A kind of passive emitter solar cell front silver paste

A technology of solar cells and passivated emitters, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of passivation layer damage, insufficient low-temperature sintering window, limiting the efficiency potential of PERC cells, etc., to widen the sintering window, The effect of good low temperature sintering characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

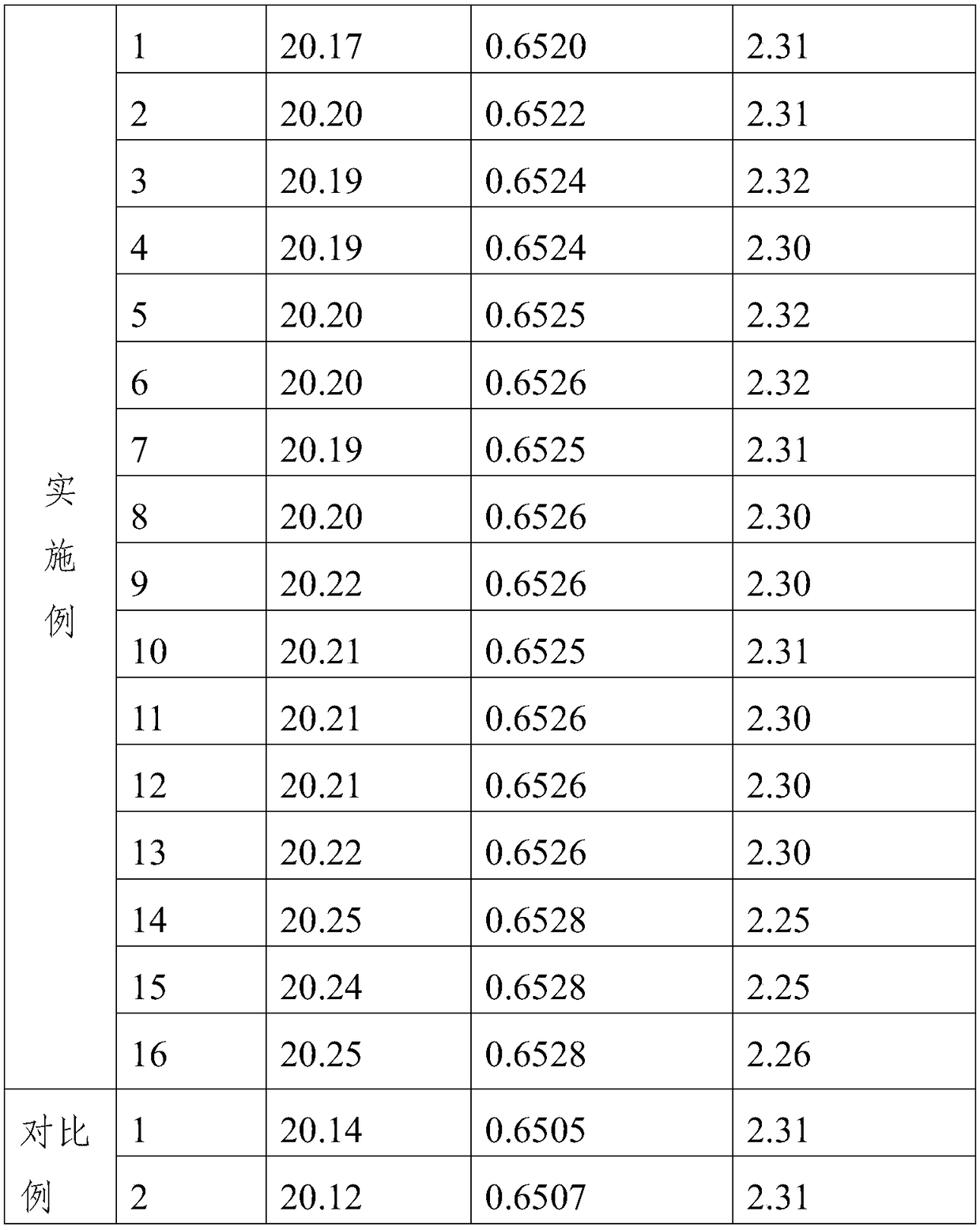

Examples

Embodiment 1

[0024] In the embodiment 1, the inorganic binder is the disclosed inorganic binder (PbO78%, SiO 2 10%, Al 2 o 3 2%, MgO 1%, ZnO 9%); wherein the organic solvent in the organic vehicle is diethylene glycol ethyl ether acetate, and the weight percentage of the organic solvent in the organic vehicle is 85%, does not include surfactant and rheological agent.

[0025] The specific surface area of embodiment 1 silver powder is 1~2m 2 / g; tap density 2.5~3.5g / cm 3 . The silver powder has a conventional particle size of 0.2-1.7 μm; the thickener is alkyd resin, and the sintering accelerator is sodium hexafluoroantimonate.

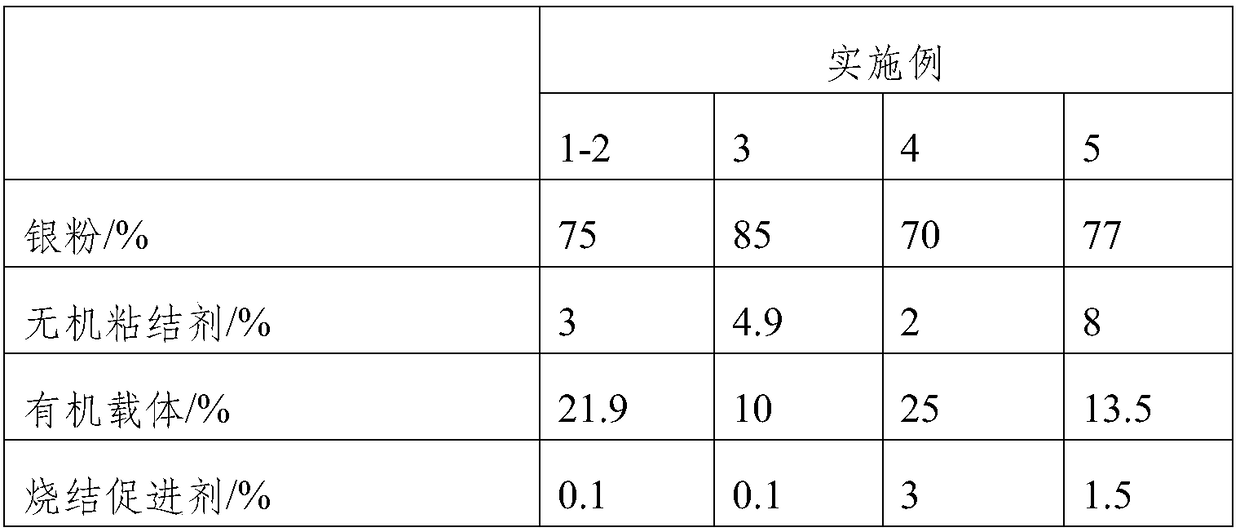

[0026] Embodiment 2-5 inorganic binding agent is PbO5%, Bi 2 o 3 50%, B 2 o 3 20%, SiO 2 14%, Al 2 o 3 3%, ZnO1%, CaO7%.

Embodiment 6

[0027] Embodiment 6 component is the same as embodiment 5, and difference only is that the composition of inorganic binder is: PbO0.5%, Bi 2 o 3 80%, B 2 o 3 5%, SiO 2 5%, Al 2 o 3 3%, ZnO2%, CaO4.5%;

Embodiment 7

[0028] The component of embodiment 7 is the same as that of embodiment 5, and the only difference is that the composition of the inorganic binder is: PbO2%, Bi 2 o 3 55%, B 2 o 3 10%, SiO 2 14%, Al 2 o 3 5%, ZnO6%, CaO8%.

[0029] By adjusting the weight percentage of the components of the inorganic binder, the sintering peak temperature changes accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com