it to the lower surface of the PET film with the existing polyurethane layer, place it in an oven at 80°C for 1 min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the above-mentioned film is irradiated to make it UV-hardened to obtain a film with a particle layer; then the solvent-free UV-curing glue is applied to the upper surface of the PET with a polyurethane coating, and it is extruded through a special engraving roller. , and at 450mj / cm 2 The high-pressure mercury lamp is irradiated to make it solidify and form, and finally a com...

Embodiment 2

[0069] The composite brightness-enhancing film provided by the present invention comprises 100 parts of polyurethane coating solution, 0.03 part of polydimethylsiloxane type leveling agent BYK-410, 0.06 part of defoamer BYK-024, 200 parts of pure water 30 parts of solvent-based UV-curable resin glue, 30 parts of solvent, 0.4 parts of PMMA particles, 0.165 parts of dispersant, After mixing evenly with a stirrer, apply it to the lower surface of the PET film with the existing polyurethane layer, place it in an oven at 80°C for 1 min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the above-mentioned film is irradiated to make it UV-hardened to obtain a film with a particle layer; then the solvent-free UV-curing glue is applied to the upper surface of the PET with a polyurethane coating, and it is extruded through a special engraving roller. , and at 450mj / cm 2 The high-pressure mercury lamp is irradiated to make it solidify and form, and finally a c...

Embodiment 3

[0073] The composite brightness-enhancing film provided by the present invention comprises 100 parts of polyurethane coating solution, 0.03 part of polydimethylsiloxane type leveling agent BYK-410, 0.06 part of defoamer BYK-024, 200 parts of pure water After mixing evenly with a stirrer, apply it to the PET base film, and place it in an oven at 150 °C for heating and drying for 3 minutes; then take 30 parts of solvent-based UV-curable resin glue, 30 parts of solvent, 0.1 part of PMMA particles, and 0.165 parts of dispersant, After mixing evenly with a stirrer, apply it to the lower surface of the PET film with the existing polyurethane layer, place it in an oven at 80°C for 1 min, and then use a high-pressure mercury lamp at 400mj / cm 2 The total energy of the above-mentioned film is irradiated to make it UV-hardened to obtain a film with a particle layer; then the solvent-free UV-curing glue is applied to the upper surface of the PET with a polyurethane coating, and it is extru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com