Ultrasonic damage-free checking focusing probe device

A focusing probe, non-destructive testing technology, used in measuring devices, using sonic/ultrasonic/infrasonic waves to analyze solids, and using sonic/ultrasonic/infrasonic waves for material analysis, etc. problem, to achieve the effect of improving resolution and detection sensitivity, easy to carry, convenient and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further illustrate rather than limit the above-mentioned implementation modes of the present invention, the following best embodiments are given in conjunction with the accompanying drawings, so that the details and advantages of the present invention become more obvious.

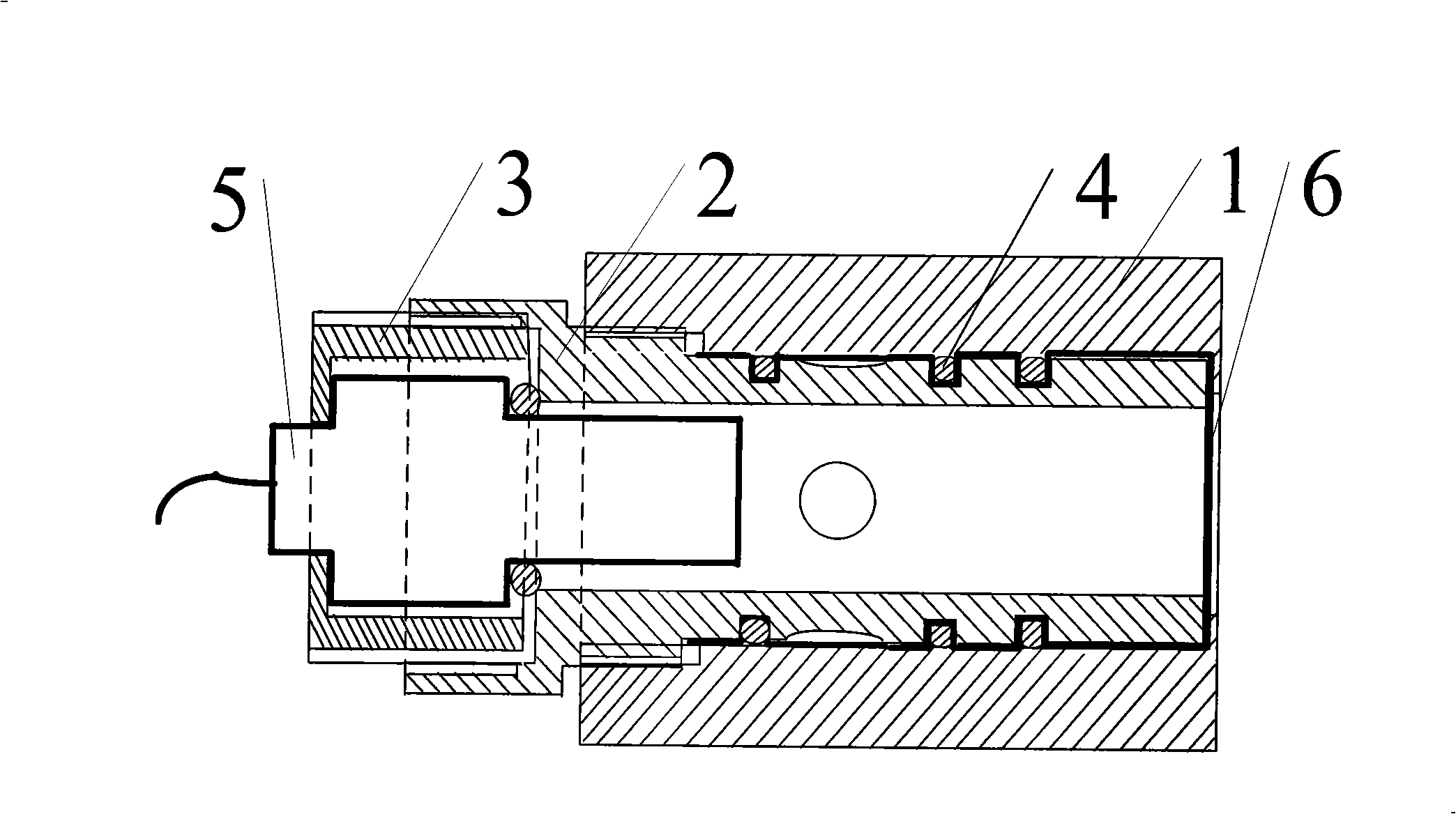

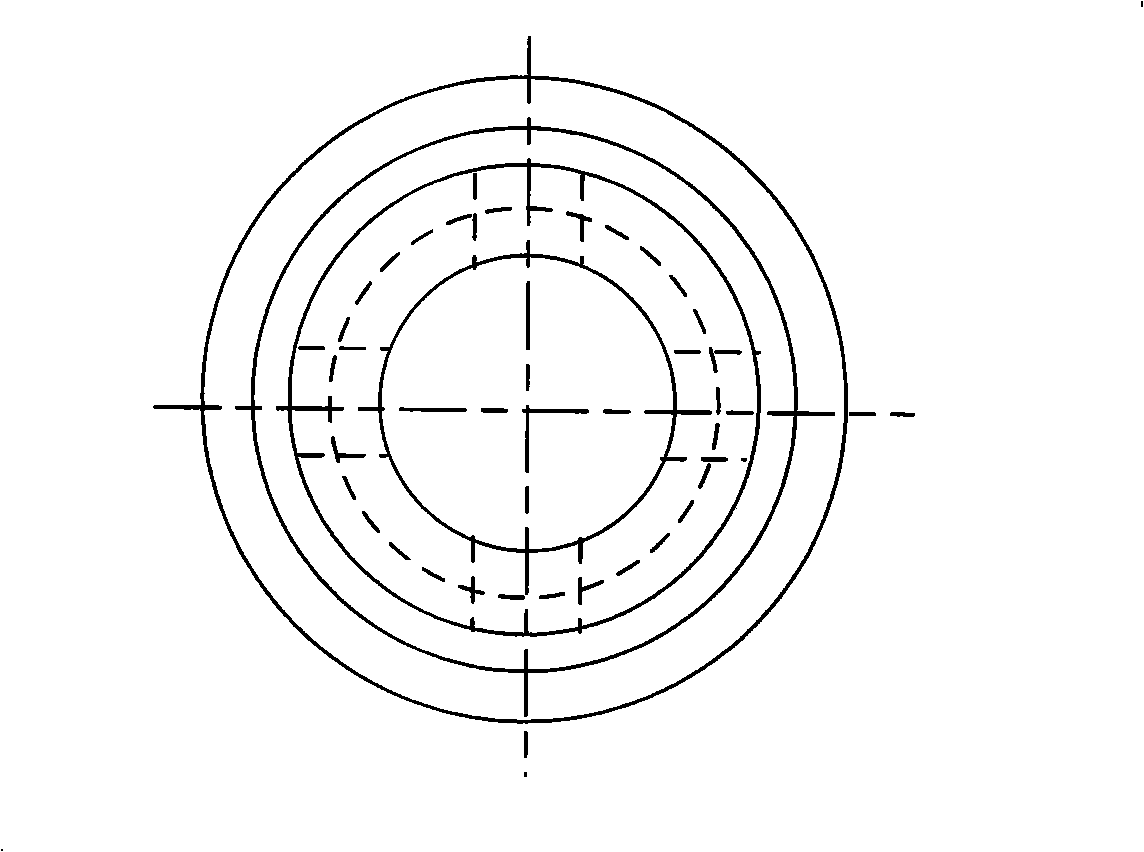

[0018] refer to figure 1 , figure 2 , The device consists of an outer cylinder, an inner cylinder, a sound-permeable membrane, a rubber ring and fasteners. The combination of the outer cylinder 1, the inner cylinder 2 and the fastener 3 is connected through threads. The probe 5 is installed in the hole of the large end of the internal thread in the inner cylinder 2 through the sealing rubber ring 4, and is screwed and fixed by the fastener 3, so that the inner cylinder and the probe are tightly connected. Seal rubber ring 4 to prevent water leakage. Make the probe form a sealed connection with the inner barrel. There is a sound-permeable film 6 at the bottom of the inner cylinder 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com