Opacity imparting liquid for zirconia

A technology of transparency and zirconia, which can be used in compression molding cups, dental repairs, dental prostheses, etc., and can solve problems such as inability to adjust shades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

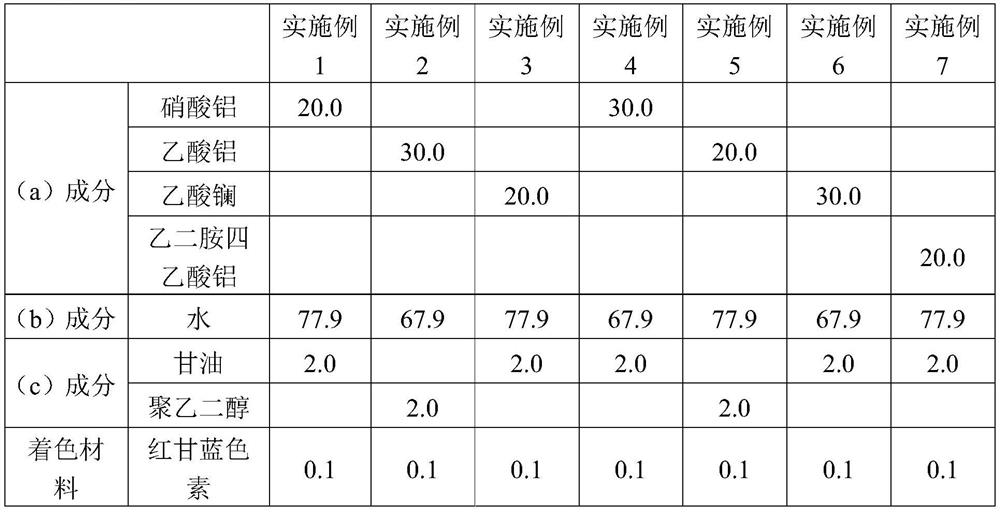

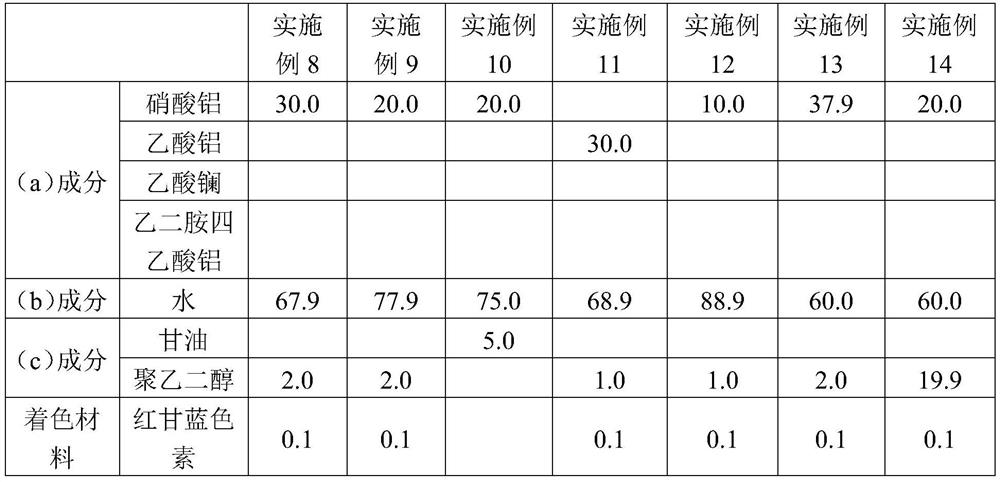

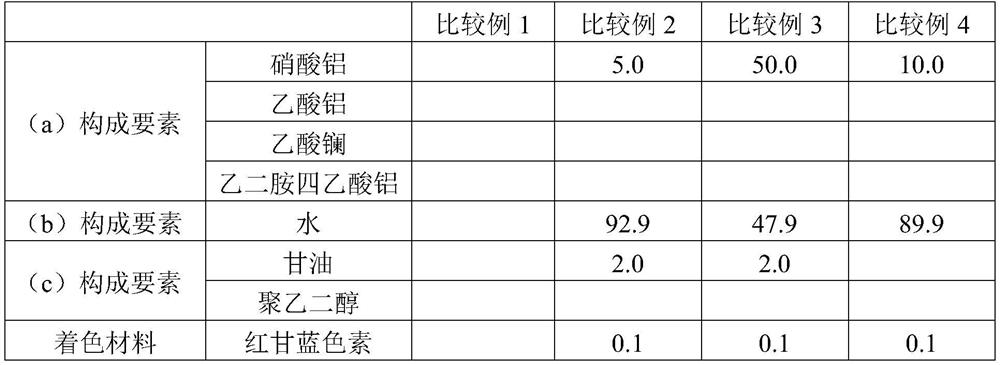

[0043] As the zirconia opacity-imparting liquid, an opacity-imparting liquid containing the components shown in the following Examples and Comparative Examples was prepared. Blending involves mixing the various reagents in a solvent for 1 hour. As the opaque zirconia disk, "Shofu disk ZR Lucent FA Superlight color (松风ディスク ZR Lucent FA superlight color)" manufactured by Nippon Matsukaze Co., Ltd. was used. Semi-sintered zirconia disk cut into 10mm x 10mm x 1mm Zirconium sheet. Thereafter, the opacity-imparting liquids described in Examples and Comparative Examples were applied with a brush. Sintering is carried out according to the method described in the instruction manual. In addition, regarding the opacity, the visible light transmittance of the non-coated opaque material was calculated as 100. Regarding the applicability, the applicability of the opacity-imparting liquid was also evaluated as A, B, and C. The applicability is as follows: A can be applied with a brush; B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com