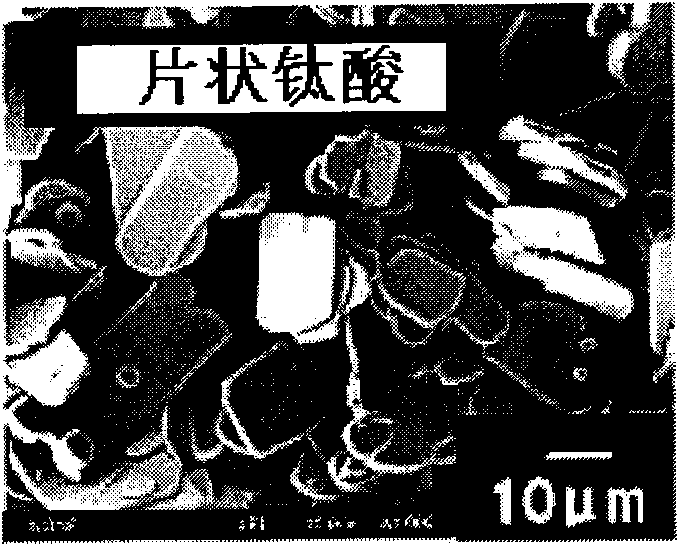

Plate-like brown pigment

A brown and flake technology, applied in the field of flake brown pigments and cosmetics containing the pigment, to achieve the effects of excellent smoothness, excellent gloss and excellent smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

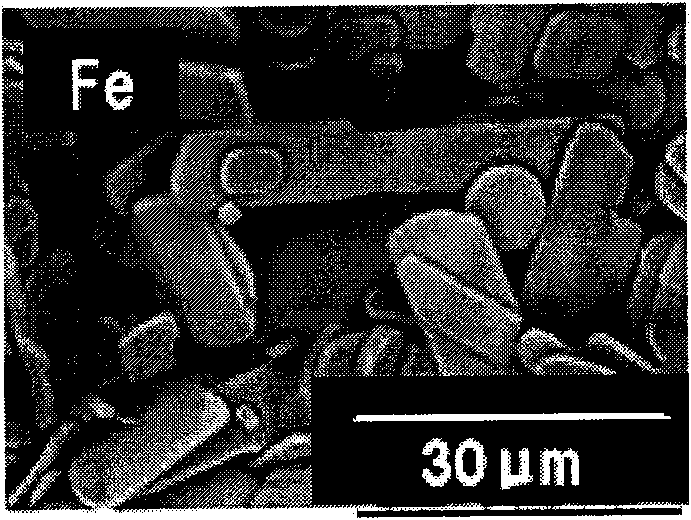

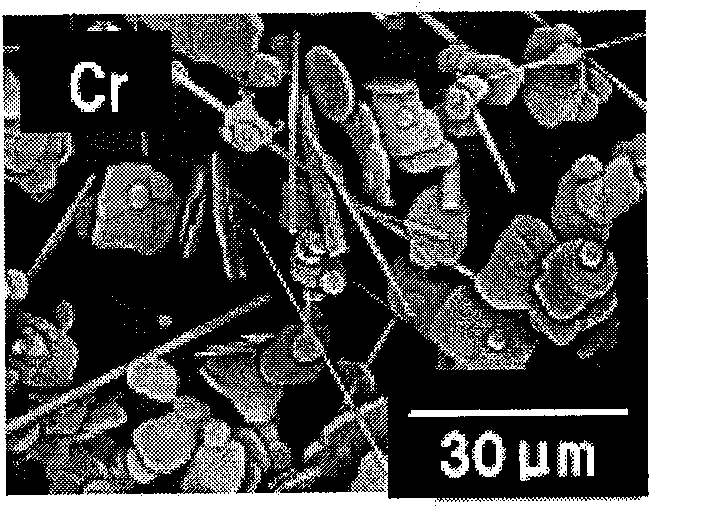

Image

Examples

Embodiment 1

[0053] Weigh TiO 2 : 3.4054g, Li 2 CO 3 : 0.24g, K 2 CO 3 : 1.355g, KCl: 5g, FeCl 2 4H 2 O: 0.34 g, mixed for about 10 minutes using a mortar. Calcined at 1000°C for 5 hours, immersed the calcined product in warm water at 80°C, and stirred for about 1 hour. The resulting powder was filtered off, and the powder was further stirred in warm water at 80° C. for about 15 minutes. The powder was filtered out and dried at 150°C for 1 hour. The composition formula of the obtained flaky brown pigment is K 0.835 Li 0.256 Ti 1.677 Fe 0.067 o 4 .

Embodiment 2

[0055] Weigh TiO 2 : 6.81g, Li 2 CO 3 : 0.48g, K 2 CO 3 : 2.71g, KCl: 11.388g, Fe(NO 3 ) 3 9H 2 O: 1.388 g, mixed for about 30 minutes using a mortar. Calcined at 950°C for 5 hours, immersed the calcined product in warm water at 80°C, and stirred for about 3 hours. The obtained powder was filtered off and dried at 150° C. for 1 hour. The composition formula of the obtained flaky brown pigment is K 0.835 Li 0.256 Ti 1.677 Fe 0.067 o 4 .

Embodiment 3

[0057] Weigh TiO 2 : 6.81g, Li 2 CO 3 : 0.48g, K 2 CO 3 : 2.71g, KCl: 11.388g, Fe(NO 3 ) 3 9H 2 O: 1.388 g, mixed for about 30 minutes using a mortar. Calcined at 1100°C for 5 hours, immersed the calcined product in warm water at 80°C, and stirred for about 3 hours. The obtained powder was filtered off and dried at 150° C. for 1 hour. The composition formula of the obtained flaky brown pigment is K 0.835 Li 0.256 Ti 1.677 Fe 0.067 o 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| Average long diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com