Electrode slurry

A technology of electrode paste and conductive powder, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of affecting the service life of cells, not meeting energy conservation and environmental protection, and easily damaging silicon wafers, so as to improve service life and reduce Small warpage, the effect of slowing down the degree of shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

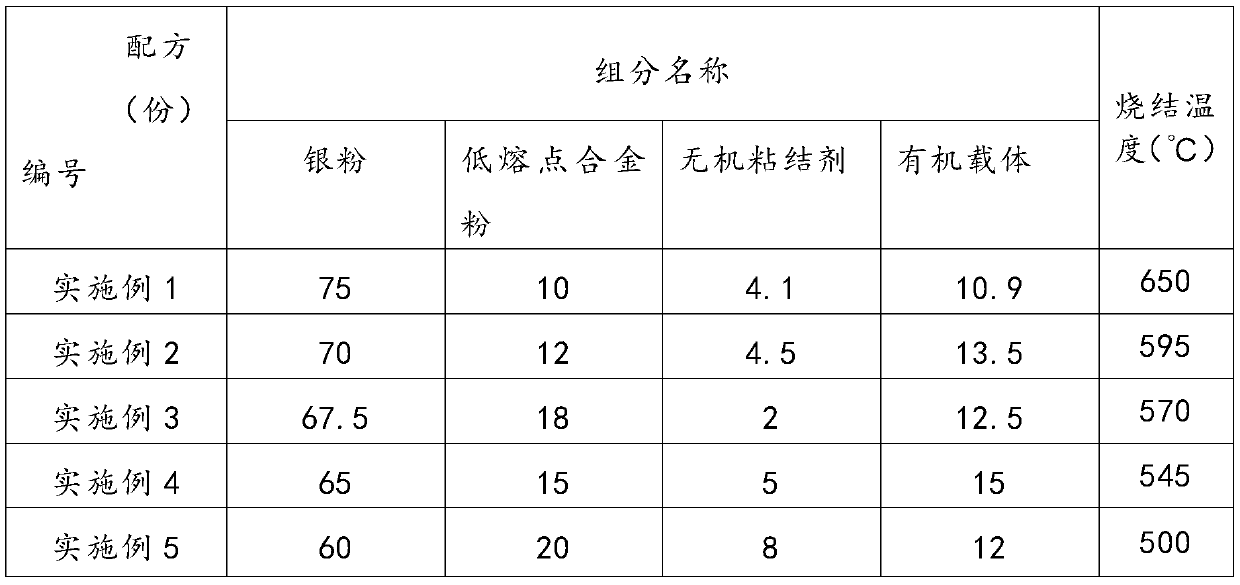

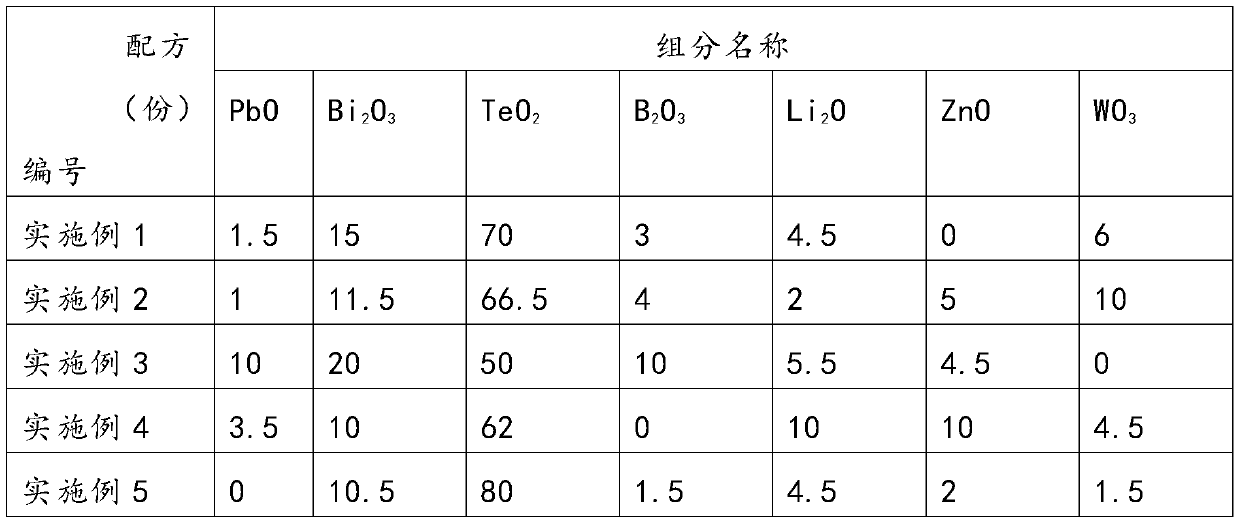

Embodiment 1

[0051] A kind of electrode slurry, its component and weight percentage thereof are: the silver powder of 75 parts, the low melting point alloy powder of 10 parts, the inorganic binding agent of 4.1 parts, the organic vehicle of 10.9 parts. The appearance of silver powder is spherical and hollow spherical, the average particle size is 1.65μm, and the tap density of silver powder is >3.5 g / cm 3 ; The low melting point alloy powder is composed of copper-tin alloy powder and Cu 2 Te, CuTe, Cu 13 Te 7 Composed of copper-tellurium intermetallic compounds, the particle size of the alloy powder is 0.05-0.2 μm; the softening point of the inorganic binder is 350-450 ° C, the average particle size is 2 o 3 , 70 parts of TeO 2 , 3 copies of B 2 o 3 , 4.5 parts of Li 2 O, 6 copies of WO 3 ; The solvent in the organic vehicle is a mixture of alcohol ester dodecyl and butyl carbitol acetate, the thickener is polyvinyl butyral, ethyl cellulose, and the surfactant is alkylphenol polyoxy...

Embodiment 2

[0053] A kind of electrode slurry, its component and percentage by weight thereof are: 70 parts of silver powders, 12 parts of low melting point alloy powders, 4.5 parts of inorganic binders, 13.5 parts of organic vehicles. The shape of the silver powder is spherical or quasi-spherical, the average particle size is 1.25μm, and the tap density of the silver powder is >4.5g / cm 3 ; Low melting point alloy powder is composed of indium tin alloy powder and Cu 2 Composed of Te copper-tellurium intermetallic compound, the particle size of the alloy powder is 0.05-0.5 μm; the softening point of the inorganic binder is 350-450 ° C, the average particle size is 2 o 3 , 66.5 parts of TeO 2 , 4 copies of B 2 o 3 , 2 parts of Li 2 O, 4.5 parts of ZnO, 10 parts of WO 3 ; The organic solvent in the organic carrier is a mixture of terpineol, DBE (mixed dibasic acid ester), the thickener is polyvinyl butyral, and the surfactant is fatty alcohol polyoxyethylene ether, and the rheology addi...

Embodiment 3

[0055] A kind of electrode slurry, its component and weight percent are: 67.5 parts of silver powders, 18 parts of low-melting point alloy powders, 2 parts of inorganic binders, 12.5 parts of organic vehicles. The shape of the silver powder is spherical or quasi-spherical, the average particle size is 1.35μm, and the tap density of the silver powder is >4.5g / cm 3 The low melting point alloy powder is composed of bismuth-tin alloy powder, indium-tin alloy powder and CuTe copper-tellurium intermetallic compound. The particle size of the alloy powder is 0.05-0.2 μm; the softening point of the inorganic binder is 350-450 °C, and the average particle size 2 o 3 , 50 parts of TeO 2 , 10 copies of B 2 o 3 , 5.5 parts of Li 2 O, 4.5 parts of ZnO; the solvent in the organic vehicle is a mixture of butyl carbitol, butyl carbitol acetate and alcohol ester twelve, the thickener is cellulose acetate butyrate, and the surfactant is castor oil Polyoxyethylene ether, the rheology additiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com