Extruded brightness enhancement film and preparation method thereof

A brightness-enhancing film and extrusion-type technology, which is applied in optics, instruments, optical components, etc., can solve problems such as complex manufacturing processes, and achieve the effects of simple and convenient processes, high light transmittance, and reduced thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

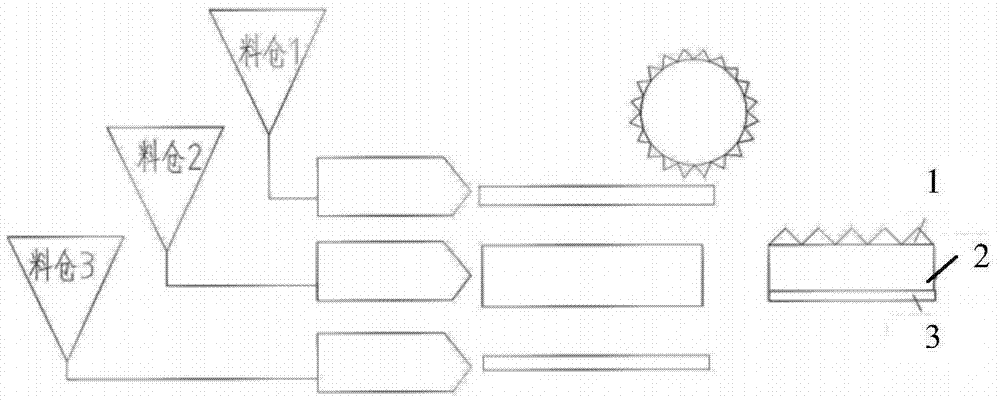

[0043] Such as figure 2 As shown, the present invention provides a kind of preparation method of extruded brightness enhancing film, and described method comprises the following steps:

[0044] (1) The three-layer co-extrusion of the extruder simultaneously extrudes the base film layer 2, the brightening layer 1, and the particle layer 3. When the molding is not cooled, the brightening layer is rolled with a prism structure embossing roller to make the brightening layer form a prism structure;

[0045] (2) Forming the brightness enhancing film after cooling and molding.

Embodiment 1

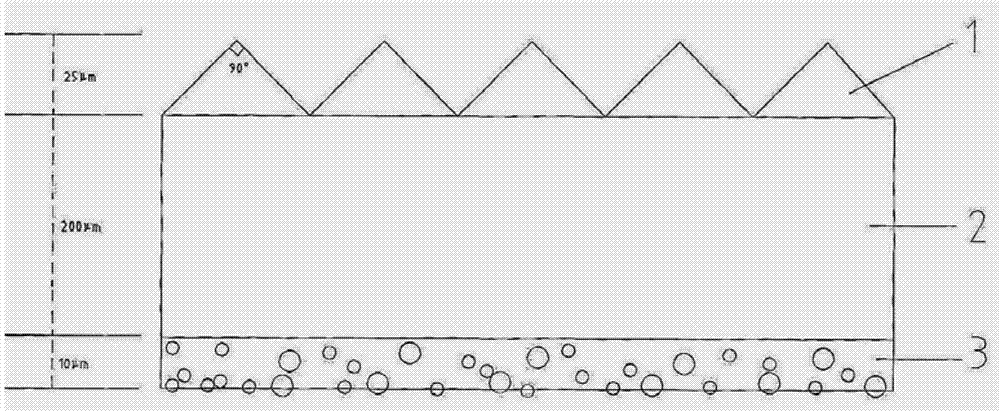

[0047] The invention provides an extruded brightness enhancing film, wherein the brightness enhancing film is composed of a base film layer, a brightness enhancing layer and a particle layer, and the brightness enhancing layer and the particle layer are respectively located on both sides of the base film layer; the The brightness enhancing film is a three-layer co-extruded structure. The brightness enhancement layer has a micro-prism structure.

[0048] The material of the brightening layer is polymethyl methacrylate (PMMA), and the height of the microprism structure is 20 μm, and the width is 40 μm.

[0049] The refractive index of the brightness enhancing layer material is 1.55.

[0050] The base film layer is made of PET with a thickness of 150 μm.

[0051] The particle layer includes diffusion particles and polyester resin, and the diffusion particles are bonded to the upper surface of the base film layer through the polyester resin.

[0052] In the particle layer, the ...

Embodiment 2

[0056] Extruded brightness enhancing film as described in embodiment 1, wherein,

[0057] The material of the brightening layer is polymethyl methacrylate (PMMA), the height of the microprism structure is 25 μm, the width is 50 μm, and the angle of the apex is 90°.

[0058] The refractive index of the brightness enhancing layer material is 1.55.

[0059] The base film layer is made of PET with a thickness of 150 μm.

[0060] The particle layer includes diffusion particles and polyester resin, and the diffusion particles are bonded to the upper surface of the base film layer through the polyester resin.

[0061] In the particle layer, the diffusion particles are organic silicon particles; the polyester is pure PET; in the particle layer, the weight of the diffusion particles accounts for 2% of the total weight of the particle layer material, and PET accounts for 98%. The particle size of the diffused particles is 2 μm, and the thickness of the particle layer is 10 μm.

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com