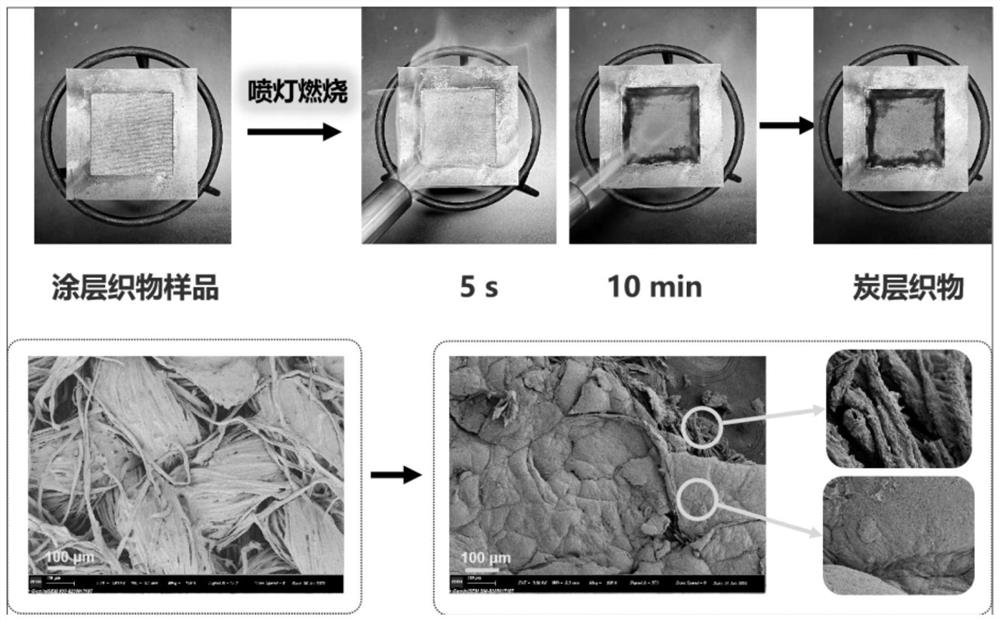

Preparation method of self-repairing electromagnetic shielding coated fabric in high-temperature environment

An electromagnetic shielding and high-temperature environment technology, which is applied in textiles and papermaking, etc., can solve the problems of insufficient consideration of the deterioration of electromagnetic shielding performance, electromagnetic wave leakage, oxidative degradation, etc., so as to extend the electromagnetic shielding function, improve the service life, prolong The effect of conduction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

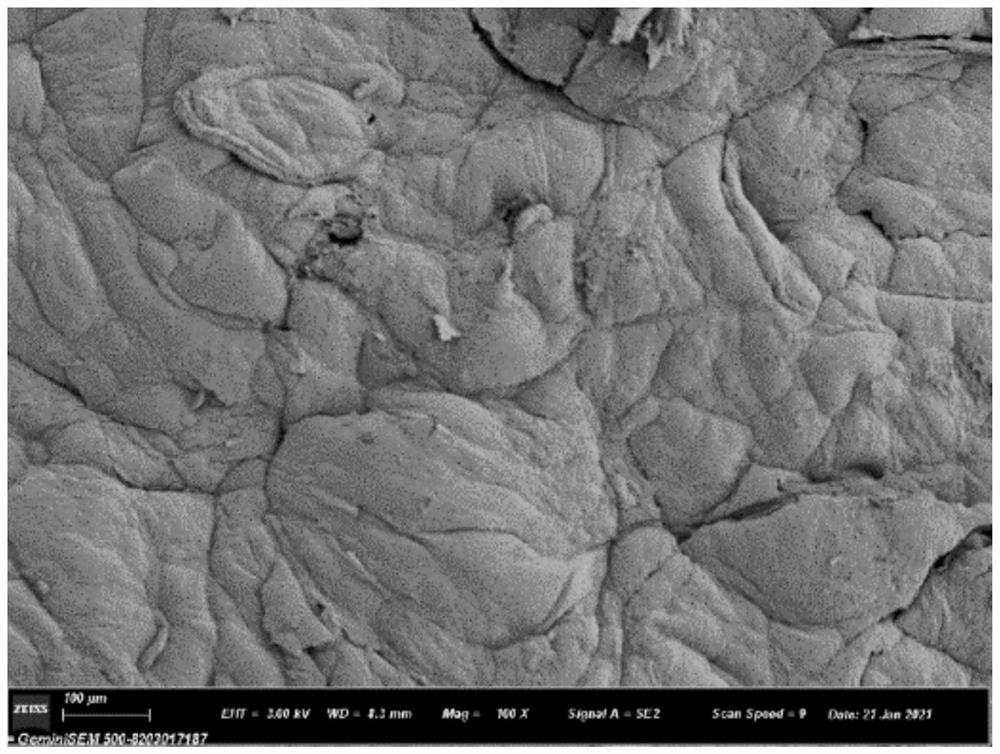

Method used

Image

Examples

Embodiment 1

[0033] Cut a 20×20cm pure cotton fabric, put it in a 1moL / L sodium hydroxide solution, and continue stirring for two hours at 90 °C to remove the excess slurry on the surface and increase the active groups on the surface of the cotton fiber. , washed three times with deionized water, and dried in a 60°C oven for later use.

[0034] Add 20g of ammonium polyphosphate (APP) to a three-necked flask containing 250mL of water, use a stirrer to condense and reflux under the condition of a constant temperature water bath at 80°C and continue to stir for two hours, and weigh 0.2g of γ-aminopropyltriethyl ether. Oxysilane (KH-550) was dissolved in ethanol, prepared into a solution, added to the above three-necked flask and stirred continuously for one hour. The ammonium ion-exchanged silane-modified ammonium polyphosphate was prepared. Ammonium polyphosphate modified with γ-aminopropyltriethoxysilane is used to give its surface amino structure, and pH is adjusted to give its surface a ...

Embodiment 2

[0038] Cut a 20×20cm pure cotton fabric, put it in a 1moL / L sodium hydroxide solution, and continue stirring for two hours at 90 °C to remove the excess slurry on the surface and increase the active groups on the surface of the cotton fiber. , washed three times with deionized water, and dried in a 60°C oven for later use.

[0039] Add 20g of ammonium polyphosphate (APP) to a three-necked flask containing 250mL of water, use a stirrer to condense and reflux under the condition of a constant temperature water bath at 80°C and continue to stir for two hours, and weigh 0.2g of γ-aminopropyltriethyl ether. Oxysilane (KH-550) was dissolved in ethanol, prepared into a solution, added to the above three-necked flask and stirred continuously for one hour. The ammonium ion-exchanged silane-modified ammonium polyphosphate was prepared. Ammonium polyphosphate modified with γ-aminopropyltriethoxysilane was used to give its surface amino structure, and a mixed solution of triethanolamine / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com