Preparation method of corundum-mullite composite ceramic push plate

A composite ceramic and mullite technology is applied in the field of preparation of corundum-mullite composite ceramic push plates, which can solve the problems of short service life and poor creep resistance, and achieve the effect of long service life and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The formula of machine-pressed corundum-mullite ceramic push plate is (percentage by weight):

[0050] Mullite particles≤3mm 12

[0051] Alumina particles≤3mm 57.8

[0052] Alumina fine powder≤180 mesh 20

[0053] Mullite fine powder≤320 mesh 0

[0054] Ultrafine silica powder ≤320 mesh 5.7

[0055] Silica-alumina gel 4.5

Embodiment 2

[0057] The formula of machine-pressed corundum-mullite ceramic push plate is (percentage by weight):

[0058] Mullite particles≤3mm 48

[0059] Alumina particles≤3mm 16.6

[0060] Alumina fine powder≤180 mesh 19.4

[0061] Mullite fine powder≤320 mesh 7.5

[0062] Ultrafine silica powder ≤320 mesh 5

[0063] Silica-alumina gel 3.5

[0064] Such as figure 2 Shown, microstructure of corundum-mullite push plate (without aluminum trifluoride).

Embodiment 3

[0066] The formula of machine-pressed corundum-mullite ceramic push plate is (percentage by weight):

[0067] Mullite particles≤3mm 12

[0068] Alumina particles≤3mm 57.8

[0069] Alumina fine powder≤180 mesh 19

[0070] Mullite fine powder≤320 mesh 0

[0071] Ultrafine silica powder ≤320 mesh 5.7

[0072] Silica-alumina gel 4.5

[0073] Aluminum trifluoride 1

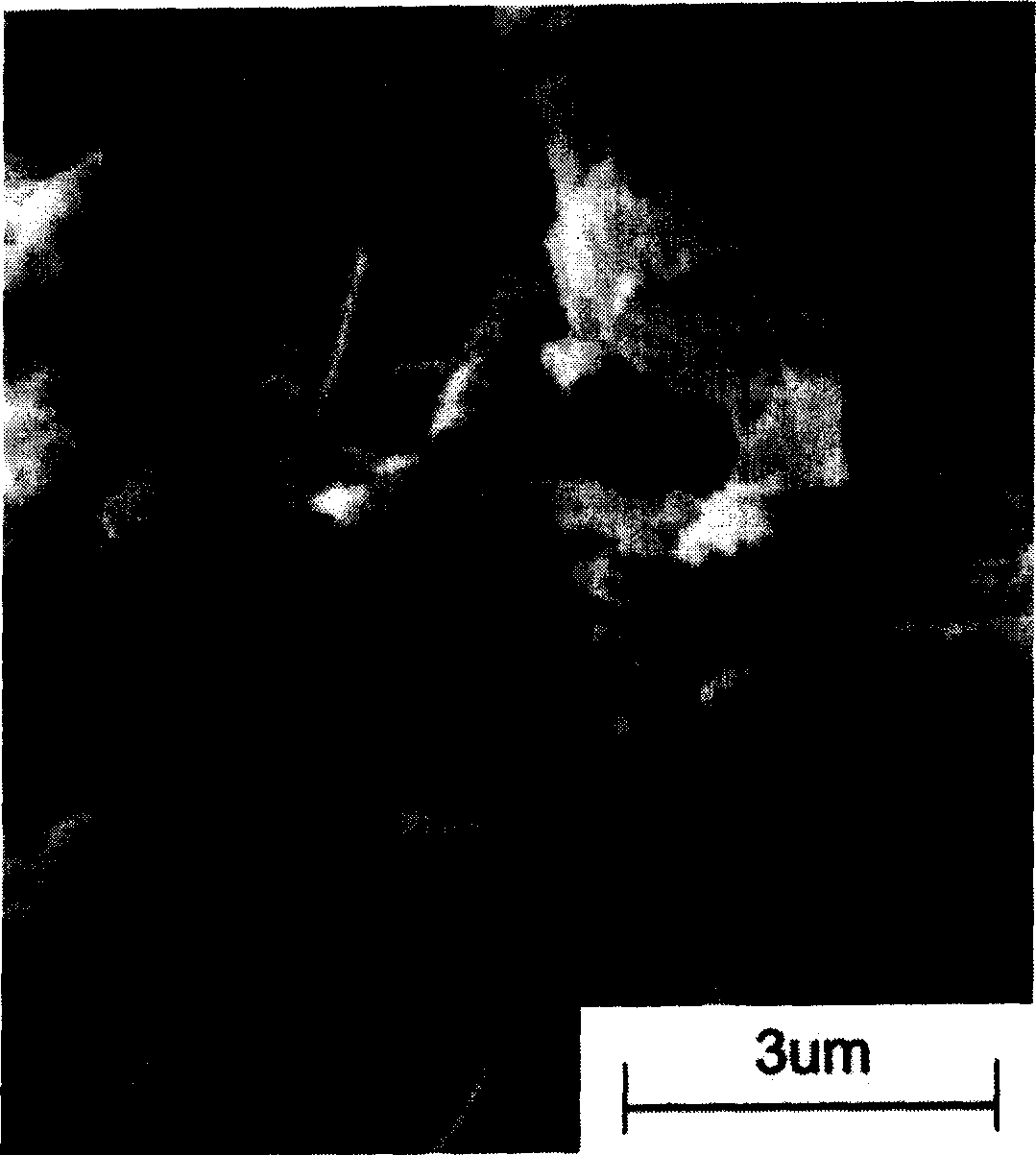

[0074] Such as image 3 Shown, the microstructure of corundum-mullite push plate (containing aluminum trifluoride).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com