Patents

Literature

48results about How to "Improve service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

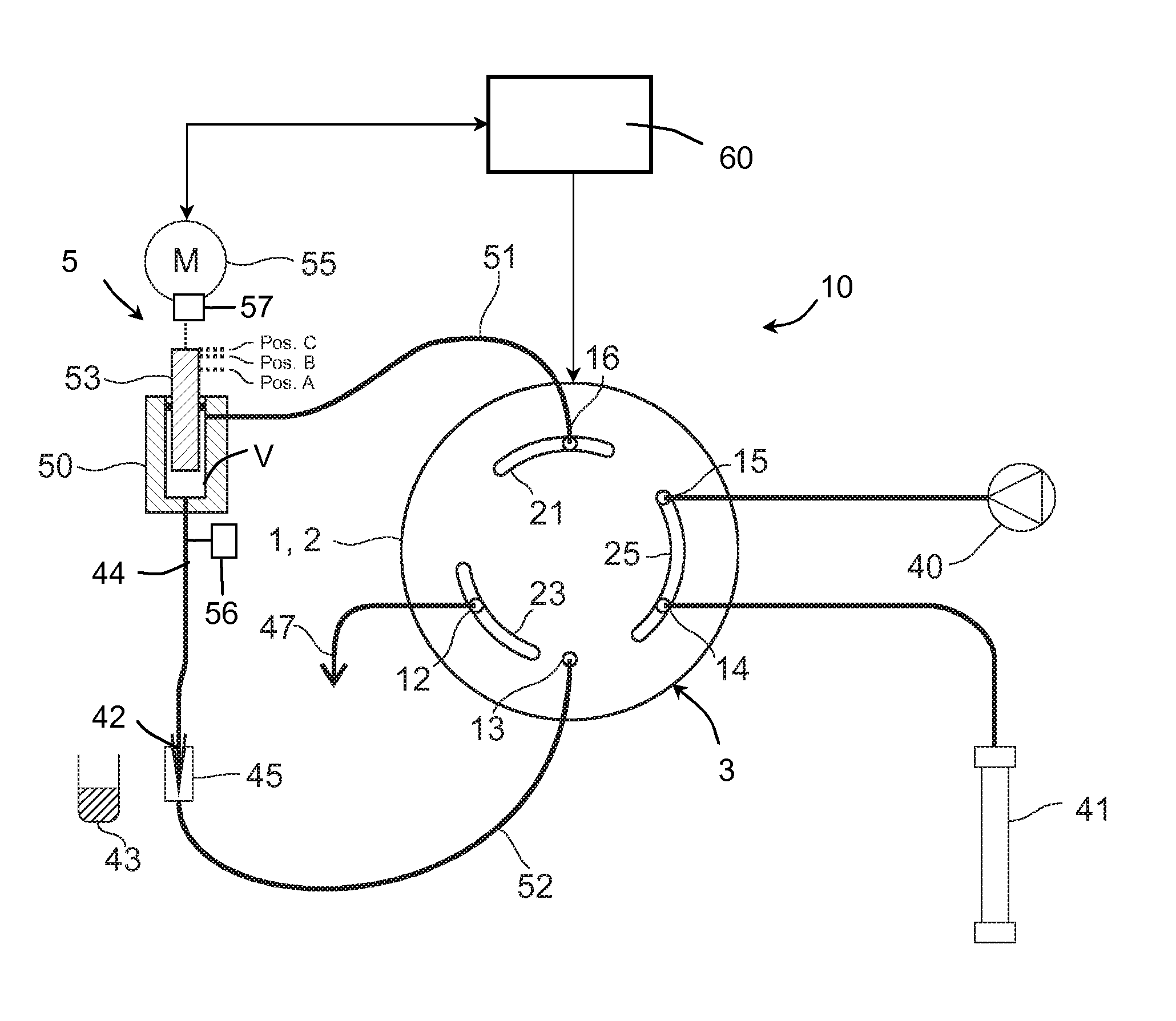

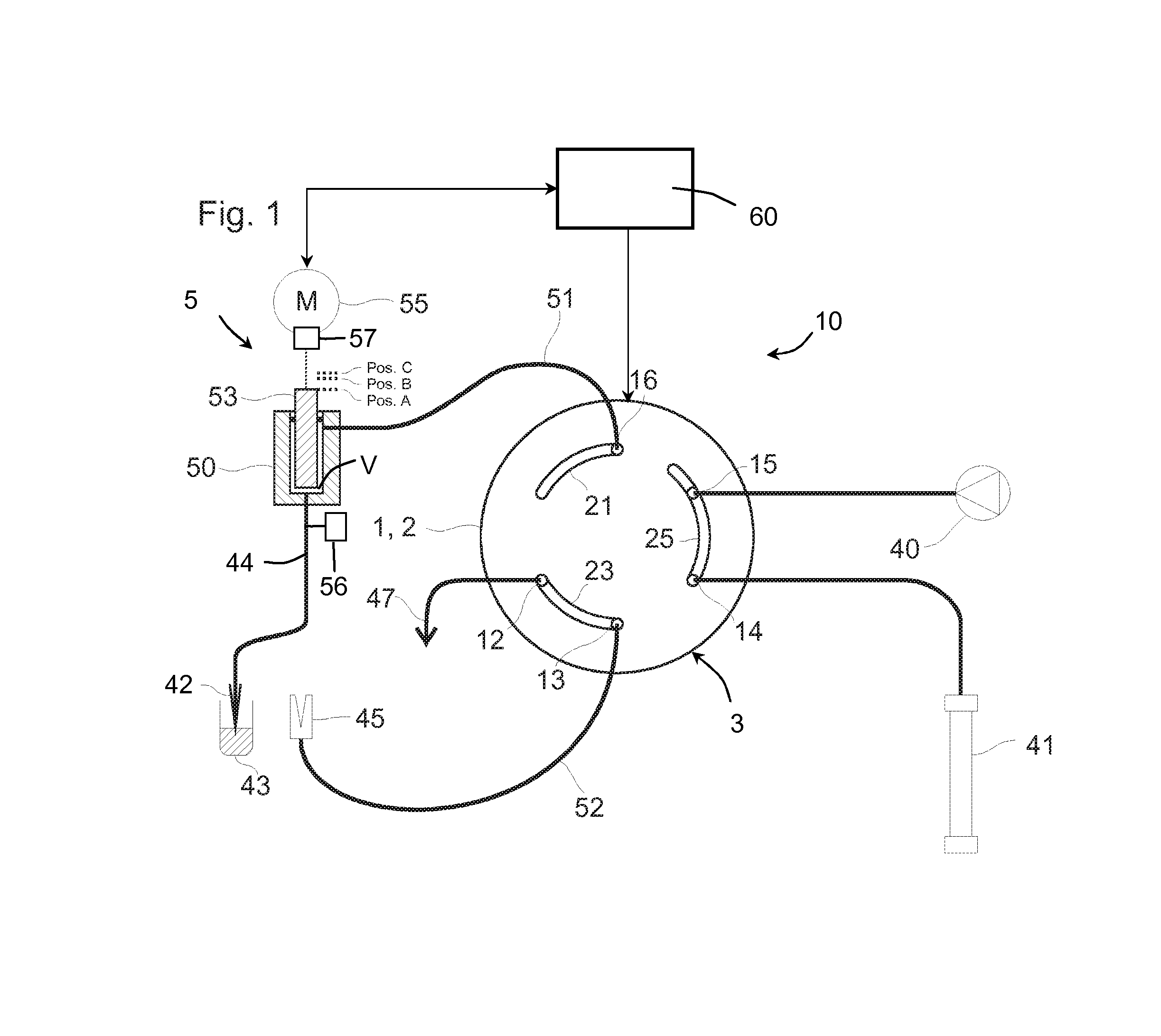

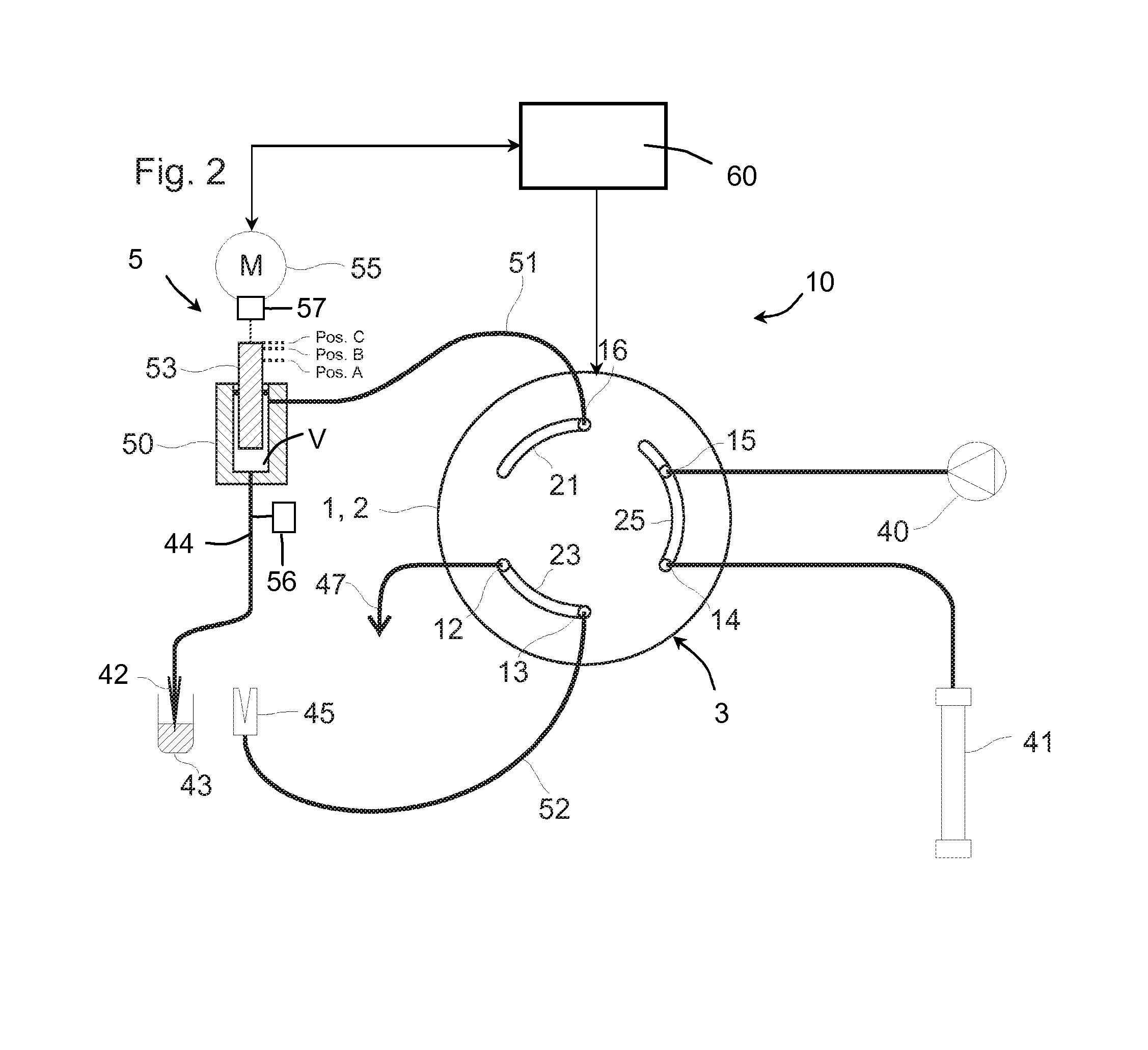

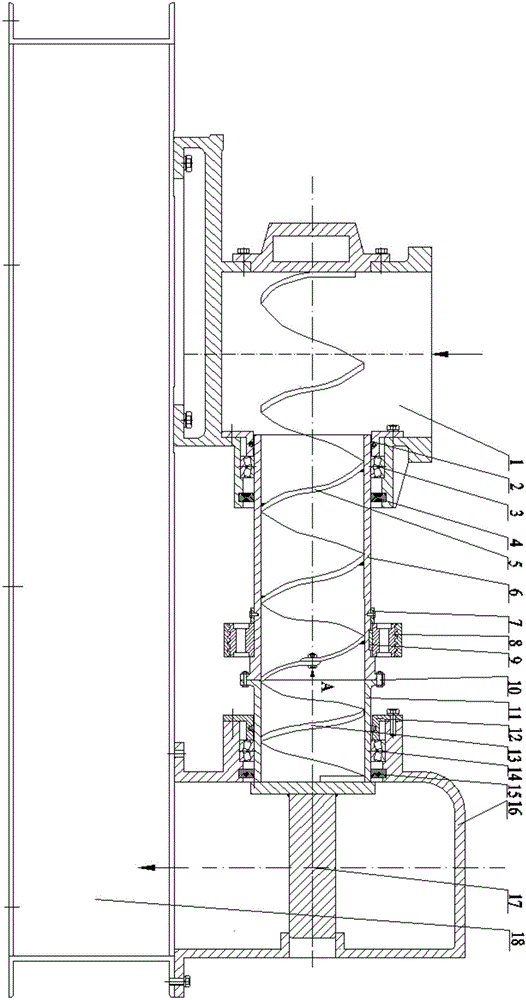

Sample injector for liquid chromatography, particularly for high performance liquid chromatography

ActiveUS8806922B2Improve service lifeExtended service lifeSamplingComponent separationChromatography columnInjector

A sample injector for liquid chromatography includes an injection valve having a waste port, two sample loop ports, and two high-pressure ports. One high-pressure port can be connected to a pump and the other high-pressure port can be connected to a chromatography column. A sample loop is connected to one of the sample loop ports on one end and to a pump volume of a sample conveying device on the other end. A section of the sample loop can be separated to facilitate receiving a sample fluid in the sample loop. A control unit controls the injection valve and the sample conveying device. The sample injector allows a sample to be loaded into the sample loop and then pressurized to an operating pressure prior to injecting the sample into the chromatography column. The sample loop may also be isolated from the operating pressure for facilitating depressurization of the loop.

Owner:DIONEX SOFTRON

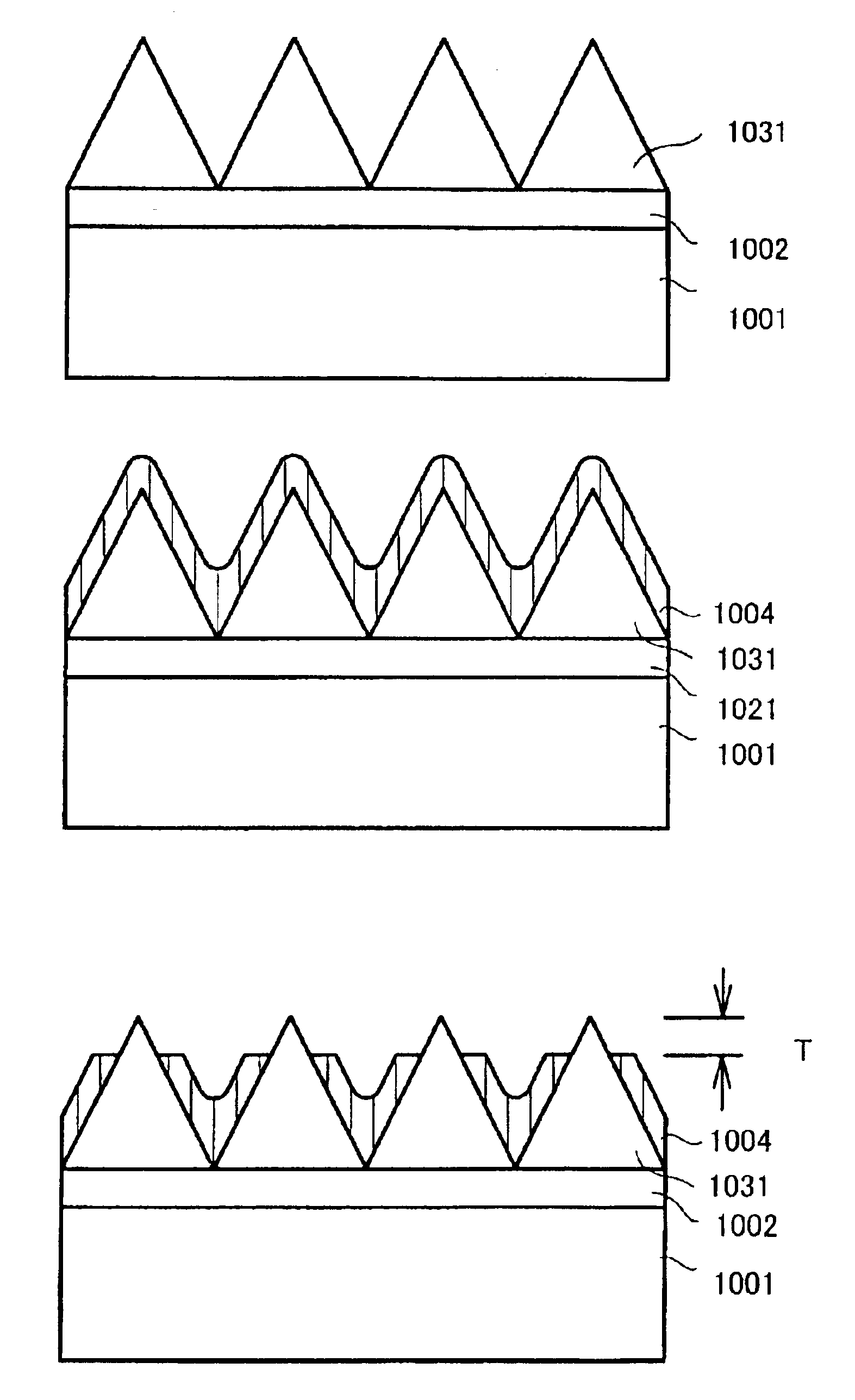

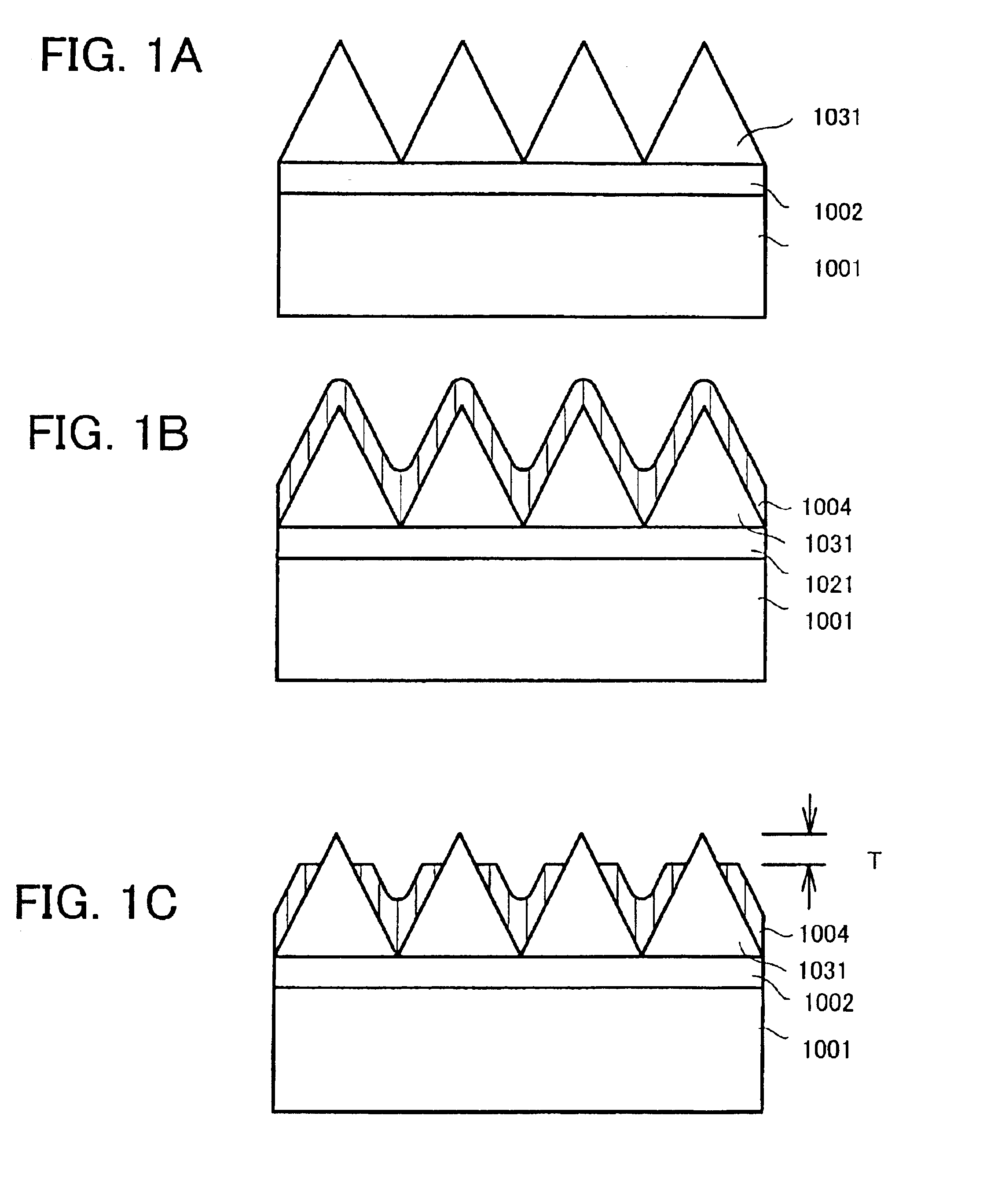

Methods for fabricating group III nitride compound semiconductors and group III nitride compound semiconductor devices

InactiveUS6861305B2High mobilityImprove service lifeSemiconductor/solid-state device manufacturingSemiconductor devicesDislocationThreading dislocations

The present invention provides a Group III nitride compound semiconductor with suppressed generation of threading dislocations. A GaN layer 31 is subjected to etching, so as to form an island-like structure having a shape of, for example, dot, strip, or grid, thereby providing a trench / mesa structure, and a mask 4 is formed at the bottom of the trench such that the upper surface of the mask 4 is positioned below the top surface of the GaN layer 31. A GaN layer 32 is lateral-epitaxially grown with the top surface 31a of the mesa and sidewalls 31b of the trench serving as nuclei, to thereby bury the trench, and then epitaxial growth is effected in the vertical direction. In the upper region of the GaN layer 32 formed above the mask 4 through lateral epitaxial growth, propagation of threading dislocations contained in the GaN layer is 31 can be prevented.

Owner:TOYODA GOSEI CO LTD

Preparation method of corundum-mullite composite ceramic push plate

The invention discloses a preparation method of corundum-mullite composite ceramic push plate by using mullite particles, aluminium oxide particles, aluminium oxide micropowder, mullite micropowder and ultra-fine silicon micronized quartz powder as raw material, using alumina silica gel as bonding agent, and introducing aluminum fluoride mineralization agent.

Owner:ZHEJIANG UNIV

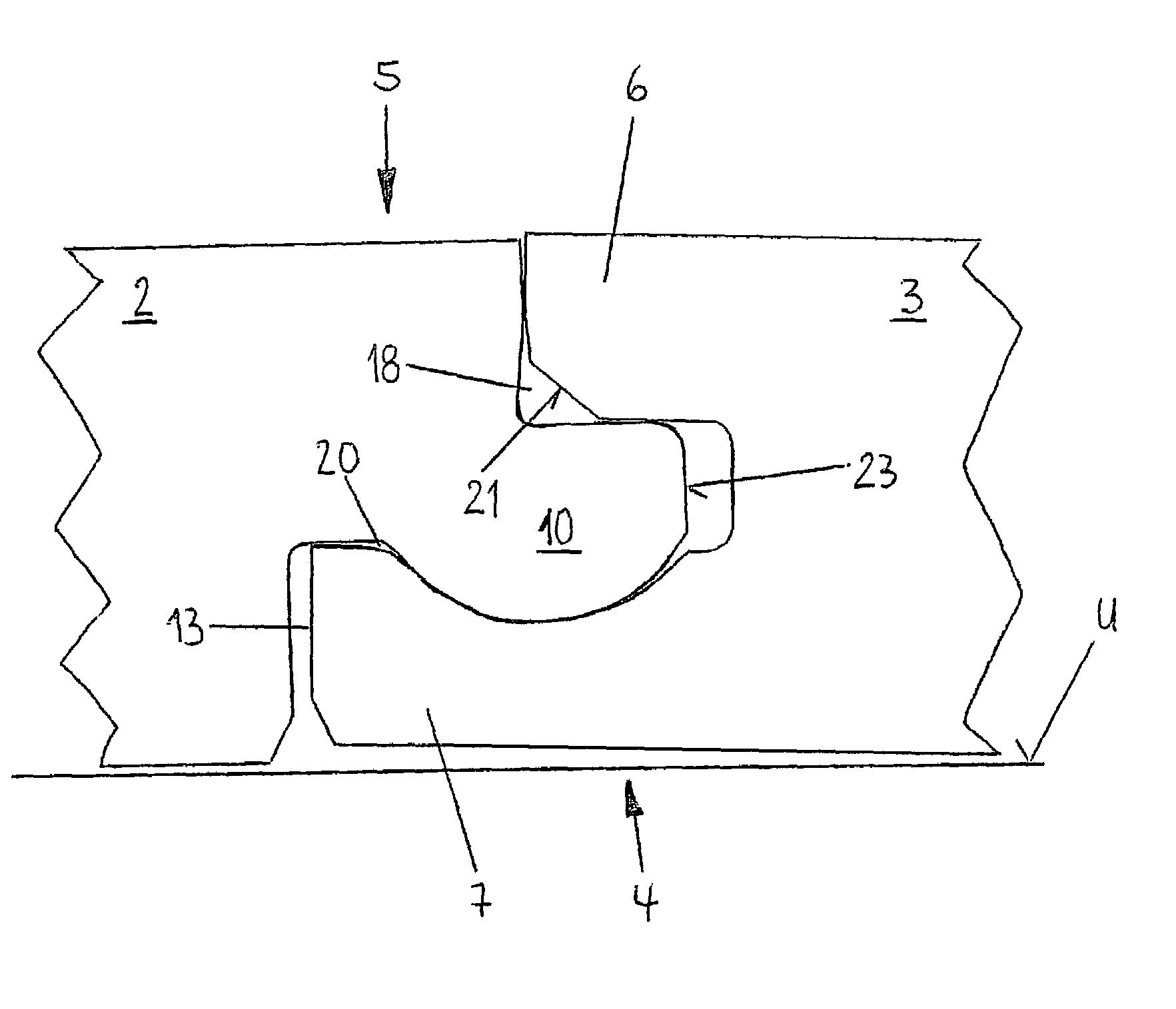

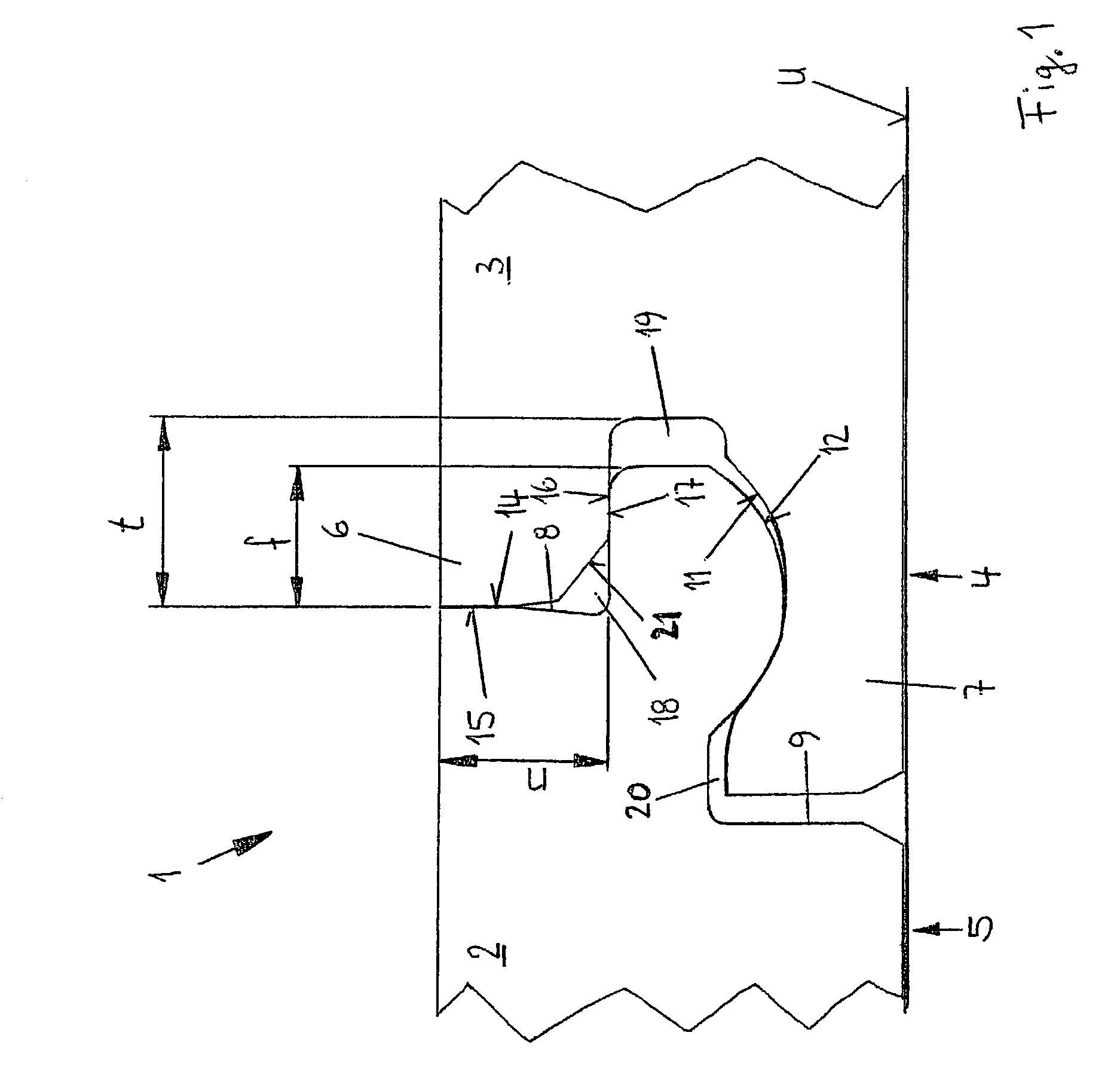

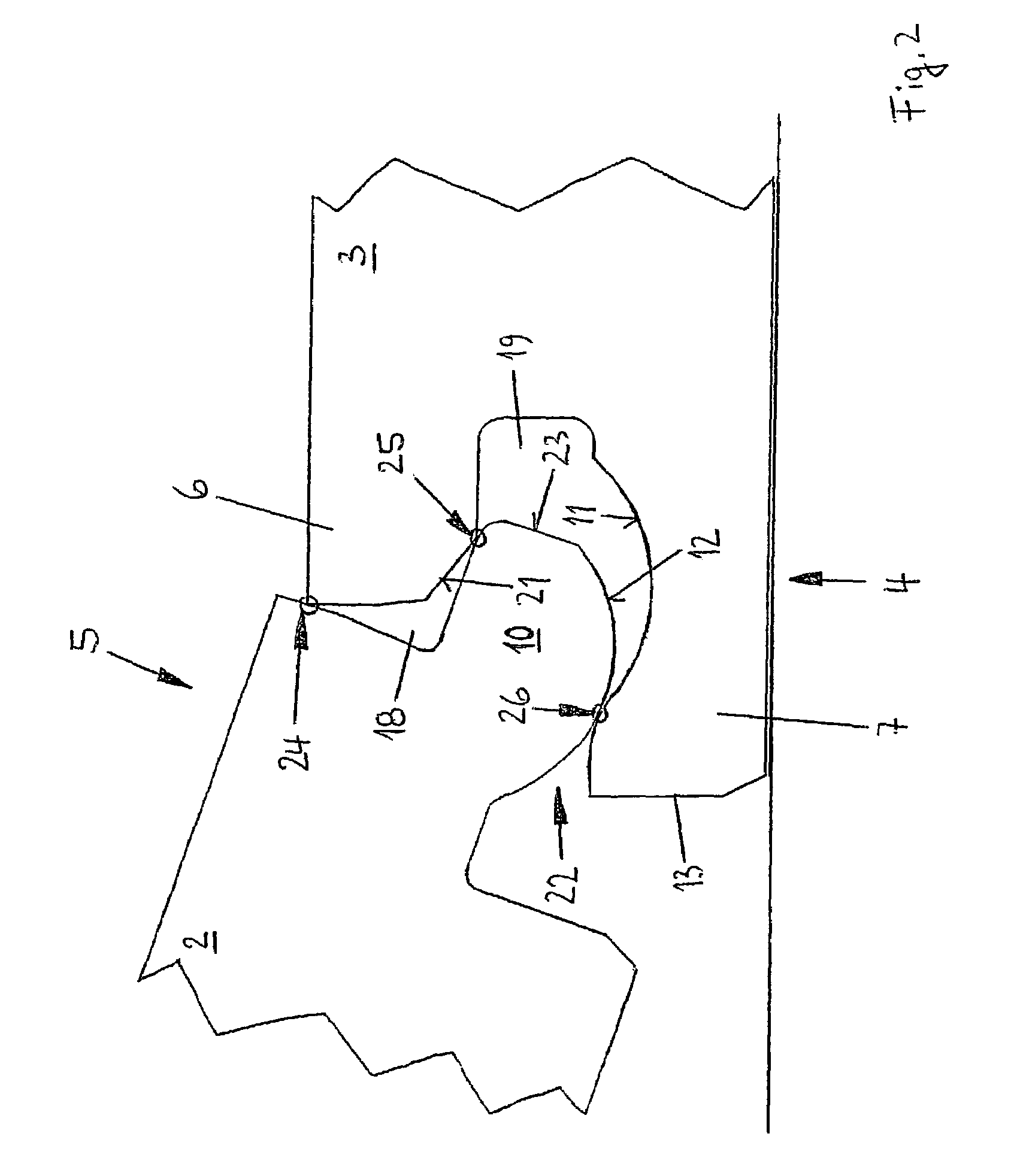

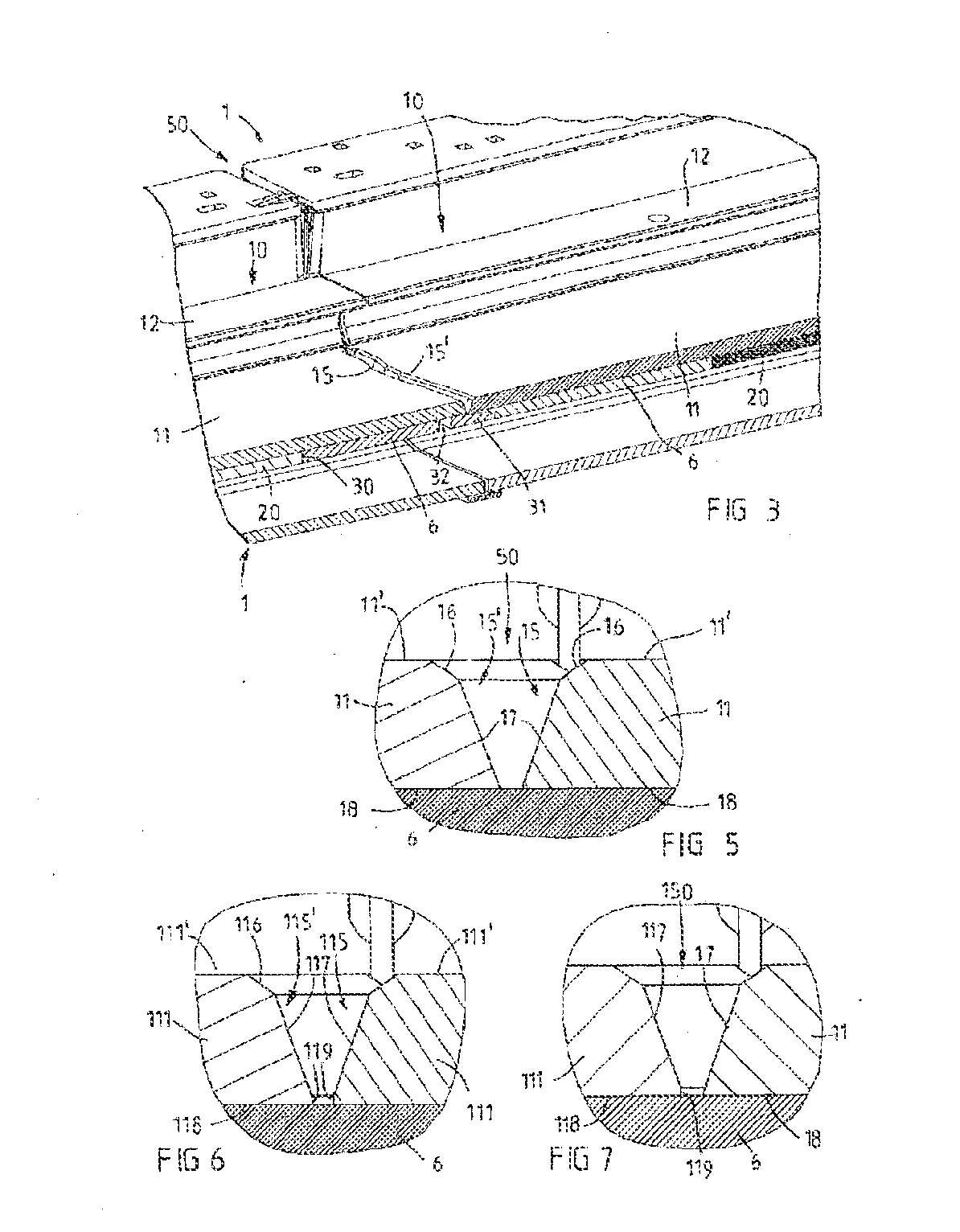

Panel and locking system for panels

The invention relates to a panel and a locking system (1) for panels (2, 3) with edge profiles provided on at least two opposite edges of the panels (2, 3) for the positive connection of similar panels (2, 3), including an edge profile designed as a groove profile (4), with an upper groove wall (6) and a lower groove wall (7), and an edge profile designed as a tongue profile (5), with a notch projection (12) on the underside of the tongue that engages a notch recess (11) in the lower groove wall (7) of an adjacent panel in the assembled state, where the engaged edge profiles form an articulated joint (G) that acts to restore the panels (2, 3) to their installation plane when deflected either up or down, where the upper groove wall (6) has a flank (21) on the inside that opens towards the free end of the groove wall (6).

Owner:AKZENTA PANEELE PROFILE GMBH

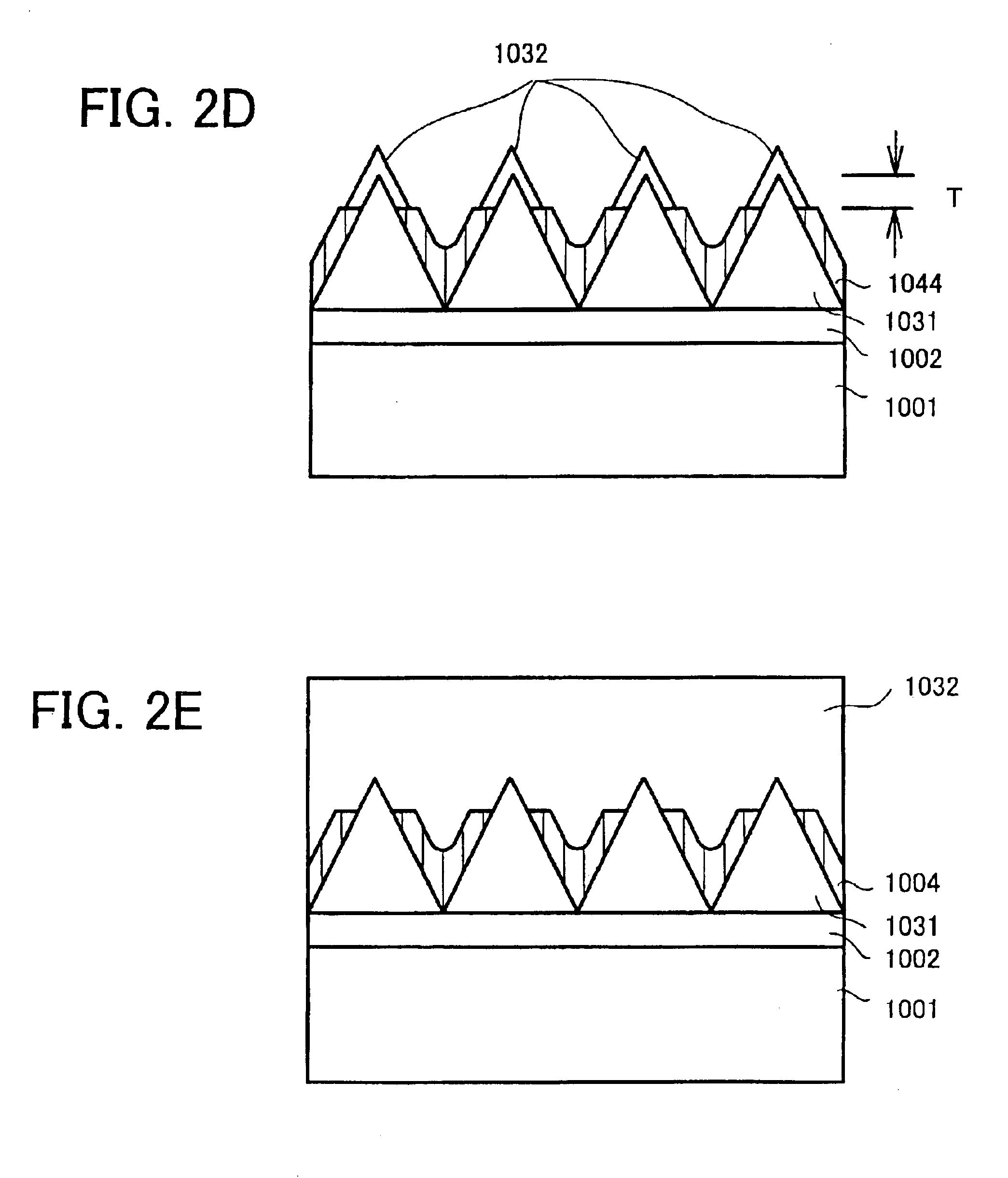

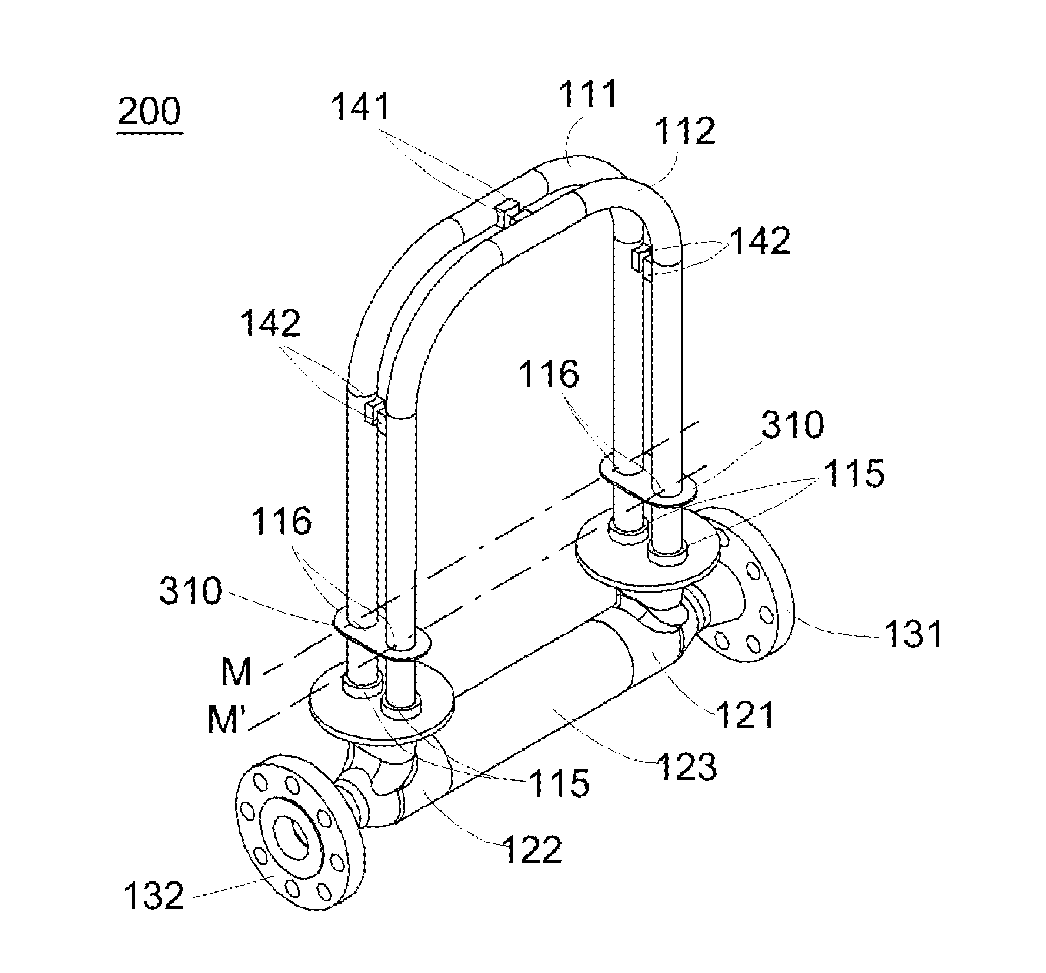

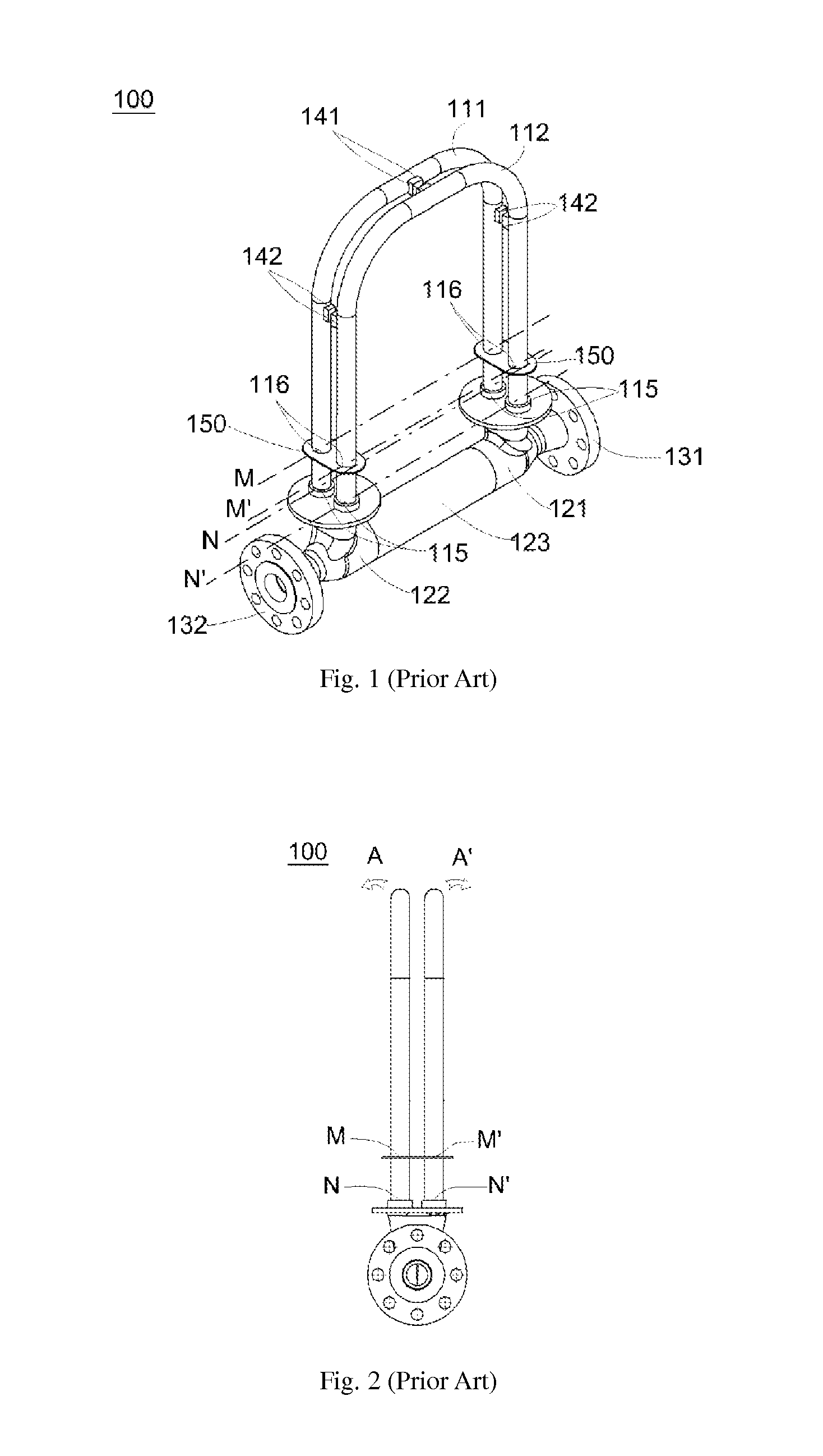

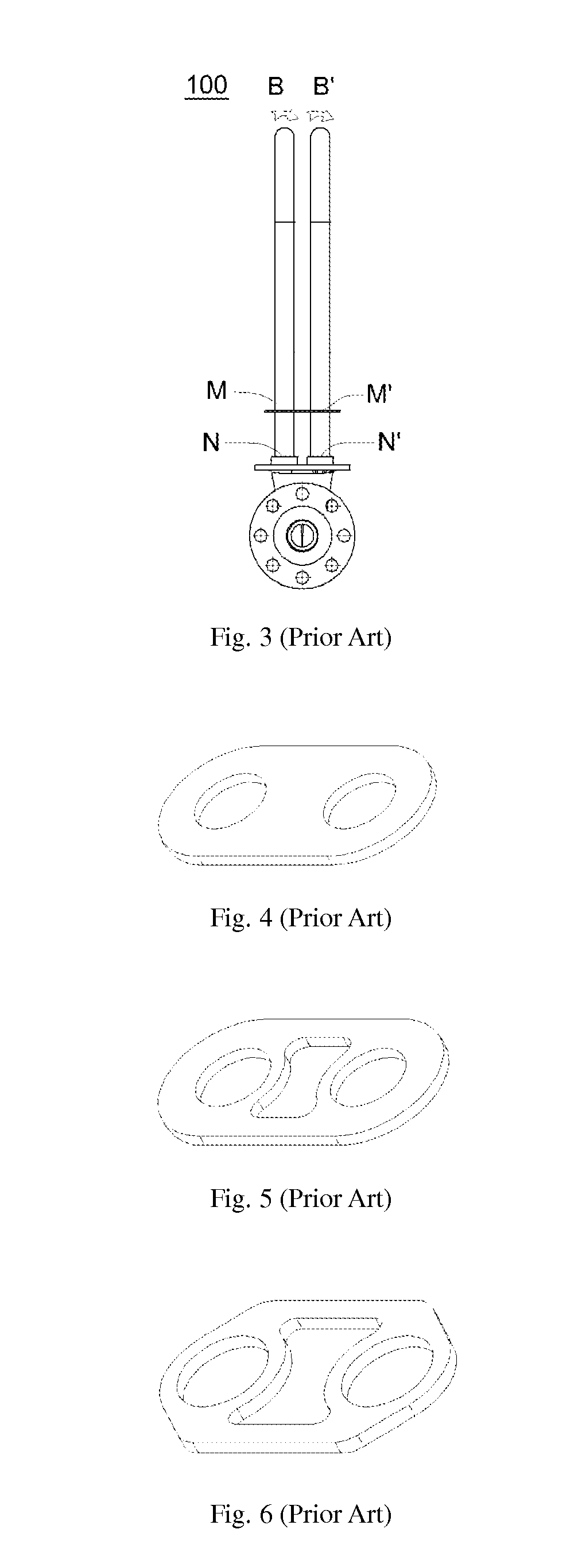

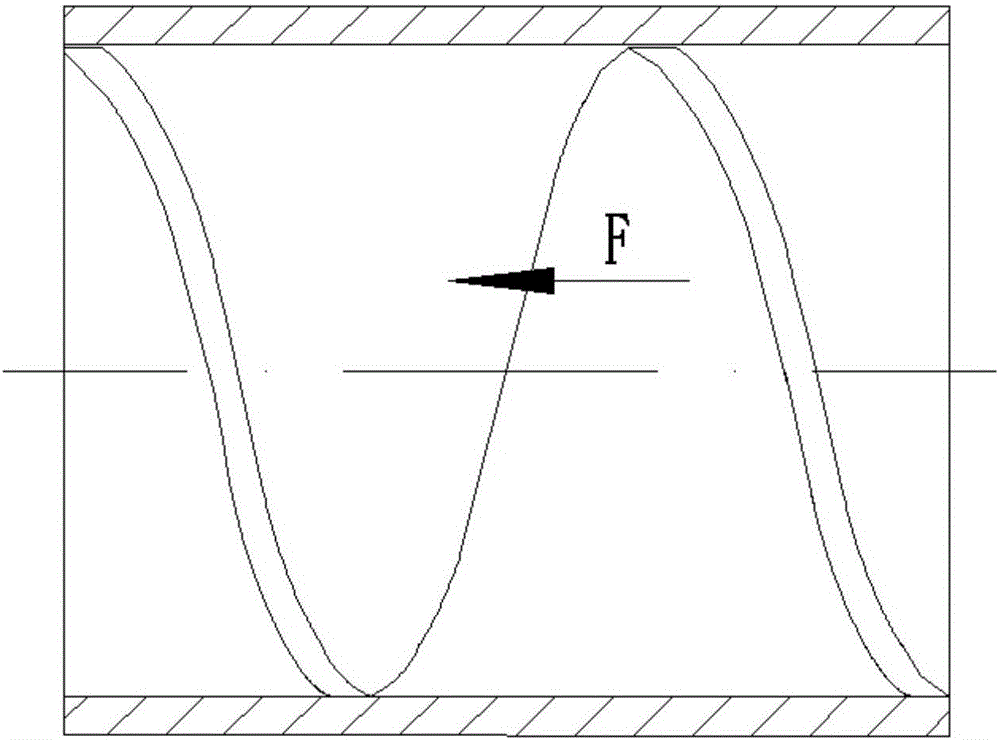

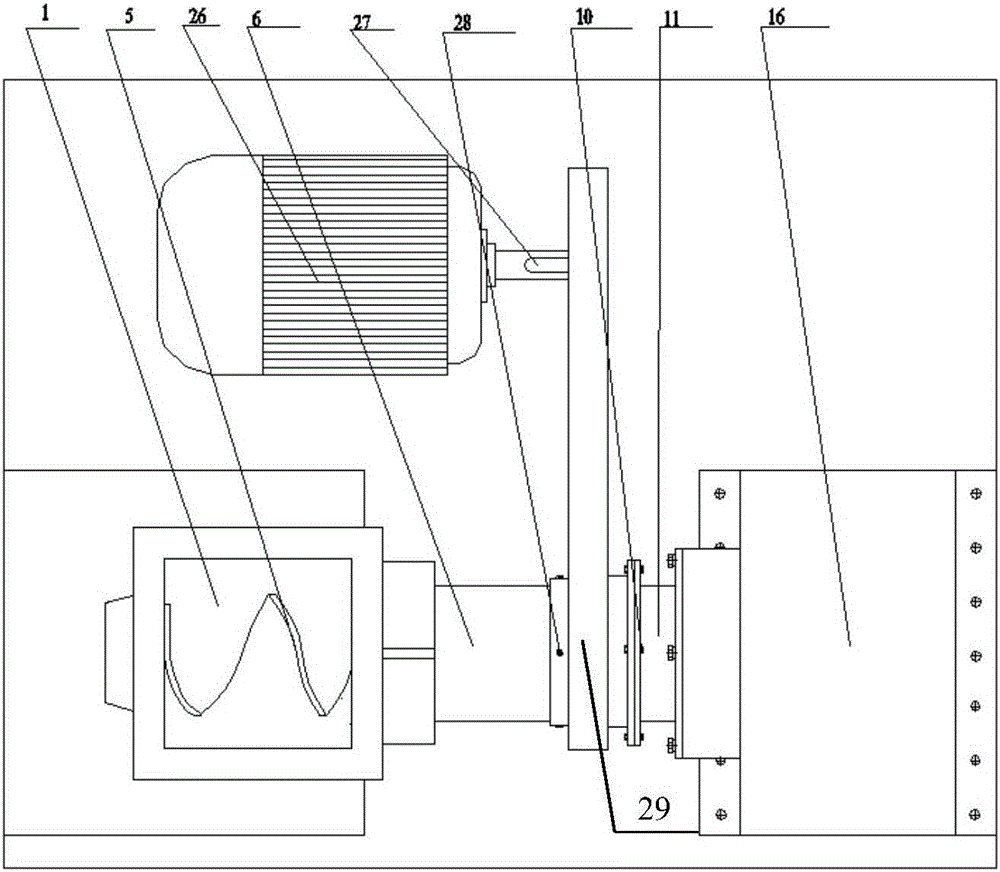

Coriolis Mass Flow Meter, Vibrating Tube Density Meter and Vibrating Sheet Used Therein

ActiveUS20150033874A1Increase service lifeImprove service lifeDirect mass flowmetersSpecific gravity measurementMeasurement precisionAccuracy and precision

The present invention relates to a Coriolis mass flow meter, a vibrating tube density meter and a vibrating sheet used therein, and more particularly, to a vibrating sheet for use in a Coriolis mass flow meter or a vibrating tube density meter, the vibrating sheet having at least one welded connecting portion that is fixedly welded to the flow tube of the Coriolis mass flow meter or the vibrating tube density meter, the flow tube being excited to vibrate around a revolving axis at the welded junction of the vibrating sheet and the flow tube. The welded connecting portions of the vibrating sheet are only formed in the stress insensitive region of the vibrating sheet, wherein the stress insensitive region is the region of the vibrating sheet which has an angle of not more than 45 degrees with respect to the revolving axis. In addition, the present invention also provides a Coriolis mass flow meter and a vibrating tube density meter using the vibrating sheet. The present invention not only simplifies the process, but also improves the measurement precision and service life of the Coriolis mass flow meter and the vibrating tube density meter.

Owner:QINGDAO ALPTEC SAFETY EQUIP

Ultrasonic damage-free checking focusing probe device

InactiveCN101339164AFocus on solvingReduce use costAnalysing solids using sonic/ultrasonic/infrasonic wavesLiquid mediumImage resolution

The invention discloses a focusing probe device of ultrasonic nondestructive detection used for detecting the defect of a detected sample, comprising a cylinder used for fixing the ultrasonic focusing probe; the ultrasonic focusing probe is connected with the big end of an inner cylinder in a sealing mode; the bottom end of the inner cylinder is encapsulated with a sound transmission film; a liquid medium used for transmission of the ultrasonic wave is arranged in the cylinder container of the inner cylinder; the inner cylinder provided with the probe is connected into a whole with an outer cylinder by thread in an adjustable mode; under the conditions of the same gain, the capability of detecting the defect of the sample is much better than a general straight probe; the water distance of the device leads the display distance of an initial wave, an interface wave, a defect wave and a bottom wave in the screen of a flaw detector to be pulled open and leads the area of the detected sample to be outside a triple near-field area of the ultrasonic wave on a beam axis, thus improving the resolution of waveform display and the detection sensitivity, leading the operation of finding and judging the defect wave in the process of detecting the defect to be convenient, saving a water tank and a water supply device and realizing field detection.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

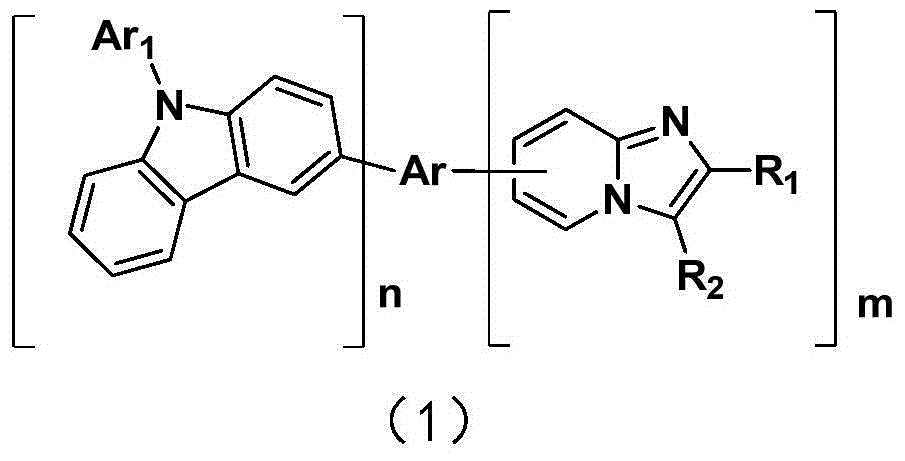

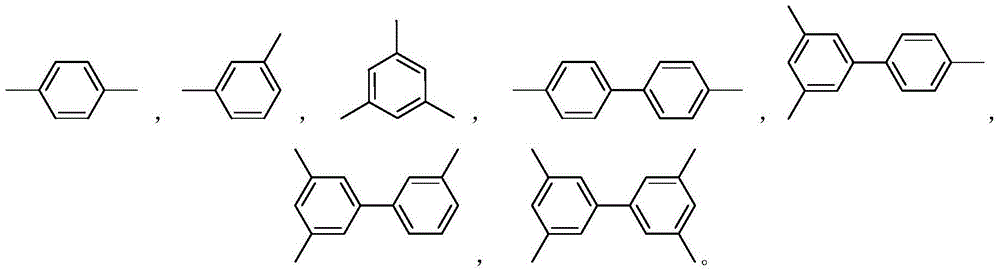

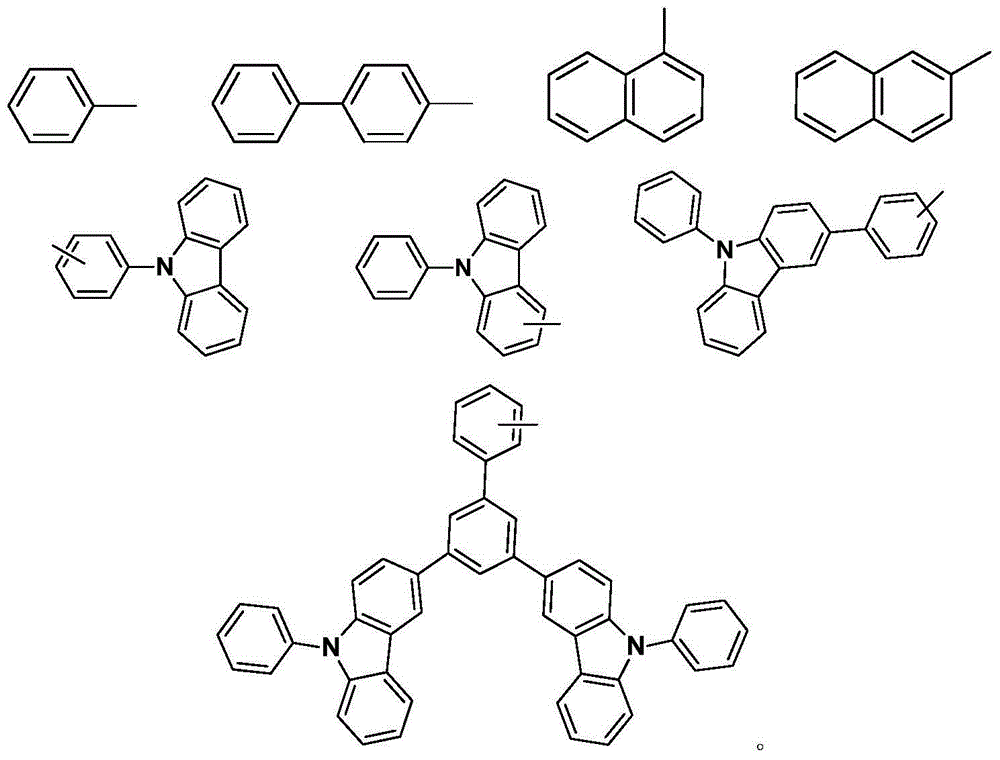

Compound containing imidazopyridine group and application thereof in organic electroluminescence

InactiveCN104650076AHigh glass transition temperatureImprove service lifeOrganic chemistrySolid-state devicesOrganic electroluminescenceSingle bond

The invention provides a novel organic compound having a structure as shown in a formula (I). In the compound, Ar is one of single bond, substituted or unsubstituted aromatic or hetero aromatic group of C6-C30, and substituted or unsubstituted condensed aromatic or condensed hetero aromatic group of C4-C30, and the number of substituent groups on Ar is 2-4; R1 and R2 are respectively and independently selected from H, substituted or unsubstituted aliphatic alkyl of C1-C12, substituted or unsubstituted aliphatic naphthenic base of C1-C12, and substituted or unsubstituted aryl or heterocyclic aryl of C6-C30; Ar1 is selected from substituted or unsubstituted aliphatic alkyl of C1-C12 or substituted or unsubstituted aryl of C6-C30; and n and m are respectively 1 or 2. The compound is stable in property and simple in preparation process, and can be used as a phosphorescence host material in an organic electroluminescence device to obtain relatively high luminescence efficiency and relatively low turn-on voltage.

Owner:BEIJING ETERNAL MATERIAL TECH +1

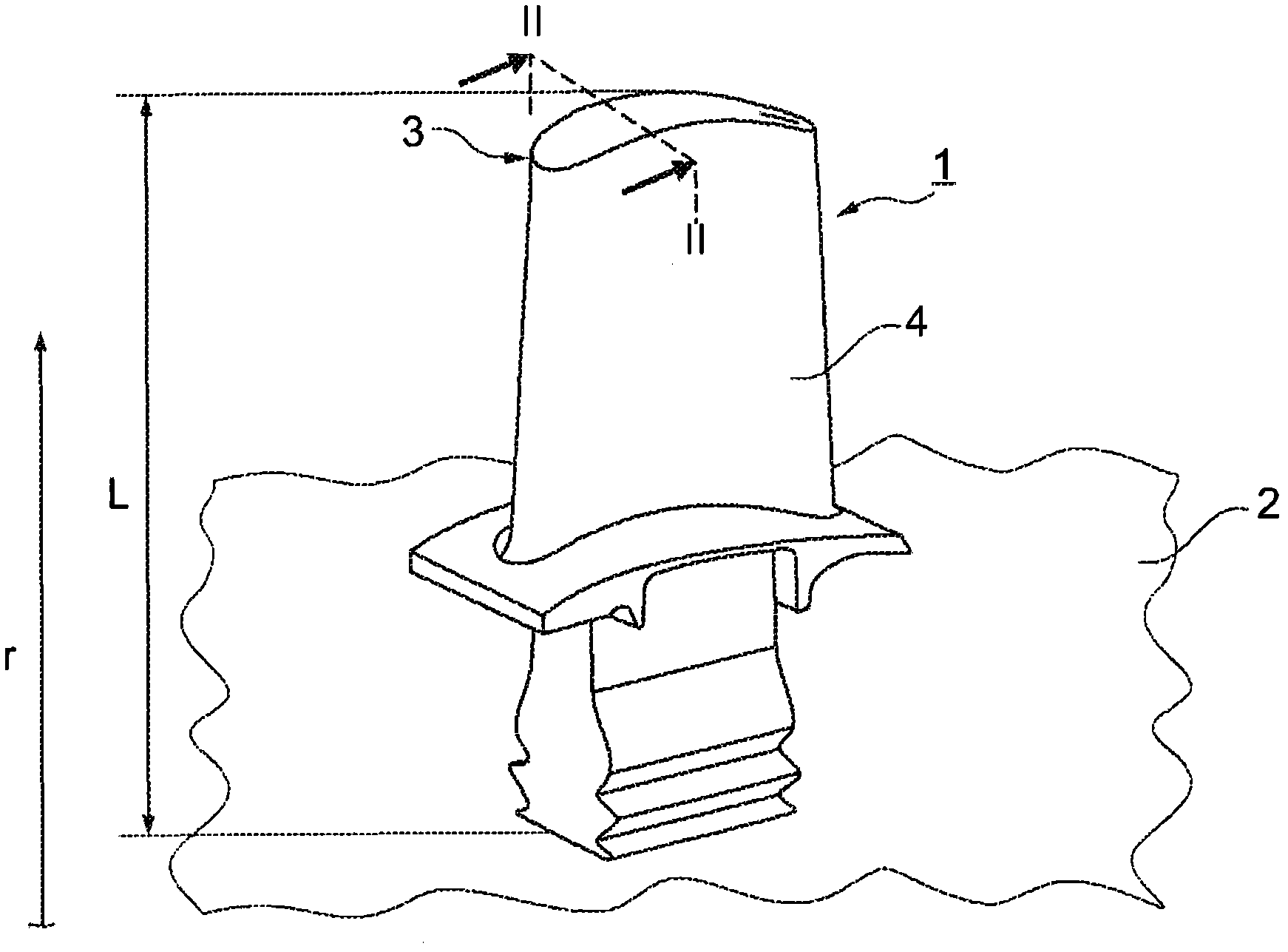

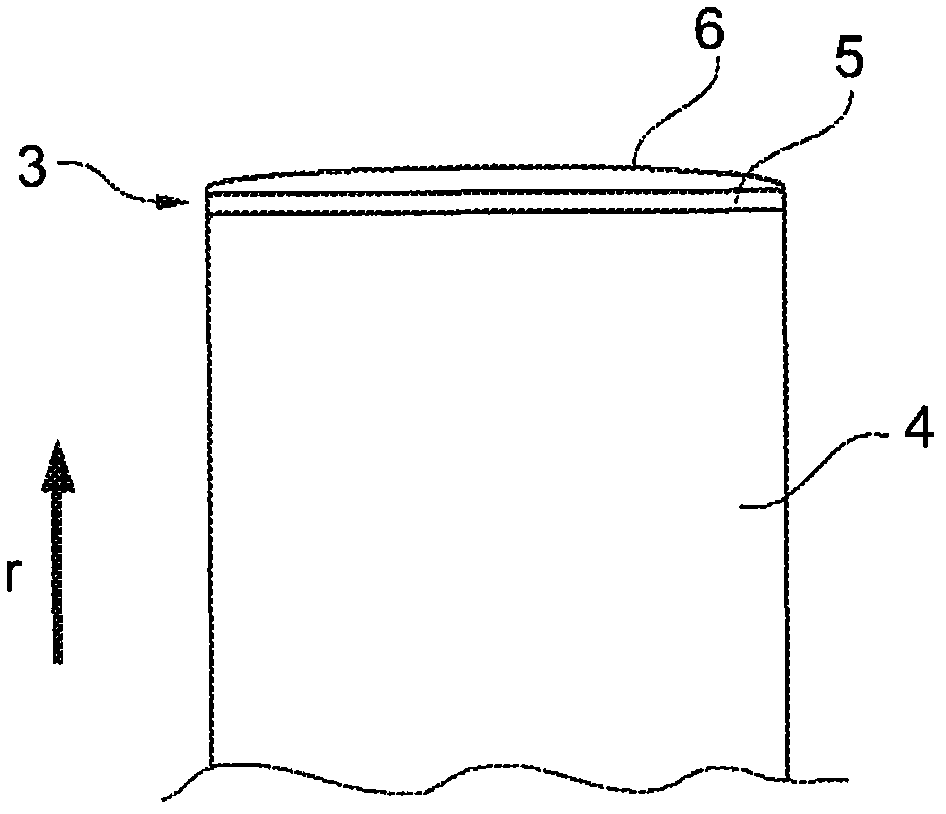

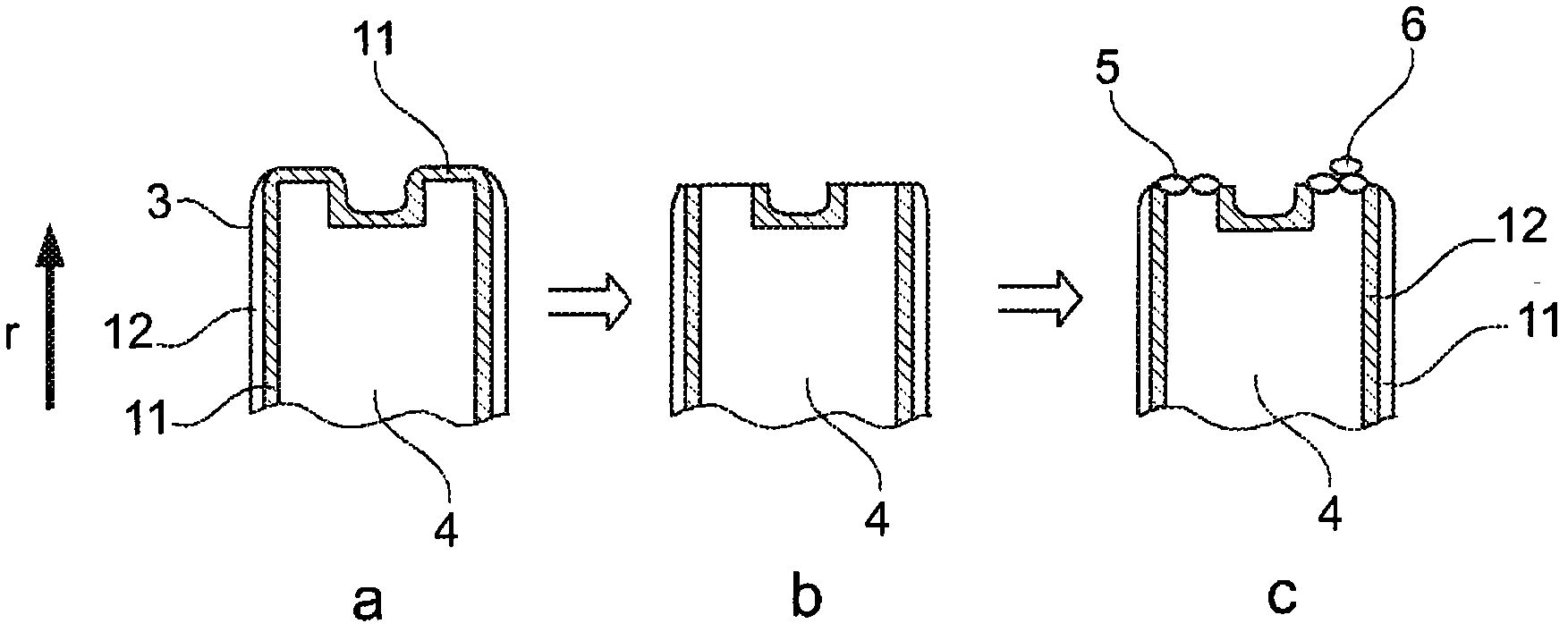

Abrasive single-crystal turbine blade

ActiveCN102052094AImprove service lifeReduce leakage lossTurbinesBy zone-melting liquidsOxidation resistantWear resistant

The invention relates to an abrasive single-crystal turbine blade, in detail, relates to a turbine blade (1) used for a turbine rotor (2).A turbine blade for a turbine rotor, is provided having a single-crystal basic body which has a blade tip and extends in the radial direction. The turbine blade includes at least one oxidation-resistant intermediate coating, which is applied by laser metal forming and is epitaxially bonded to the basic body, is arranged on the radially outer blade tip, and in that an at least single-layer, wear-resistant and oxidation-resistant coating, which is applied by laser metal forming and consists of oxidation-resistant binder material and abrasive particles embedded therein, is arranged on at least certain regions of said epitaxial intermediate coating.

Owner:ANSALDO ENERGIA IP UK LTD

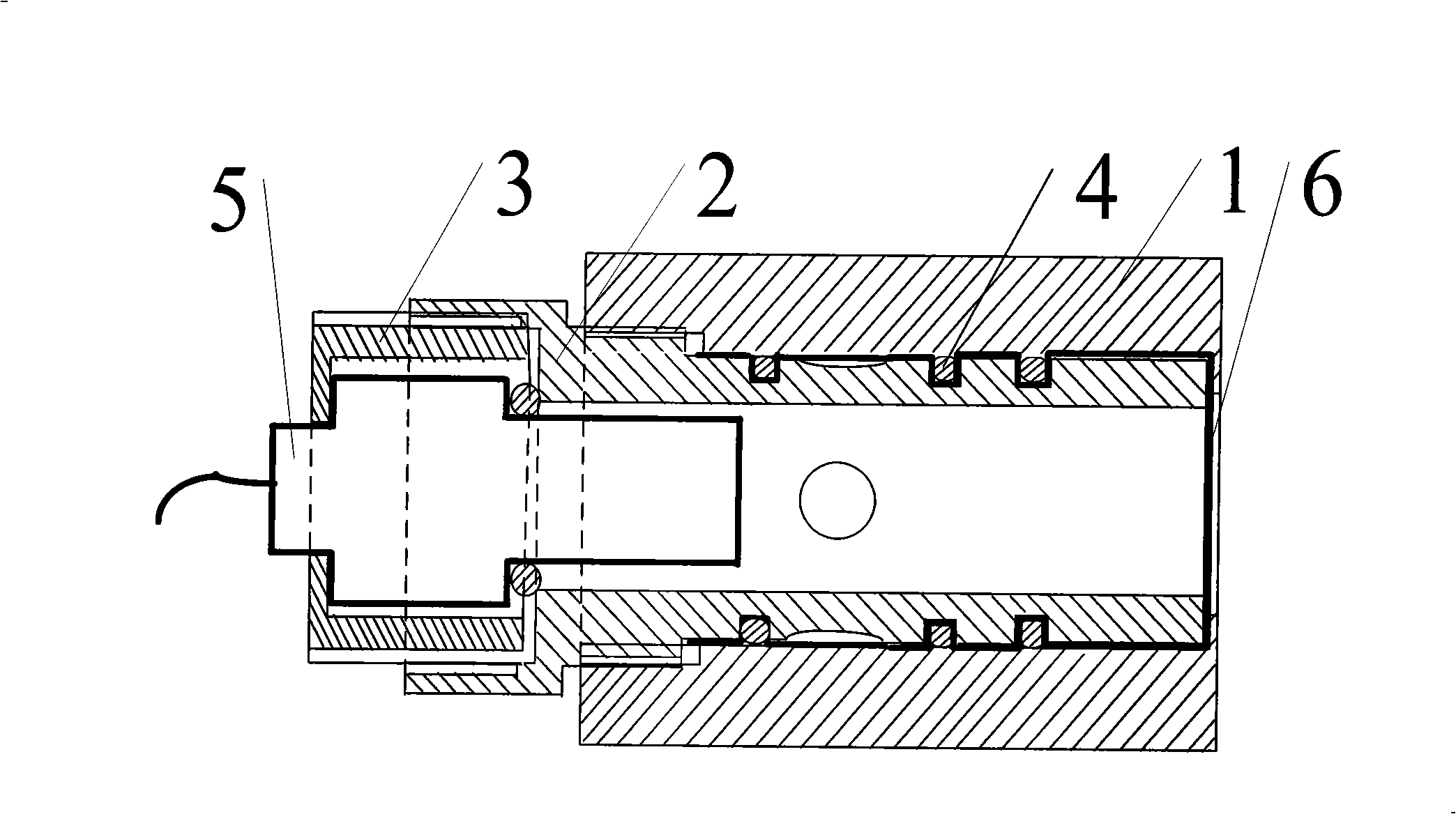

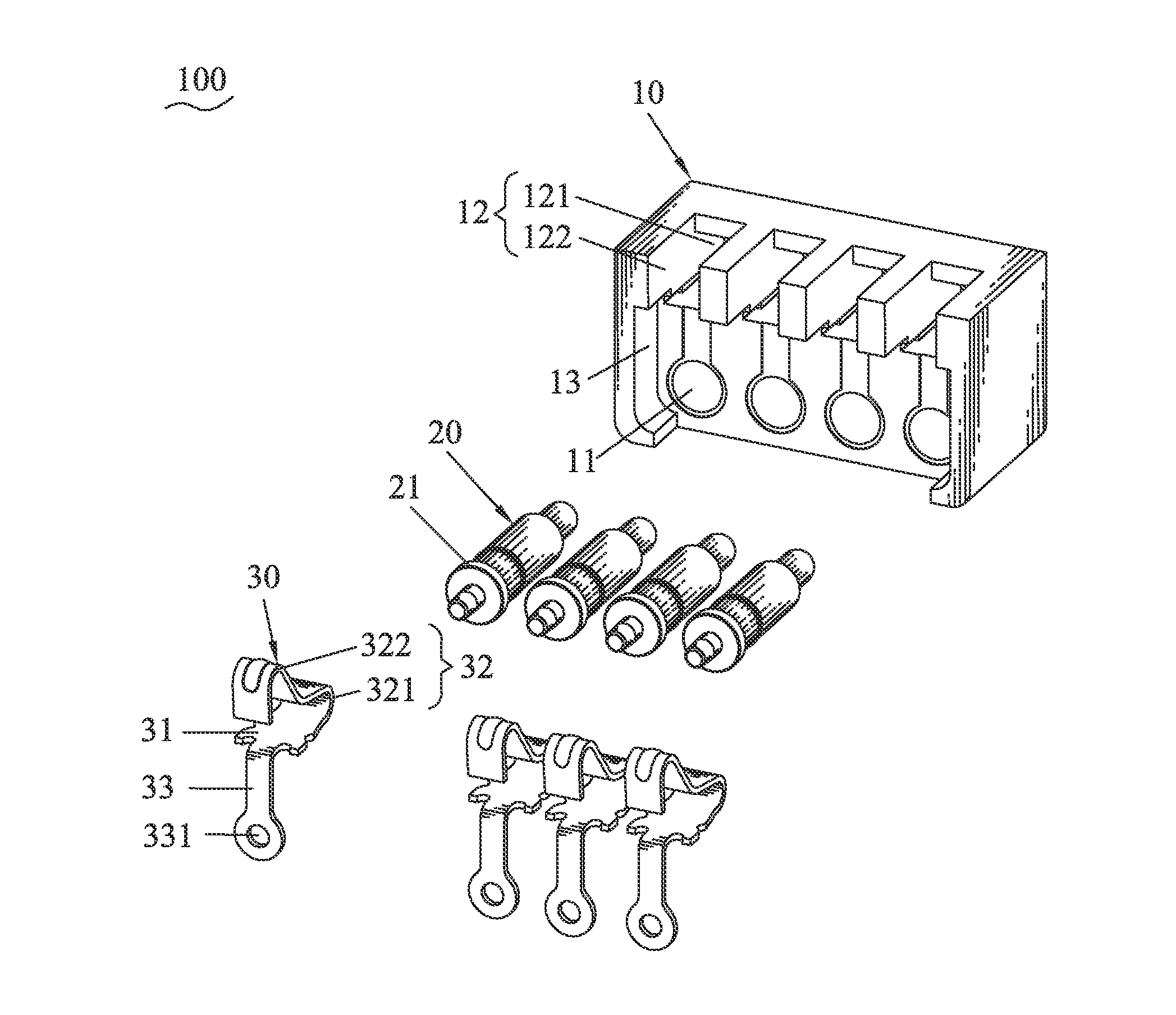

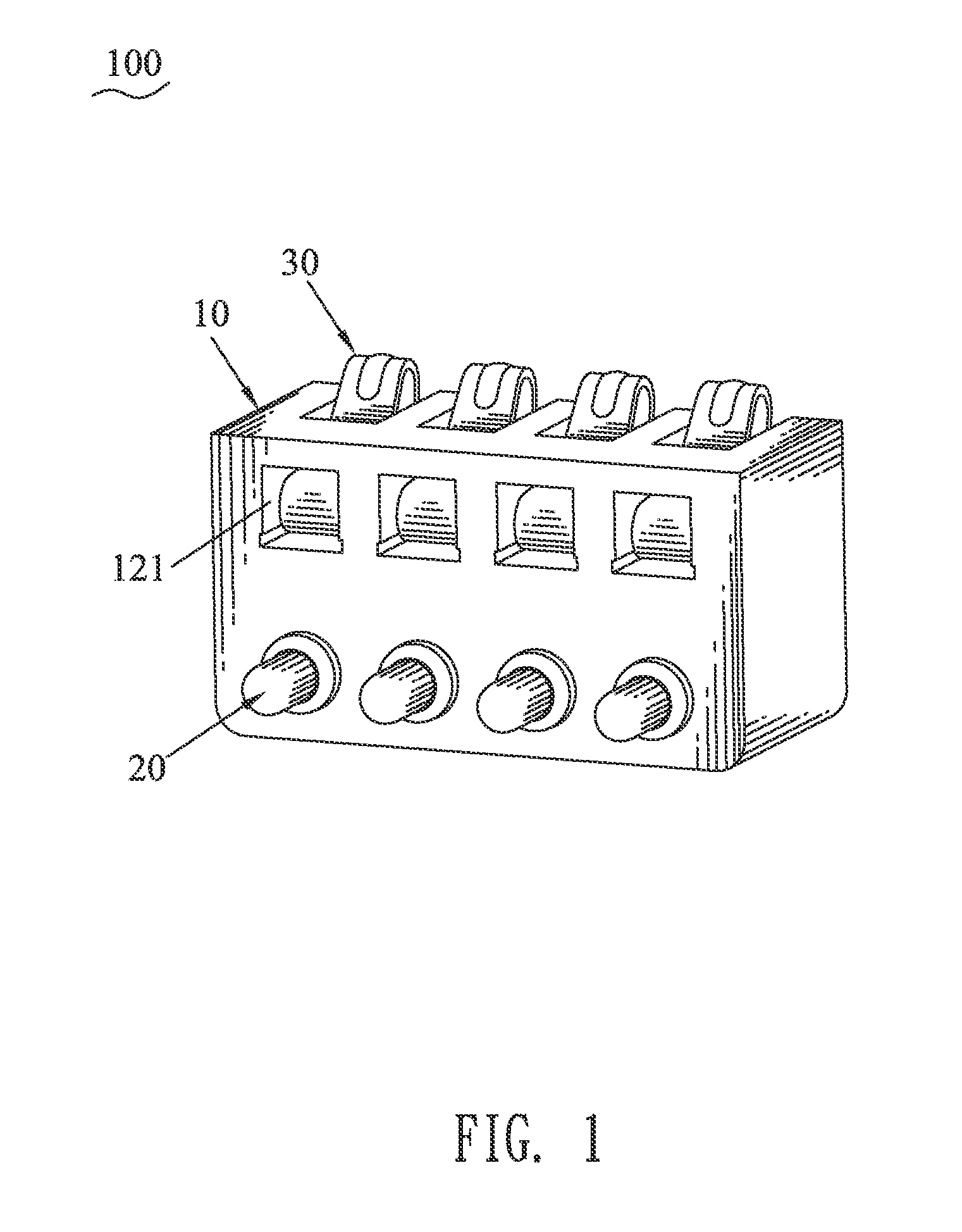

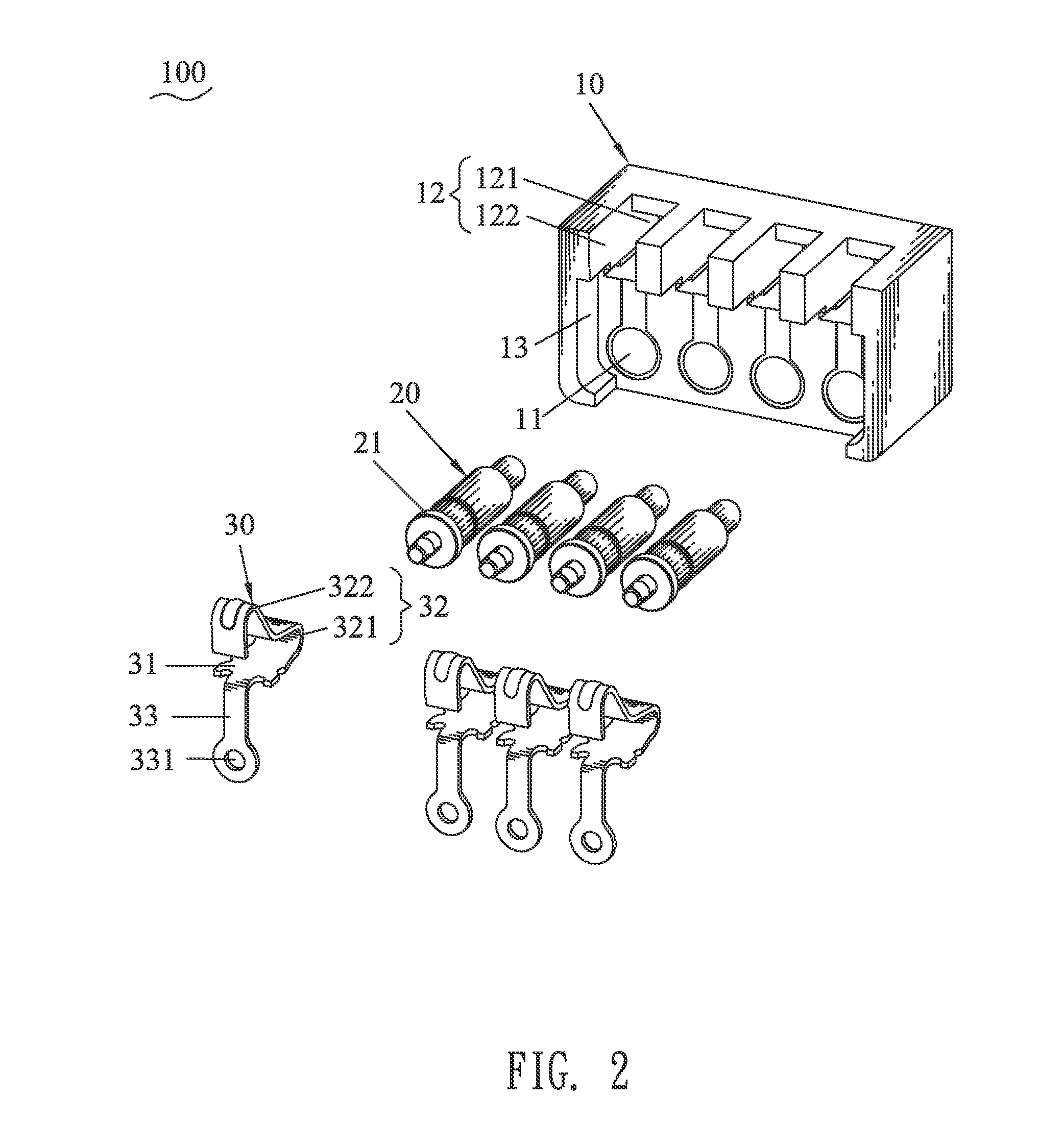

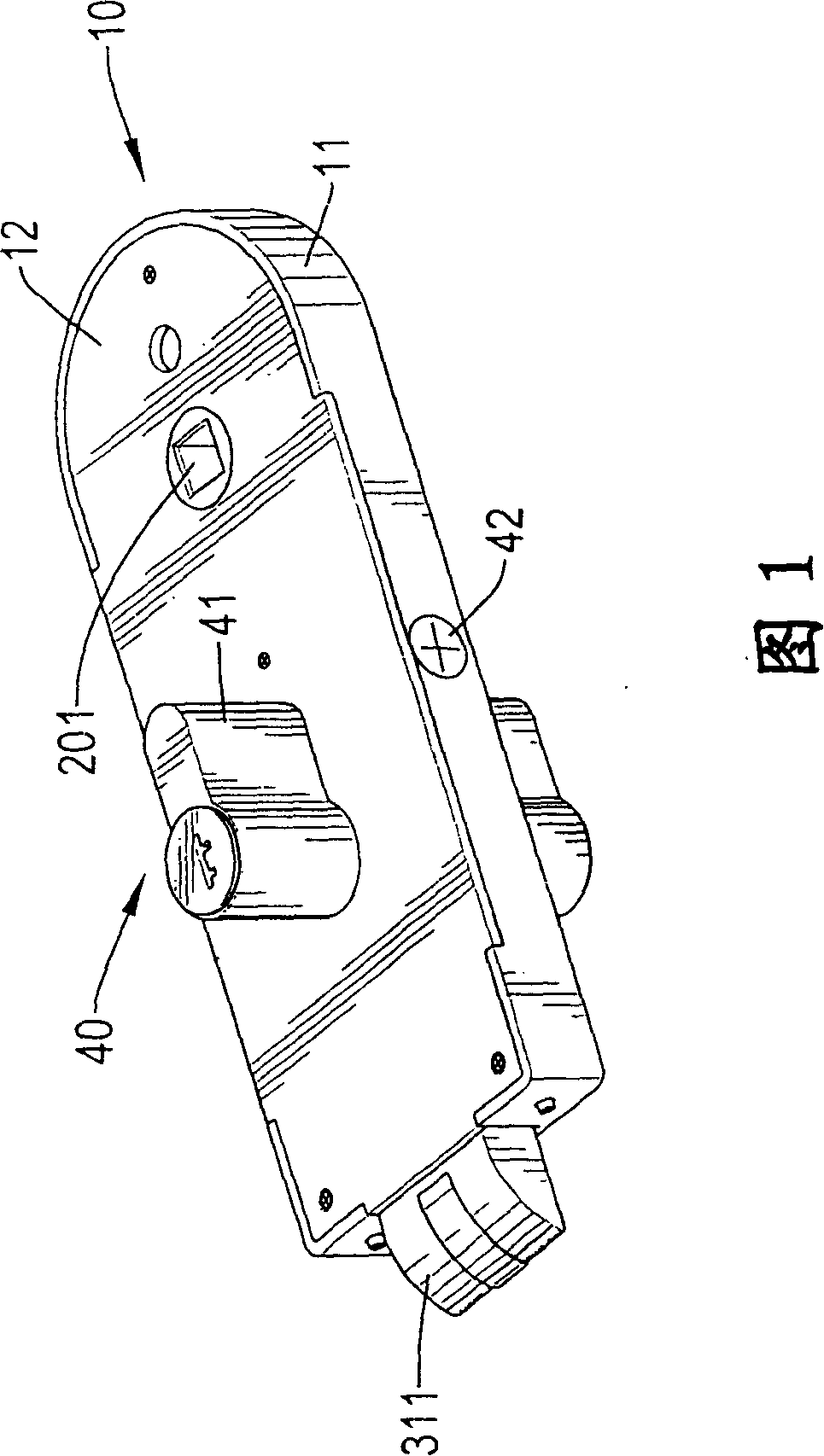

Pogo pin connector

InactiveUS20150056870A1Avoid deformationImprove service lifeCoupling contact membersPogo pinEngineering

A pogo pin connector includes an insulating housing, a plurality of pogo pins and contact terminals assembled forward in the insulating housing respectively. Front ends of the pogo pins retractably project beyond a front face of the insulating housing. A rear end of each of the pogo pins protrudes outward to form a riveted flange. Each of the contact terminals has a fastening plate placed levelly, an elastic contact arm curvedly extending upward from a front end of the fastening plate to elastically project beyond a top face of the insulating housing, and a fixing strip extending downward from a rear end of the fastening plate with a through hole being opened in a bottom end thereof. The rear ends of the pogo pins pass through the through holes of the contact terminals respectively to make the riveted flanges and the corresponding fixing strips riveted together.

Owner:CHENG UEI PRECISION IND CO LTD

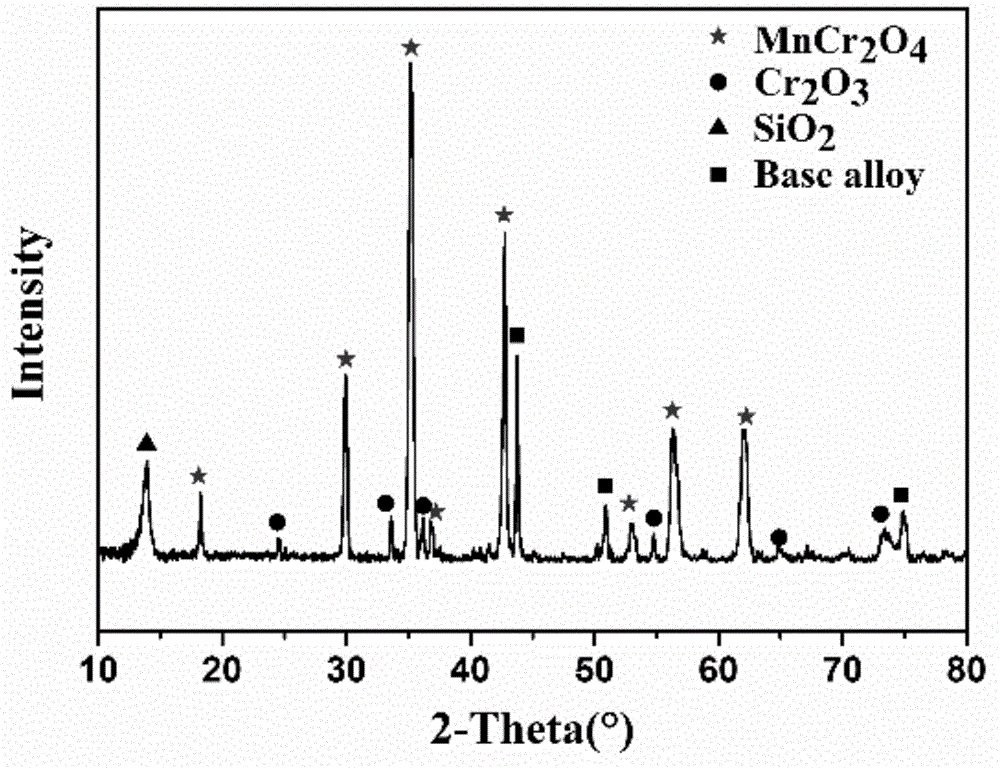

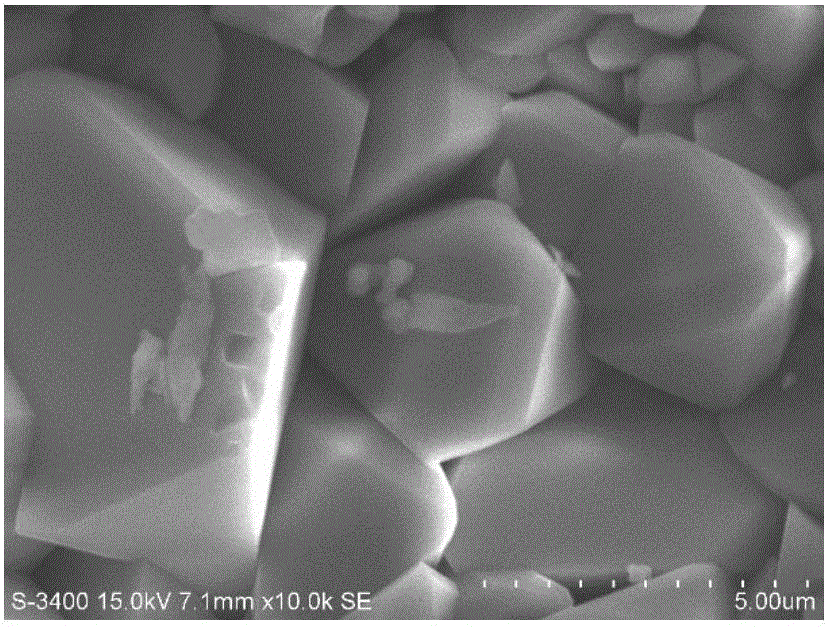

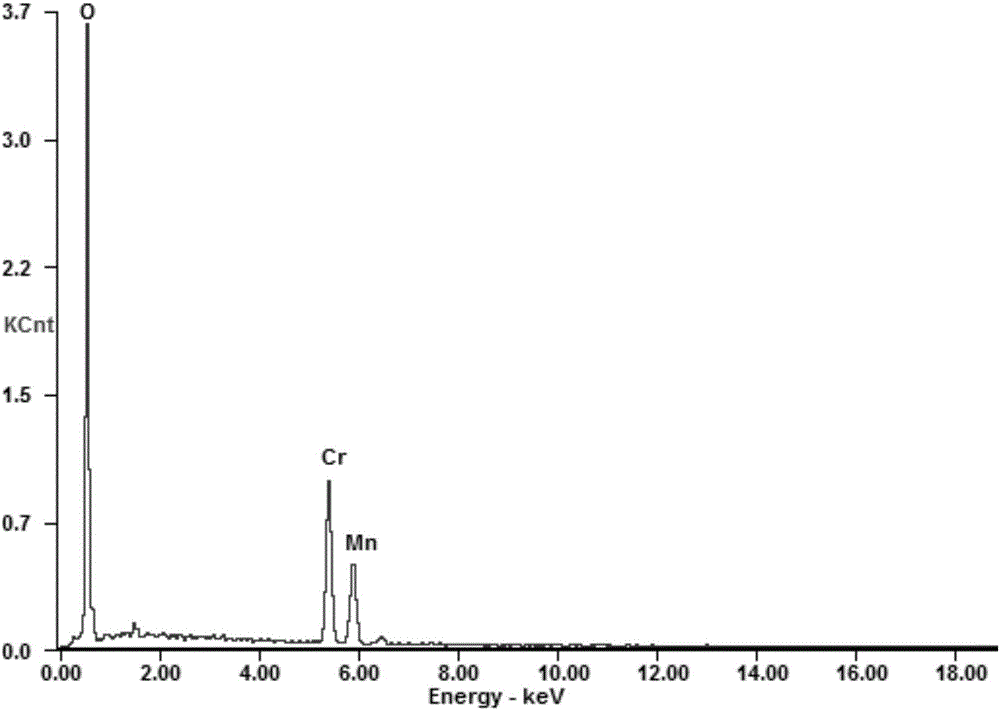

Preparation method of manganese-chromium ceramic coating on surface of alloy material

ActiveCN106011743AIncreasing the thicknessImprove service lifeSolid state diffusion coatingChromiumAlloy surface

The invention relates to a preparation method of a manganese-chromium ceramic coating on the surface of an alloy material. The preparation method comprises the steps that firstly, Mn and Cr are made to permeate into an alloy surface layer through a two-step pack cementation technique, and the Mn and Cr are made to distributed according to a specific concentration gradient; and secondly, the surface of the alloy material is oxidized through a low-oxygen partial pressure method, so that the compact manganese-chromium ceramic coating is formed. By the adoption of the preparation method, the coating can have a large thickness, the high-temperature oxidation resistance, high-temperature carburization resistance and high-temperature coking resistance of the alloy material are effectively improved, and the service life is long.

Owner:EAST CHINA UNIV OF SCI & TECH

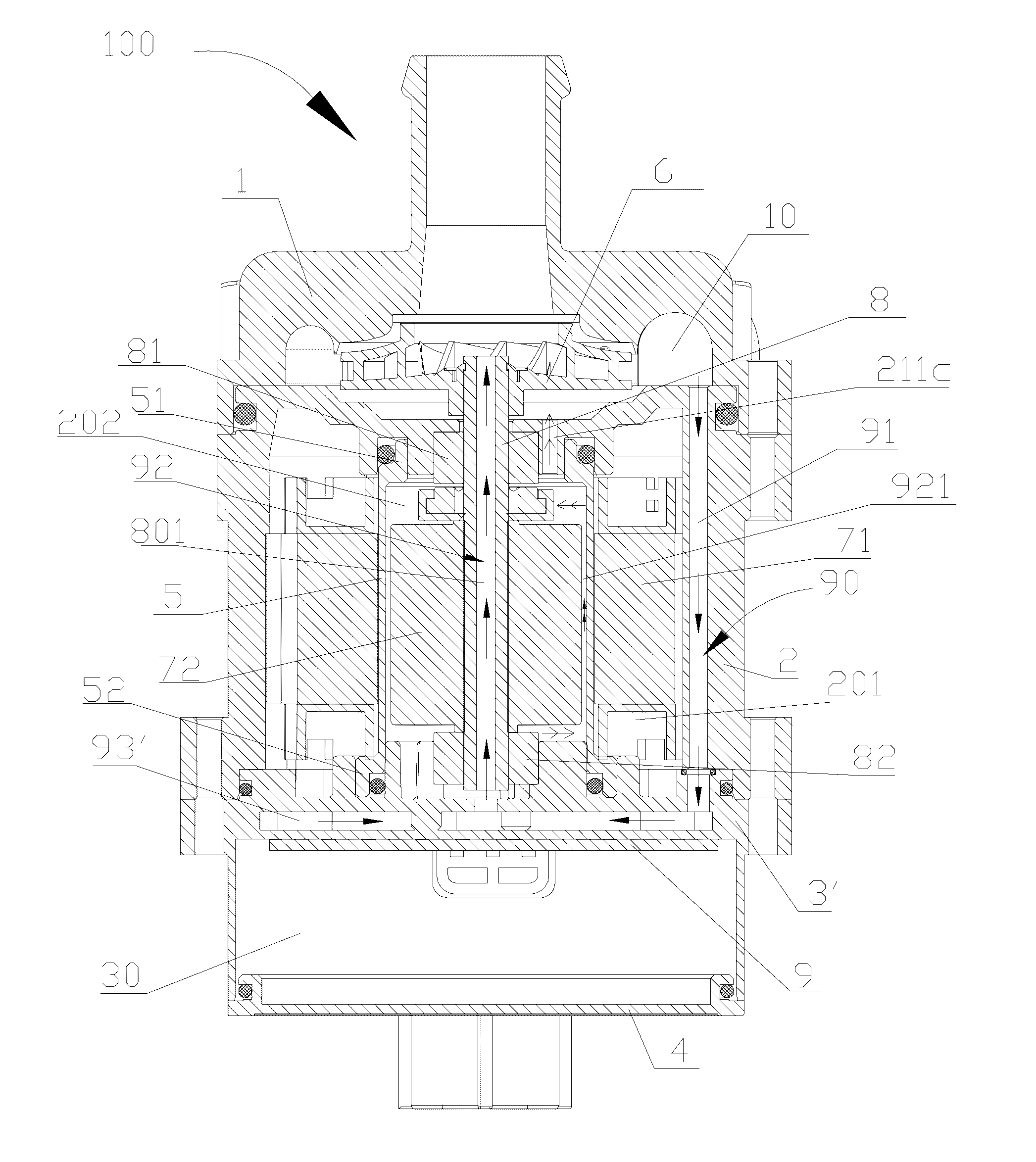

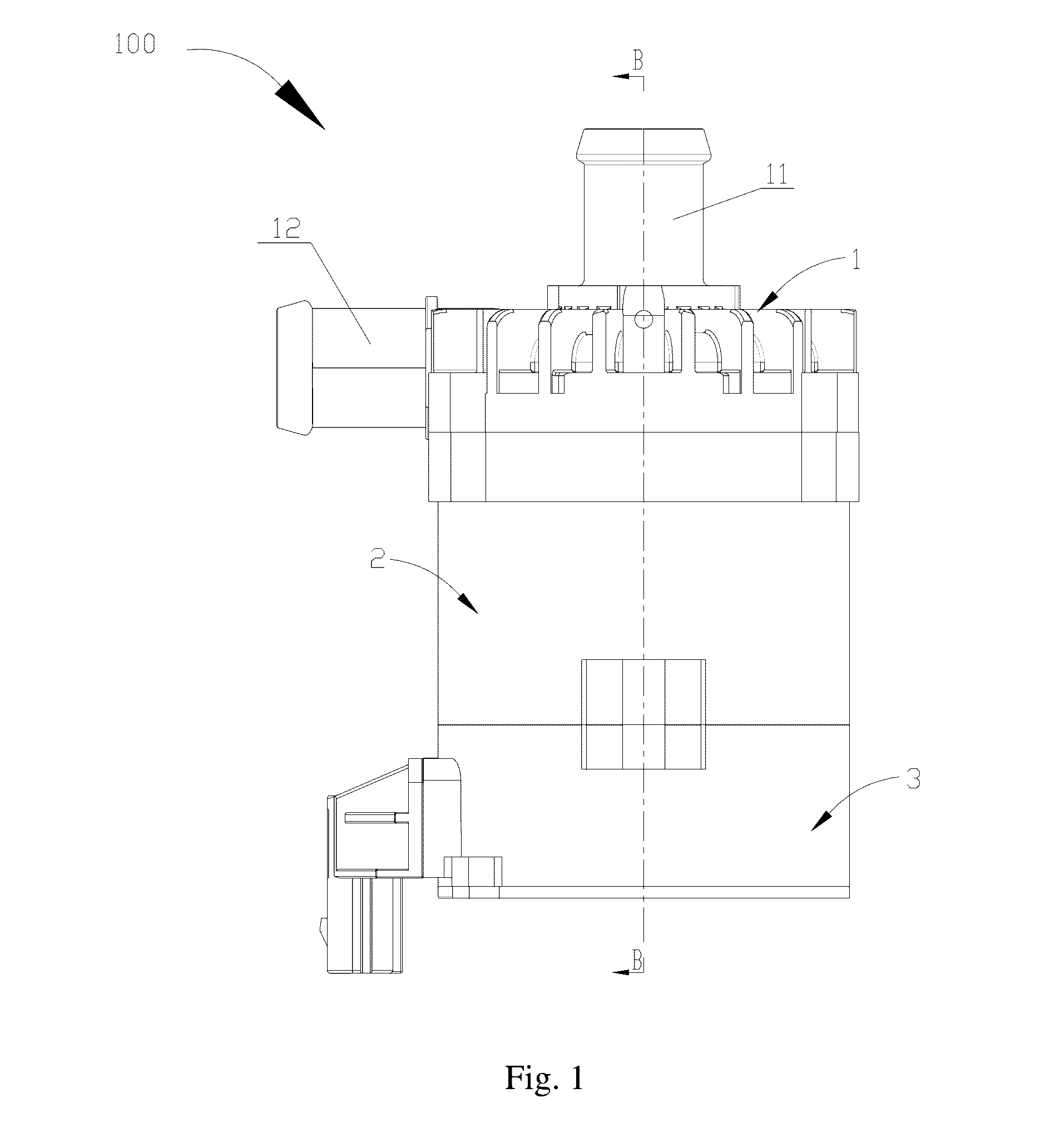

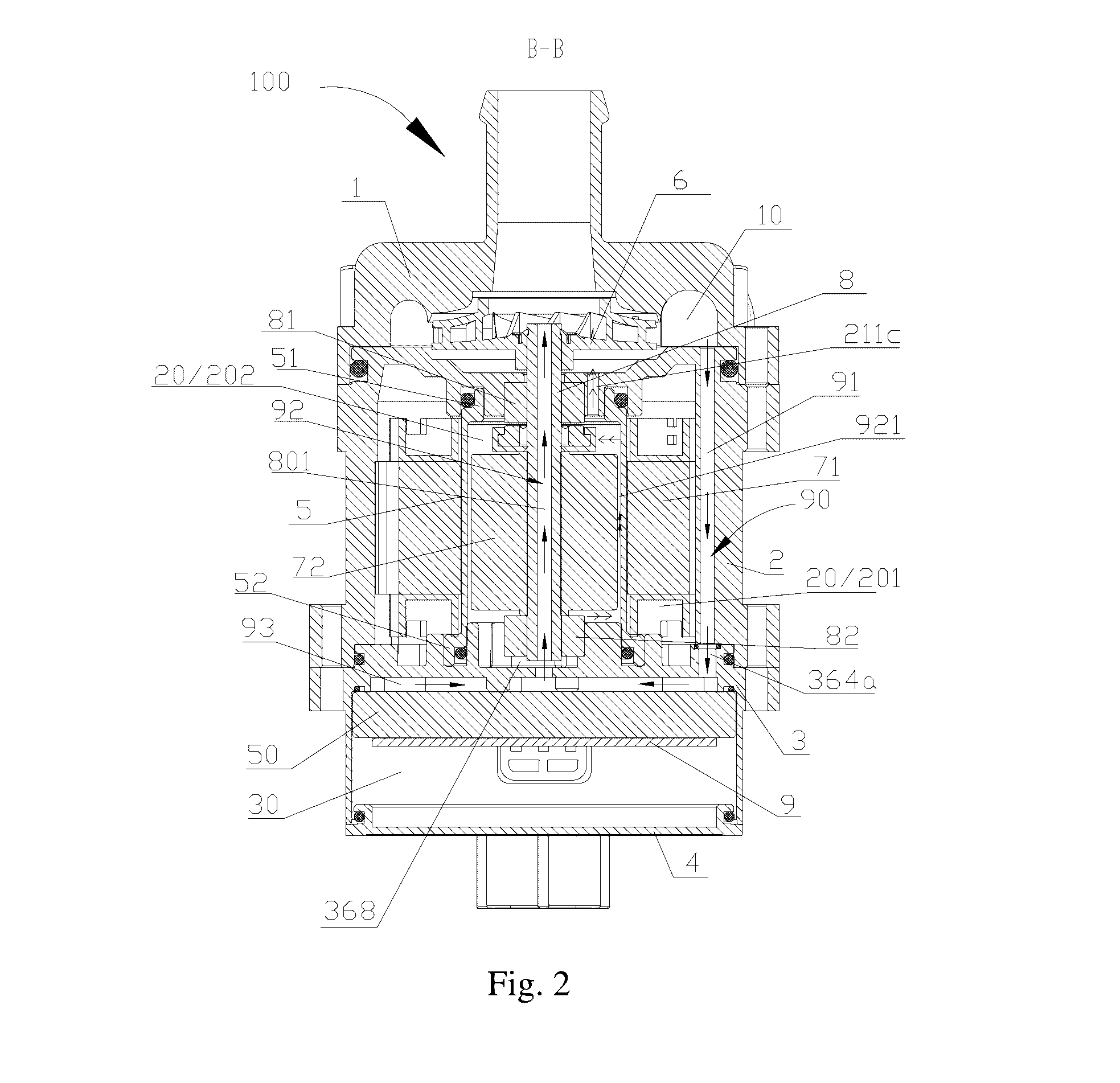

Electrically driven pump

ActiveUS20160281718A1Improve service lifeFacilitate heatingPump componentsPump installationsElectronic control unitImpeller

An electrically driven pump includes a first housing and a second housing, and the first housing and the second housing are fixed to form an impeller chamber for receiving an impeller. The second housing and a rear housing are fixed to form a first receiving chamber for receiving a motor assembly; and the motor assembly includes a stator and a rotor, the rotor is arranged in an inner cavity enclosed by the stator, and the rotor drives the impeller to rotate. An electronic control unit is cooperated with the motor assembly, and the electronic control unit controls the operation of the motor assembly. The electrically driven pump includes a cooling passage for accommodating a working medium, and the working medium in the cooling passage may exchange heat with the electronic control unit, thereby facilitating improving the service life of the electrically driven pump.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS

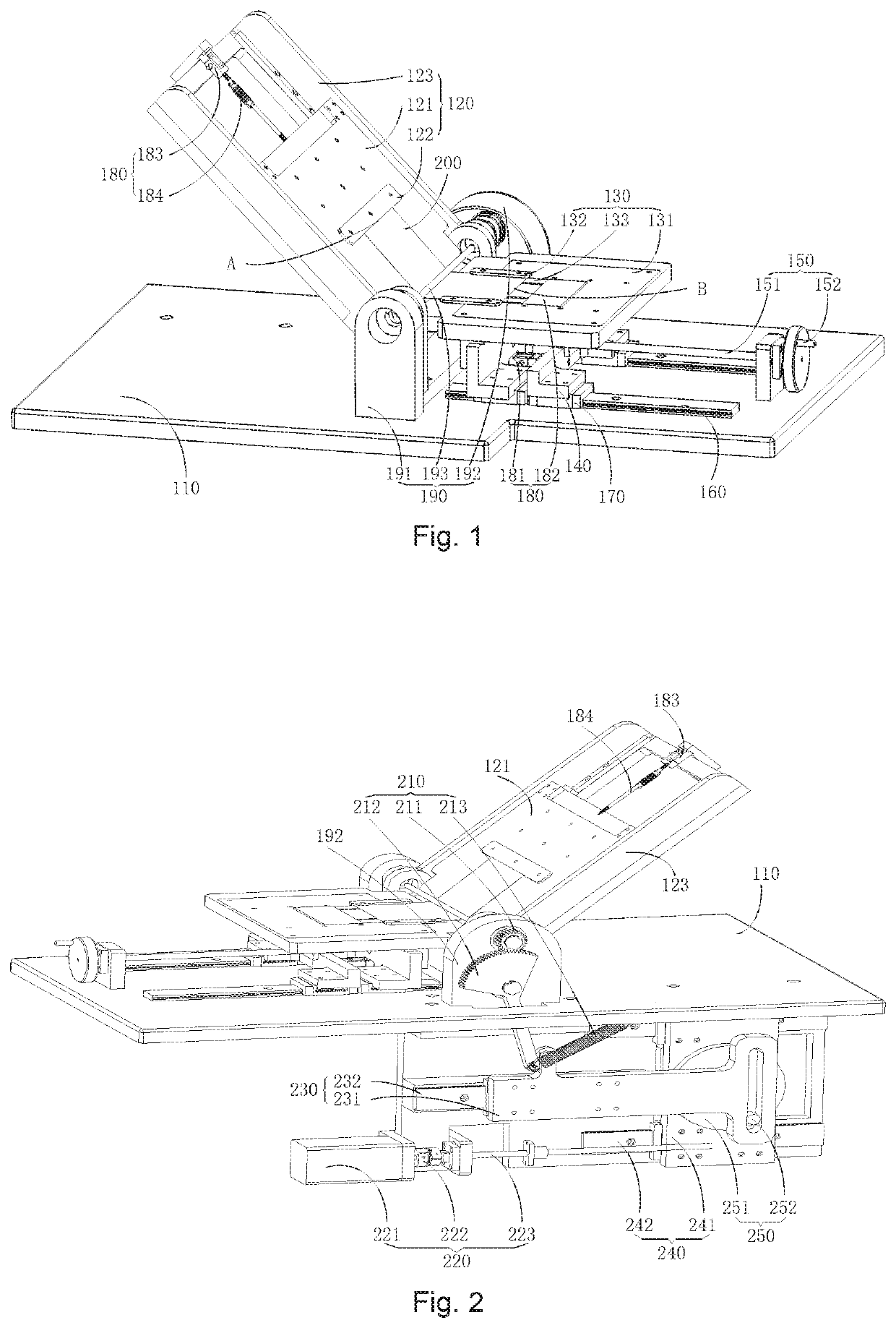

Flexible display auxiliary device and foldable mobile terminal

ActiveUS20200032952A1Improve service lifeExtended service lifeMachine supportsStatic indicating devicesEmbedded systemComputer hardware

The present disclosure discloses a flexible display auxiliary device and a foldable mobile terminal. The flexible display auxiliary device includes a platform, a first stage, a second stage, a sliding mechanism and an enabling mechanism. The first stage is used for fixing the first end of the flexible display screen, the second stage is used for fixing the second end of the flexible display screen opposite to the first end. The second stage is fixedly arranged on the sliding mechanism, the sliding mechanism is arranged on the platform, the enabling mechanism is connected to the sliding mechanism to control the sliding mechanism to move on the platform so as to change the relative distance between the first stage and the second stage and change the tension on the flexible display screen. In the above manner, the present disclosure enables the flexible display to always be in a flat state.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

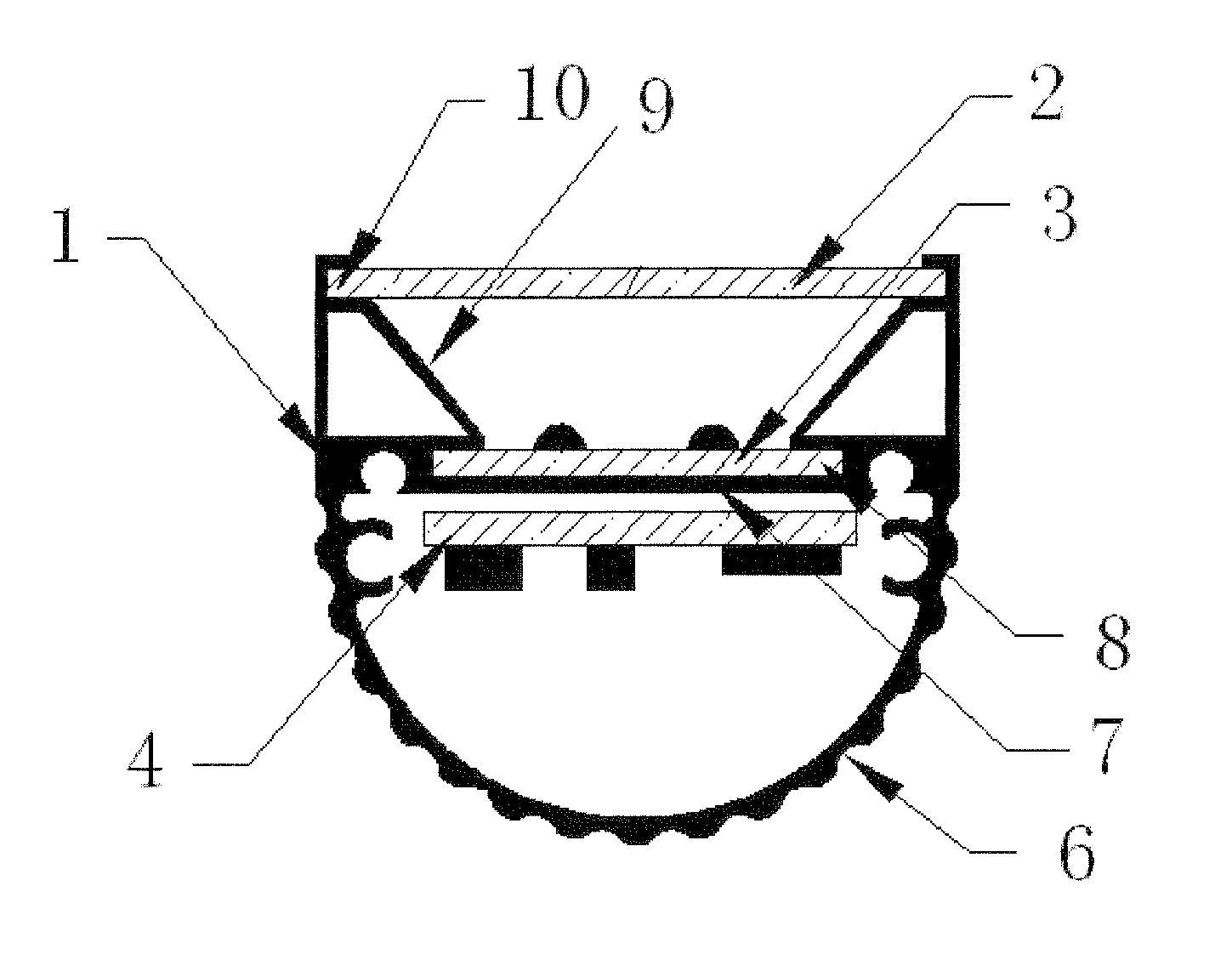

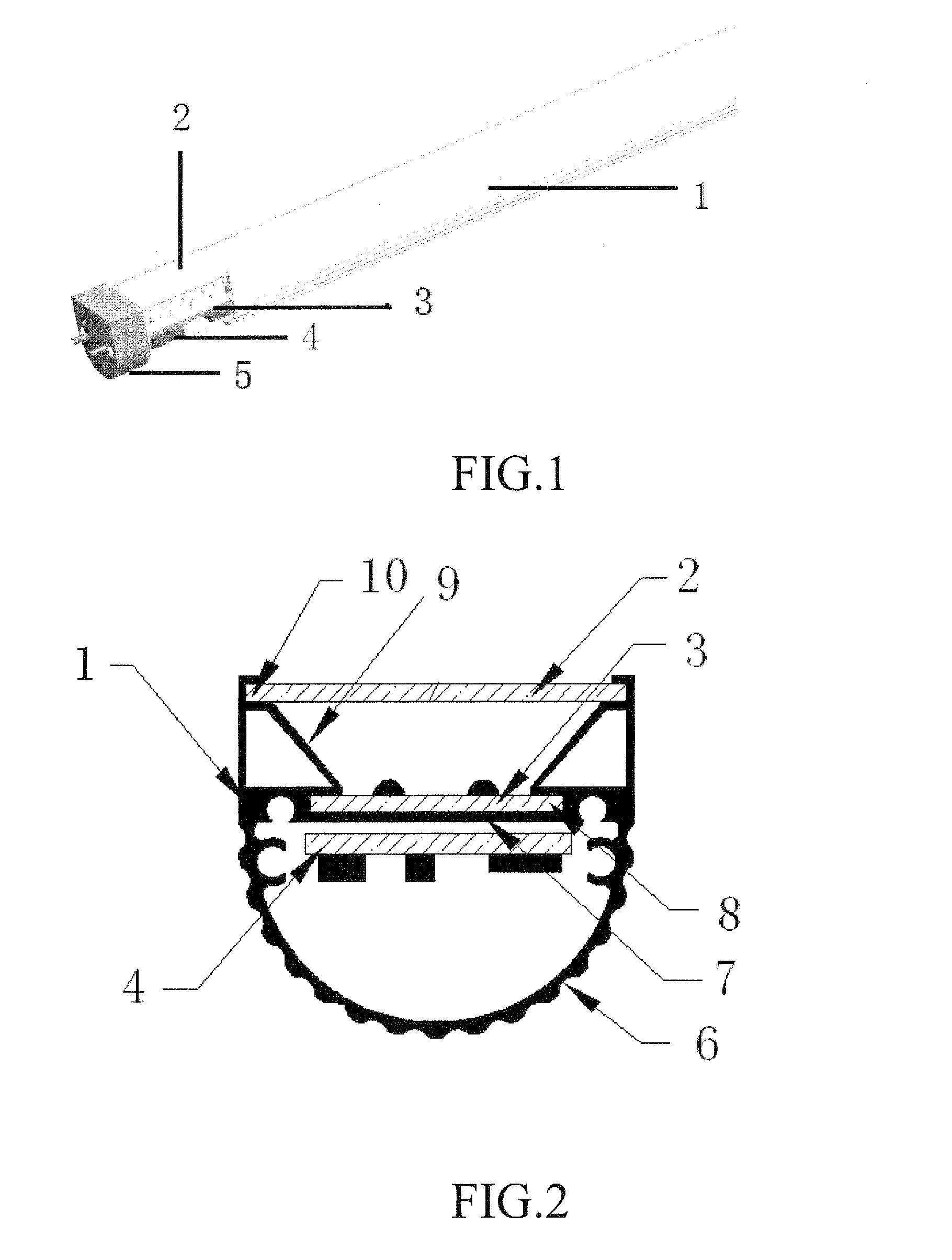

LED lighting tube adopting isolated fluorescent conversion technology

InactiveUS20110148298A1Improve service lifeImprove brightness uniformityPoint-like light sourceElongate light sourcesLight sourceEngineering

An LED lighting tube includes a strip-shaped metal shell, a LED light source, a white light conversion film, and a driving power supply. The metal shell defines two spaced slots inwardly. The white light conversion film and the LED light source are respectively fixed in the two slots. The white light conversion film is isolated from the LED light source. The driving power supply is accommodated in the metal shell.

Owner:SHENZHEN CGX LED LIGHTING INDAL

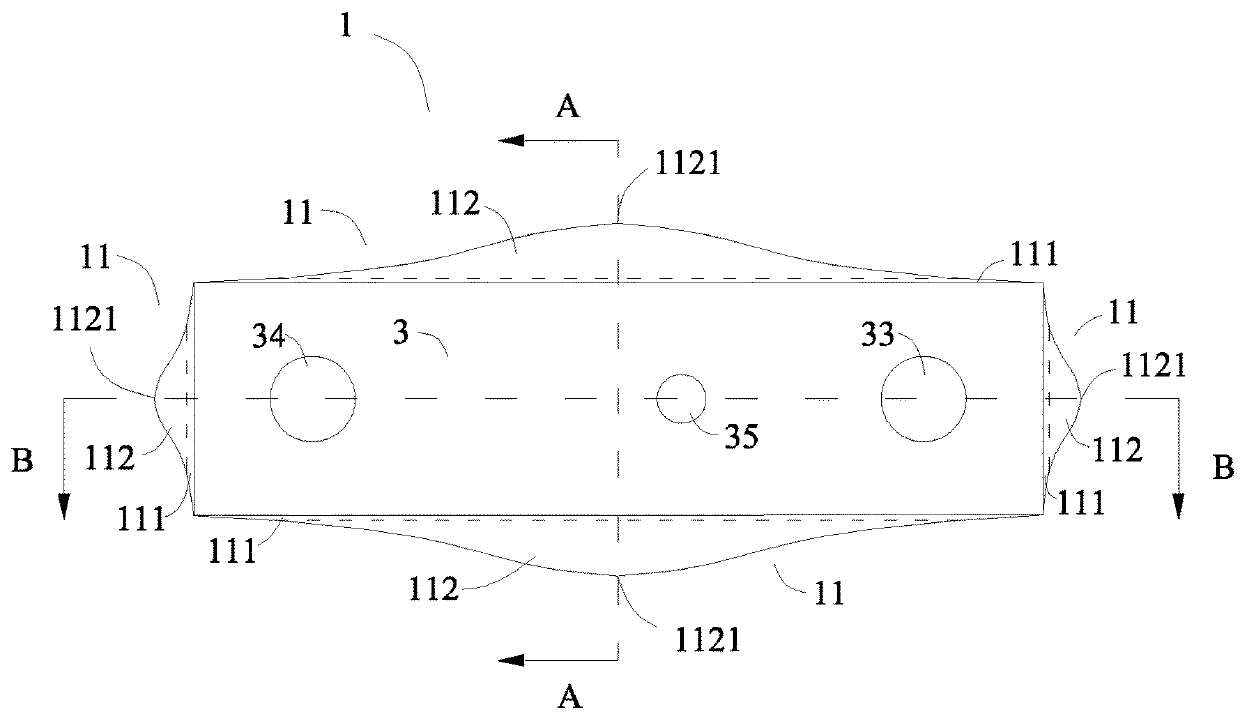

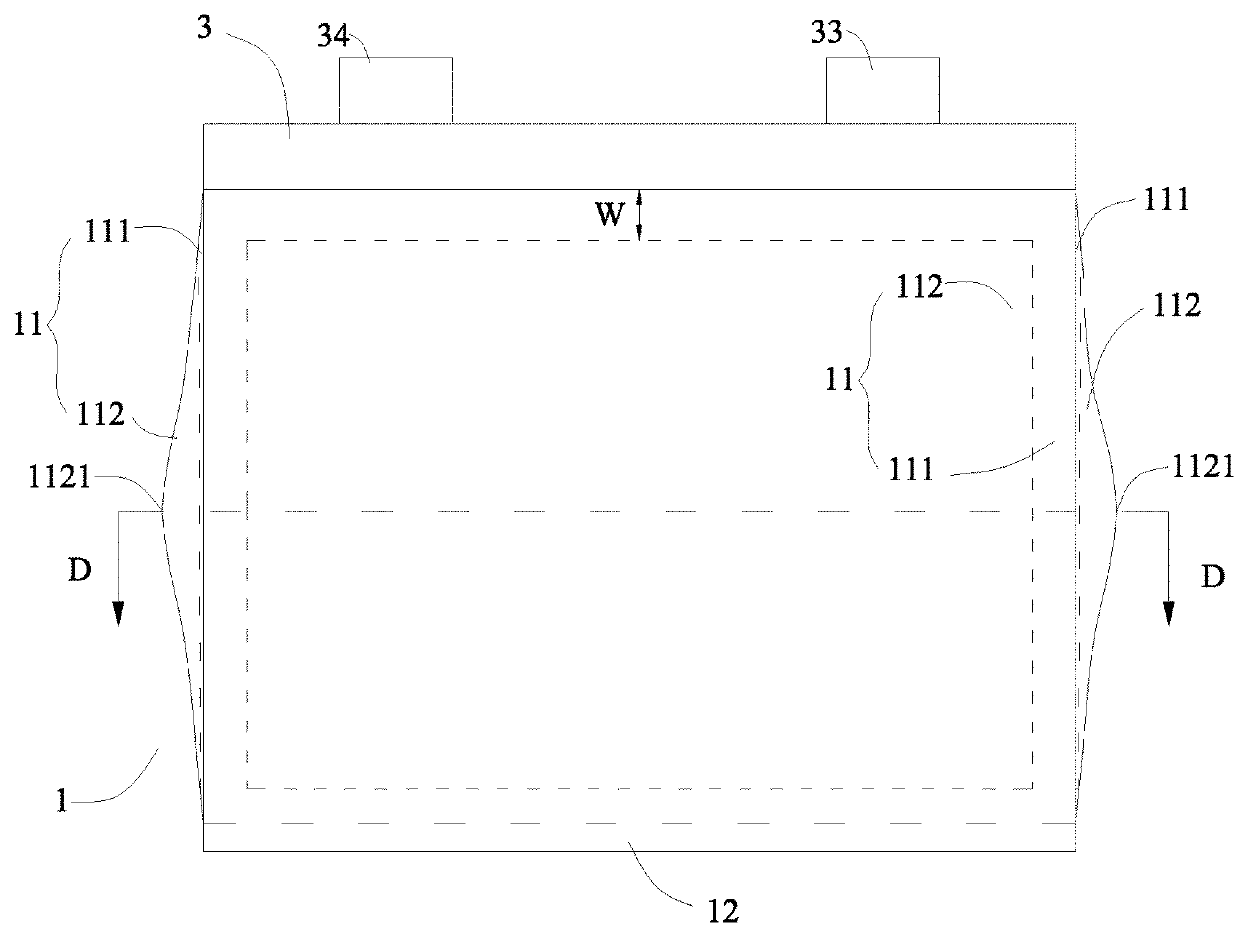

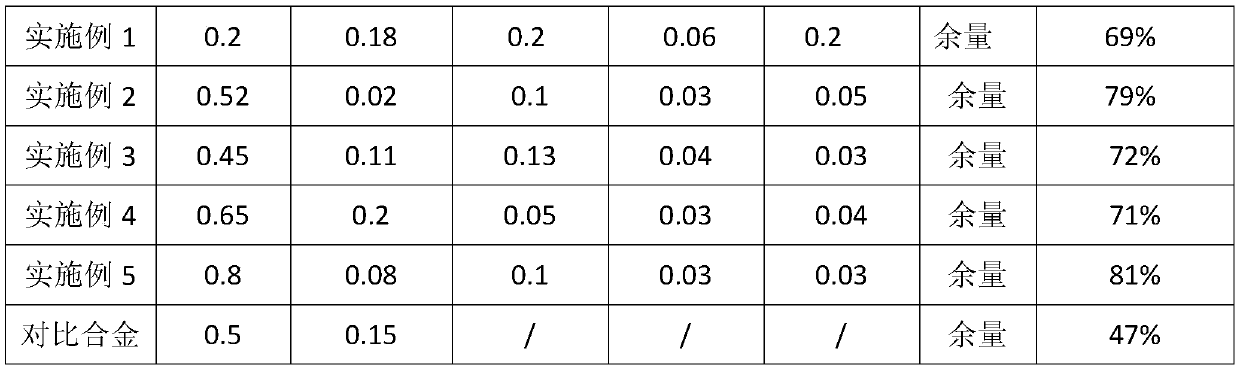

Secondary battery and manufacturing method therefor

InactiveUS20180277824A1Reduce riskImprove service lifeSmall-sized cells cases/jacketsCell sealing materialsInternal pressureType safety

The present disclosure provides a secondary battery and a manufacturing method therefore. The secondary battery comprises a case, an electrode assembly and a cap assembly. The case has four side walls and a bottom wall which enclose an internal space; the electrode assembly is received in the internal space of the case. The cap assembly is provided to a top of the case and seals the electrode assembly in the internal space; the cap assembly comprises a safety mechanism configured to make an electrical current not flow through the electrode assembly when a gas pressure in the internal space reaches a predetermined value. At least one of the four side walls of the case bulges outwardly, and the internal space protrudes correspondingly. The secondary battery according to the present disclosure can provide an expanding space for an electrode plate of the electrode assembly, avoid the electrode plate being fractured by the internal pressure, prevent the electrolyte being squeezed out of the electrode assembly and avoid the infiltration capability of the electrode assembly decreasing, reduce risk of short circuit of the secondary battery, slow down the decay of cycle performance and prevent the diving of cycle performance, improve service life of the secondary battery. At the same time, the secondary battery also can avoid the gas-pressure type safety mechanism of the secondary battery being actuated in the normal state and prevent failure.

Owner:CONTEMPORARY AMPEREX TECH CO

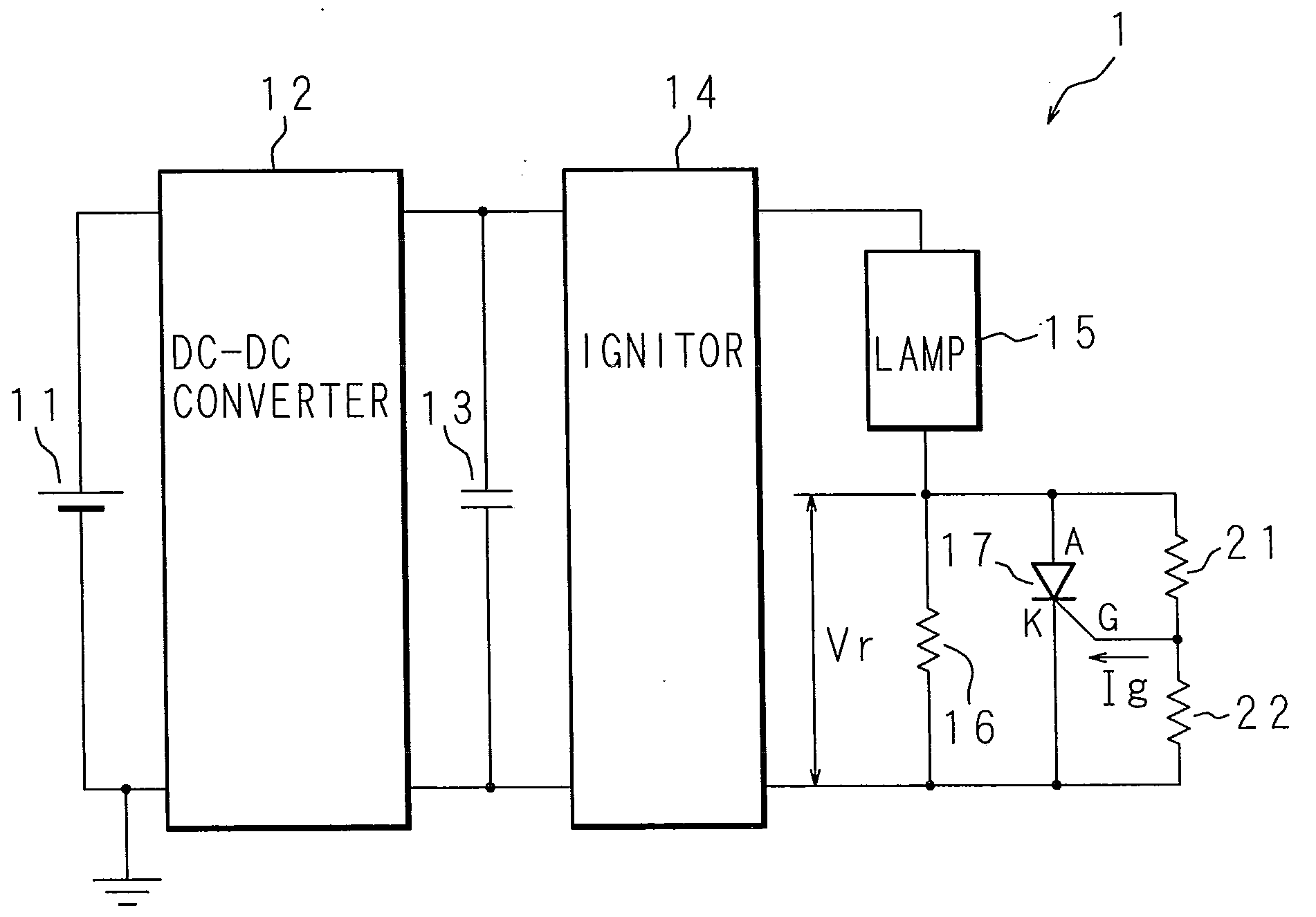

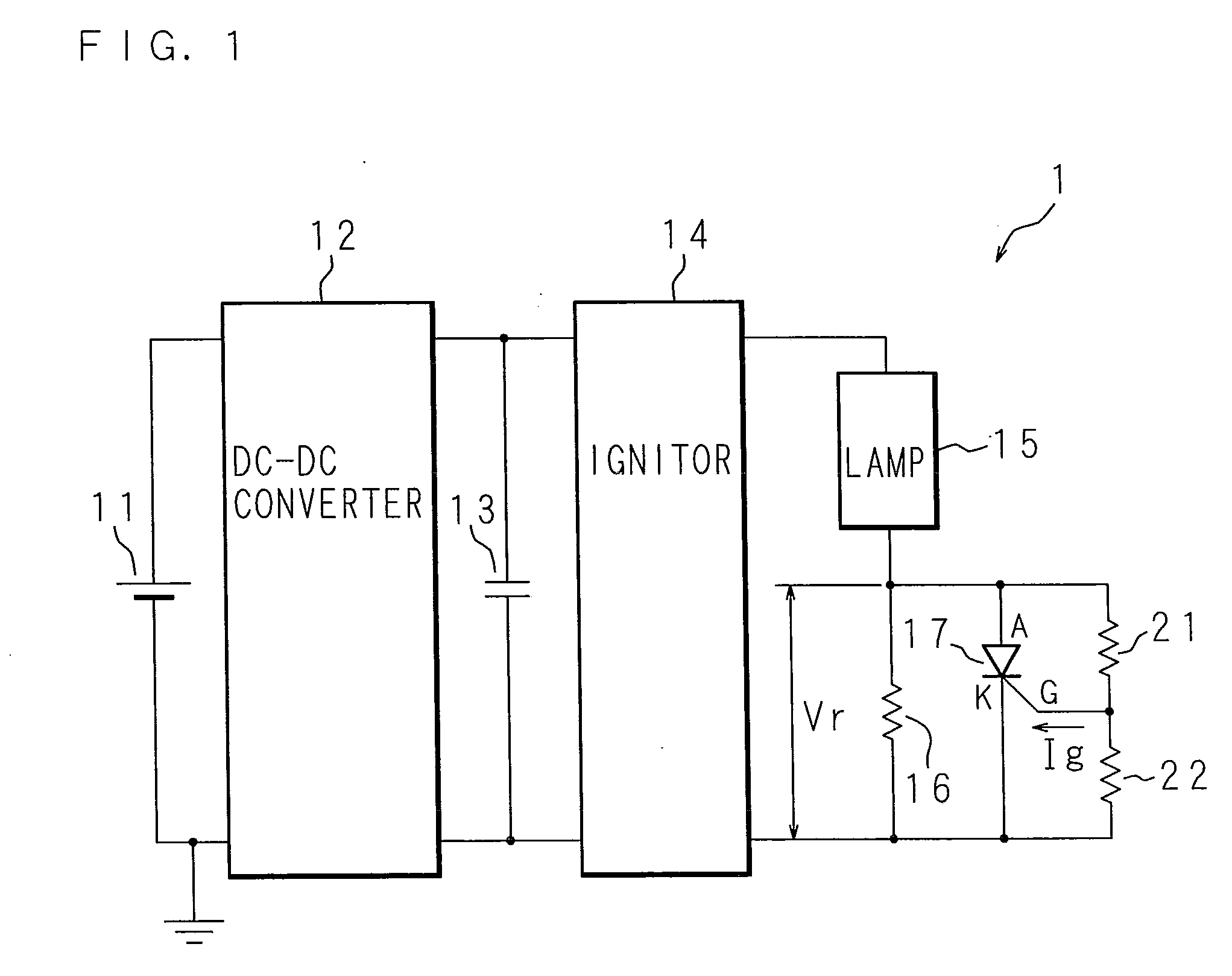

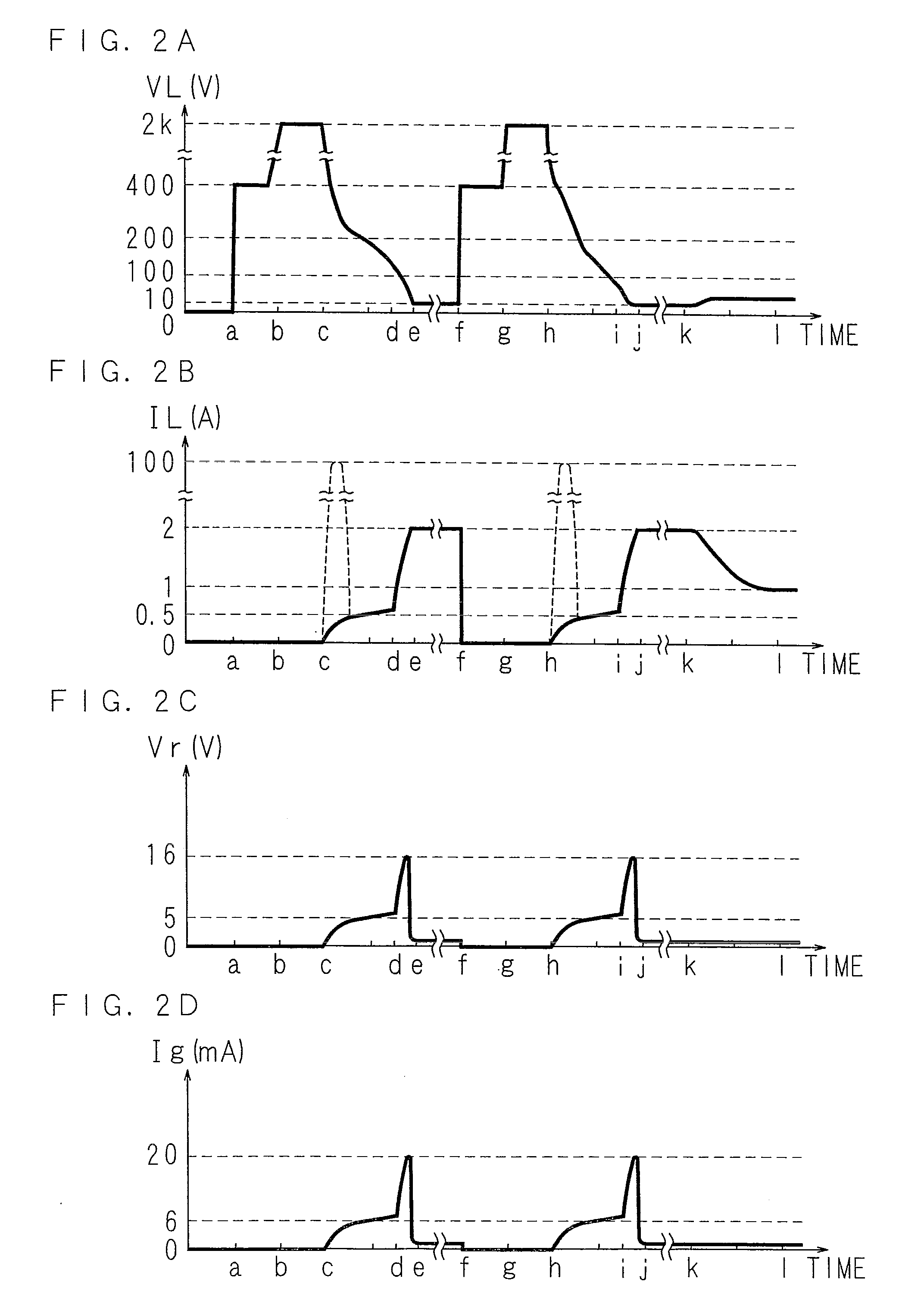

Discharge lamp lighting device and projector

InactiveUS20100066265A1Improve service lifeHigh resistance valueElectrical apparatusElectric light circuit arrangementThyratronAnode

A thyristor and an auxiliary resistor having one end connected to a gate of the thyristor are connected in parallel with a resistor connected in series with a lamp. A resistance value of internal equivalent resistance of the thyristor in an on-state is smaller than a resistance value of the resistor. The resistor absorbs a rush current at a lighting time. Then, a current flows between an anode and a cathode of the thyristor.

Owner:SHARP KK

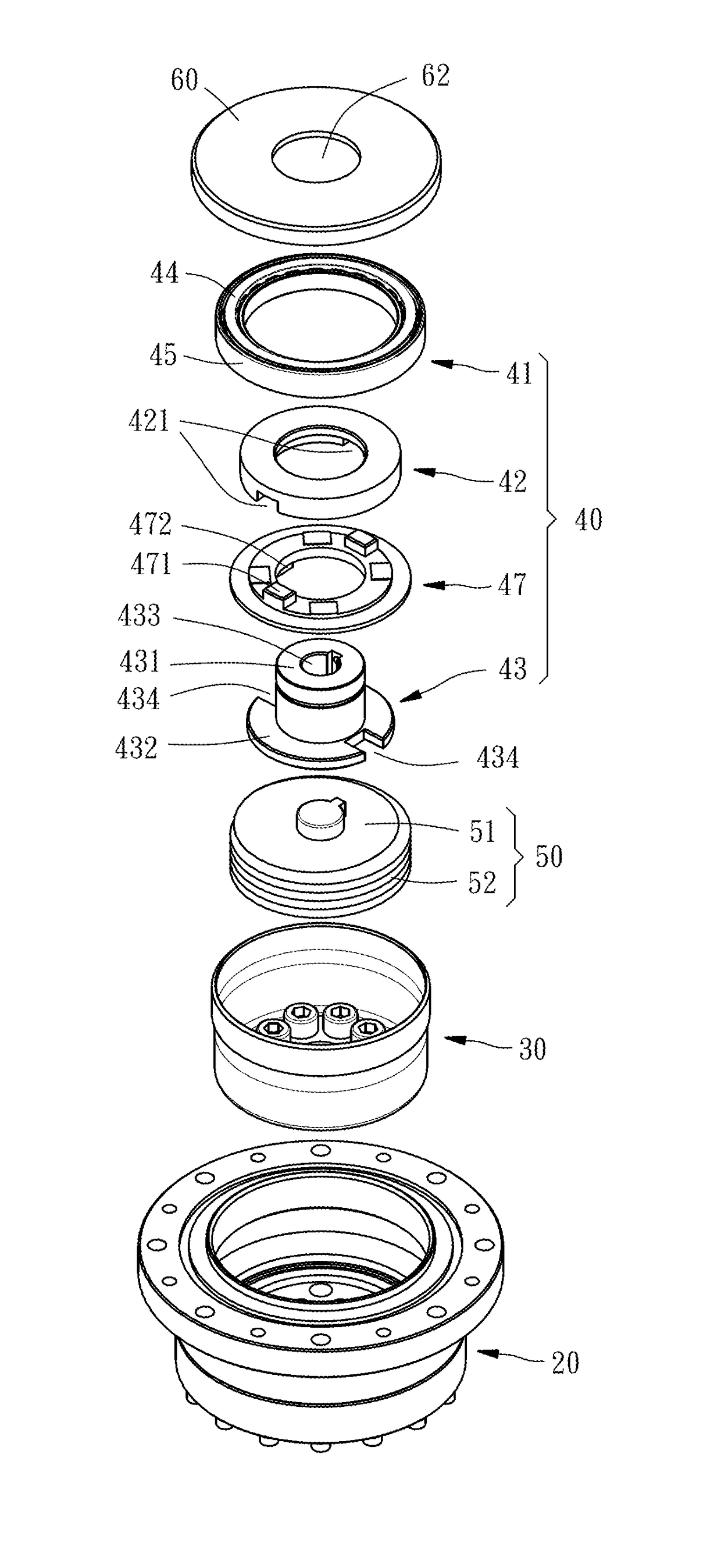

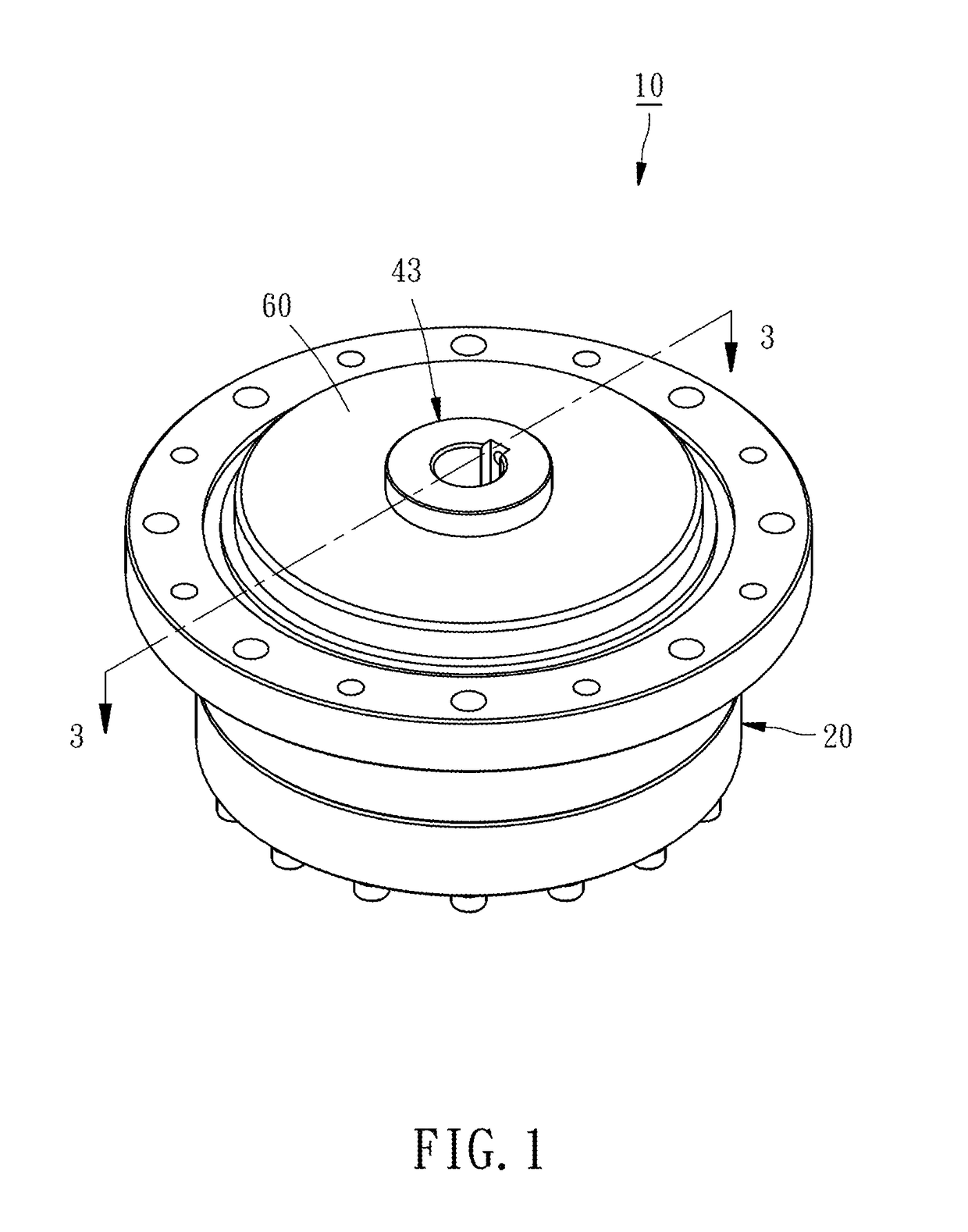

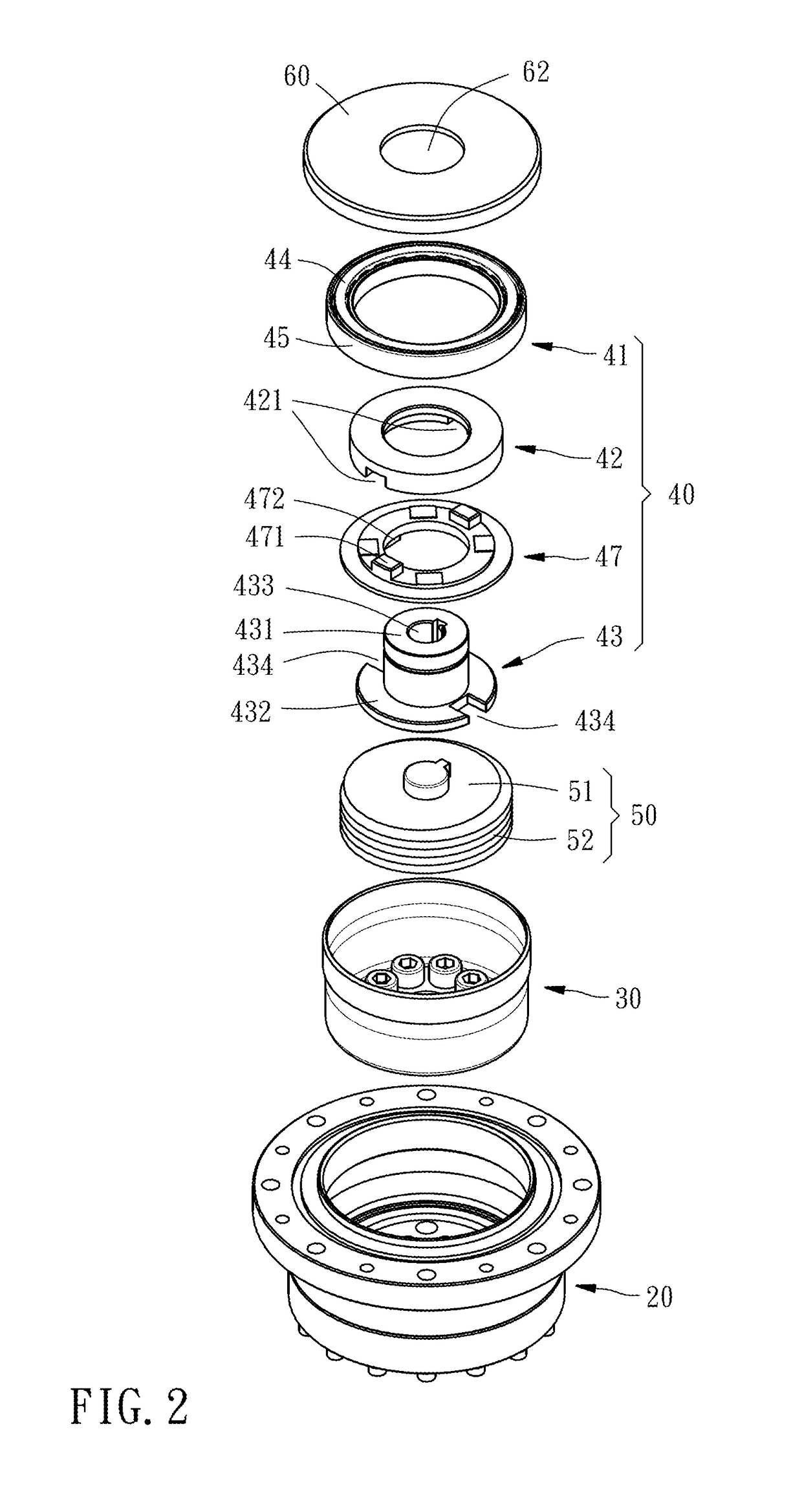

Harmonic drive featuring helix-facilitated lubrication

ActiveUS20170097082A1Improve service lifeReduce wearGearingGear lubrication/coolingLubricationEngineering

A harmonic drive featuring helix-facilitated lubrication includes a circular spline, a flexspline, a wave generator, and an agitating member. The flexspline meshes with the circular spline. The wave generator has a bearing installed within the flexspline, an elliptic wheel positioned in the bearing, and a shaft coupling connecting the elliptic wheel. The agitating member is located in a lubricant-holding space between the wave generator and the flexspline, and has a rotatory part and blade parts formed about a rotatory part. The rotatory part of the agitating member is connected to the shaft coupling of the wave generator, so that when the agitating member is driven by the shaft coupling, the helical blade parts agitate lubricant to perform convection, thereby better lubricating the bearing of the wave generator.

Owner:HIWIN TECH

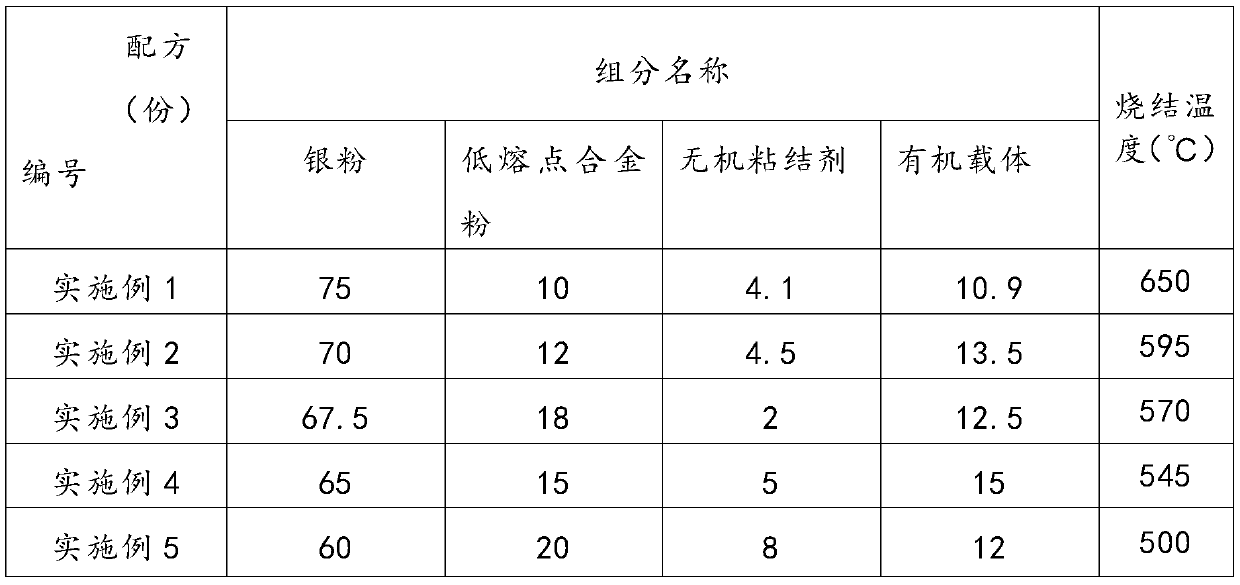

Electrode slurry

InactiveCN111599508AGood low temperature sintering propertiesWon't hurtNon-conductive material with dispersed conductive materialPhotovoltaic energy generationAlloySlurry

The invention discloses electrode slurry, which comprises the following components in parts by weight: 5-15 parts of an organic carrier, 0.5-5 parts of an inorganic binder, and 70-95 parts of conductive powder, wherein the conductive powder comprises the following components in parts by weight: 60-75 parts of silver powder and 10-20 parts of low-melting-point alloy powder. According to the invention, experiments show that the sintering temperature and the silver powder content of the electrode slurry are reduced by adding the low-melting-point alloy powder, wherein the sintering temperature isreduced to 500-650 DEG C from 750-830 DEG C. According to the invention, the low electrode sintering temperature does not damage the silicon wafer, the shrinkage degree of the aluminum slurry is reduced, the warping degree of the solar cell is reduced, and the service life of the solar cell is prolonged; and due to the low sintering temperature, energy consumption in the sintering process is reduced, and the energy-saving and environment-friendly requirements are met.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

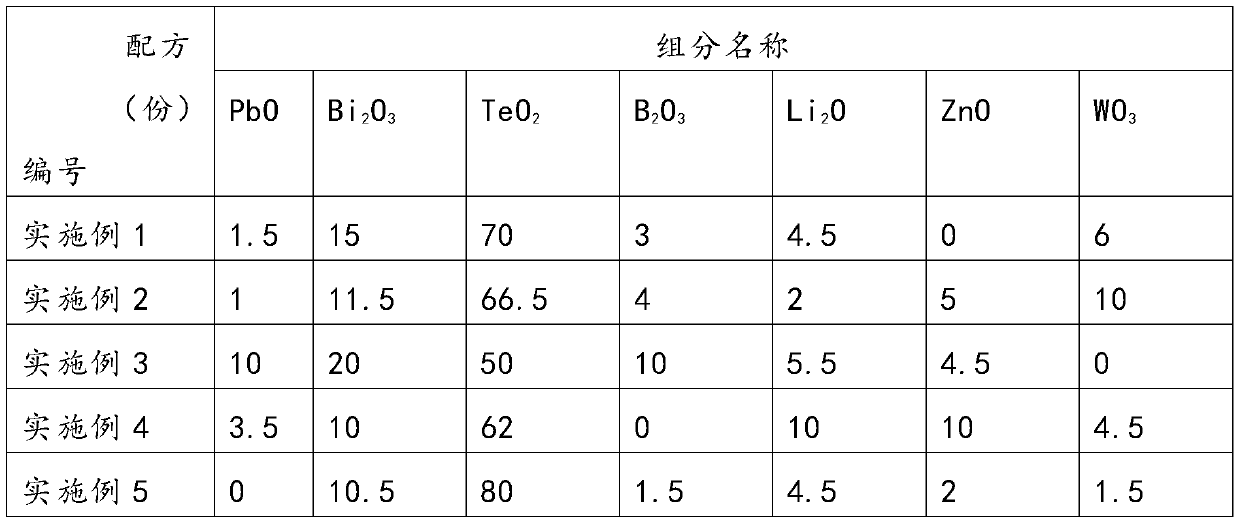

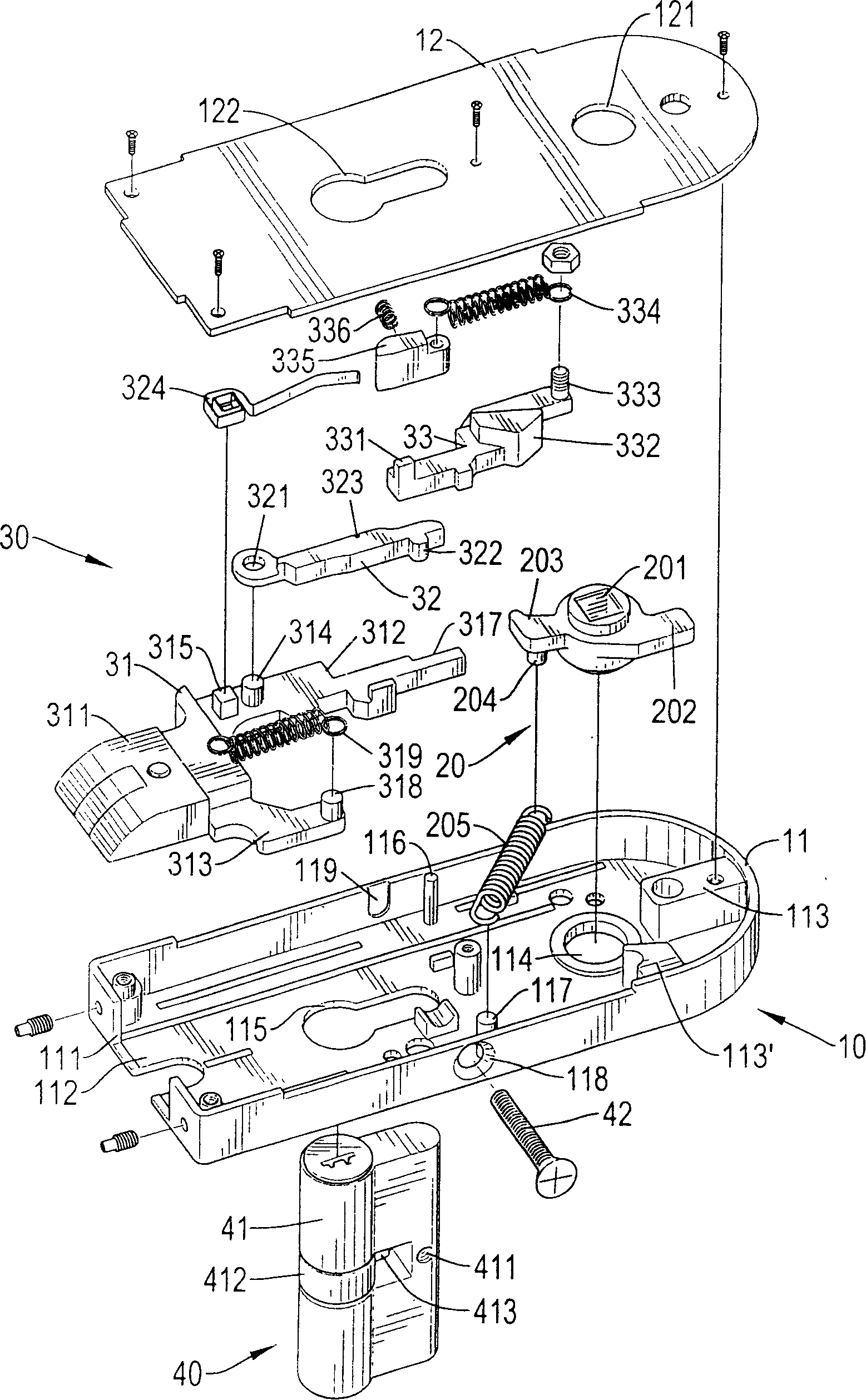

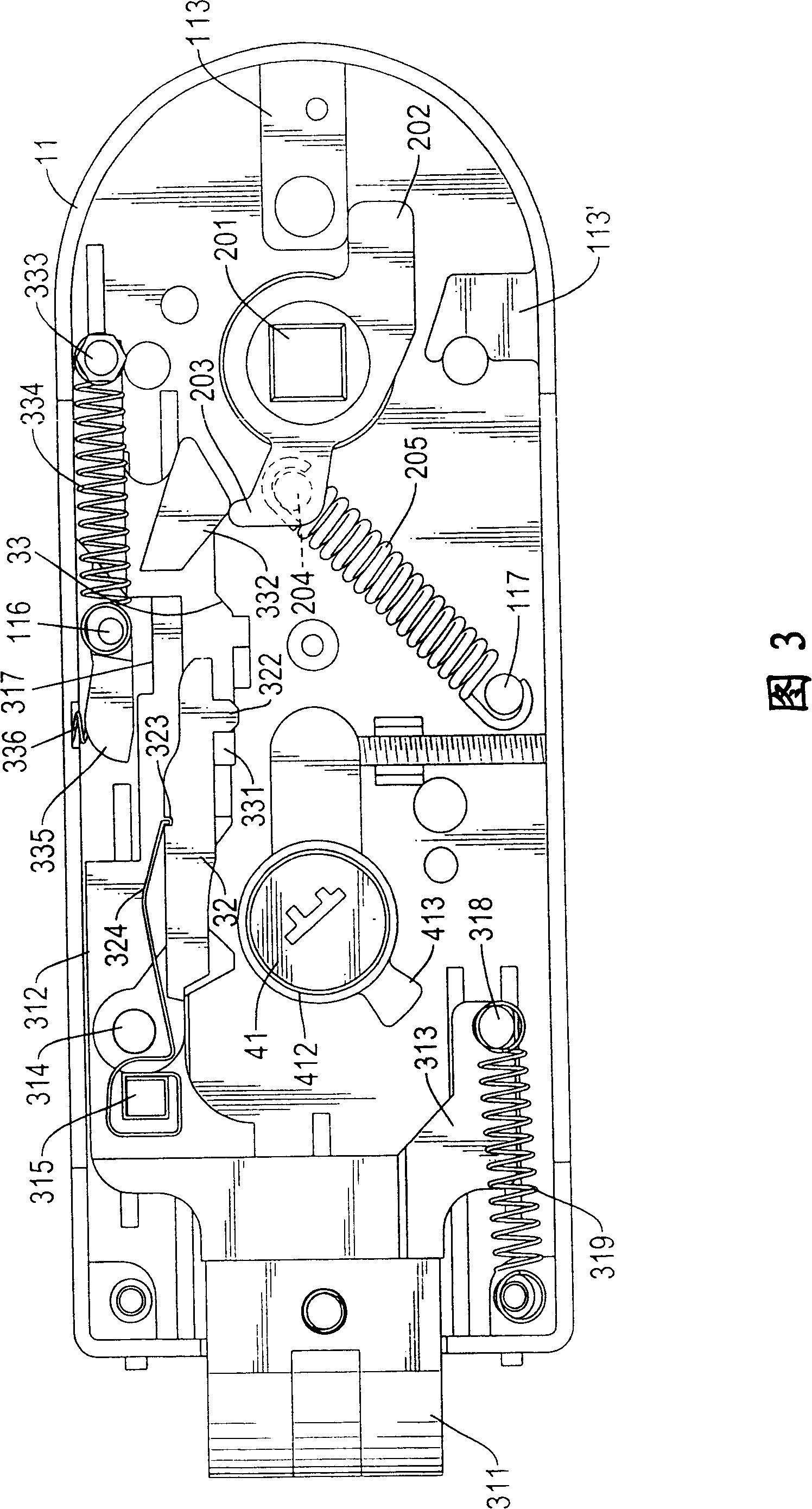

Locking device for non-frame glass door

InactiveCN101161969AExtended service lifeImprove service lifeBuilding locksGlass wingsEngineeringMechanical engineering

Owner:DOOR & WINDOW HARDWARE

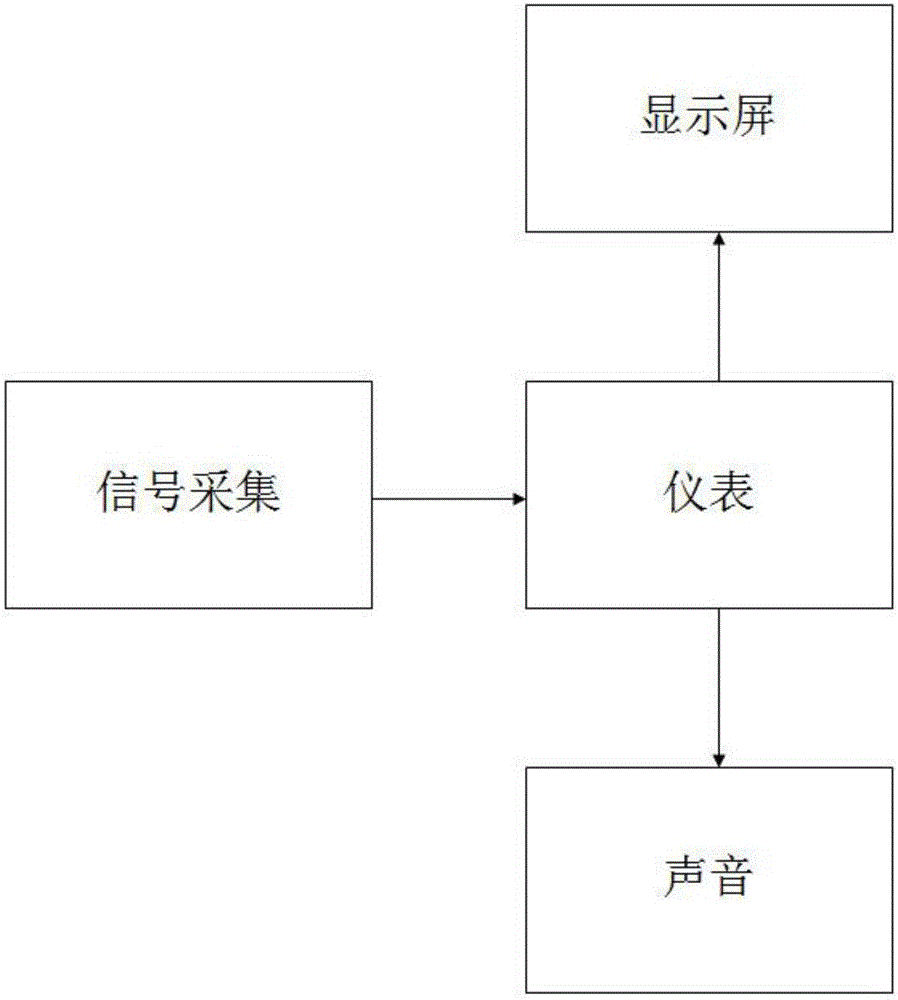

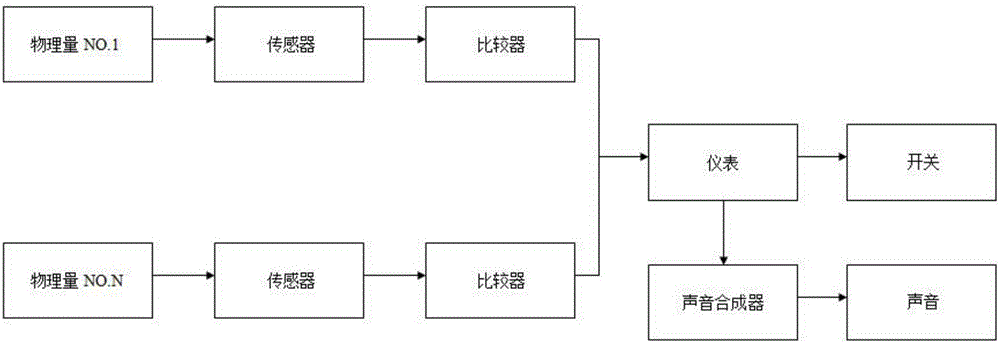

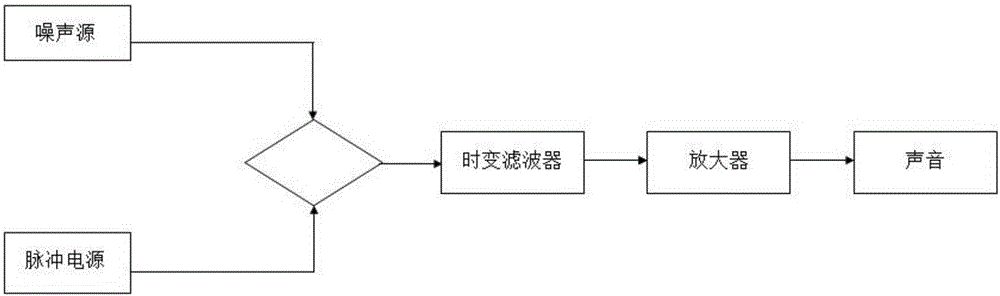

Buzzer or voice prompt system for automobile instrument

InactiveCN105882418AImprove safety and reliabilityImprove service lifeVehicle componentsDriver/operatorEngineering

The invention discloses a buzzer or a voice prompt system for an automobile instrument. The buzzer comprises a signal collecting circuit, an instrument, a display screen and a sound module, wherein a signal collecting module is used for receiving the data on an automobile bus, a level signal and a voltage signal and transmitting the data, the level signal and the voltage signal to the instrument; the instrument is used for analyzing the data, the level signal and the voltage signal, expressing the analyzed signal by the sound module in a sound form and expressing the analyzed signal by the display screen in an image form. According to the technical scheme provided by the invention, an automobile state signal is accurately told to a driver in a language form, so that the safety and reliability of the automobile are promoted.

Owner:ZHEJIANG ZHONGKE AUTOROCK AUTOMOBILE ELECTRONICS

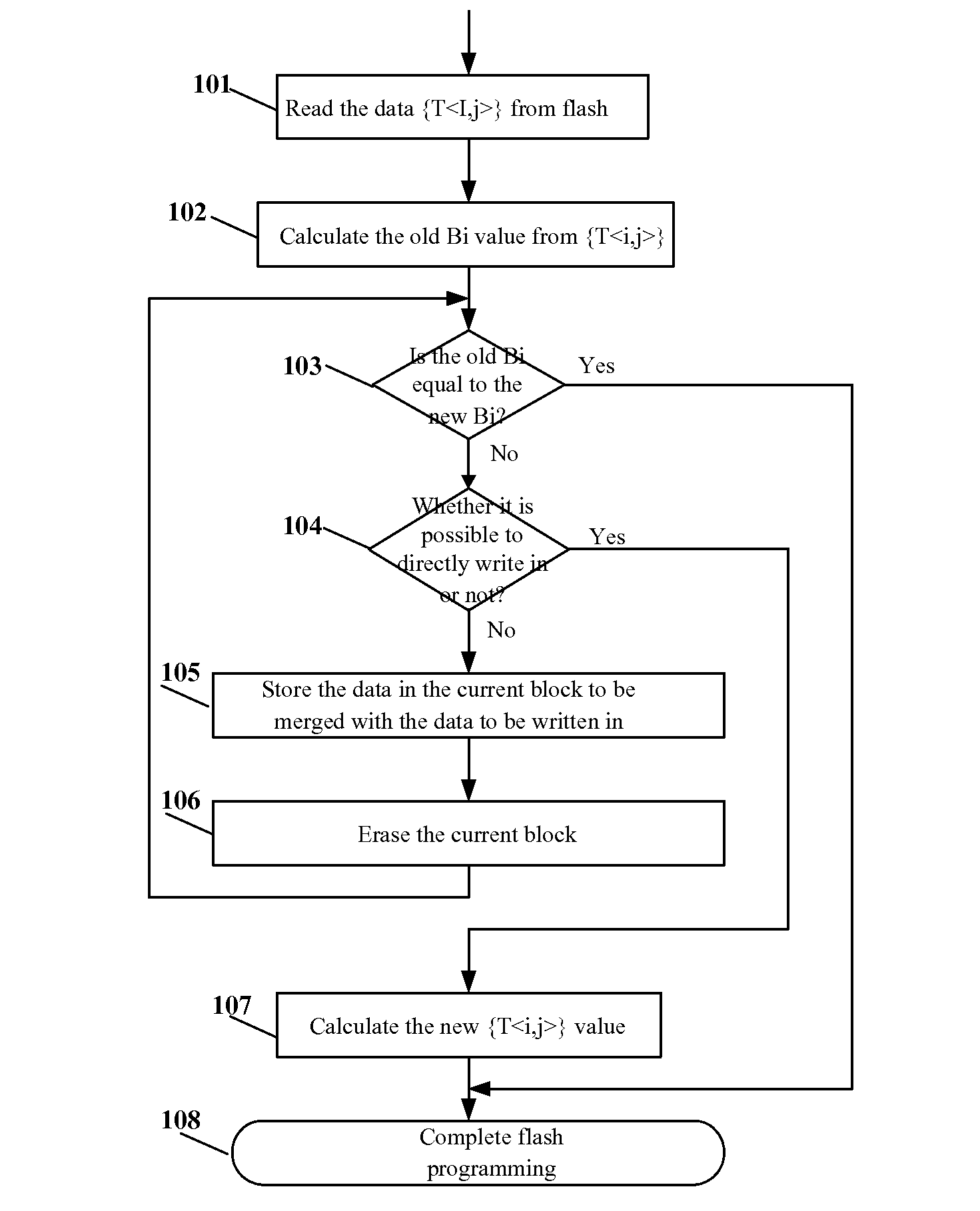

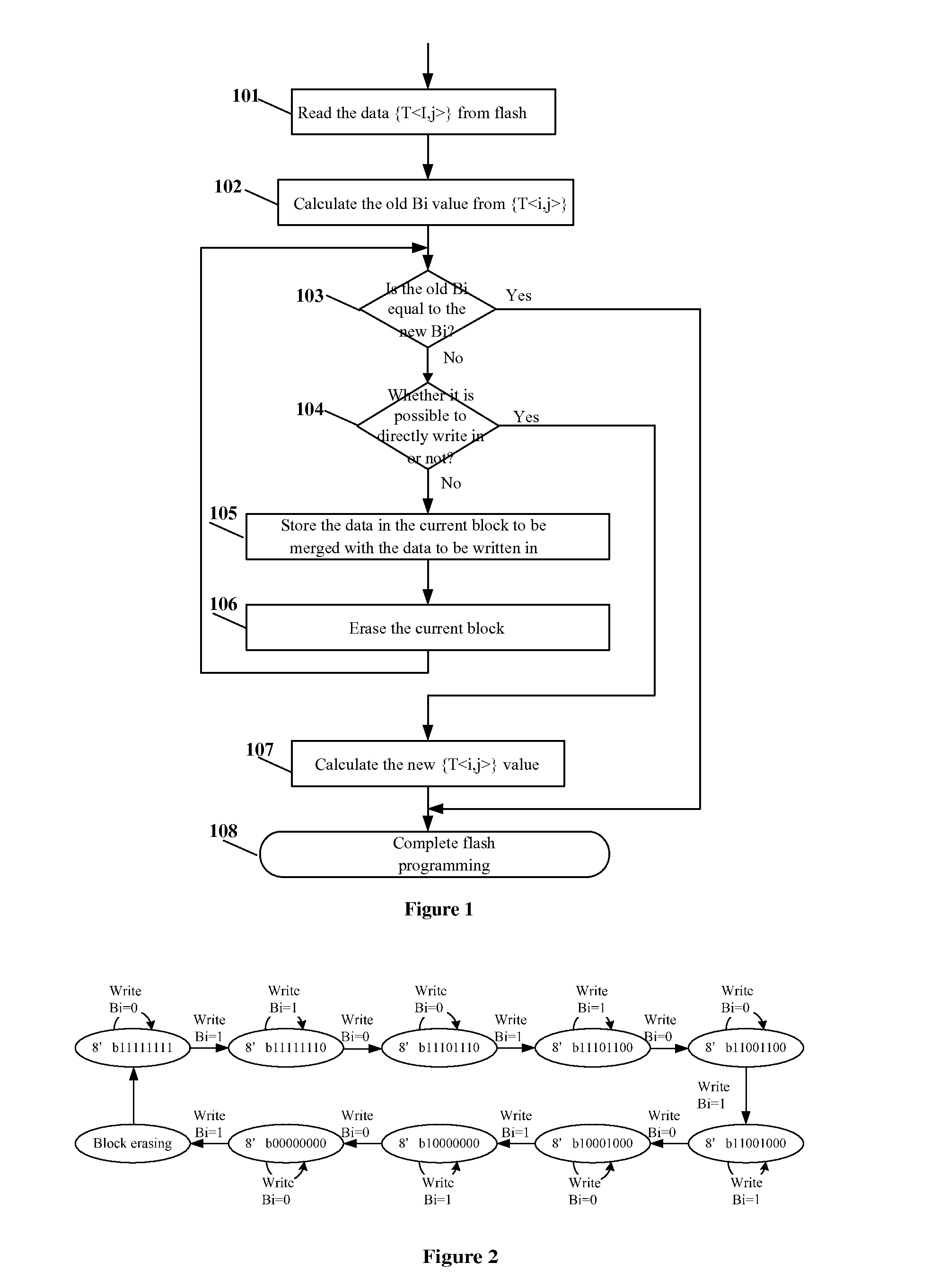

Method for Improving Service Life of Flash

A method for increasing service life of flash is provided. The method comprises the following steps: reading a data {T<i,j>} from the flash, calculating and obtaining the corresponding old original data Bi according to the mapping relationship, wherein i is a natural number, j=(n−1)˜0, n is an even number; determining whether the data Bi to be written in is the same as the old original data Bi by comparison, if they are the same, it is not necessary to update the data of this byte in the flash; if the value of the data Bi to be written in is not the same as the value of the old original data Bi, checking whether it is possible to write into the flash directly; if possible, writing into the flash directly; and if it is impossible to write into the flash directly, performing the operation of erasing block.

Owner:ZTE CORP

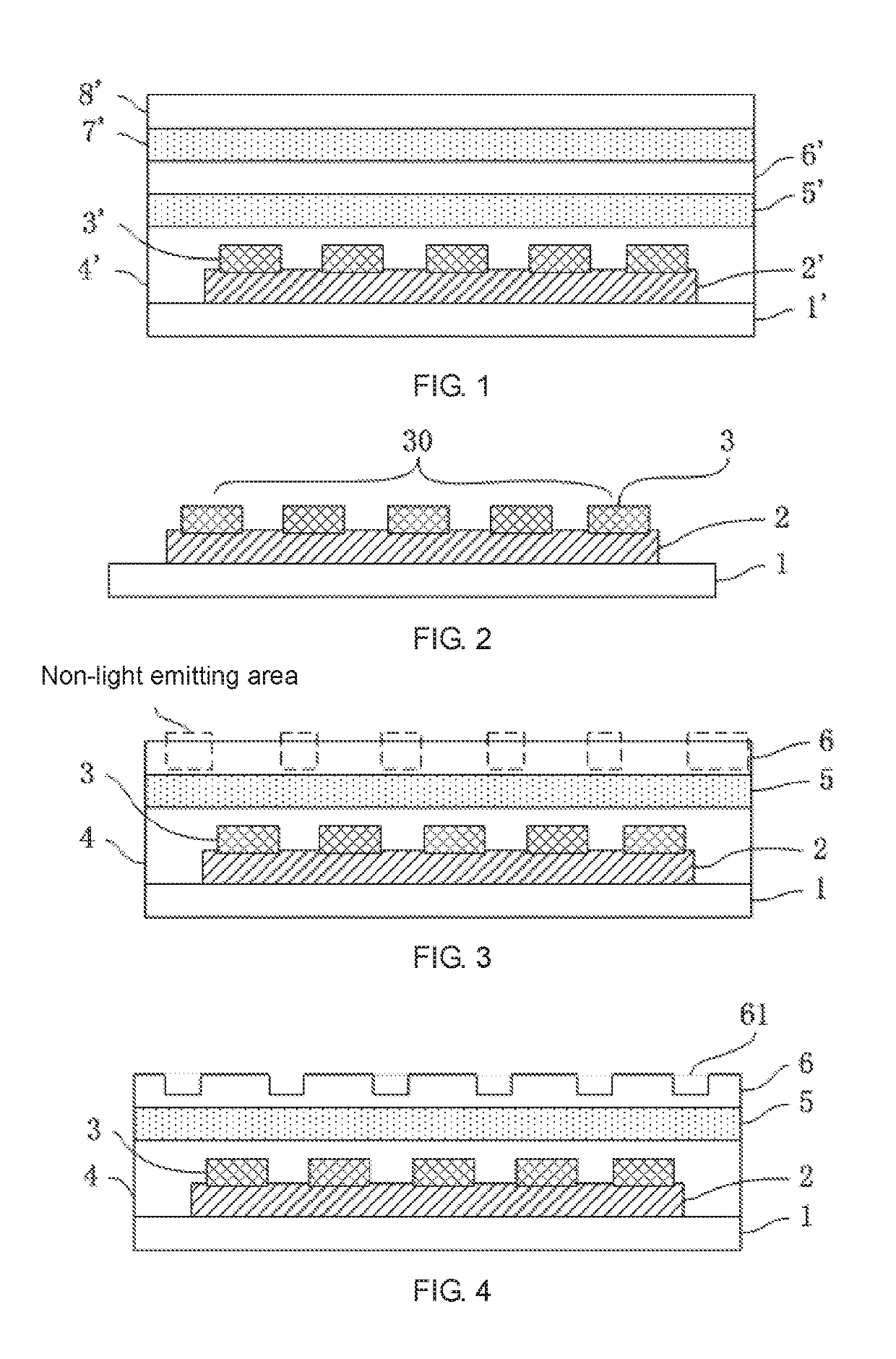

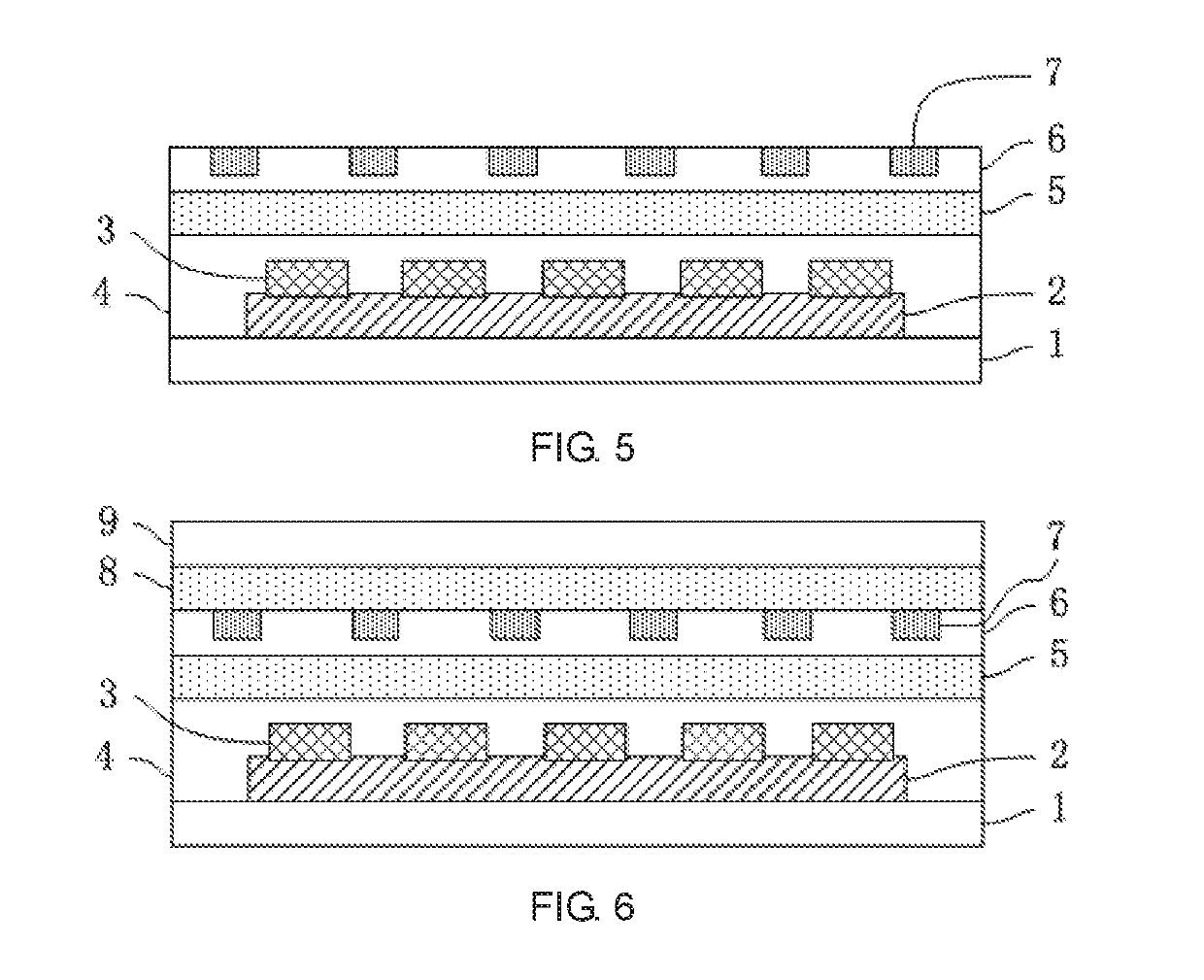

Organic light emitting diode display device and manufacturing method thereof

ActiveUS20190312231A1Water oxygen permeability be reduceImprove service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOLED

Provided are an organic light emitting diode display device and a manufacturing method thereof. The method includes: preparing a thin film transistor layer on a glass substrate; preparing an organic light emitting diode element layer on the thin film transistor layer, and preparing a barrier layer and a buffer layer on the glass substrate, wherein the barrier layer covers the OLED element layer; preparing the plurality of grooves in the barrier layer, and preparing a water absorbing material layer in the plurality of grooves. The permeability of water and oxygen is reduced for lowering the risk of breakage of the barrier layer and the buffer layer, and improving the service life of the OLED display device.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

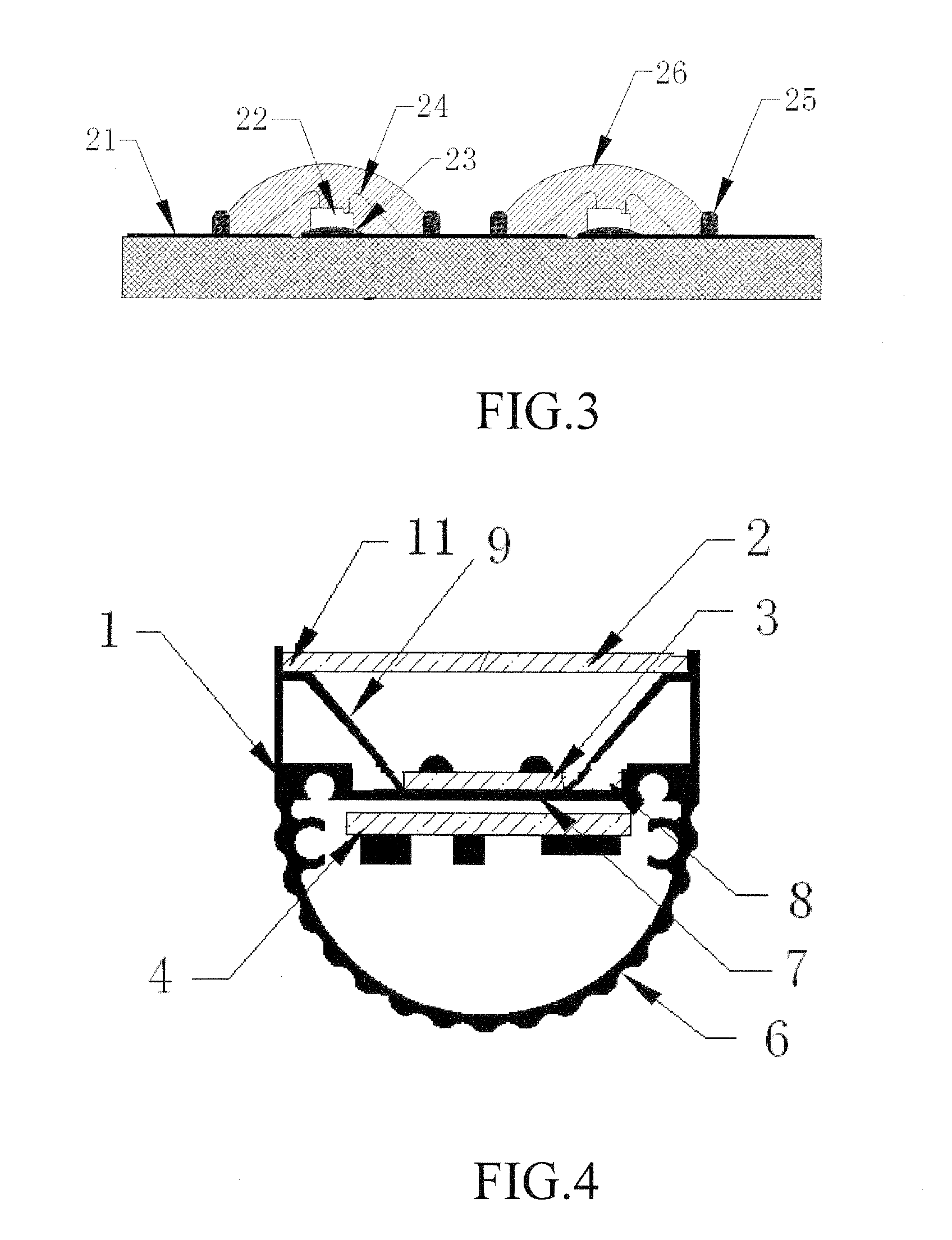

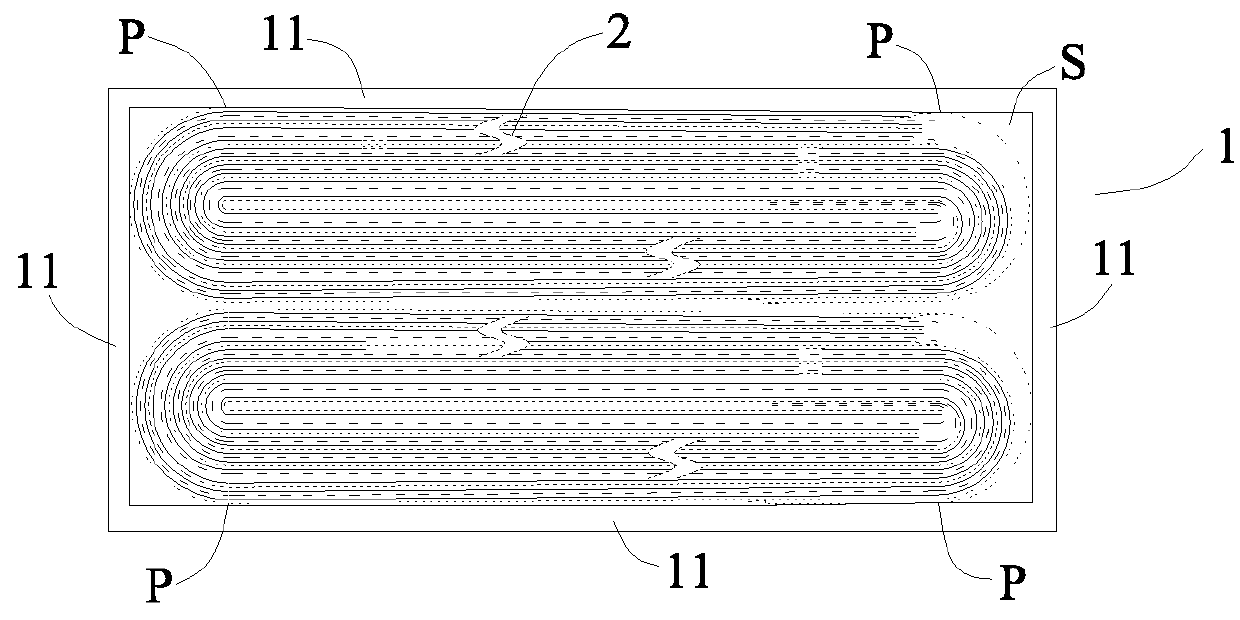

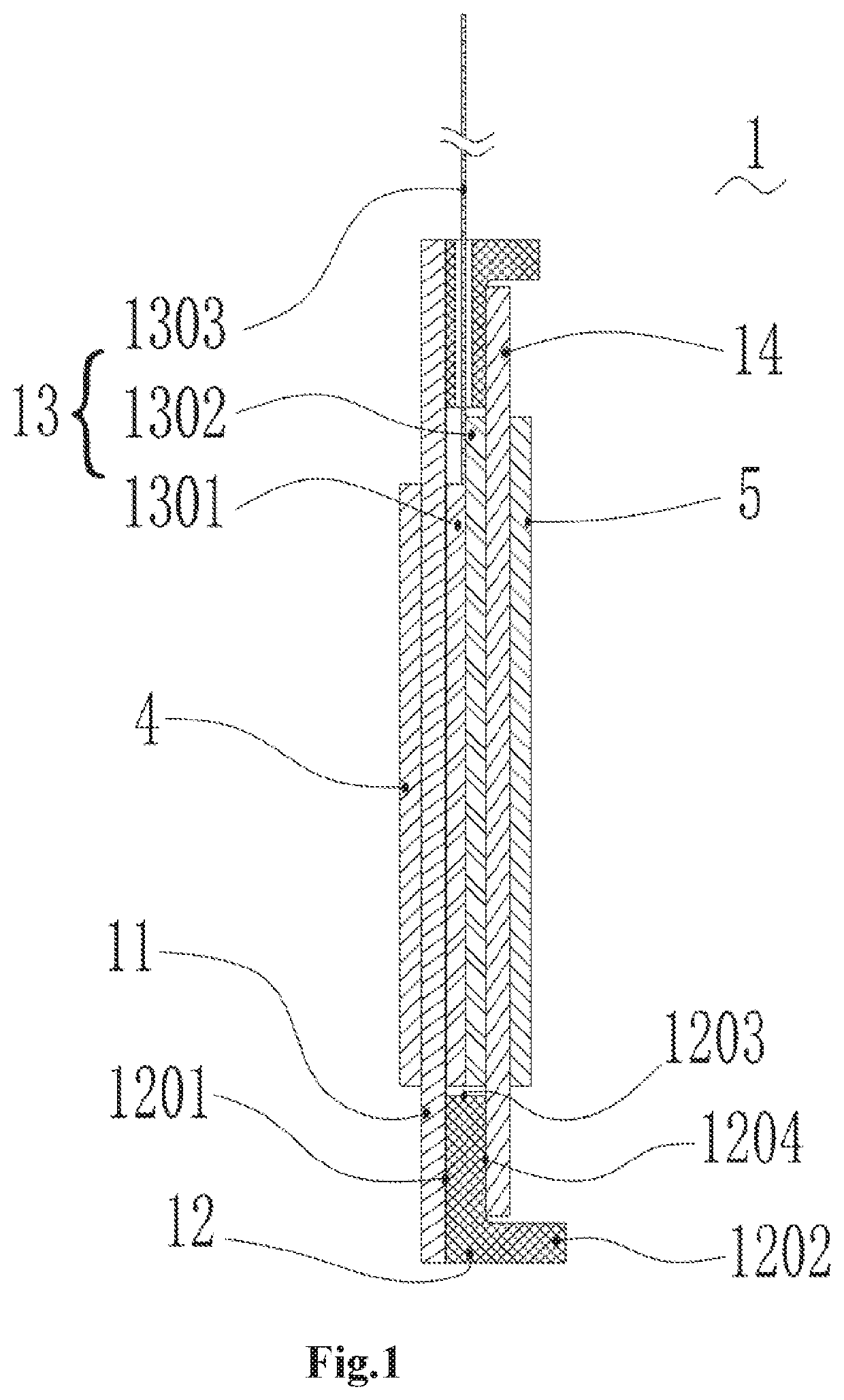

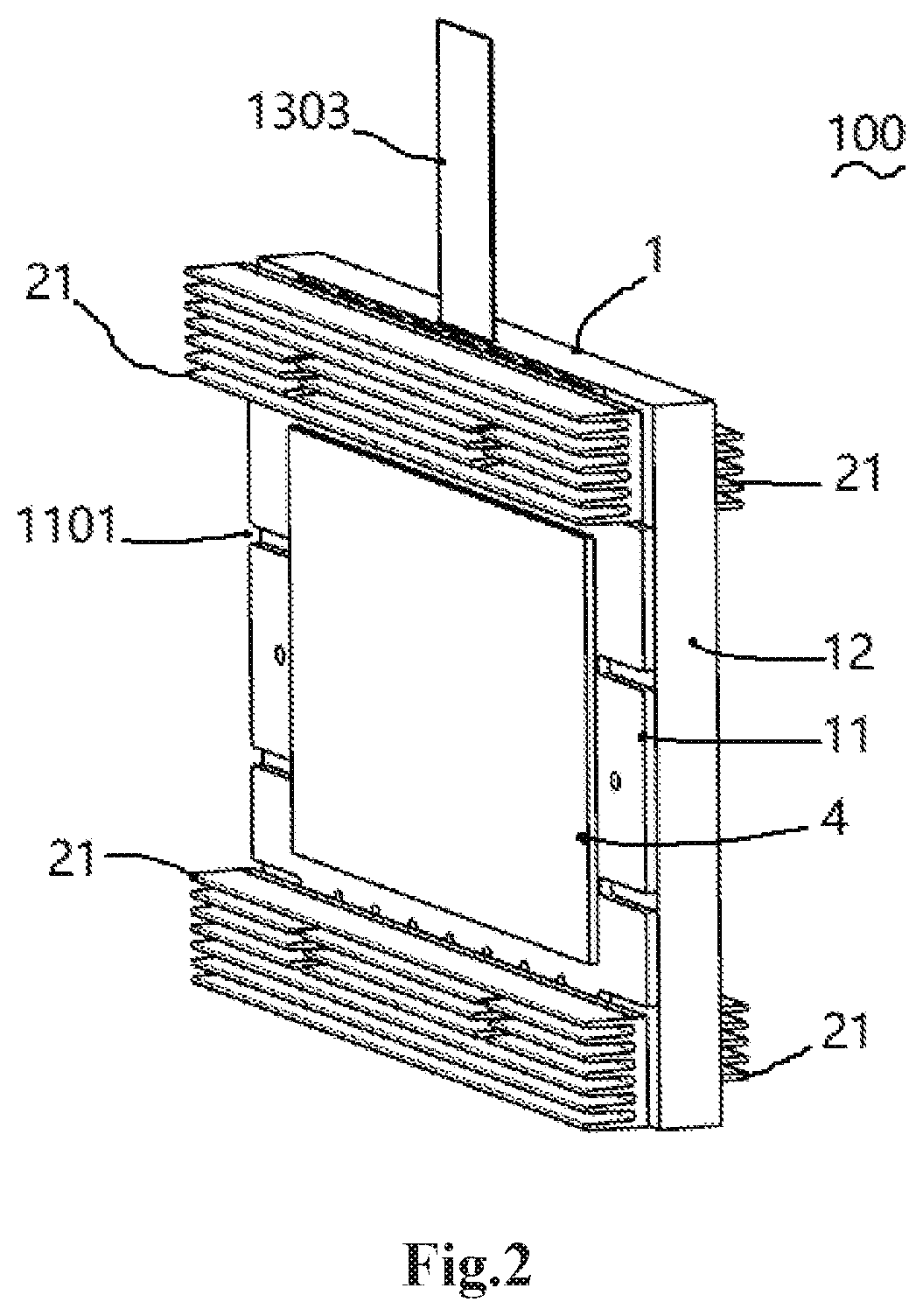

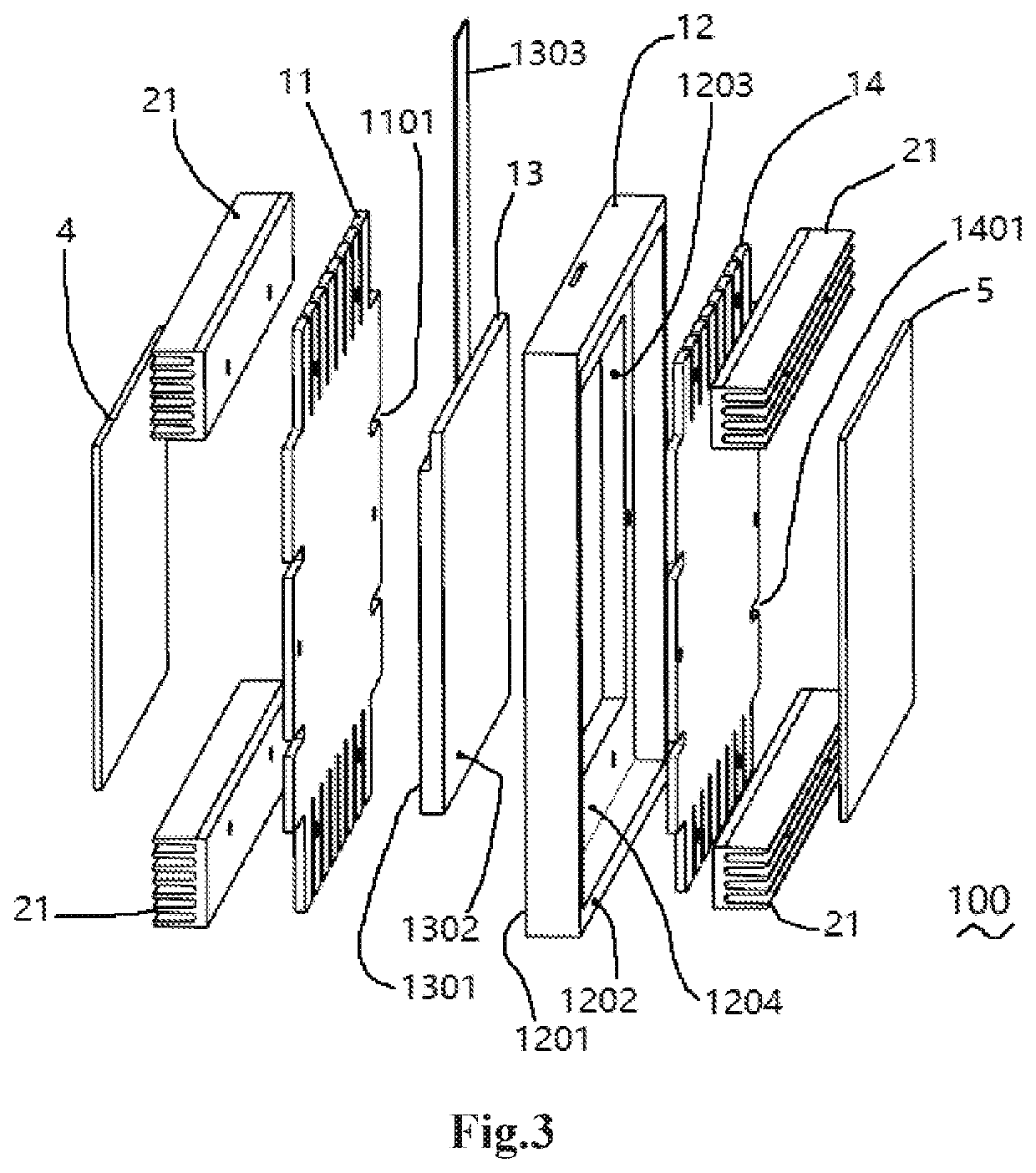

Self-conducting light valve module and light valve heat dissipation device

ActiveUS20200341328A1Rapid heat dissipationImprove service lifeProjectorsColor television detailsPhysicsExit surface

A self-conducting light valve module includes: a first transparent graphene thermal conductive film, a panel frame, an LCD light valve, and a second transparent graphene thermal conductive film; wherein the panel frame has a first plane and a second plane at two ends, respectively; a rectangular through hole is drilled at a center of the panel frame, and the LCD light valve is installed in the rectangular through hole; the first transparent graphene thermally conductive film is attached to the first plane and the incident surface of the LCD light valve; and the second transparent graphene thermally conductive film is attached to the second plane and the emergent surface of the LCD light valve. A light valve heat dissipation device includes: a heat diffusion device installed on an external peripheral wall of the self-conducting light valve module.

Owner:NANHUA INTELLIGENT PRECISION MACHNE (SHENZHEN) CO LTD

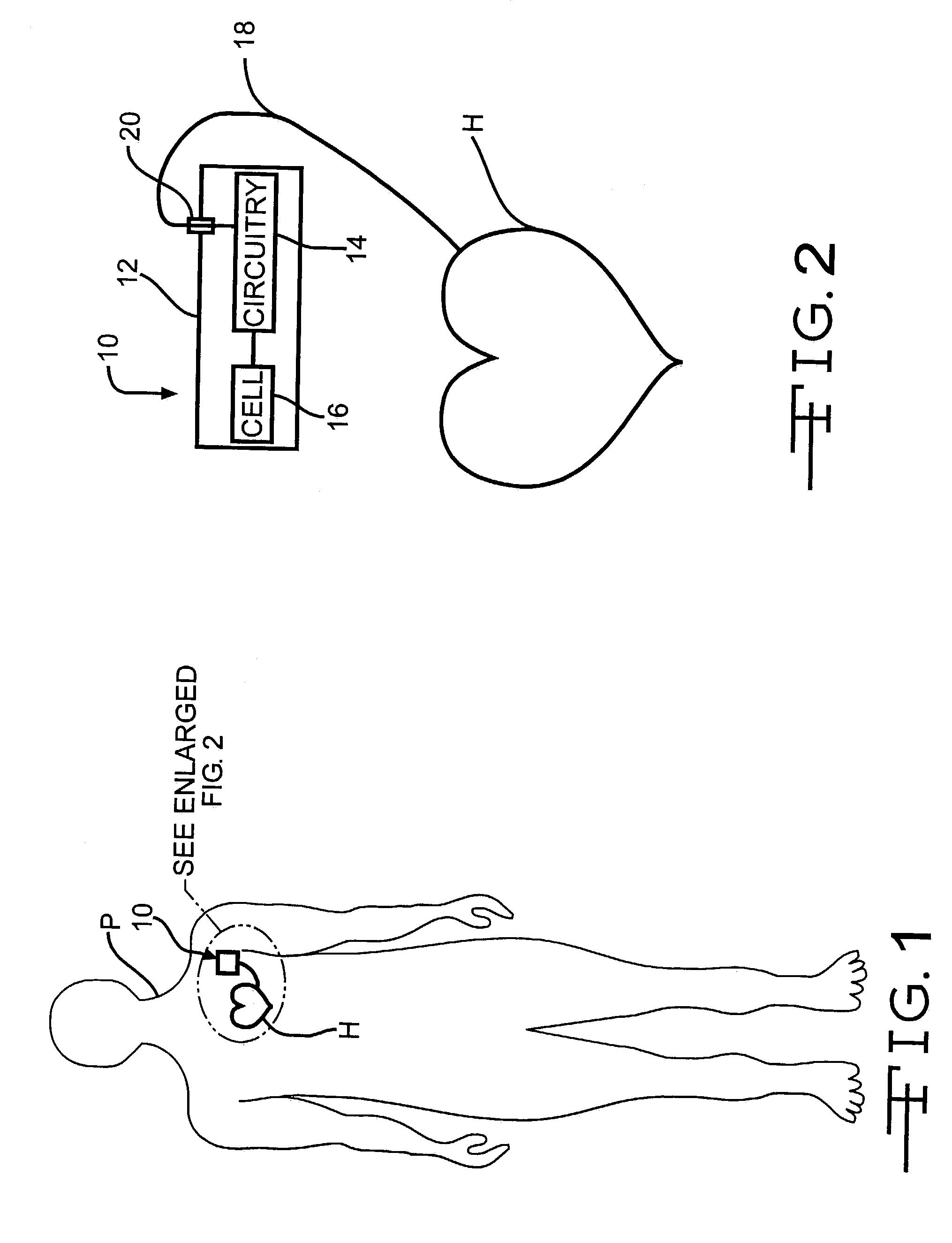

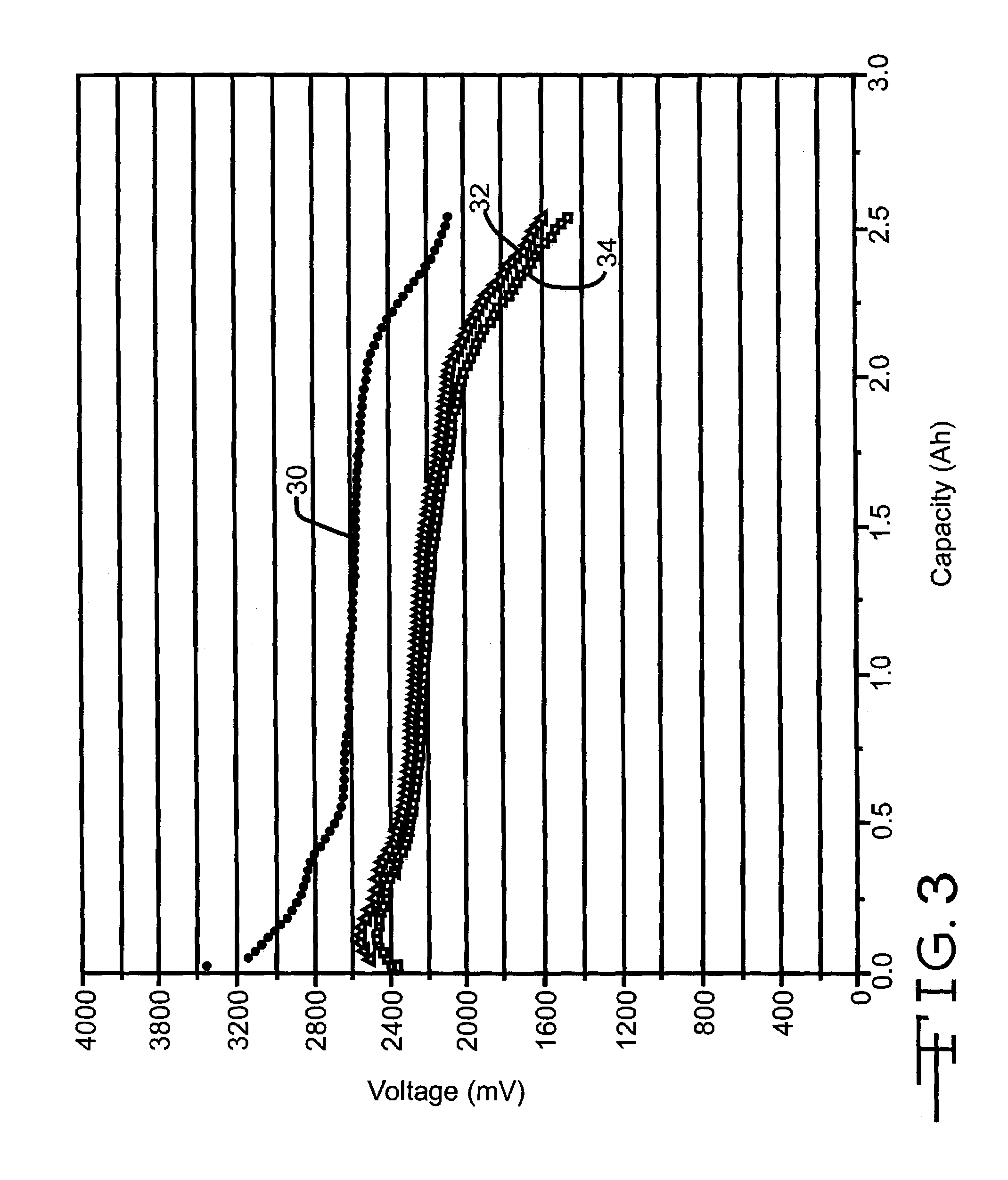

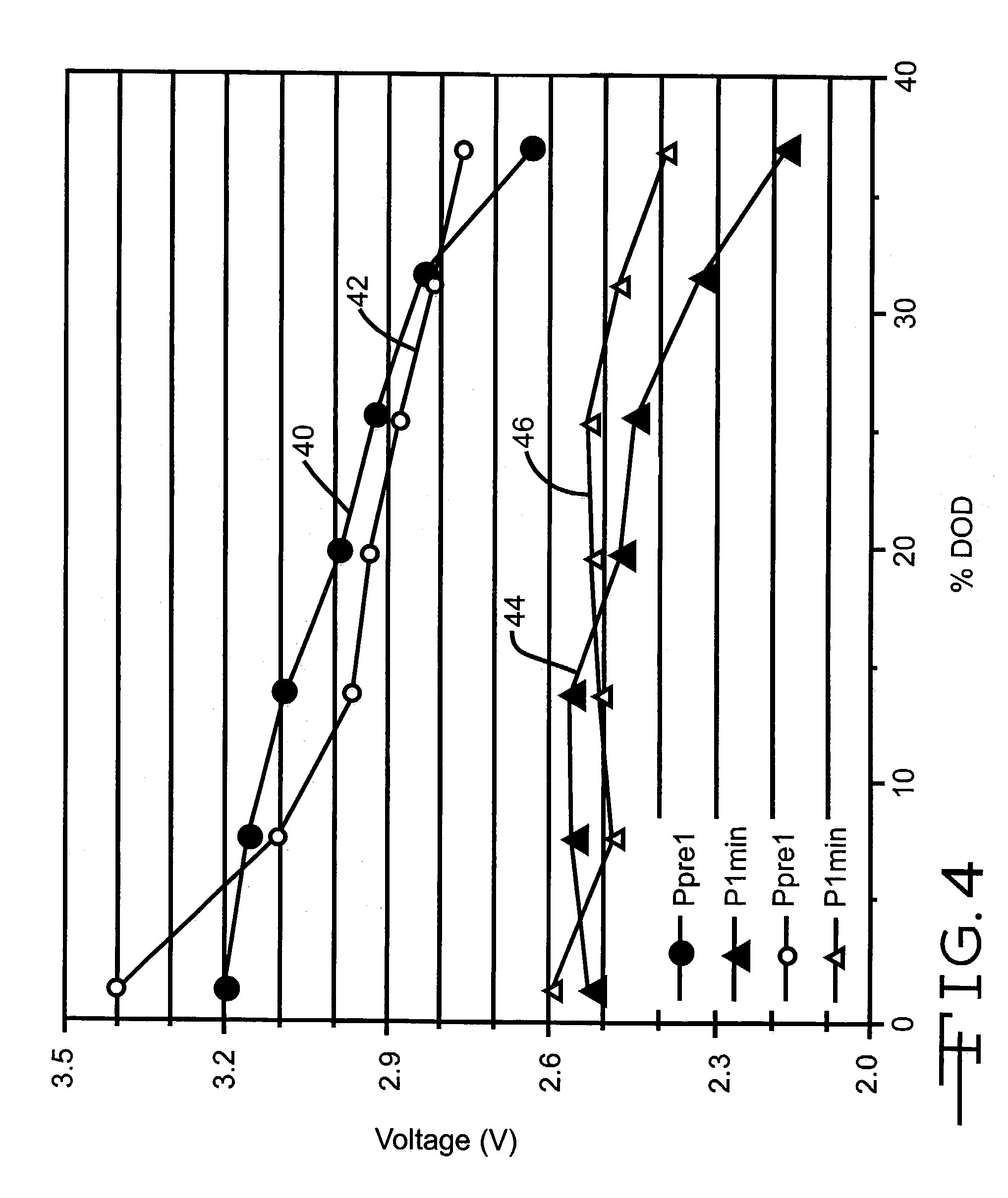

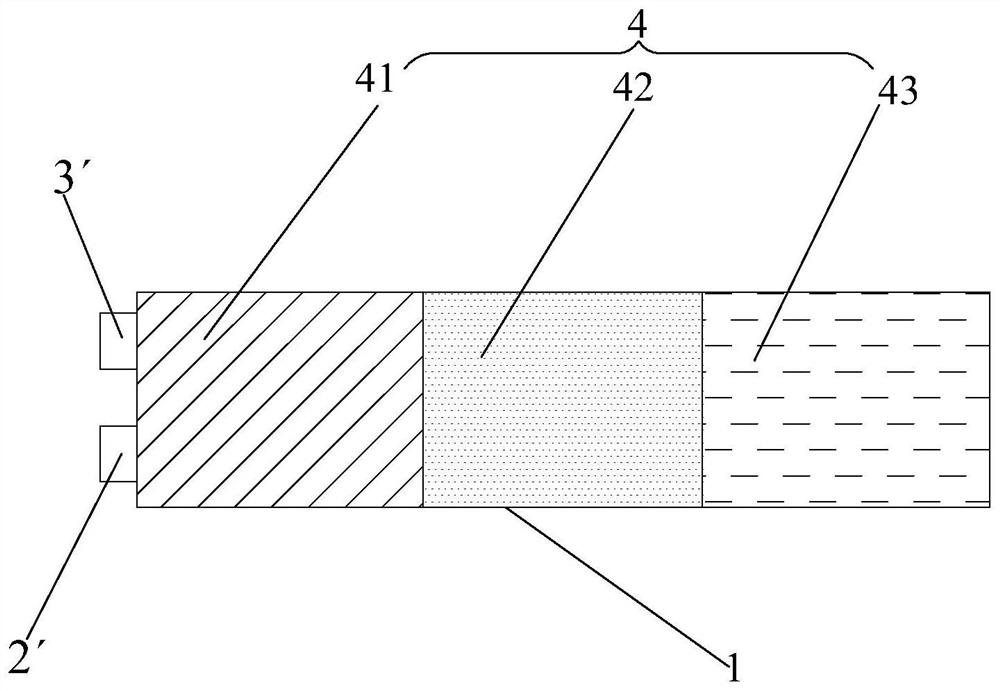

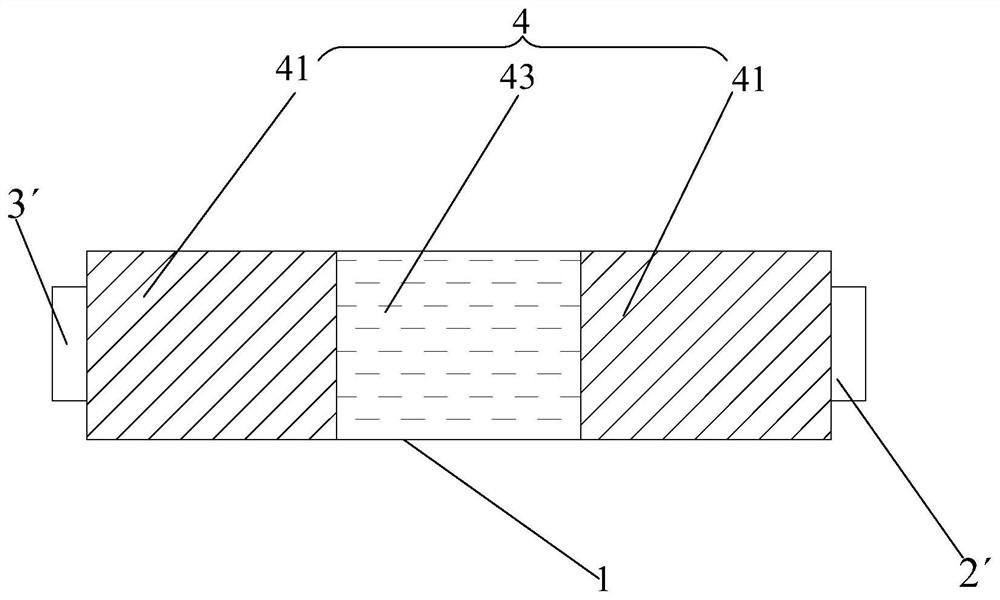

Method for using high rate lithium electrochemical cell containing SVO/CFchi/SVo sandwich cathodes having gamma-SVO and mixture of gamma-SVO/epsilon-SVO

InactiveUS7056358B2Improve service lifeExtended service lifeSilver accumulatorsPrimary cellsHigh rateElectrochemical cell

A method for powering an implantable medical device with a lithium electrochemical cell having a sandwich cathode electrode of SVO / CFx / SVO active materials is described. A preferred cathode is of a γ-SVO / CFx / γ-SVO or (γ+ε)-SVO / CFx / (γ+ε)-SVO sandwich configuration.

Owner:WILSON GREATBATCH LTD

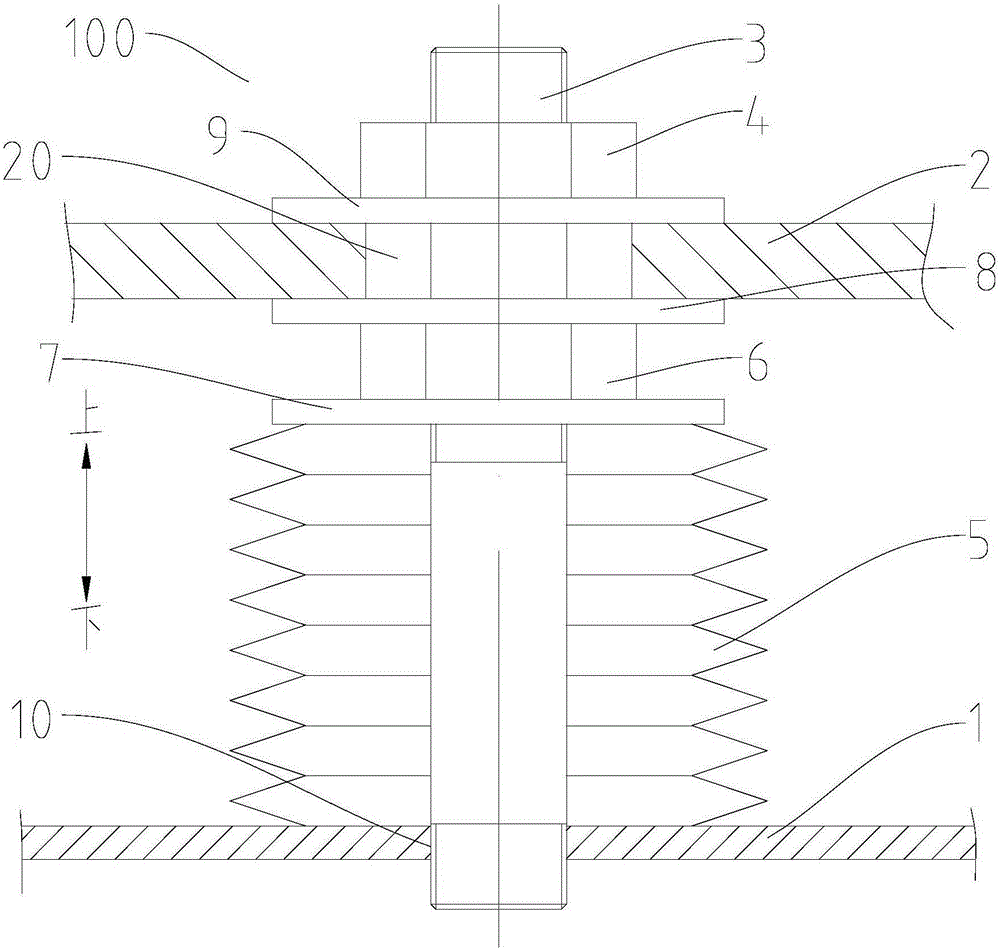

Shaftless screw conveyor

The invention provides a shaftless screw conveyor. The shaftless screw conveyor comprises a motor, a first cylinder conveying cylinder, a second cylinder conveying cylinder, spiral blades, a feed bin, a material discharge box and a material mixing box. One end of the first cylinder conveying cylinder is rotationally installed on one side of a discharge port of the feed bin, and the other end of the first cylinder conveying cylinder is fixedly connected with one end of the second cylinder conveying cylinder. The other end of the second cylinder conveying cylinder is rotationally installed on one side of a feed port of the material discharge box. The first spiral blade is fixedly connected to the inner wall face of the first cylinder conveying cylinder. The other end of the first spiral blade is fixedly connected with one end of the second spiral blade. The outer side face of the second spiral blade keeps being tangent to the inner wall face of the second cylinder conveying cylinder and is detachable. Because of the split structure of a conveying barrel, under the condition that the second spiral blade is damaged, the whole section of spiral blade does not need to be replaced, the use cost is saved, and replacement is easy.

Owner:NANJING AIR CONVEYING SYST +1

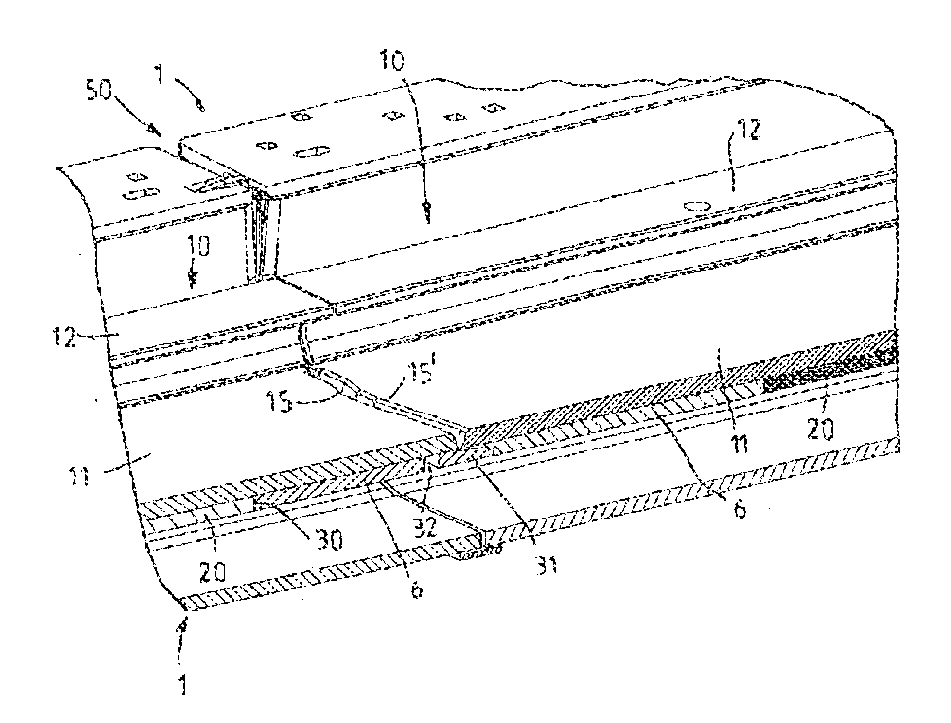

Upper-strand well for a trough pan and trough pan having such an upper-strand well

ActiveUS20120080289A1Good movabilityImprove service lifeConveyorsEarth drilling and miningChain conveyorEngineering

A trough pan with an upper strand trough and to an upper strand trough for a trough pan of a scraper chain conveyor, with two side profiles, and with a trough bottom. The trough bottom has two side edges and two end edges which have at least partially a wavy boundary line and which are provided at the transition of a top side into the end edge with a chamfer having a chamfer angle. In order to improve the upper strand troughs and the trough pans equipped with these in terms of the problem of the penetration of fine coal into the intermediate gap of the bearing region between the trough bottom and intermediate bottom, the end edges are provided with a bevel between the chamfer and an underside, the bevel sloping more steeply than the chamfer.

Owner:CATERPILLAR INC

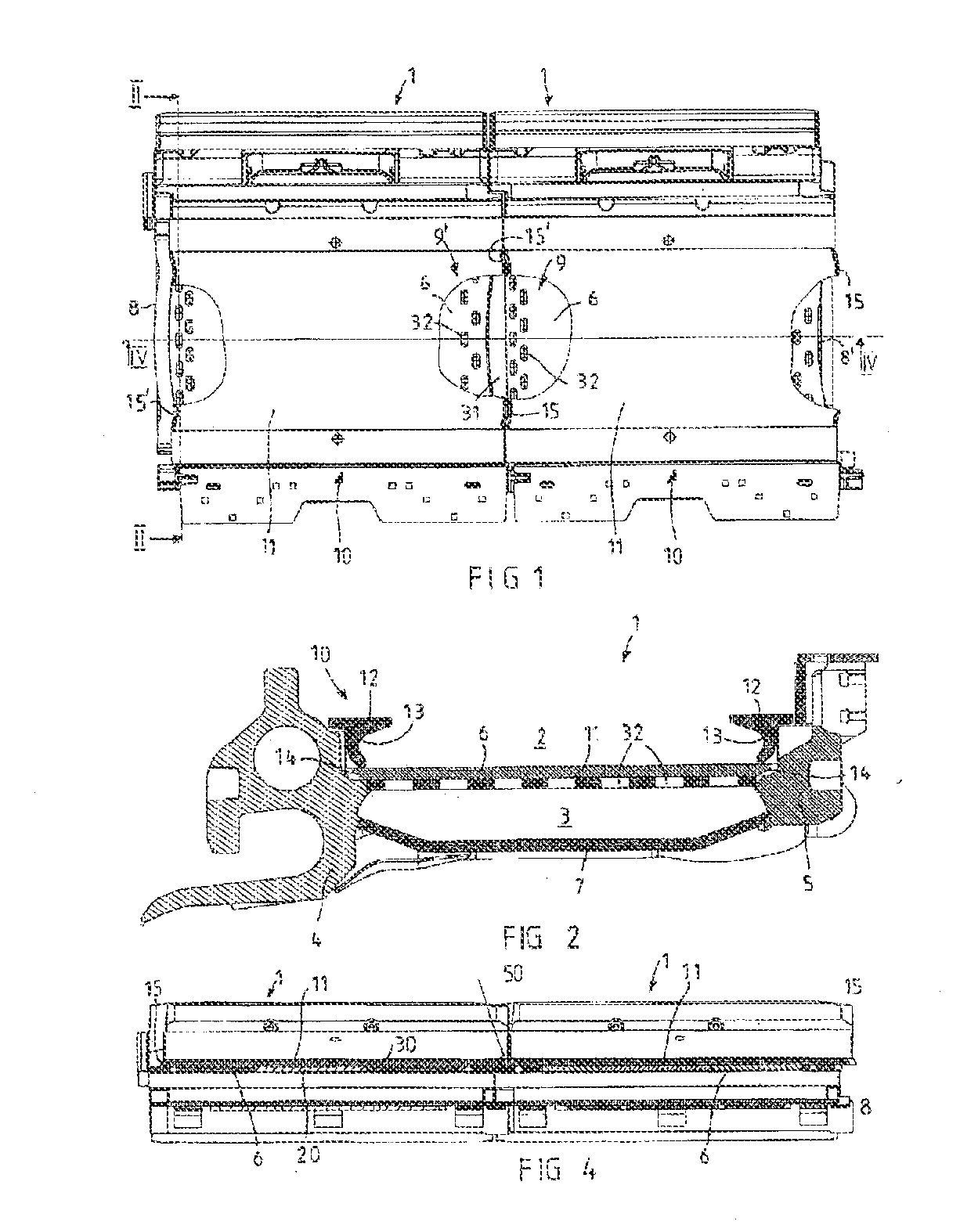

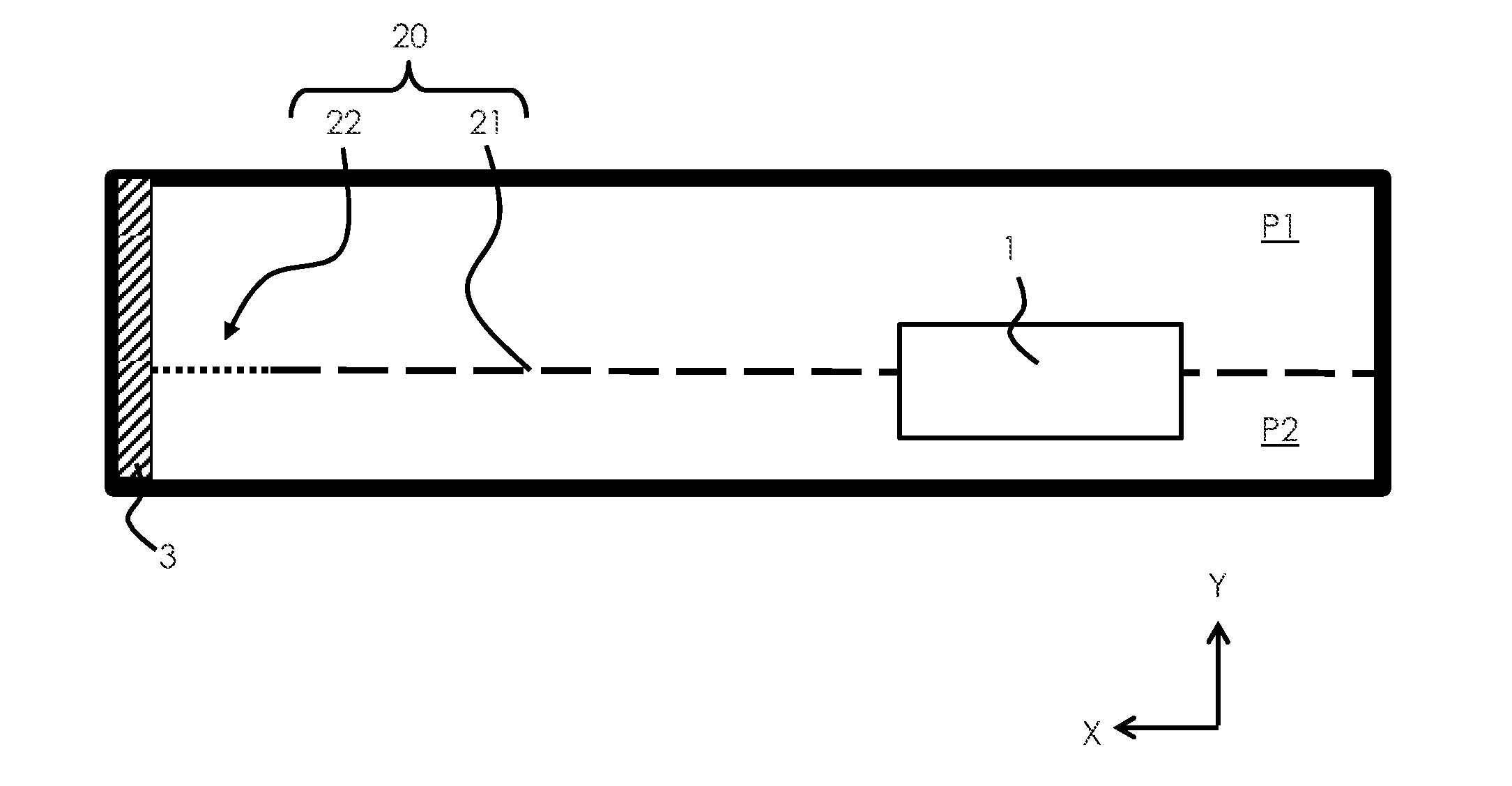

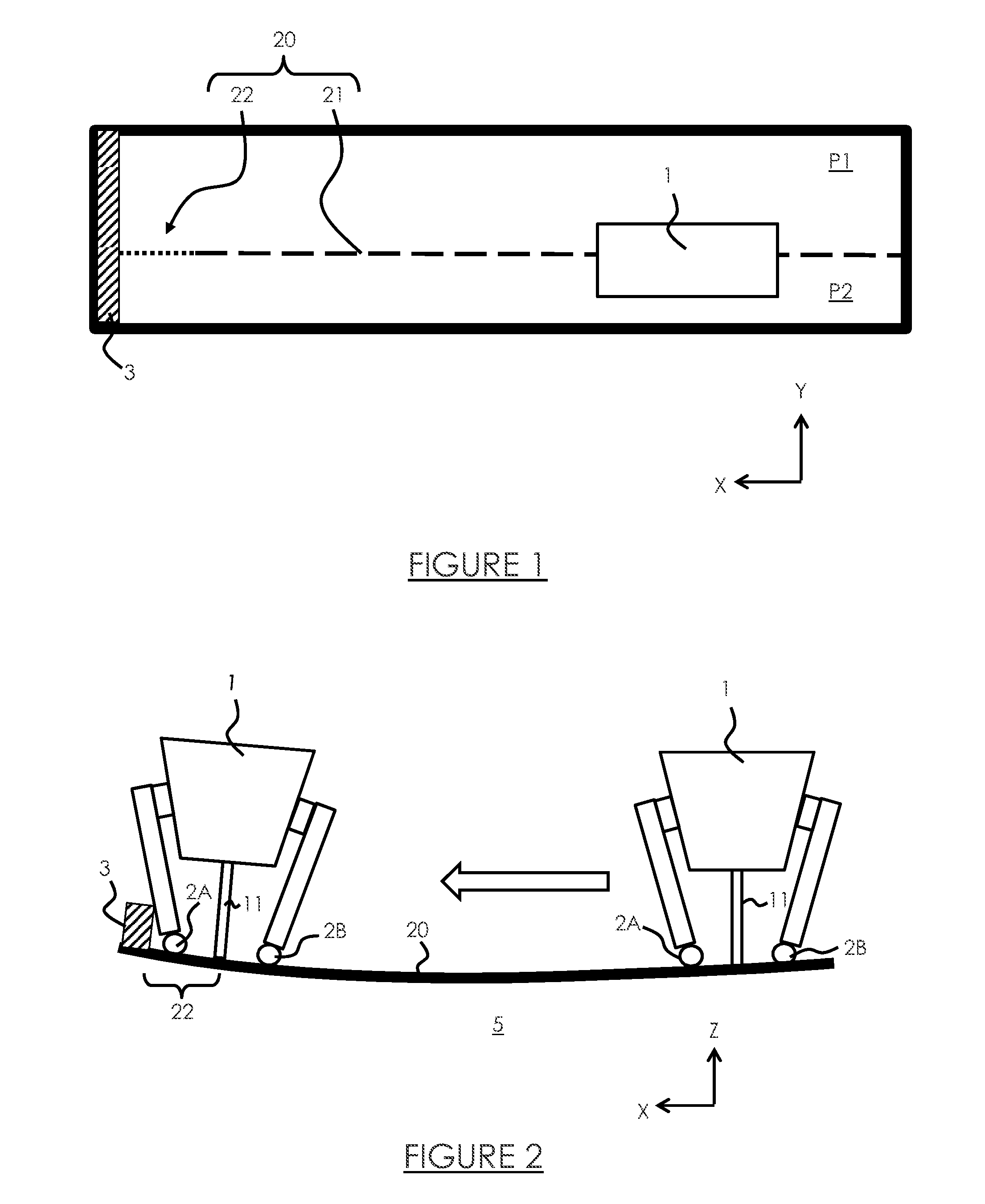

Friction stir welding tool comprising a retractable guide member and a welding process

ActiveUS20160089748A1Improve service lifeEasy accessWelding/cutting auxillary devicesAuxillary welding devicesFriction stir weldingMechanical engineering

A friction stir welding tool with a base, a rotating friction stir slug mounted in the said base and at least one guide member connected to the said base, the welding tool being adapted to move from upstream to downstream; a welding tool having at least one displacement member of the guide member relative to the said base between at least one guiding position in which the guide member extends in a scout area located downstream and facing the friction stir slug and at least one retracted position in which the guide member is offset from the said scout area.

Owner:STELIA AEROSPACE

Compressor installing structure and refrigerator provided with same

InactiveCN105180565AReduce noiseImprove service lifeLighting and heating apparatusDomestic refrigeratorsAbsorption effectEngineering

The invention discloses a compressor installing structure and a refrigerator provided with the same. The compressor installing structure comprises a compressor installing plate, a compressor body and a disc-shaped spring. The compressor body is provided with a compressor installing lug, and the compressor installing lug is installed on the compressor installing plate through a lifting rod bolt and an installing nut which is in thread fit with the lifting rod bolt. The disc-shaped spring is arranged between the compressor installing lug and the compressor installing plate. By means of the compressor installing structure, the buffer and shock absorption effect is good, and noise of the refrigerator can be reduced; in addition, the service life is long, and the performance of the compressor installing structure is stable. Furthermore, the axial structure of the compressor installing structure is compact and easy to assemble.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Preparation method of dry specimen of coleopteran insects

InactiveCN113115762AImprove moisture resistanceImprove service lifeDead animal preservationEducational modelsChemistryOrder Coleoptera

According to the invention, drying agent, a mildew preventive and the like are mostly adopted for preparation and preservation of a dry coleopteran insect specimen in a dry environment, the requirement for the environment is strict, a temperature and humidity control device needs to be matched, once the specimen is exposed in air for a long time, the specimen is prone to being affected with damp and damaged due to moisture absorption and the like, protectiveness is low, and the specimen protection cost is high. The invention provides a novel preparation method of a dry specimen, which comprises the following steps of: softening, needle inserting, drying, permeating and film forming, so that a film-forming material permeates and treats a substrate of the dry specimen, the appearance characteristics and the form of the specimen are not changed, a non-polar protective layer is formed in a capillary structure of the dry specimen, the moisture resistance of the specimen is improved, and therefore, the service life of the dried specimen is prolonged.

Owner:上海市林业总站

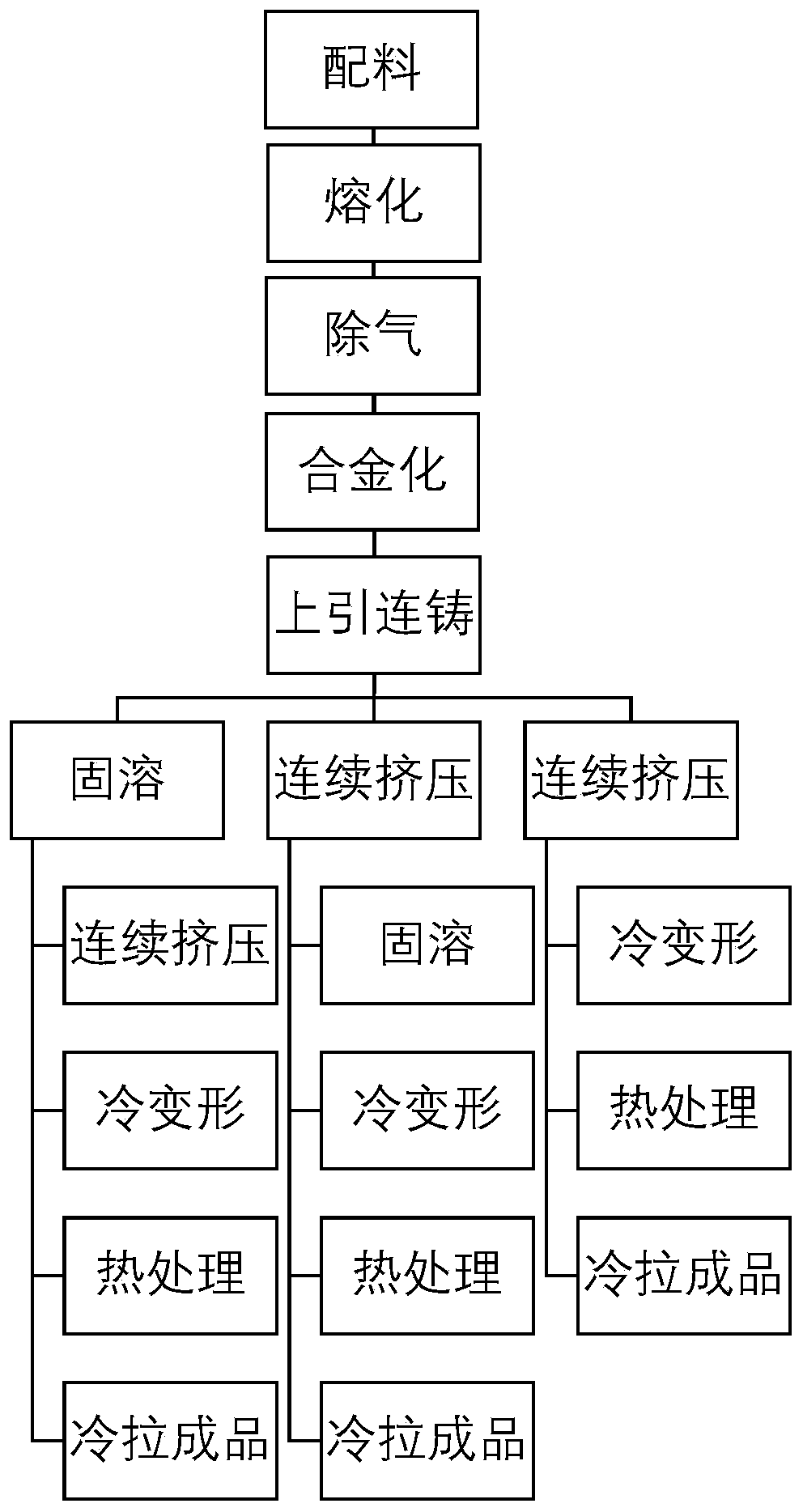

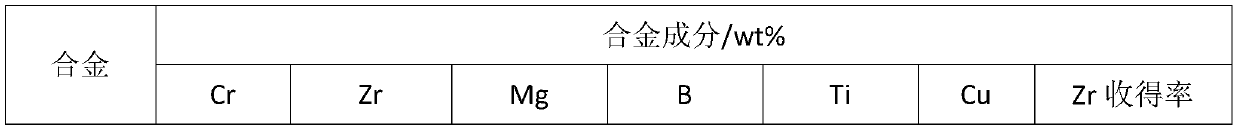

Method for preparing copper alloy for contact wire

A method for preparing a copper alloy for a contact wire comprises the steps of (1) melting, wherein cathode copper is added into a smelting furnace, a covering agent is added, and melting is carriedout in a protective atmosphere; (2) melt degassing, wherein the obtained copper melt is degassed, so that the oxygen content in the melt is 50 ppm or below, and the treated melt is strictly covered and subjected to inert gas shielding; (3) alloying, wherein Cu-Mg-Zr and other intermediate alloys are added into the copper melt, and copper alloy melt is obtained; (4) up-drawing continuous casting, aSiC / graphite composite liner continuous casting crystallizer is adopted for carrying out up-drawing continuous casting on the obtained copper alloy melt, and a copper alloy ingot casting is obtained;and (5) machining, wherein the obtained copper alloy ingot casting is machined into the contact wire. According to the method, the roll weight of the obtained Cu-Cr-Zr contact wire of 150 mm<2> is 2.5 tons, the performance can reach the tensile strength of 560 MPa to 650 MPa, the ductility ranges from 5% to 12%, and the conductivity is 75-85% IACS.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Insulating film for battery heat conduction and battery thereof

PendingCN112072205AEnsure consistencyImprove service lifeFinal product manufactureElectrolyte accumulators manufactureComposite materialElectrical battery

The invention provides an insulating film for heat conduction of a battery and the battery thereof, the insulating film for heat conduction of the battery covers the outer side of the battery, the battery is provided with a pole or a lug arranged at one end part in the length direction, and the heat conductivity coefficient is gradually reduced in a gradient manner from one end provided with the pole or the lug to the length direction of the battery. According to the heat dissipation characteristics of the battery, the insulating film with high heat conductivity coefficient is arranged on theouter side of the pole or the lug with high heat generation quantity, the insulating film with low heat conductivity coefficient is arranged at one end, far away from the pole or the lug, of the length direction, and the heat of the battery is quickly transferred through the gradient change of the heat conductivity coefficient of the insulating film; the temperature consistency of each part of thebattery is ensured and the service life of the battery is prolonged. Especially for the battery module, the heat of the battery top cover can be quickly transferred to the bottom, i.e., to the water-cooling heat dissipation system, so as to accelerate the heat dissipation of the battery.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com