A casting special-shaped crimping clamp

A crimping and special-shaped technology, applied in the direction of clamping/spring connection, multi-conductor connectors, electrical components, etc., can solve the problems of galvanic corrosion, poor reliability of crimping quality, poor contact, etc., and achieve oxidation resistance and corrosion resistance Strong performance, stable and reliable performance, and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these embodiments are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to the conditions of specific manufacturers, and implementation conditions not specified are usually conditions in routine experiments.

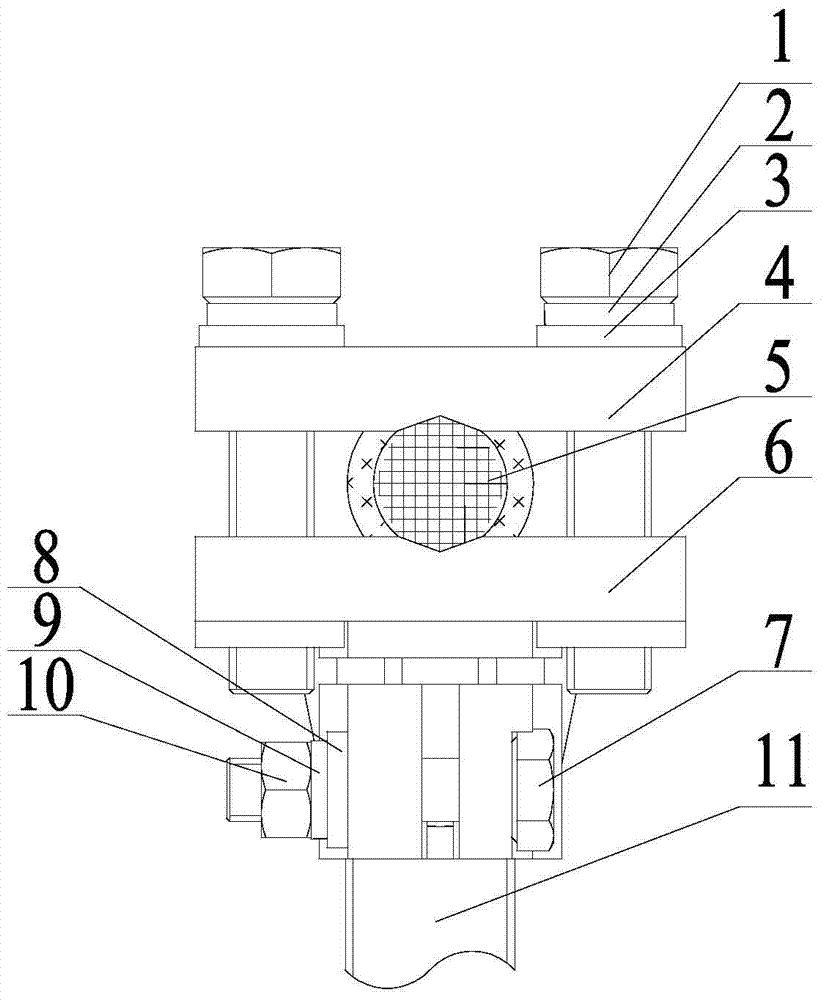

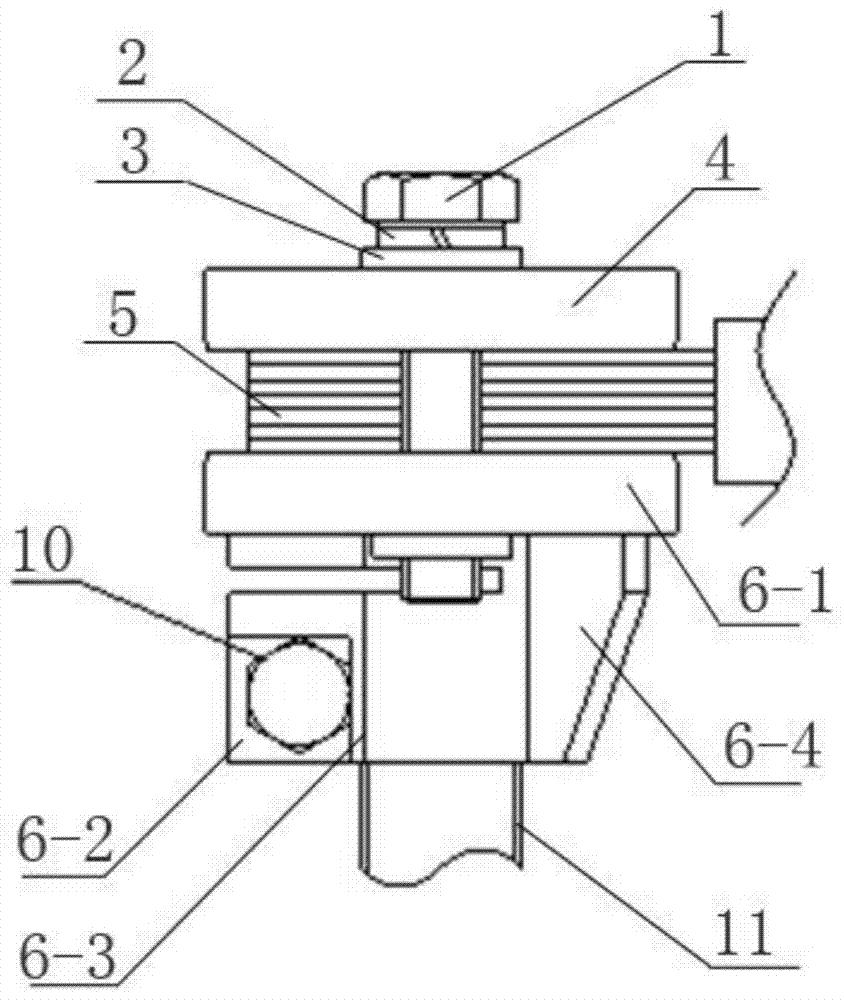

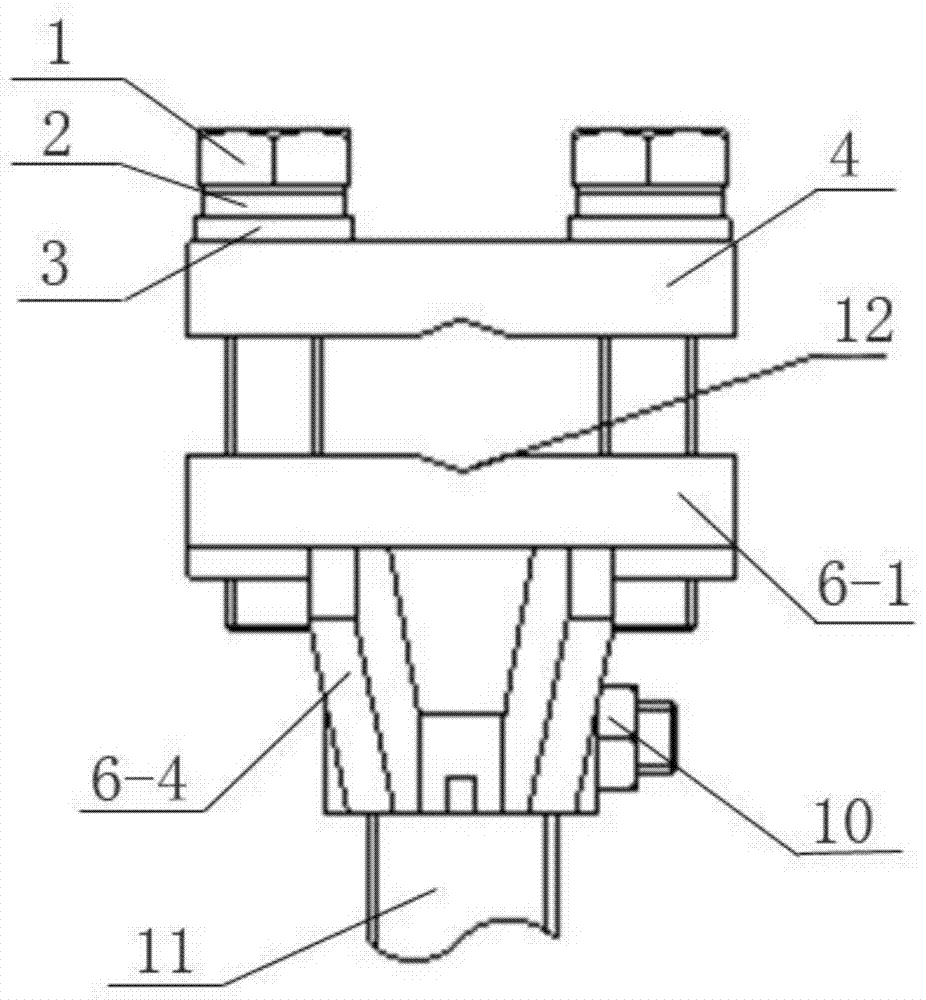

[0025] See Figure 1-3 , Is an embodiment of a casting special-shaped crimping clamp of the present invention, which includes an upper crimping plate 4 and a lower crimping plate 6 that are copper castings or copper alloy castings, and the conductor 5 is pressed on the upper crimping plate Between 4 and the lower crimping plate 6, the lower crimping plate 6 is connected to the terminal bolt 11. The adoption of this structure can ensure reliable contact between the conductor 5, the terminal bolt 11 and the crimping pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com