High brightness diffusion film for laptop and manufacturing method thereof

A notebook computer, protruding height technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of back and forth scattering of light sources, low light energy utilization rate, and reduce the brightness of backlight units, so as to reduce back and forth scattering and improve light The effect of improving utilization rate and brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

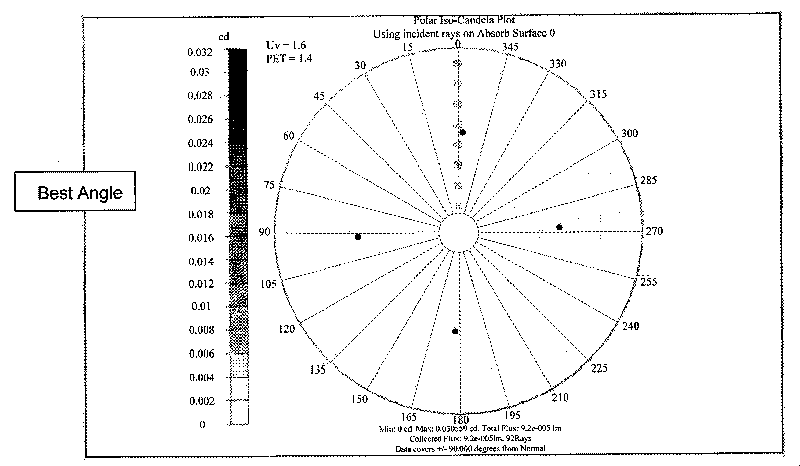

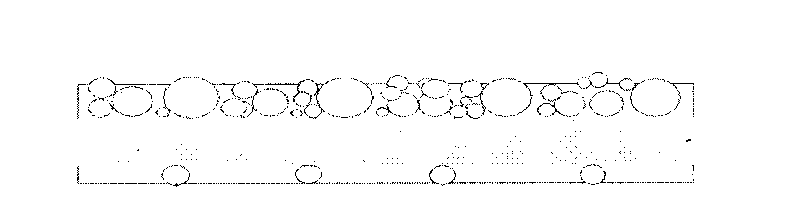

[0031] figure 1 A schematic diagram of the structure of particle size-dispersed diffusion particles in the prior art is shown. When the lower diffusion film is used in the backlight unit of a notebook computer, due to the distribution form of the multi-layer stack, the lower diffusion film cannot control the height of the particles protruding from the glue plane at all. Therefore, the light source is easy to scatter inside, resulting in loss of light energy.

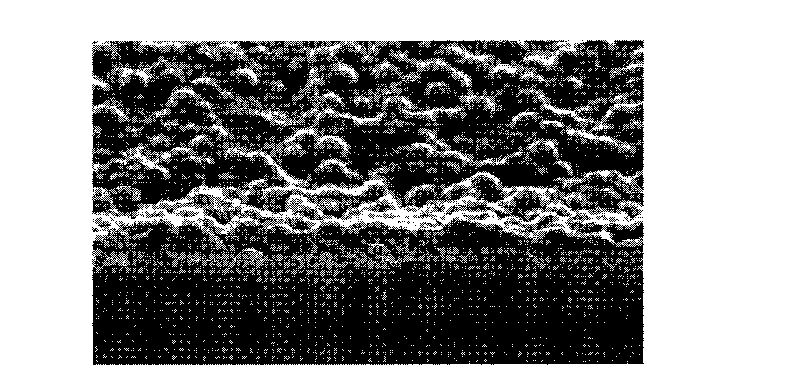

[0032] figure 2 show figure 1 Schematic representation of the size-dispersed diffusing particles shown under a scanning electron microscope. Similarly, image 3 A schematic diagram showing particles under a scanning electron microscope after using a high-brightness diffuser film in a backlight unit of an LCD TV, and Figure 4 Schematic showing particles under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com