Preparation method of manganese-chromium ceramic coating on surface of alloy material

A technology of ceramic coating and alloy material, applied in metal material coating process, coating, solid diffusion coating and other directions, can solve the problems of poor Cr substrate, low bonding force between coating and substrate, easy to fall off and failure, etc. Improve service life, good stability, excellent anti-coking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

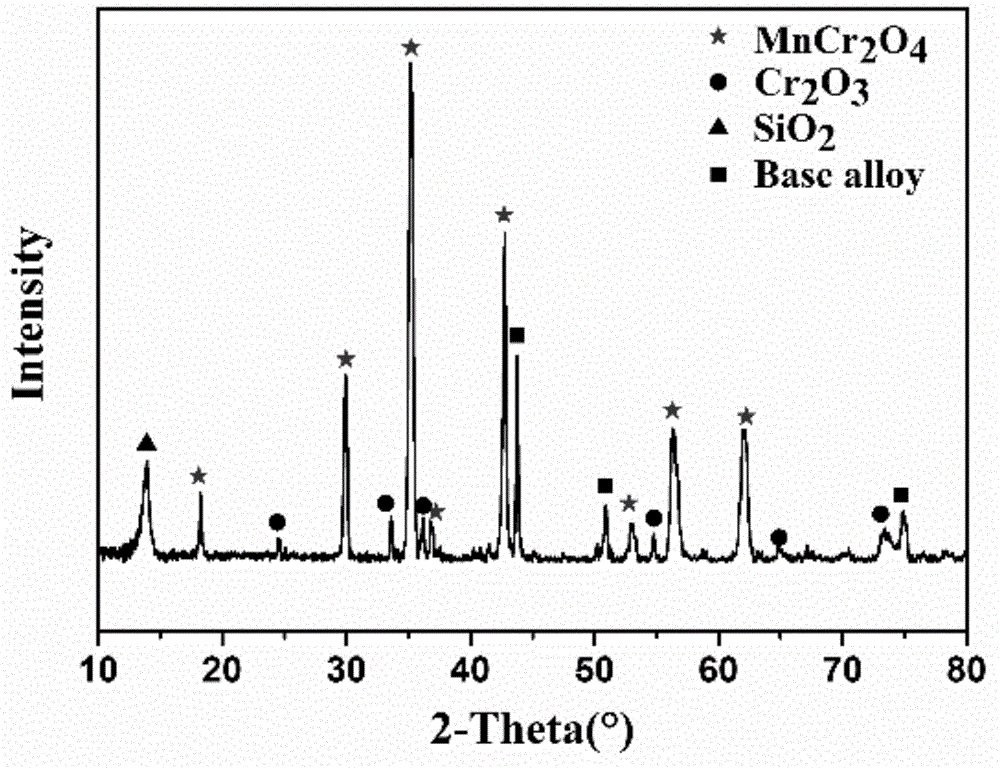

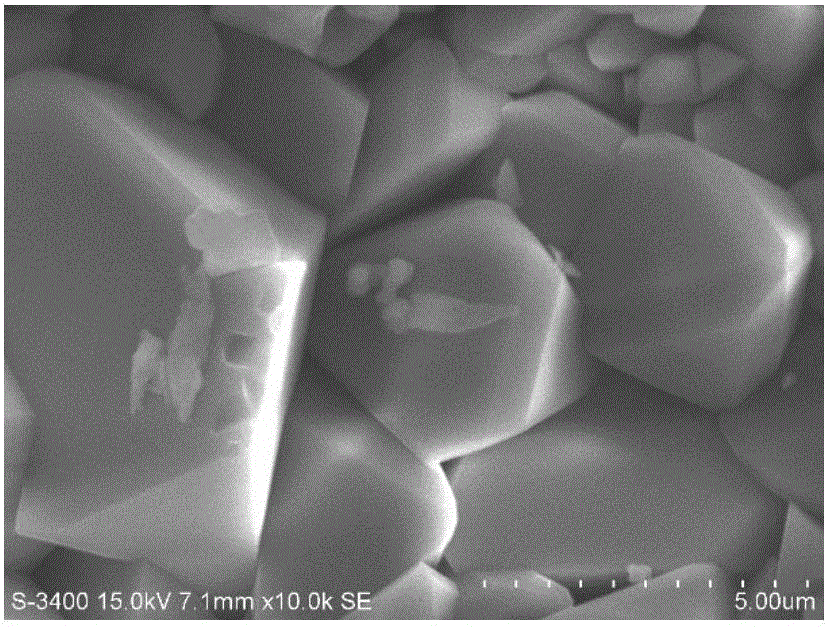

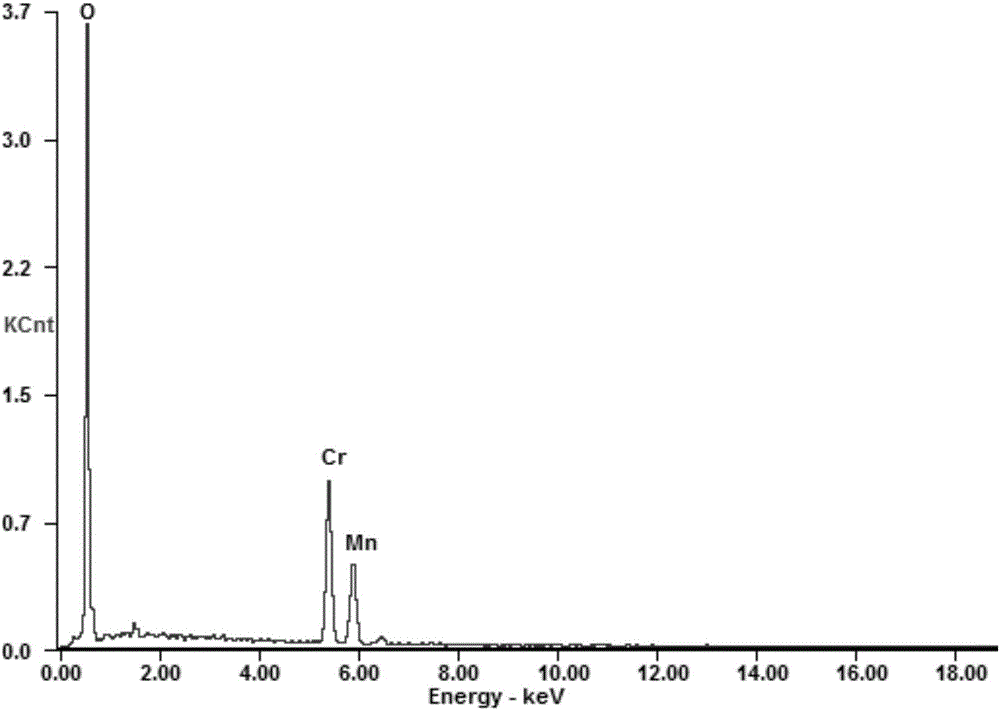

[0043] Example Preparation of ceramic coating on the surface of ZG45Cr35Ni25NbM alloy material.

[0044] The ZG45Cr35Ni25NbM alloy material is treated with alkali and pickling, and after the surface is degreased and derusted, it is put into the manganese infiltration tank together with the manganese infiltration tank, and the manganese infiltration tank is sealed with refractory mud, and then the infiltration tank is put into the muffle furnace Carry out high temperature manganese infiltration treatment. The heat treatment temperature is 950°C, the heating rate is 10°C / min, and the holding time is 6h. When the temperature of the infiltration tank drops to room temperature, take out the alloy material, remove the manganizing agent attached to the surface, put it into the chromizing tank together with the chromizing agent, seal the chromizing tank with refractory mud, and then put the infiltration tank into the muffle furnace high temperature chromizing treatment. The heat tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com