Locking device for non-frame glass door

A technology of locking device and glass door, applied in all-glass wings, building locks, buildings, etc., can solve the problems of short process, short service life, increased safety hazards, etc., and achieve improved service life, long service life, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, Features and their functions are described in detail below.

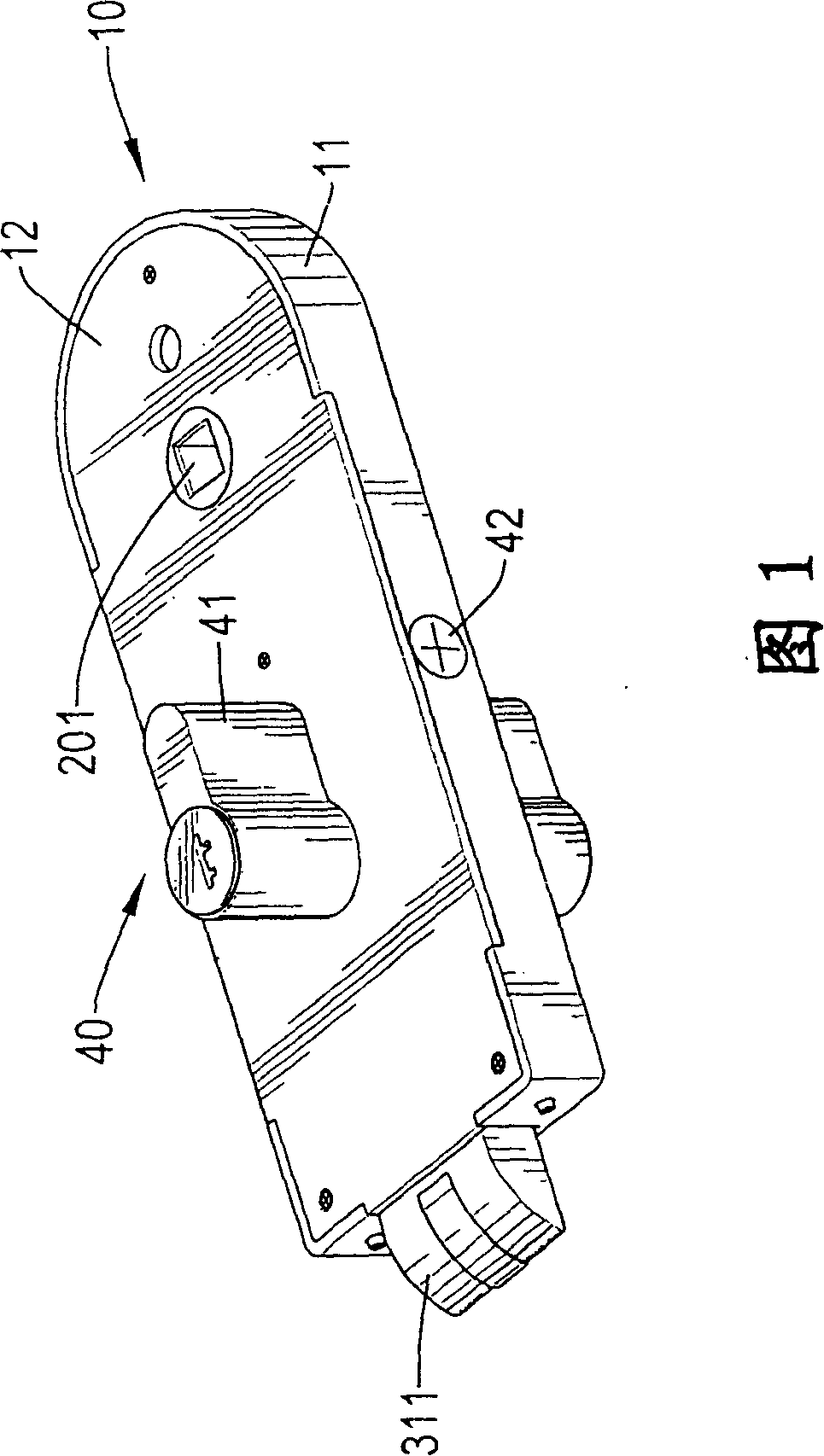

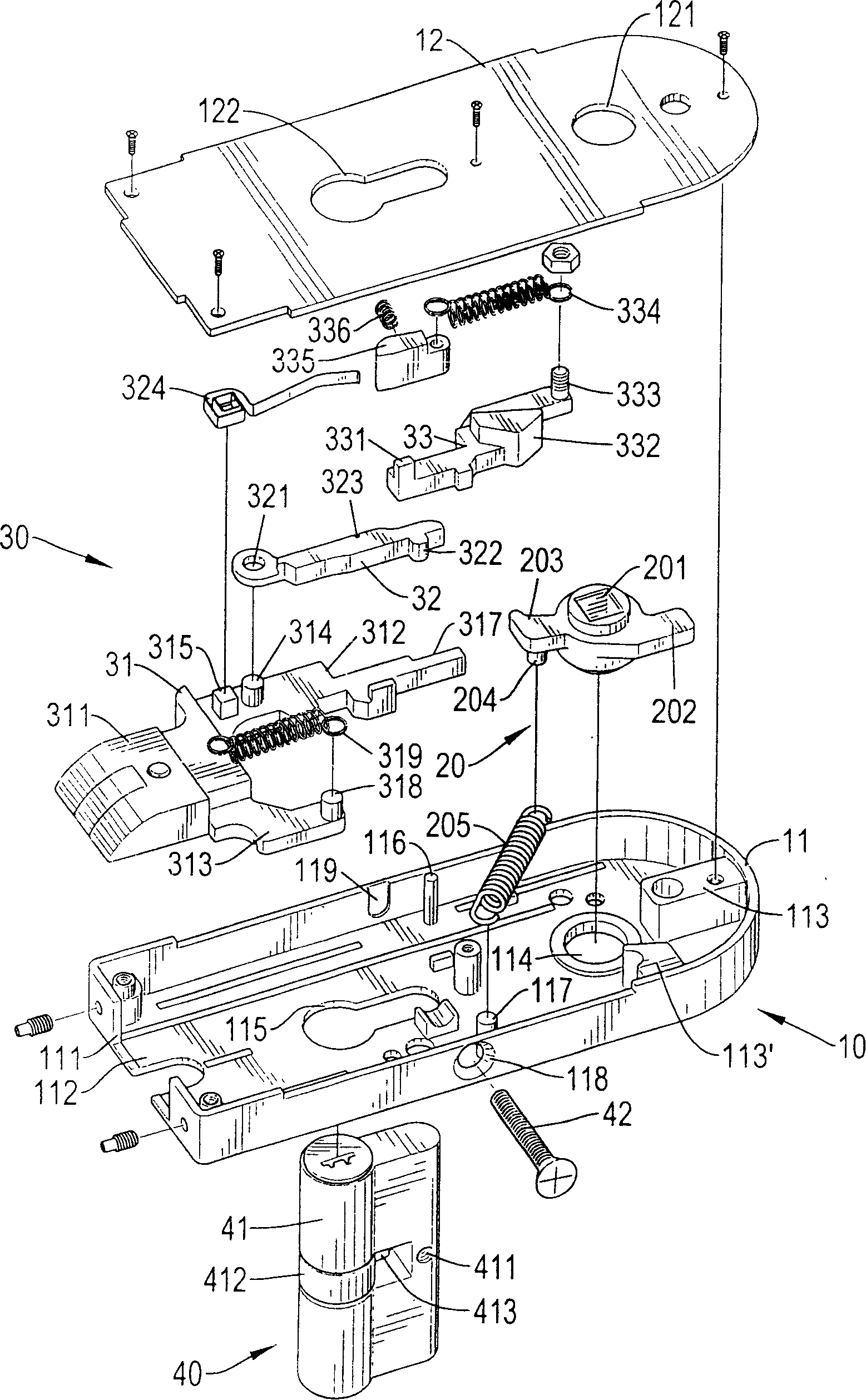

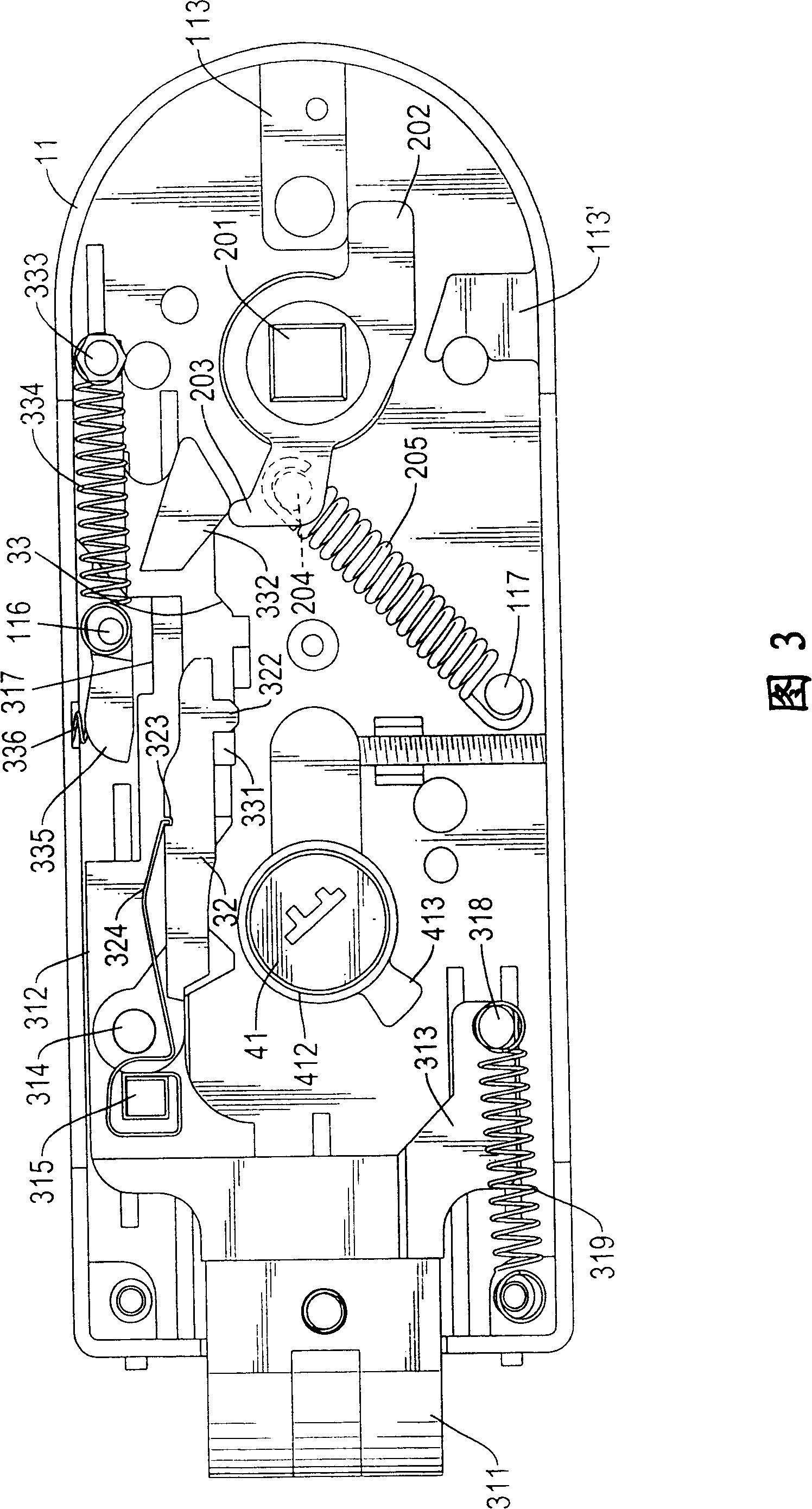

[0089] Please refer to the locking device of the frameless glass door shown in Fig. 1 to Fig. 3 is located on the door, and is provided with a body 10, an operating part 20, an interlocking device 30 and a lock 40, wherein:

[0090]The main body 10 is provided with a box body 11 and a cover plate 12. One end of the box body 11 is provided with an opening 111 and the other end is in a closed shape. A chamber 112 is formed between the opening 111 end and the closed end. An upper limit block 113 is formed on the box body 11 at the end, and an installation hole 114 is perforated on the end edge of the upper limit block 113, and a lower limit block 113' is provided below the installation hole 114, and the box body 11 is in the Between the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com