Patents

Literature

33results about How to "Save thickness space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solid electrolytic capacitor and manufacture method thereof

InactiveCN101527203AReduce the overall heightMeet the higher requirements for thinnerSolid electrolytic capacitorsCapacitor terminalsElectrolysisEngineering

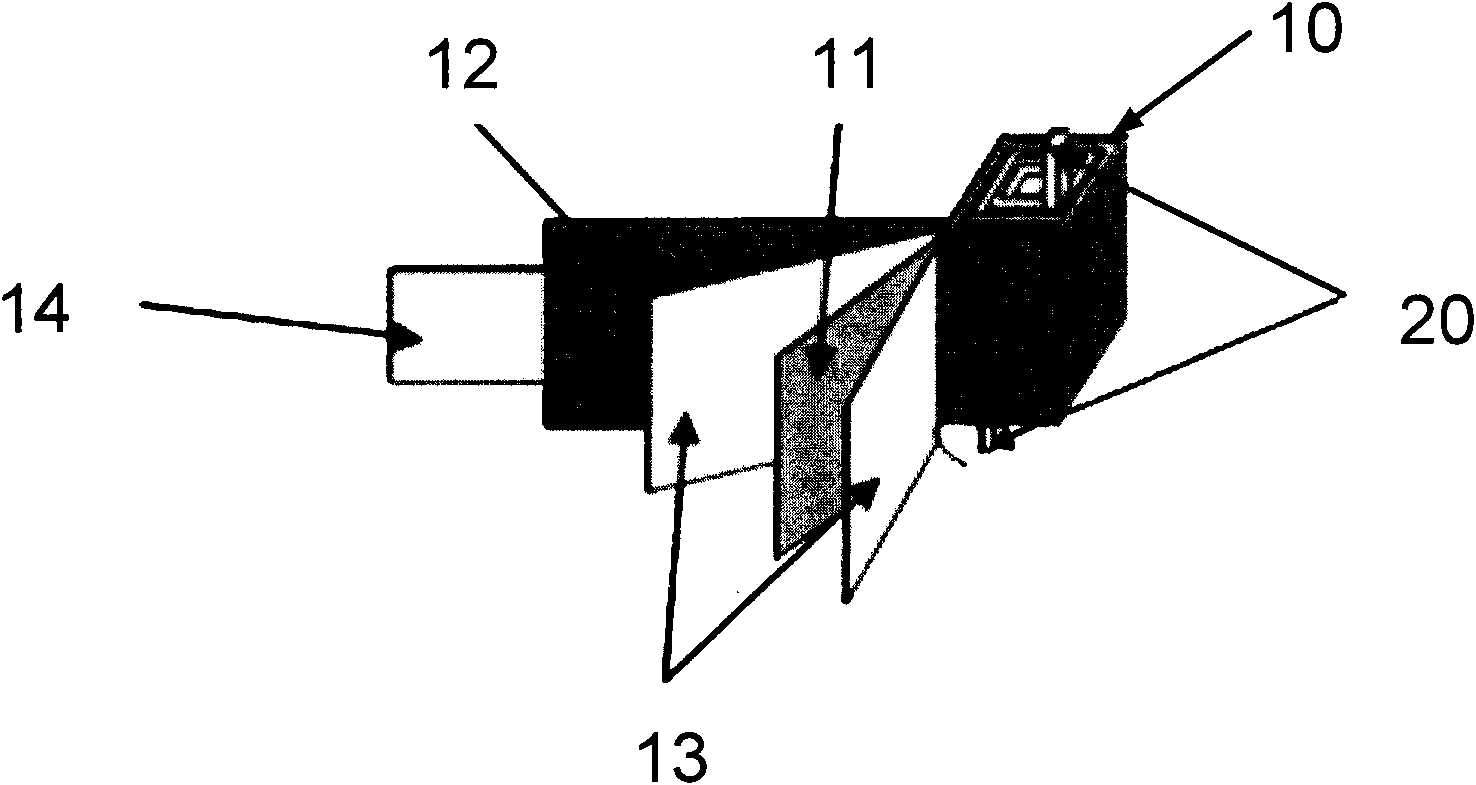

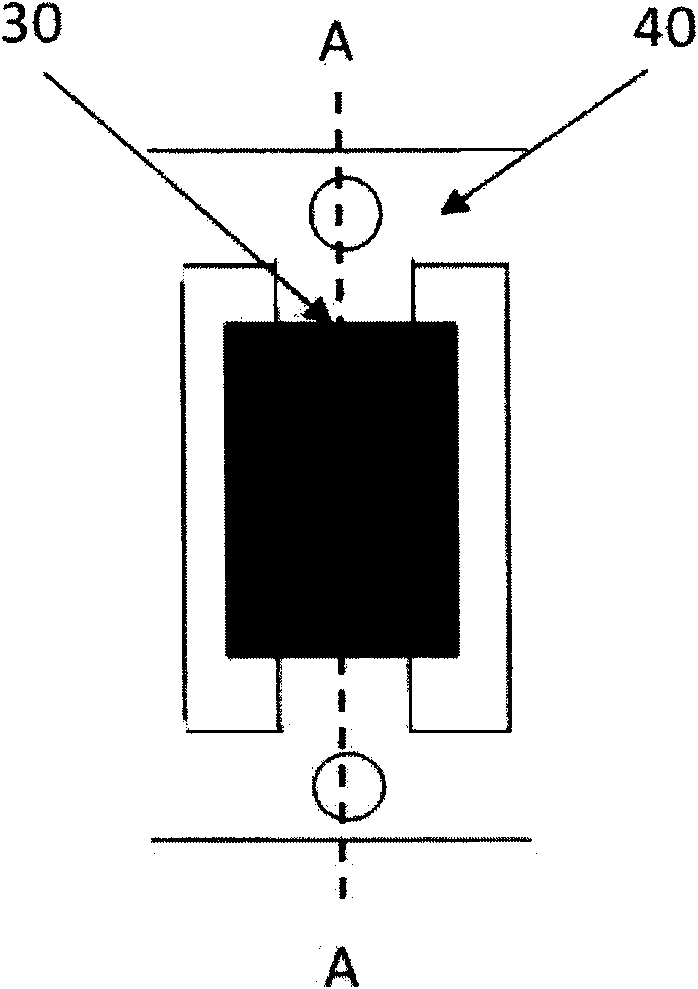

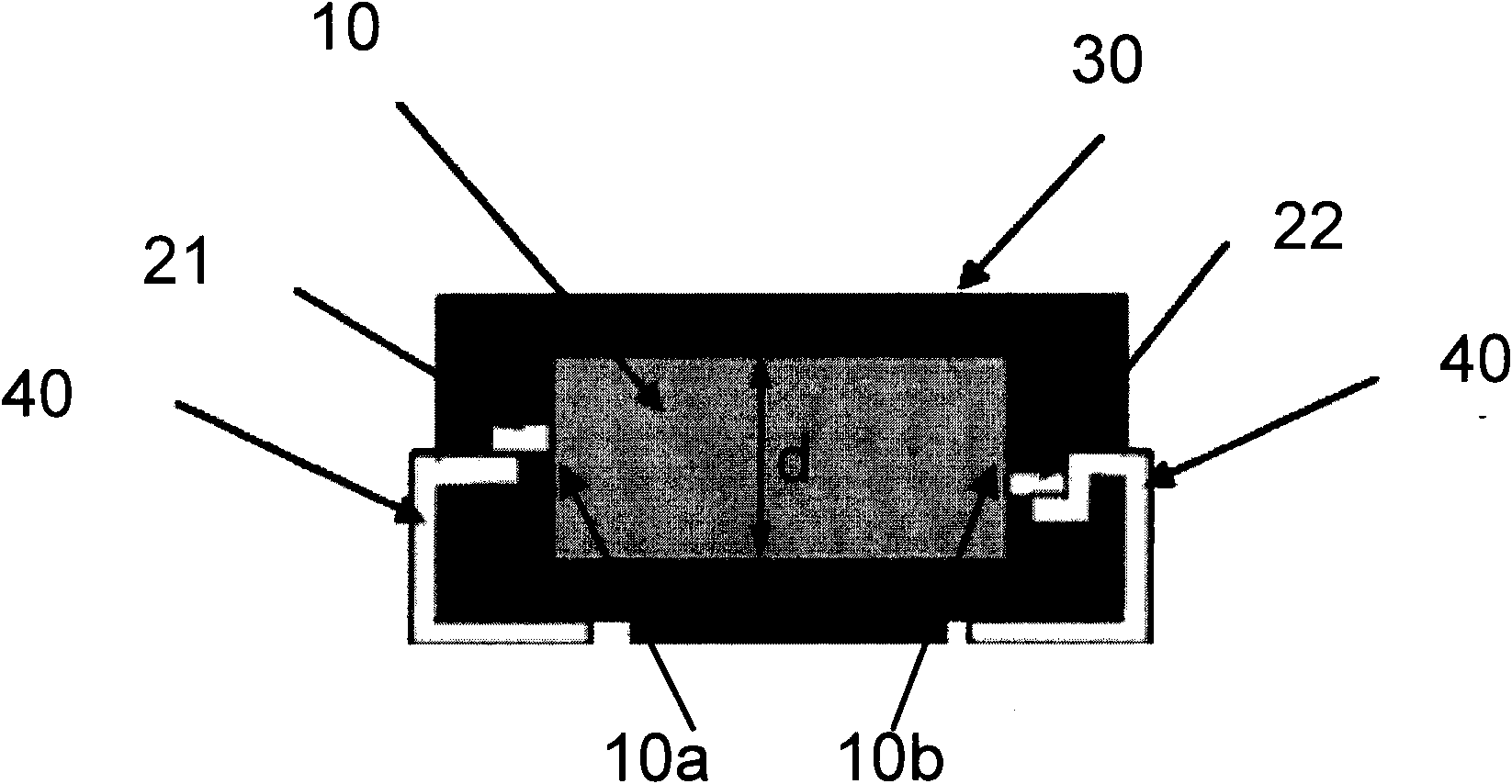

The invention provides a solid electrolytic capacitor and a manufacture method thereof. The solid electrolytic capacitor comprises anode foil, cathode foil, a rectangular core package, electrode extraction terminals and a packaging body, wherein the rectangular core package is formed by coiling a solid electrolytic layer clamped between the anode foil and the cathode foil, and the electrode extraction terminals are connected with the core package which is coated by the packaging body. The method comprises the following steps: providing the anode foil, the cathode foil and electrolytic paper which are cut into special widths; connecting the electrode extraction terminals with the anode foil and the cathode foil; coiling the anode foil, the cathode foil and the electrolytic paper into a cylindrical stud; deforming the cylindrical stud into the rectangular core package; forming the solid electrolytic layer between the anode foil and the cathode foil of the core package; connecting the electrode extraction terminals of the core package with a pin frame; and packaging the core package. The technical scheme can realize an SMD solid electrolytic capacitor with lower height so as to occupy a smaller thickness space and satisfy the higher requirements for thin electronic equipment.

Owner:FUJITSU MEDIA DEVICES SUZHOU

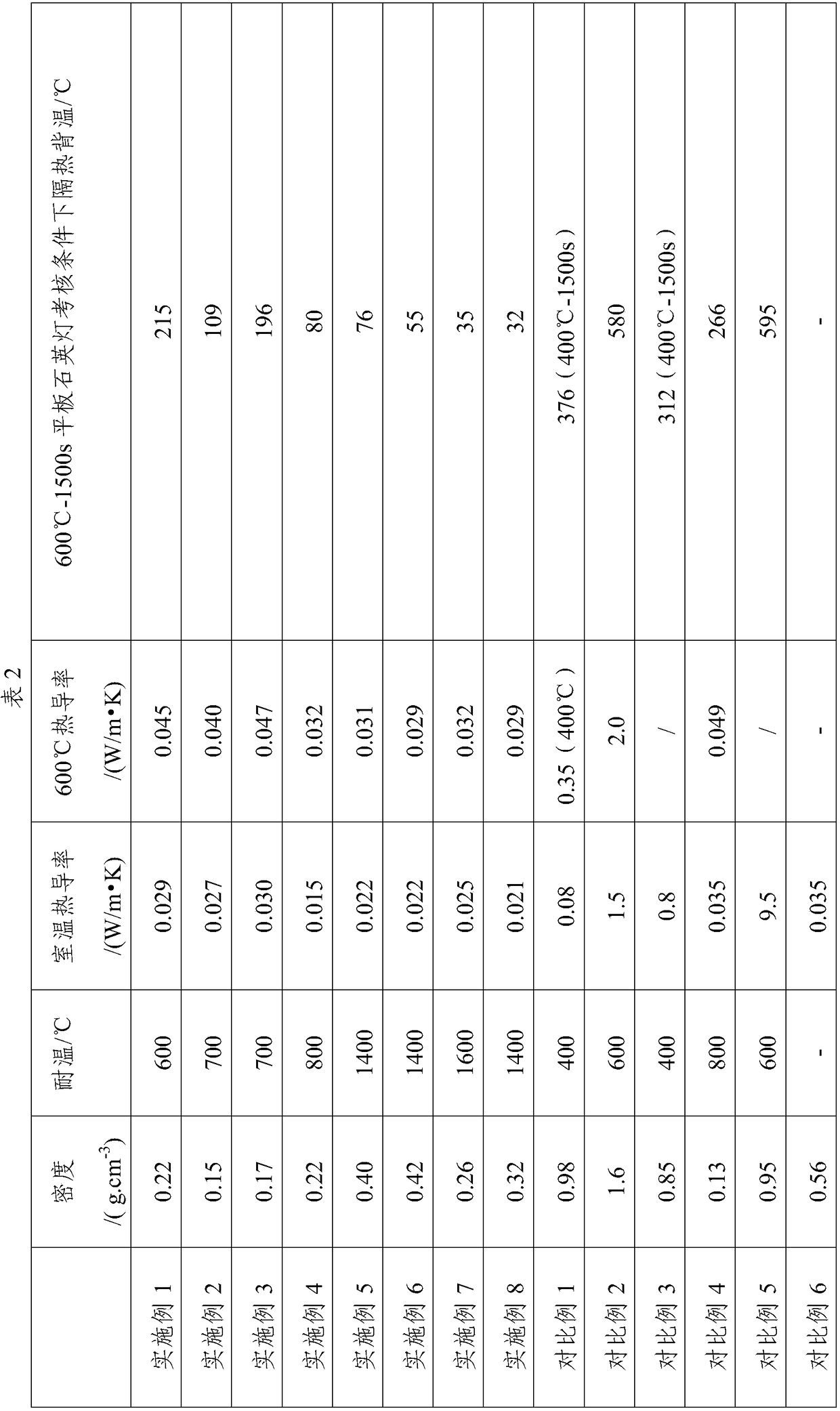

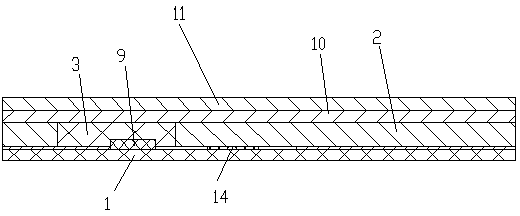

Multi-layer composite thermal protective material and preparation method thereof

PendingCN109177386AShort preparation cycleSolving Thermal Protection IssuesSynthetic resin layered productsPaper/cardboard layered productsThermal insulationTemperature resistance

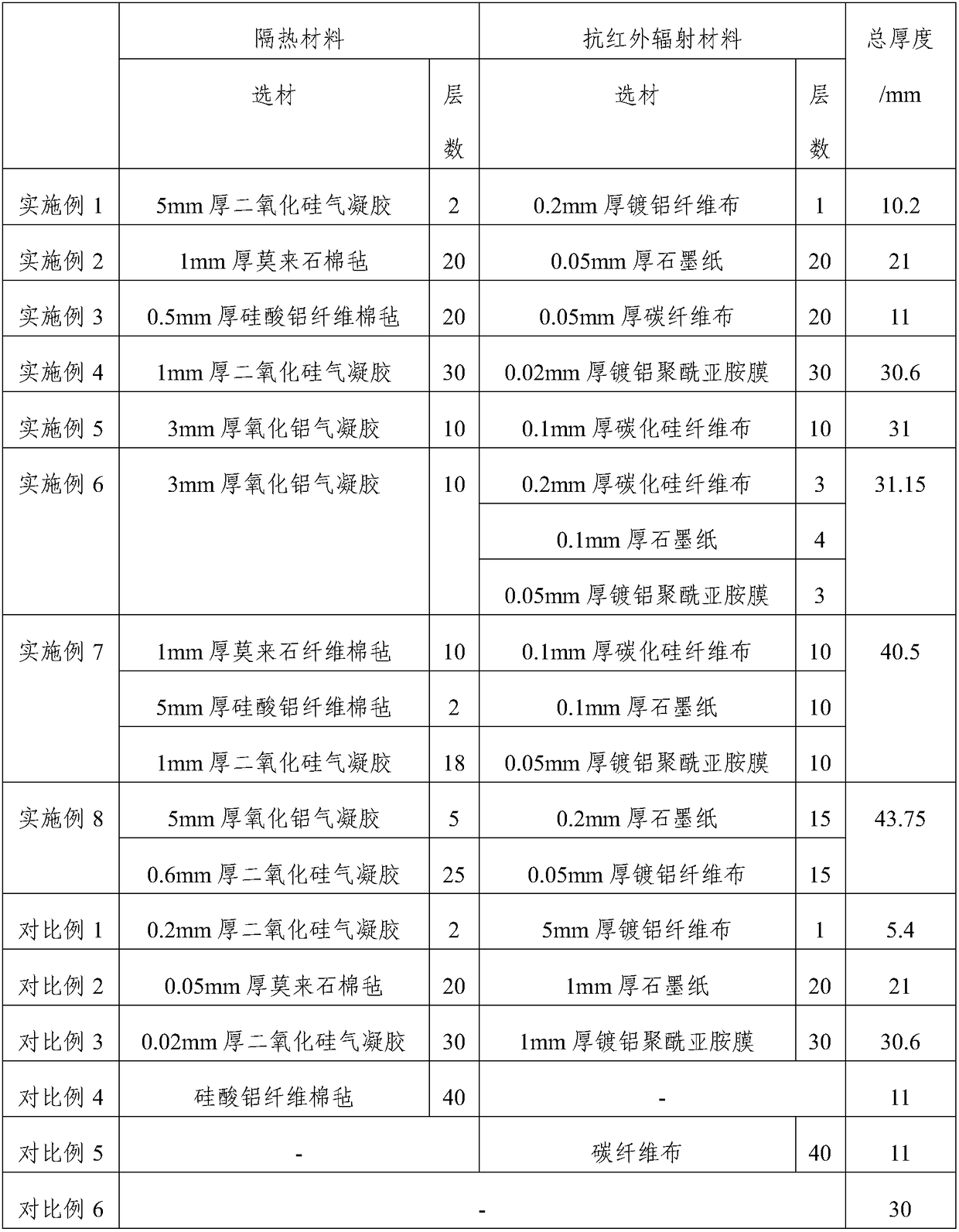

The invention relates to a multi-layer composite thermal protective material and a preparation method thereof. The thermal protective material is prepared by alternately laminating thermal insulationmaterials with the first thickness and anti-infrared radiation materials with the second thickness. The multi-layer thermal protective material is formed by combination of thermal insulation, thermalprevention, gas convection resistance and infrared radiation resistance multi-heat insulation mechanism, and the purposes of high performance heat insulation, thickness space saving and lightweight weight reduction are achieved. The thermal protective material is green and environmentally friendly in production process, is a thermal protective material with high price / performance ratio, has the highest temperature resistance reaching up to 1600 DEG C, and can be applied in industrial kilns, metallurgy, heat supply network pipelines, aerospace and other fields.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

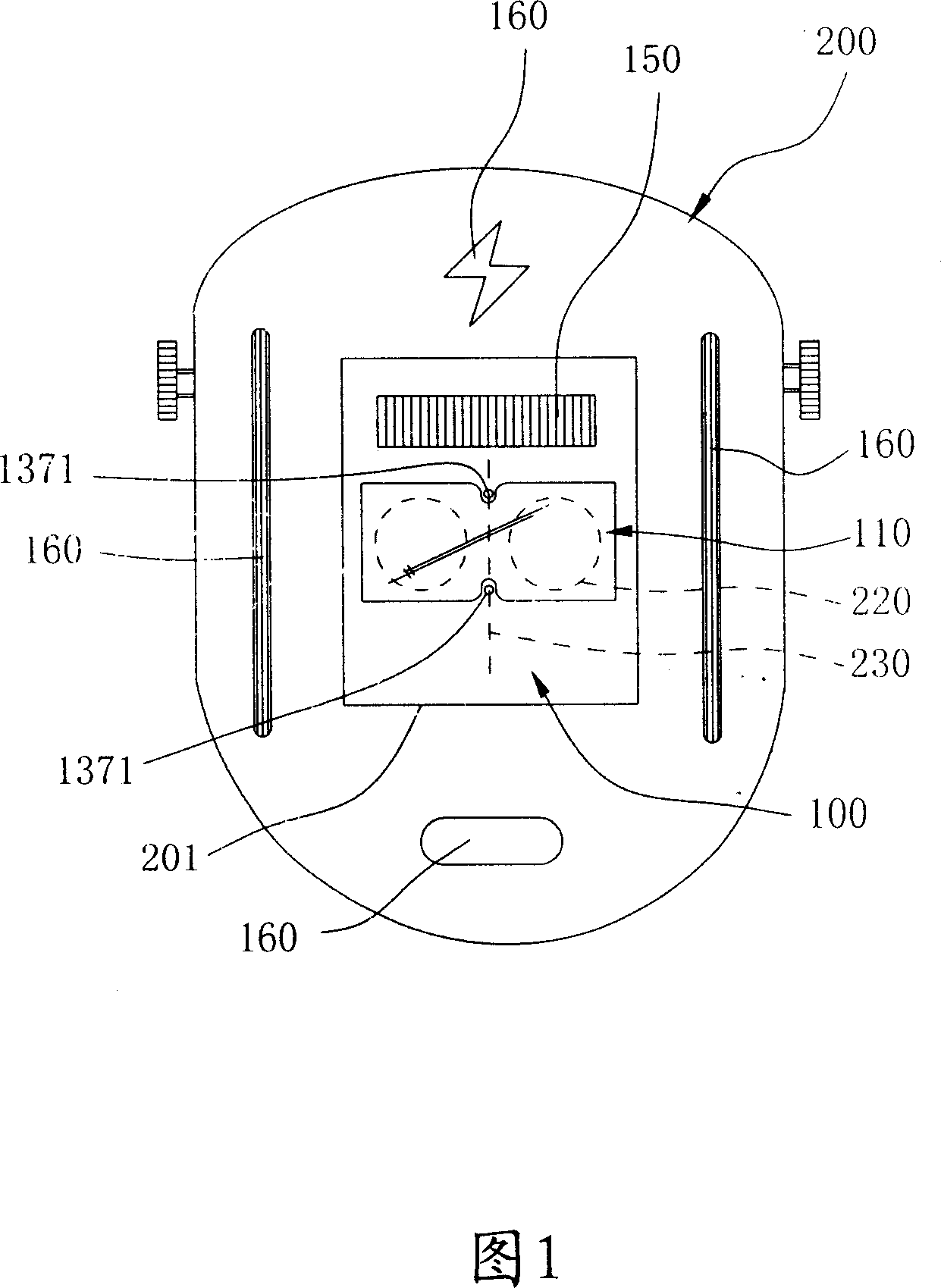

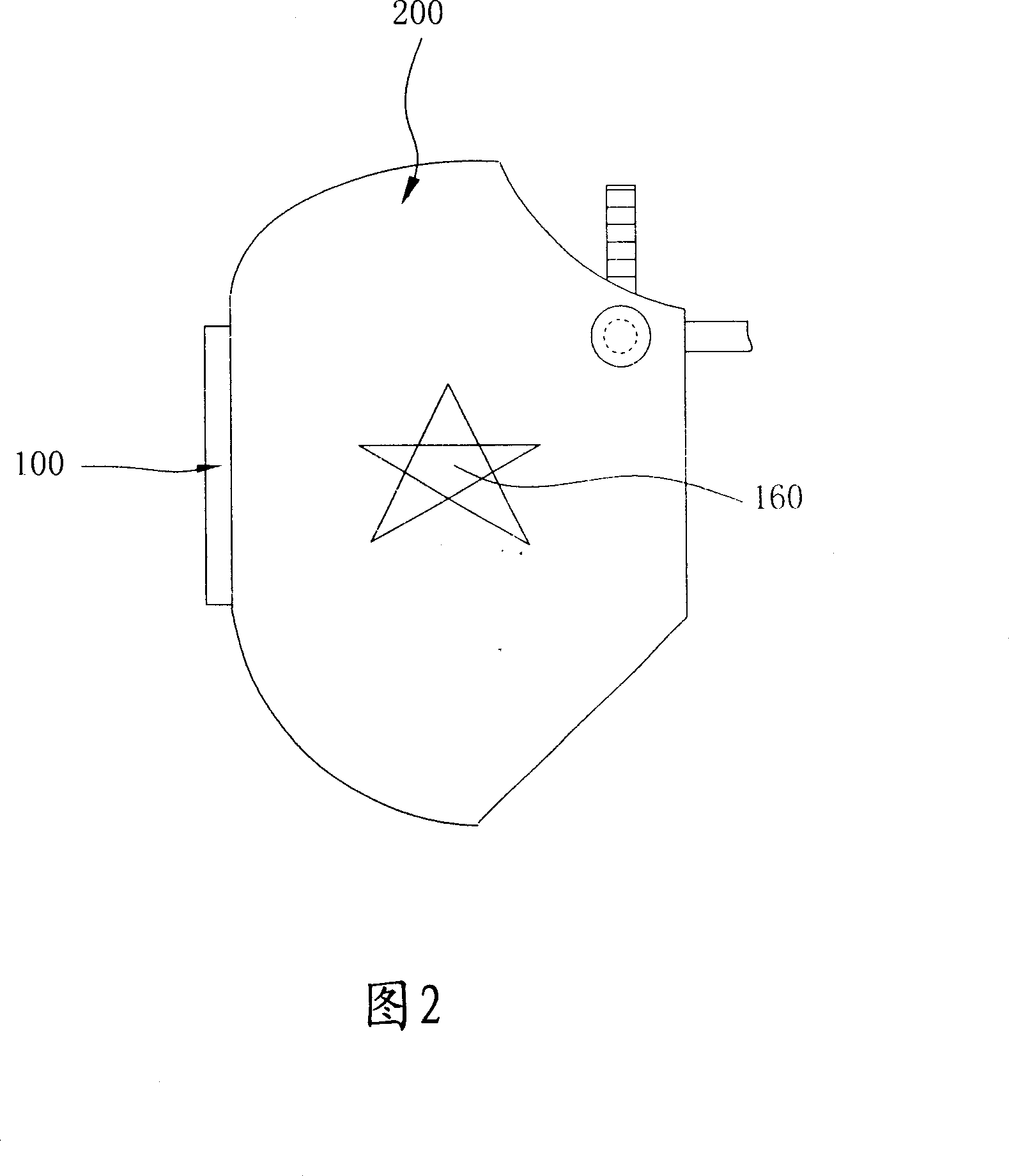

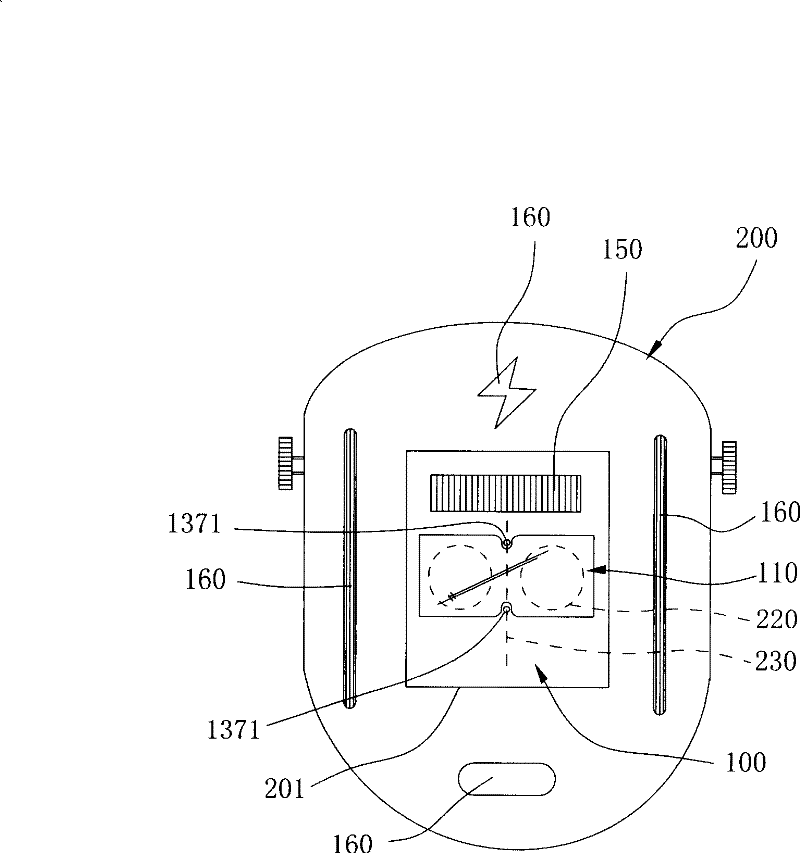

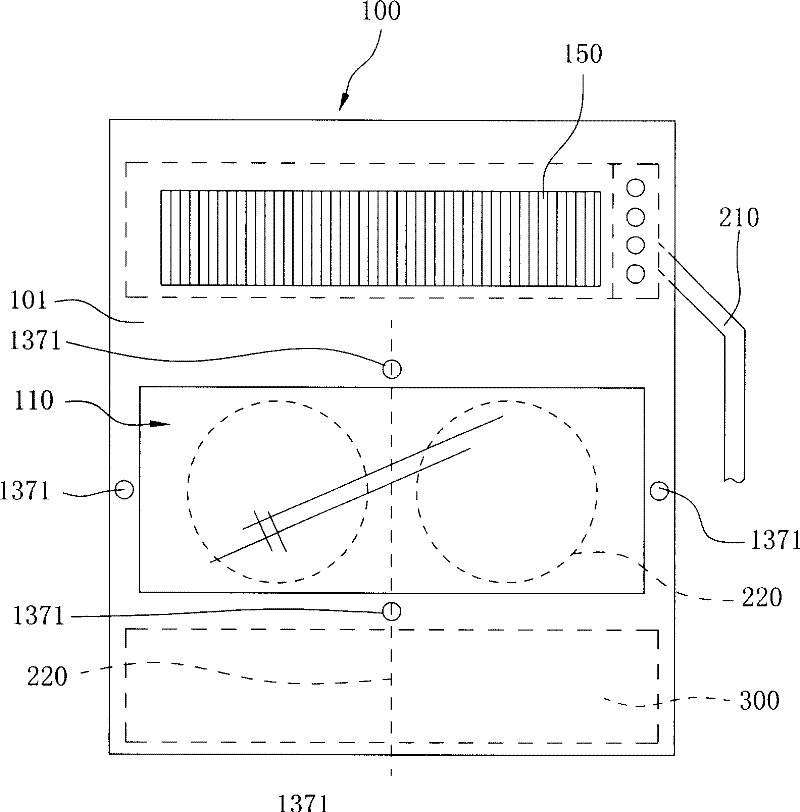

Safety goggles with phonetic output

InactiveCN101088481AReduce distractionsReduce power consumptionGogglesEye-masksDisplay deviceOutput device

The present invention relates to one kind of safety goggles with phonetic output. The safety goggles include one goggles body, light filters, one display device, and one phonetic output device. The phonetic output device connected electrically to the display device includes one main controller, one power source unit, one sound output control unit, one sensing circuit with at least sensor set on the goggles, and one driving circuit connected electrically to the light filters. It has the welding operation state output to the phonetic output device and the plate display, so that the operator can obtain welding operation state indication auditorily and visually.

Owner:杨雅琪

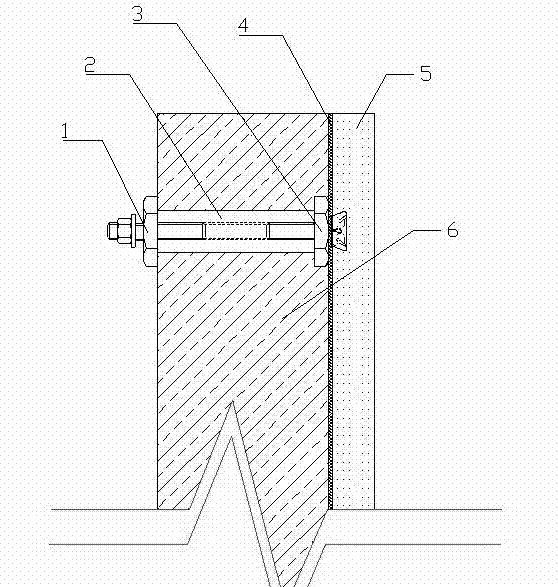

Insulation decoration integrated exterior wall

InactiveCN103195189AReduce energy consumptionAchieve the goal of energy saving and emission reductionCovering/liningsWallsGlass fiberInsulation layer

An insulation decoration integrated exterior wall comprises a plate-shaped insulation layer and a facing layer which are fixedly attached through connecting members, every connecting member is pre-embedded in the facing layer, penetrates through the insulation layer and is fastened and fixed on the side surface of the insulation layer, and heavy-duty glass fiber cloth is arranged between the insulation layer and the facing layer and is attached to the facing layer through adhesive. The insulation decoration integrated exterior wall can effectively solve the problem of energy source loss caused by indoor and outdoor temperature difference in summer and winter, has integrated functions of insulation and decoration, can greatly reduce the structural weight to improve usage safety of buildings, and is applicable to new construction as well as energy saving transformation of old buildings.

Owner:UNIVERSAL MARBLE & GRANITE DONGGUAN

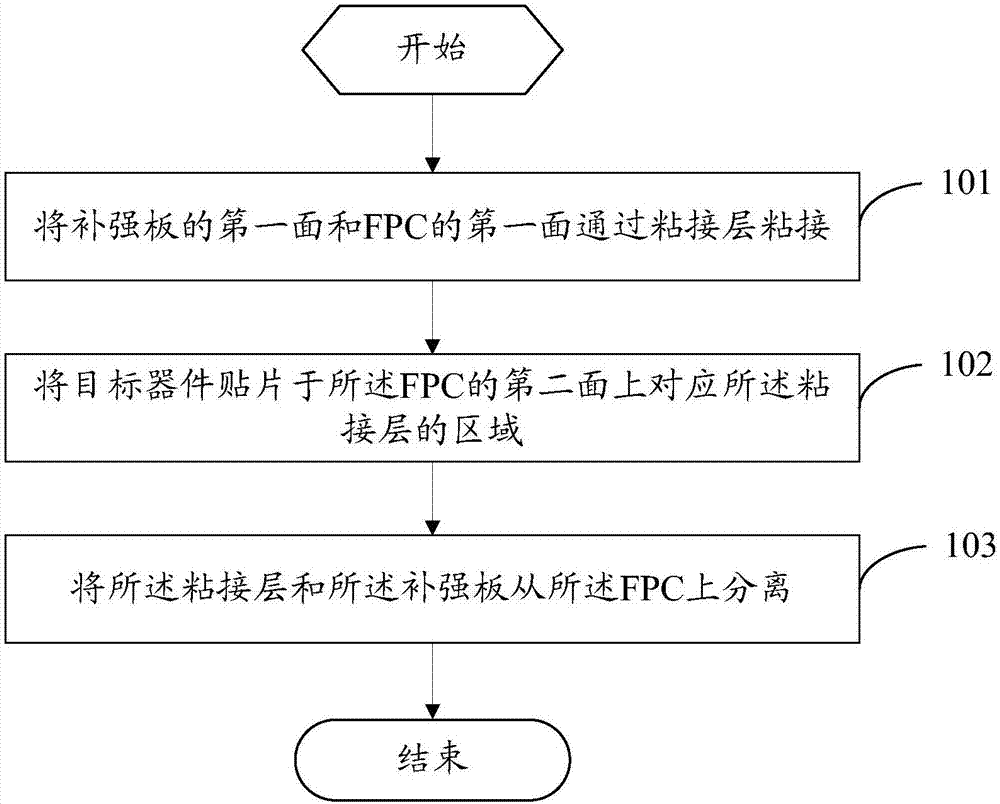

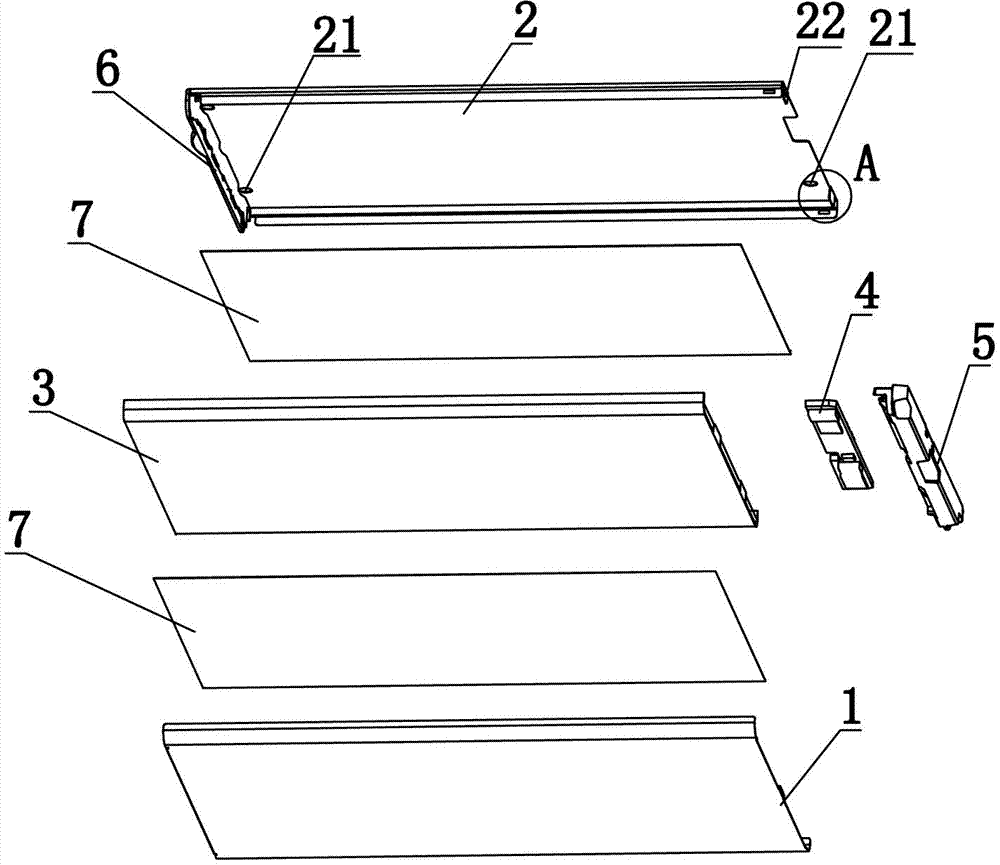

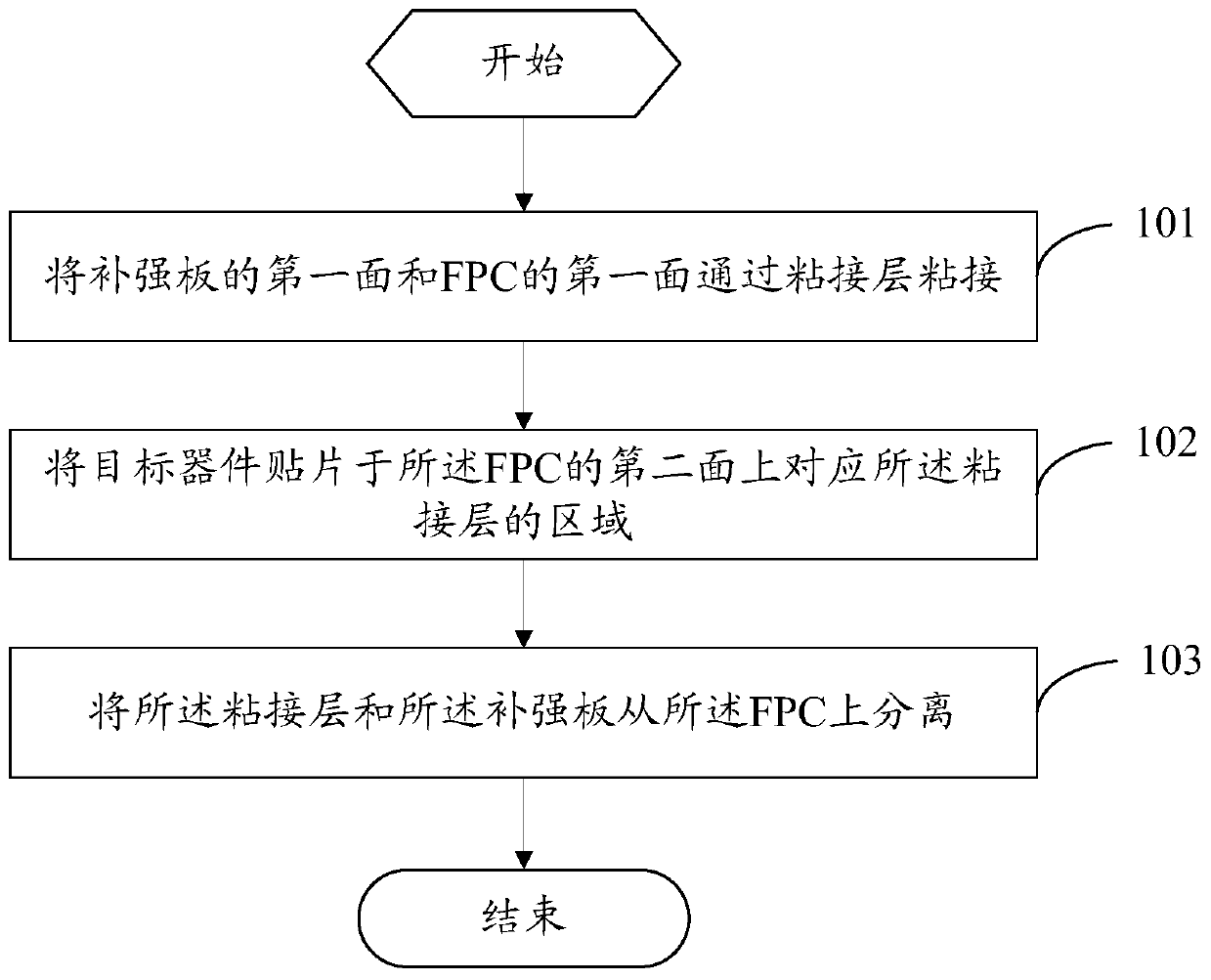

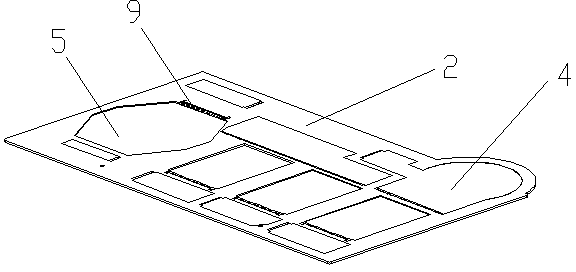

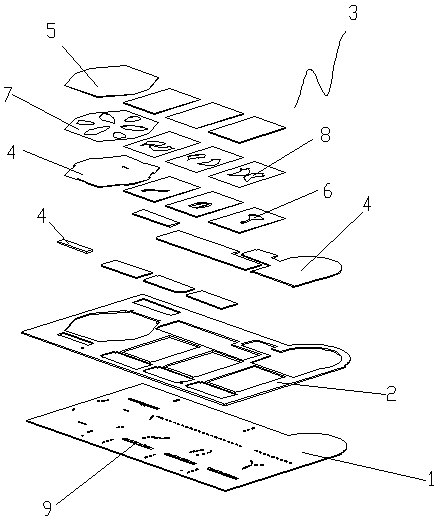

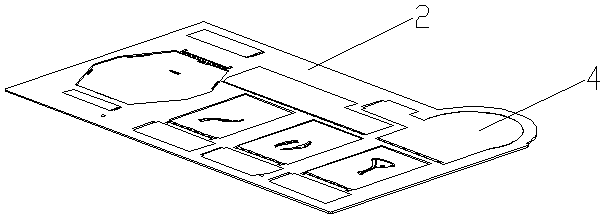

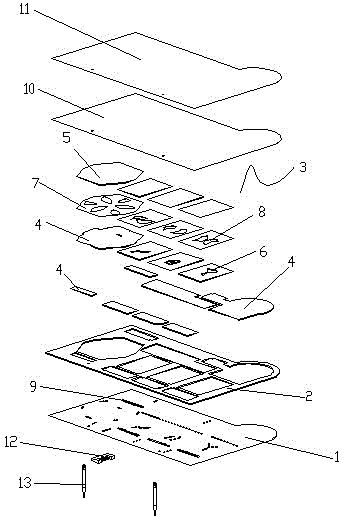

Flexible printed circuit (FPC) device surface-mounting method, FPC assembly and terminal

ActiveCN107454756AGuaranteed smoothSave thickness spacePrinted circuit assemblingSurface mountingEngineering

The invention provides a flexible printed circuit (FPC) device surface-mounting method, an FPC assembly and a terminal. The method comprises the following steps of pasting a first surface of a reinforcement plate and a first surface of an FPC by an adhesive layer; attaching a target device onto a region, corresponding to the adhesive layer, of a second surface of the FPC; and separating the adhesive layer and the reinforcement plate from the FPC, wherein the first surface of the FPC and the second surface of the FPC are two surfaces, opposite to each other, of the FPC. Therefore, the FPC and the reinforcement plate are pasted to ensure that the FPC is smooth during device surface-mounting on the FPC, the FPC carried with the target device is separated from the adhesive layer after surface mounting of the target device is completed, the purpose of removing the reinforcement plate after FPC surface-mounting is achieved, so that the integral thickness of the FPC device region is thinned, and the thickness space occupied by the FPC is favorably saved.

Owner:VIVO MOBILE COMM CO LTD

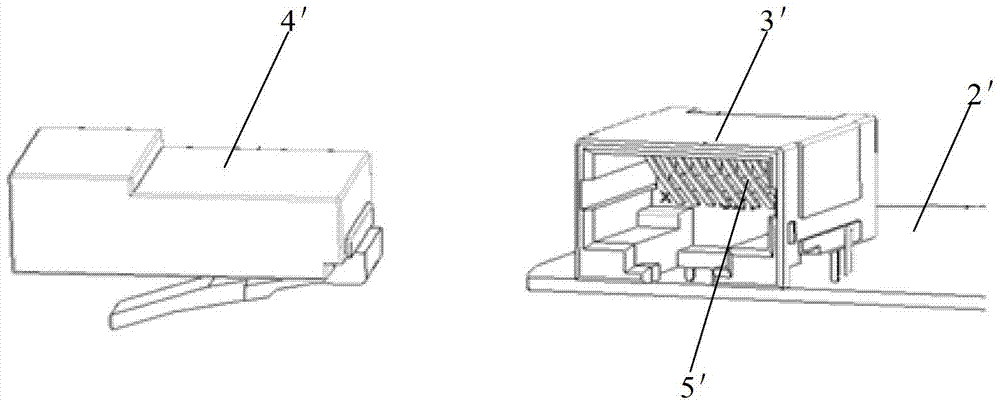

Interface device and electronic equipment

ActiveCN102842799ASmall footprintSave thickness spaceLine/current collector detailsCouplings bases/casesButt jointPrinted circuit board

The invention discloses an interface device and electronic equipment, relating to the technical field of plugging-in devices and aiming at being better applied to equipment with strict requirement on thickness. The interface device comprises a socket which is arranged on an equipment shell and provided with an opening, wherein the socket is formed by mutual butt joint of a first socket and a second socket, and the second socket and the equipment shell are integrally formed; and the interface device also comprises a pin, wherein the pin is arranged in the opening of the socket, and the pin is electrically connected with a PCB (Printed Circuit Board) in the equipment shell. The interface device disclosed by the invention is mainly suitable for being used in the electronic equipment.

Owner:HONOR DEVICE CO LTD

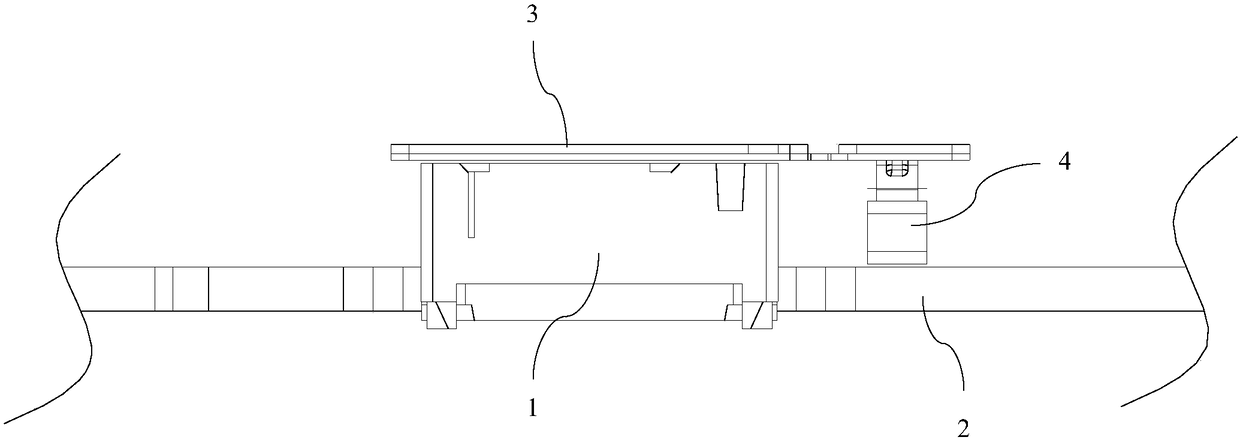

Circuit allocation switching unit

ActiveCN102244370ASave thickness spaceIncrease depth using spaceBus-bar/wiring layoutsSwitchgear detailsEmbedded systemElectricity

The invention discloses a circuit allocation switching unit, comprising a circuit allocation adapter and a low-current unit drawer, wherein the circuit allocation adapter comprises a metal shell; the metal shell is internally provided with an incoming line bus and an outgoing line bus; an outgoing line end of the incoming line bus and an outgoing line end of the outgoing line bus pass through a jack of the drawer on a metal shell panel respectively to form a static bus socket; and the low-current unit drawer is provided with a movable plug which is electrically connected with the static bus socket of the circuit allocation adapter in an insertion mode. Only one movable contact exists between the circuit allocation adapter and the low-current unit drawer when the circuit allocation adapter is connected with the low-current unit drawer in an insertion mode, thus the temperature is low, the inserted connection reliability is high and the manufacturing cost is reduced.

Owner:周金隆

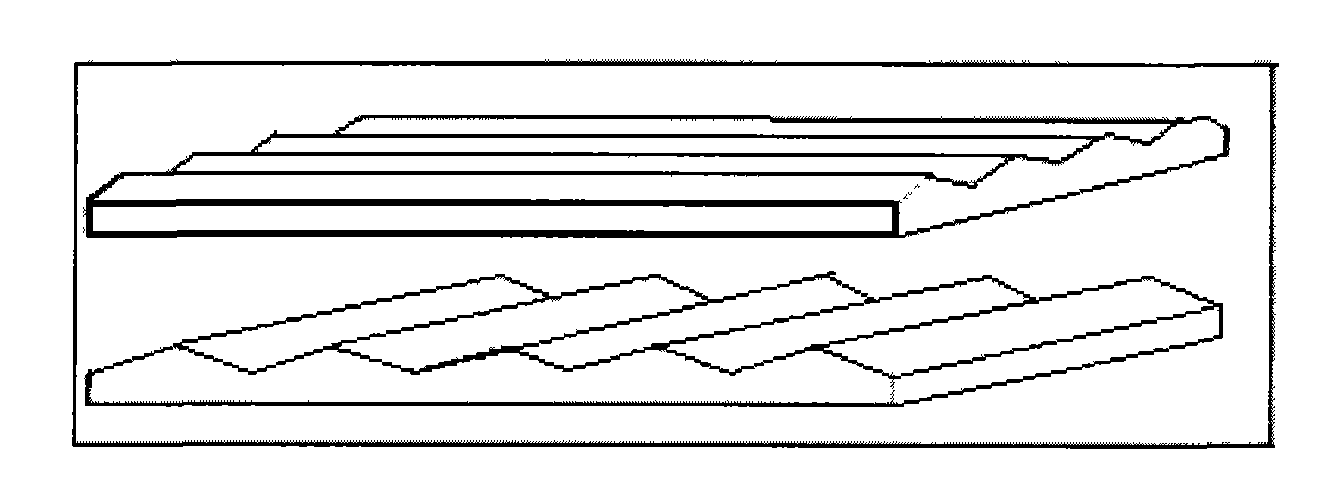

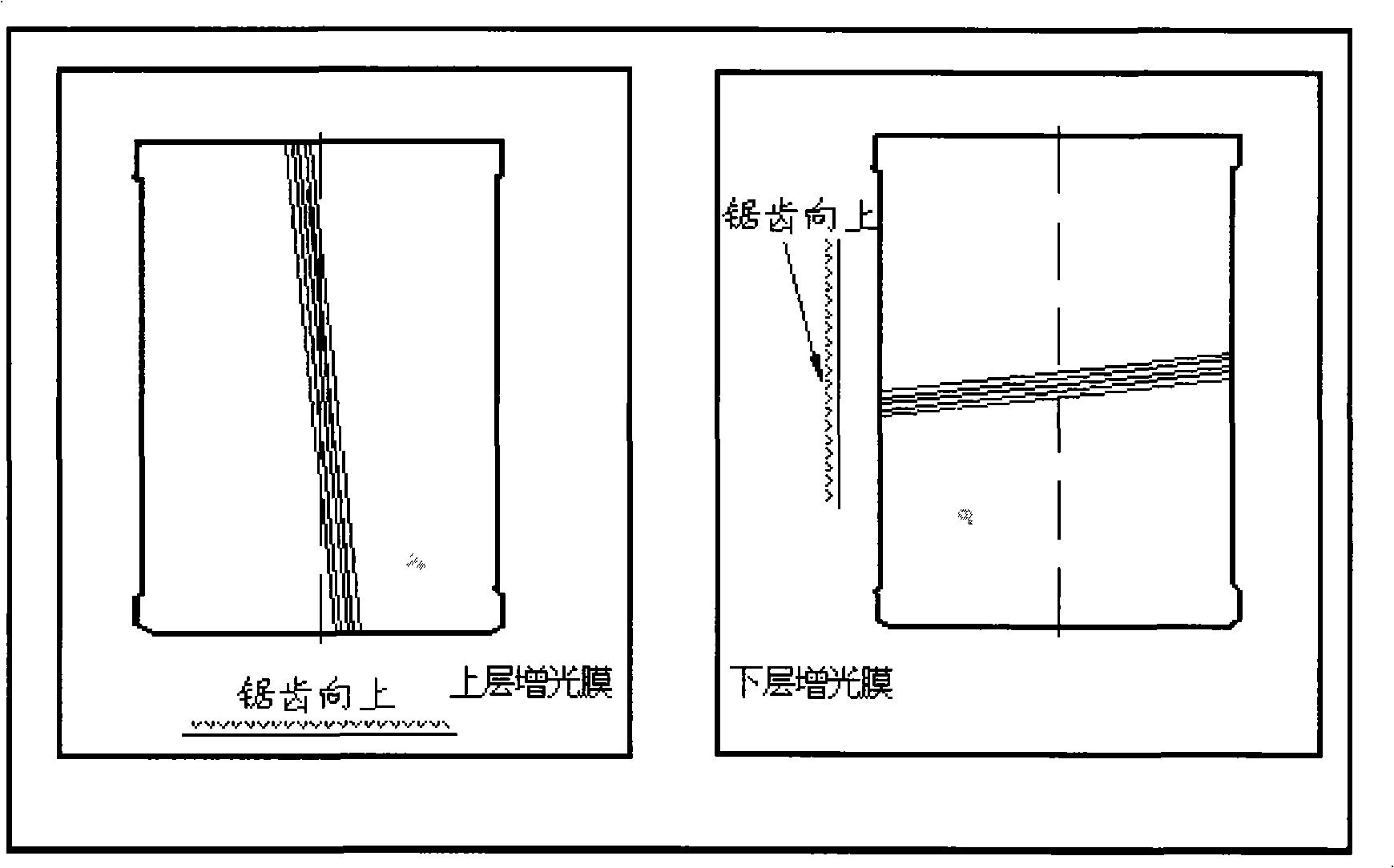

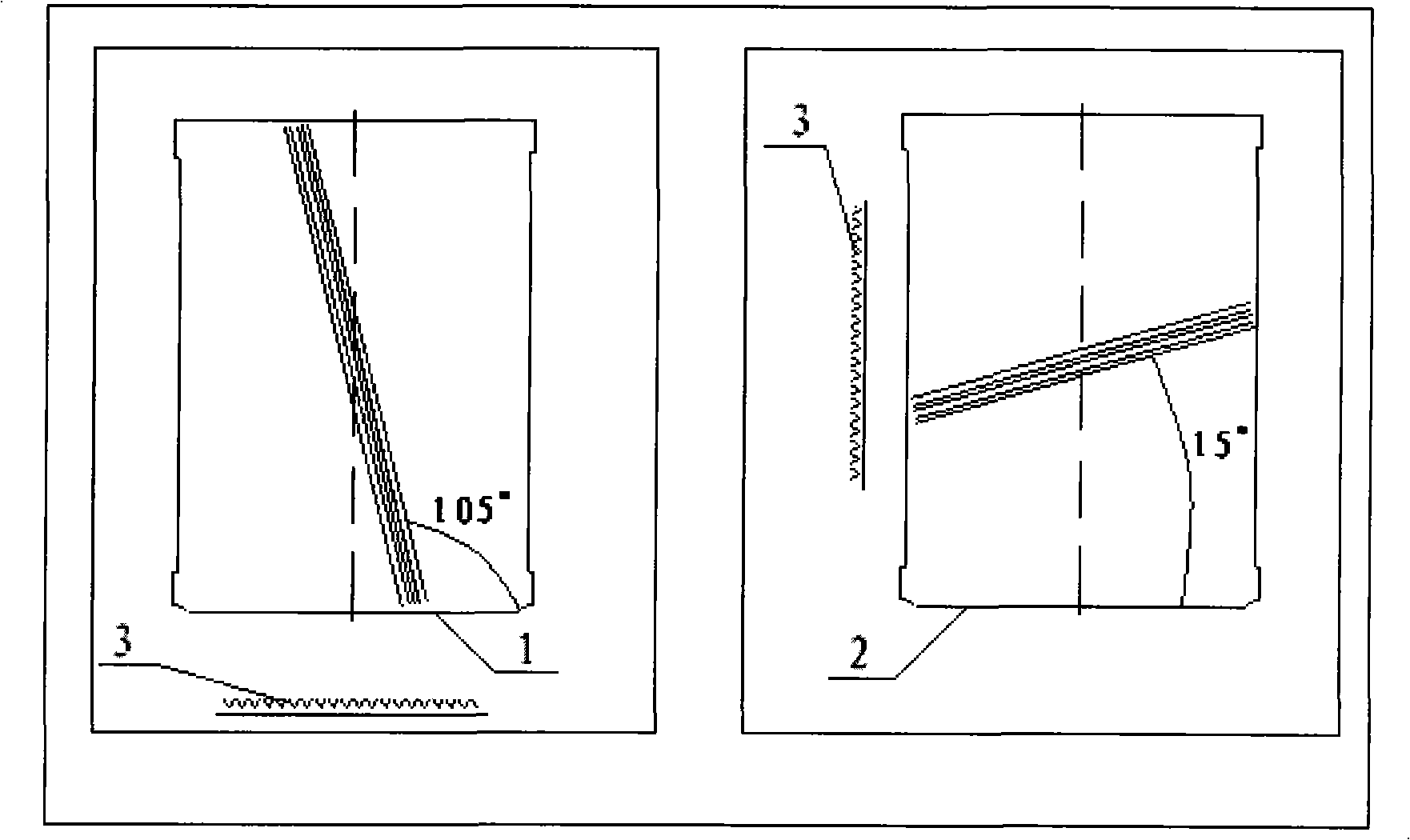

Backlight product interference grain processing process

InactiveCN101311790ASave thickness spaceGood product uniformityDiffusing elementsNon-linear opticsPhysicsBrightness perception

The invention provides an interference line treatment technology of a backlight product used for smoothing out the interference line after the backlight product passes through an LCD to improve the display effect of an LCD panel. The invention comprises an intensifying film. The angle of the intensifying film is adjusted to 15 degrees, 30 degrees or 45 degrees from the conventional angle of 6 degrees or 94 degrees according to the angel of LCD combined with backlight, or the intensifying film selects the sawing distance of 90 / 20 or 90 / 50, so the angle of the intensifying film is matched with the angle of an LCD polaroid, thus achieving the aim of smoothing out the interference line. In addition, by adopting the interference line treatment technology, the brightness of the product can be increased; cost can be saved and the market competitive strength of the product is improved.

Owner:星磊电子(深圳)有限公司

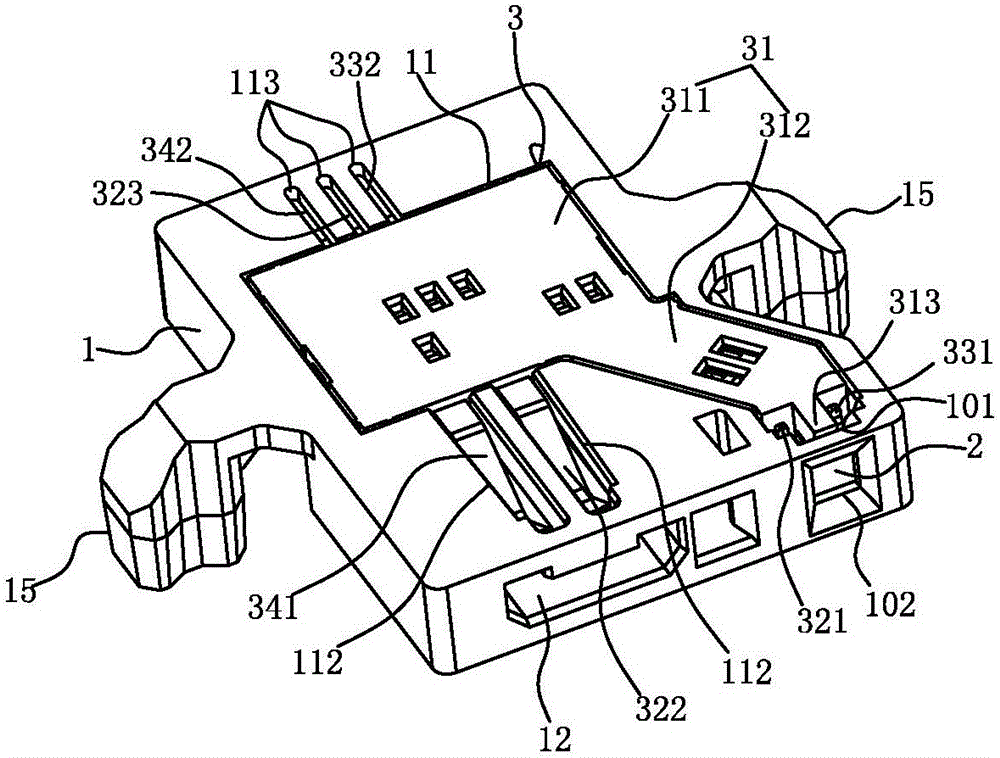

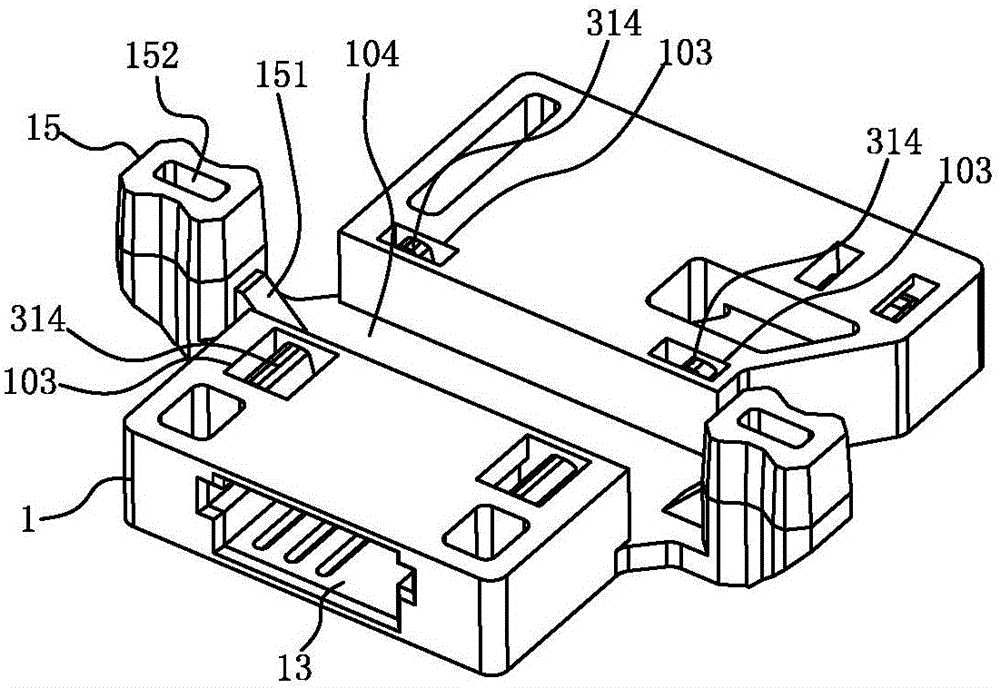

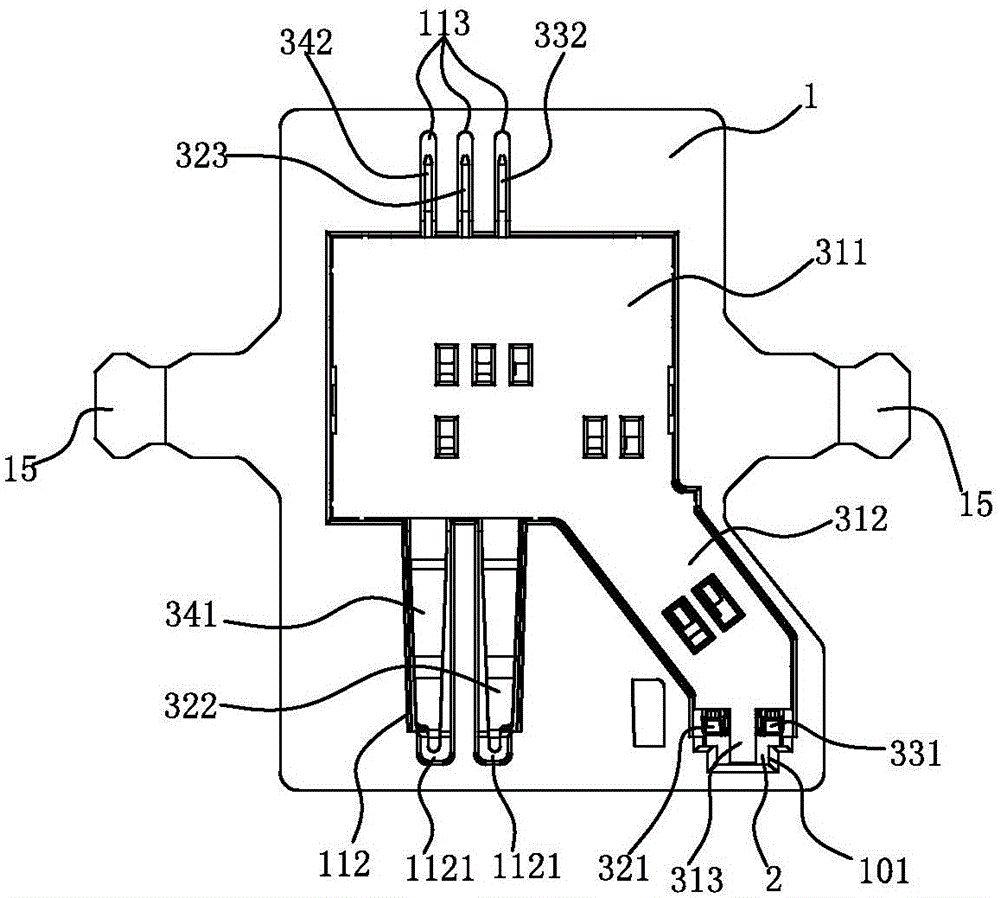

Intelligent label connector

ActiveCN105789959AMeet different installation requirementsSimplify complexitySecuring/insulating coupling contact membersCoupling contact membersElectrical and Electronics engineeringWelding

The invention discloses an intelligent label connector. The connector comprises a plastic seat, an LED chip and a terminal assembly, wherein the plastic seat is provided with an accommodation groove, a first plug port and a second plug port; the LED chip is installed in the plastic seat; the terminal assembly includes a terminal seat installed in the accommodation groove, a power supply terminal, a grounding terminal and a signal terminal, and the power supply terminal, the grounding terminal and the signal terminal are arranged in the terminal seat; a first elastic contact arm of the power supply terminal and an elastic conduction connection arm in the grounding terminal abut against a positive electrode and a negative electrode of the LED chip respectively so as to form non-welding-type conduction connection; a second elastic contact arm of the power supply terminal and an elastic plug arm of the signal terminal are inserted into the first plug port; and first, second and third contact portions of the power supply terminal, the grounding terminal and the signal terminal are inserted into the second plug port. When the terminal assembly is inserted, embedded and fixed into the plastic seat from top to bottom, the first elastic contact arm and the elastic conduction connection arm abut against and contact with the positive electrode and the negative electrode of the LED chip respectively so as to form non-welding-type conduction connection and lead welding is not needed. Therefore, structure complexity and assembling difficulty of the structure are simplified.

Owner:DONGGUAN YUQIU ELECTRONICS CO LTD

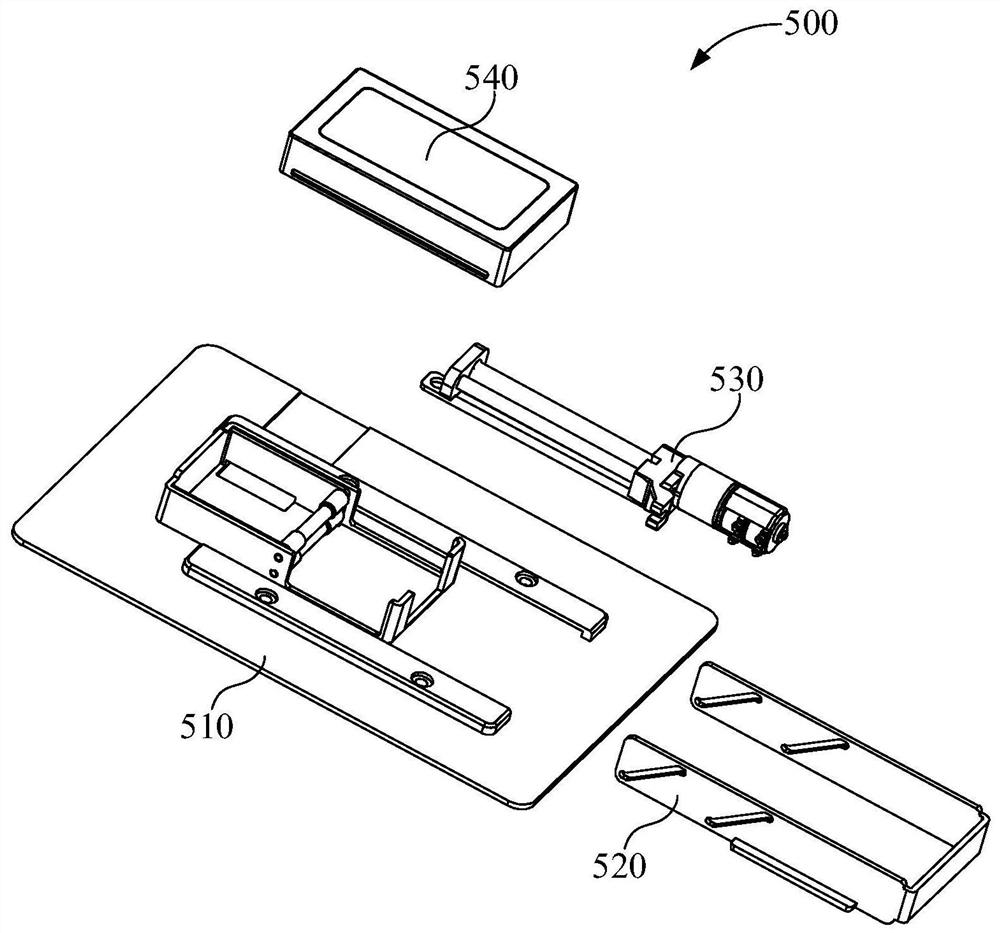

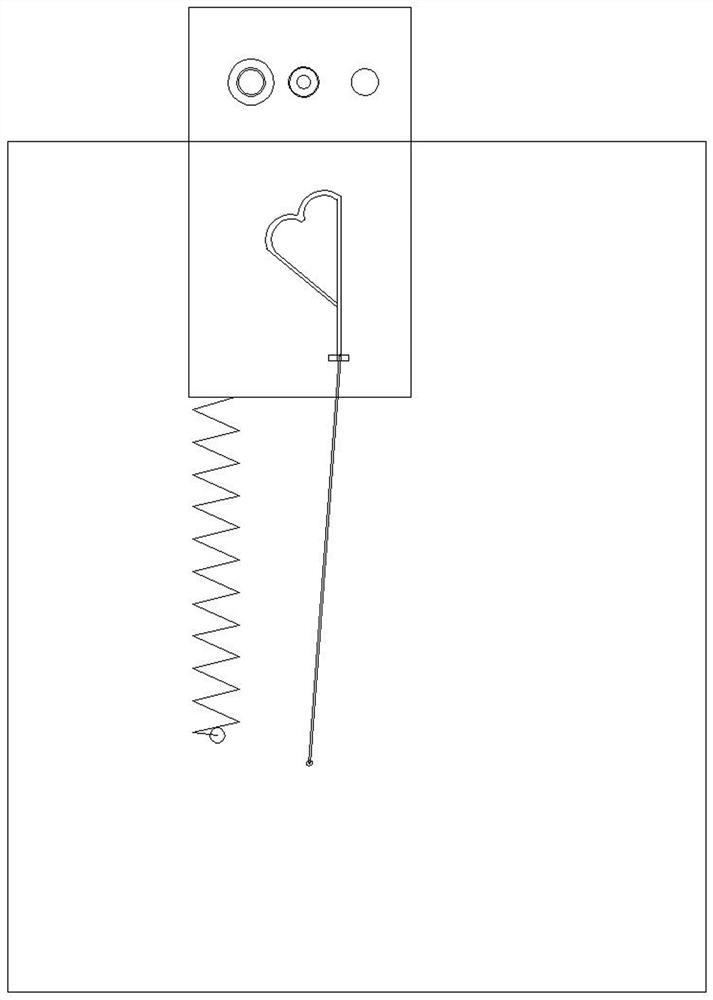

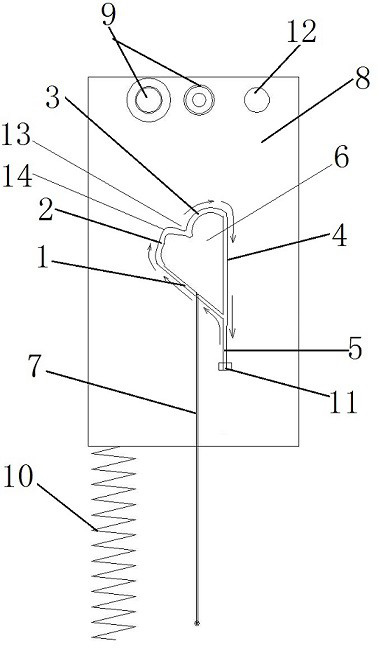

Pressing pop-up mobile phone camera device

ActiveCN111343313AGuaranteed aestheticsCut costTelevision system detailsColor television detailsControl theoryMechanical engineering

The invention discloses a pressing pop-up mobile phone camera device, and relates to a lifting device for a front camera of a mobile phone. The pressing pop-up mobile phone camera device is provided with a sliding base, a camera is installed above the sliding base, the camera is in signal connection with a processor of a mobile phone, a beveled heart-shaped stop block is arranged on the side faceor the lower portion of the sliding base, and a sliding rail is arranged around the stop block. The sliding rails are formed by sequentially and smoothly connecting a first sliding rail, a second sliding rail, a third sliding rail, a fourth sliding rail and a fifth sliding rail, the first sliding rail and the fourth sliding rail are located on the two sides below the stop block respectively, the second sliding rail and the third sliding rail are located on the two sides above the stop block respectively, the fifth sliding rail is located below the first sliding rail and the fourth sliding rail, and the fifth sliding rail and the fourth sliding rail are connected into a straight line; a sleeve rod is placed in the sliding rail, and the other end of the sleeve rod is movably connected to theinterior of the mobile phone; and an elastic piece for pushing the sliding base to slide up and down is arranged in the mobile phone.

Owner:无锡鸿儒网络科技有限公司

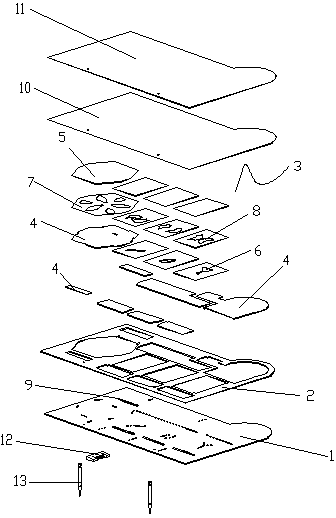

Pressure sensing structure, electronic equipment border and mobile electronic equipment

ActiveCN104898776ASave thickness spaceReduce installation difficultyDigital data processing detailsMobile electronicsEngineering

The present invention relates to a pressure sensing structure, an electronic equipment border and mobile electronic equipment. The pressure sensing structure comprises an operation panel, a deformation amplification part and a sensing unit, wherein the operation panel is used for allowing a force applier to apply force; after the force applier applies pressure to the operation panel, small physical deformation is generated, wherein the small physical deformation can generate relatively large physical deformation through deformation amplification part; the sensing unit is used for converting the physical deformation generated by the deformation amplification part into an electric signal for outputting; one end of the deformation amplification part is fixedly connected to the back surface of the operation panel and corresponds to a force-receiving part of the front surface of the operation panel, and the other end of the deformation amplification part is connected with the sensing unit. According to the invention, a pressure sensor does not need to be directly mounted on the relatively narrow back surface of the force-applying surface, so that the thickness space of the electronic equipment is reduced and the manufacturing difficulty is lowered.

Owner:SHENZHEN NEW DEGREE TECH

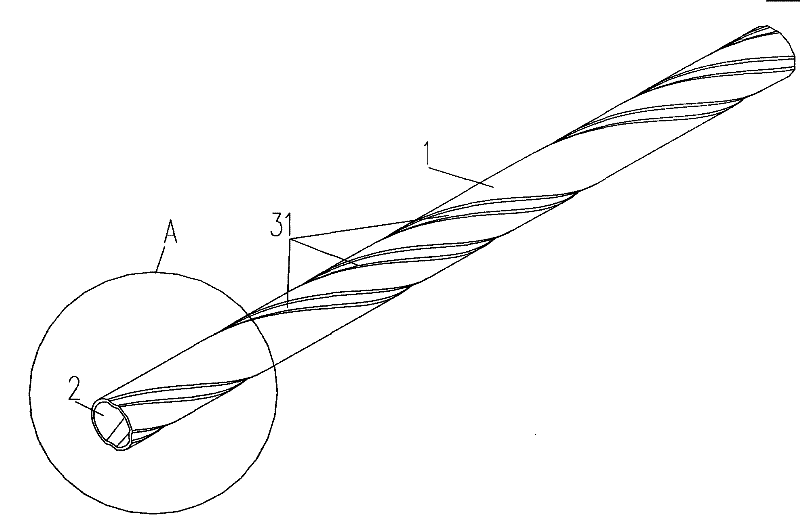

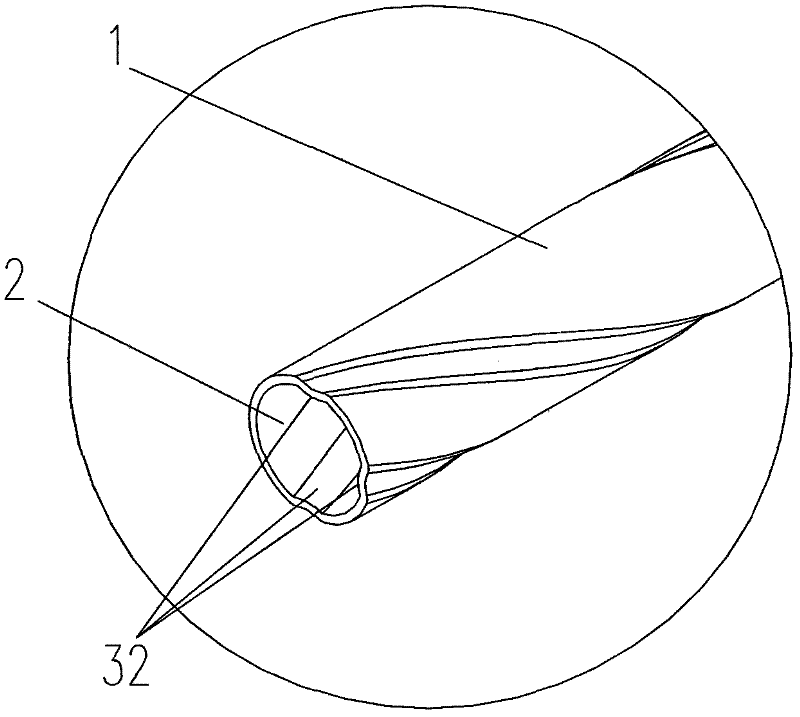

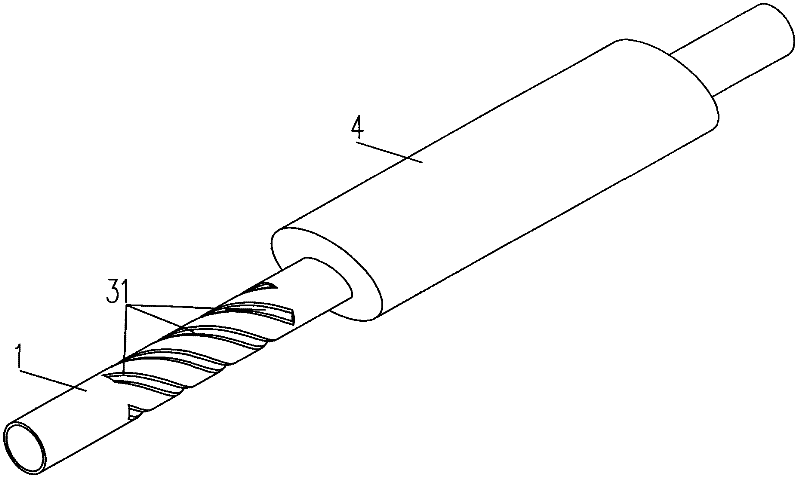

Exhaust pipe applying rotary arc-shaped heat exchange tube

InactiveCN102330594AImprove cooling efficiencyReduce manufacturing costExhaust apparatusSilencing apparatusEngineeringAbnormal shaped

The invention discloses an exhaust pipe applying a rotary arc-shaped heat exchange tube; the main body of the exhaust pipe is the rotary arc-shaped heat exchange tube; the rotary arc-shaped heat exchange tube at least comprises a tube body, and the tube body is encircled to form an air channel; the tube body is an abnormal tube section; a groove which extends in an arc shape is formed on the wall of the abnormal tube section; the groove and the axis of the tube body form a rotary included angle; and the inner wall of the tube body is correspondingly provided with protruded arc-shaped lines by the groove. According to the exhaust pipe, because the rotary arc-shaped heat exchange tube is adopted, the heat exchange efficiency is greatly improved, the overall heat exchange efficiency of the exhaust pipe is far higher than that of an existing exhaust pipe, and the exhaust pipe applying the rotary arc-shaped heat exchange tube has the beneficial effects of low cost, convenience in manufacturing and the like.

Owner:SHANGHAI KEMI STEEL TUBE

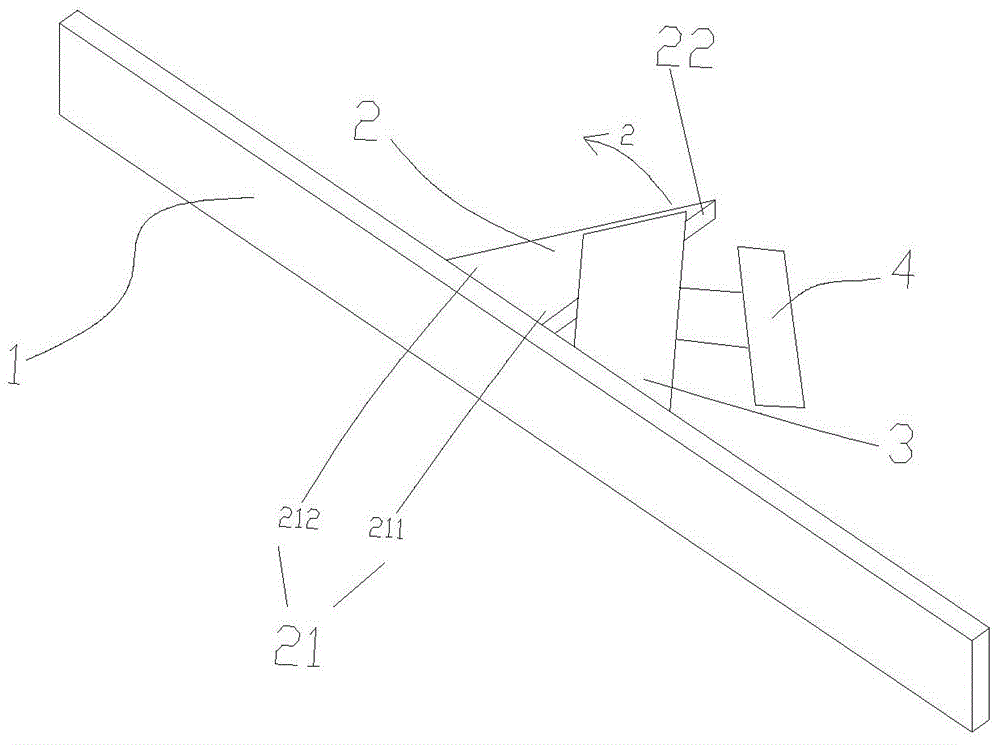

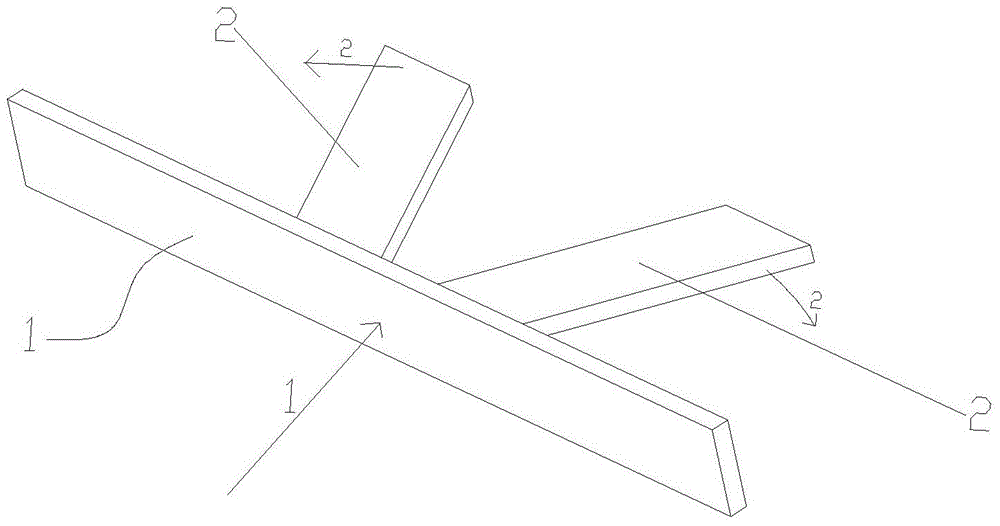

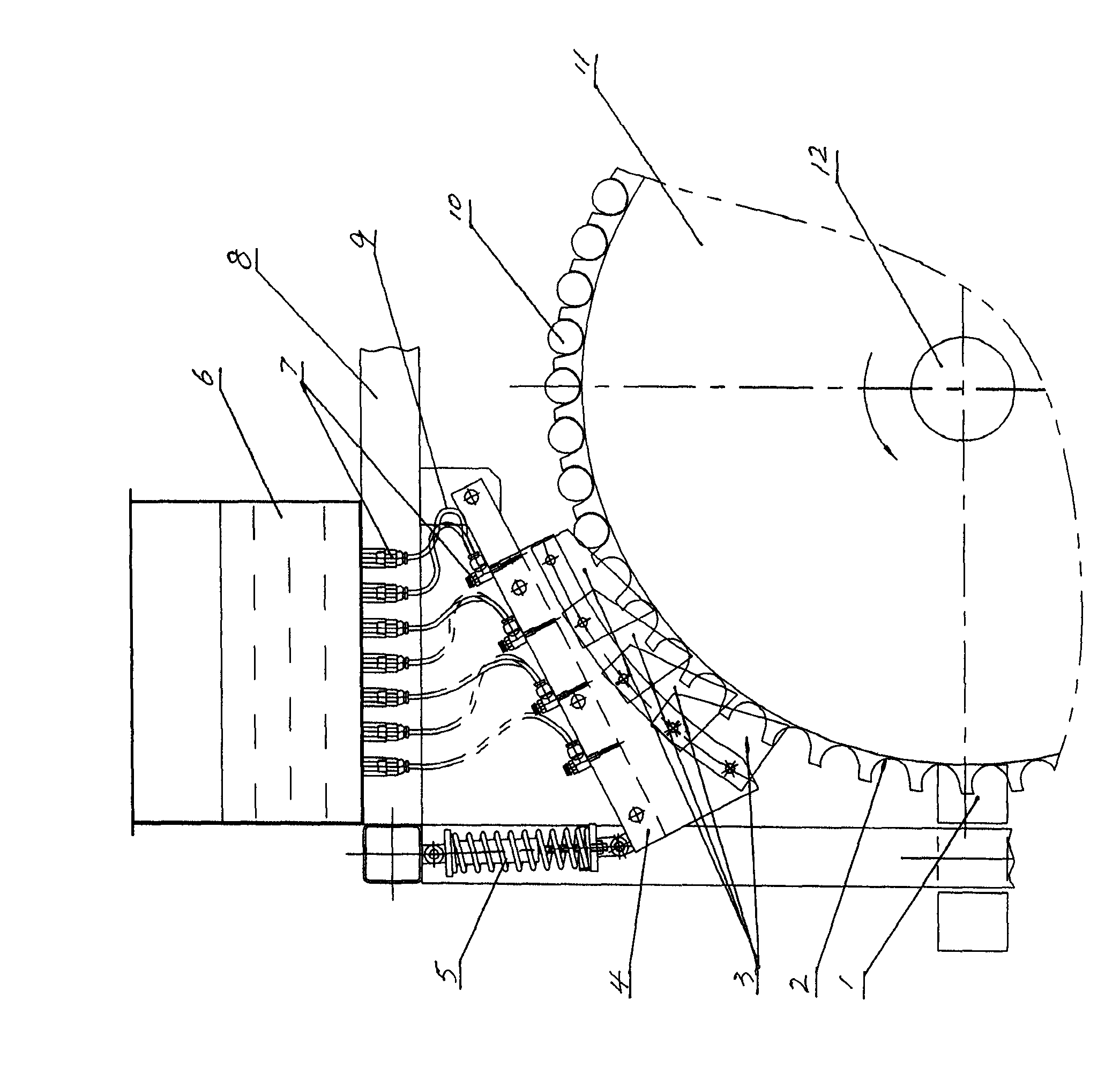

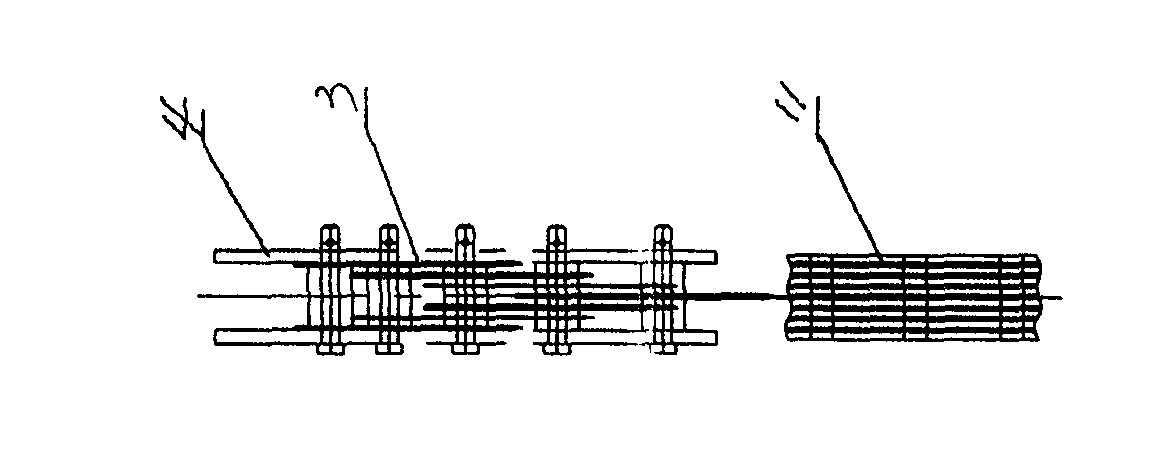

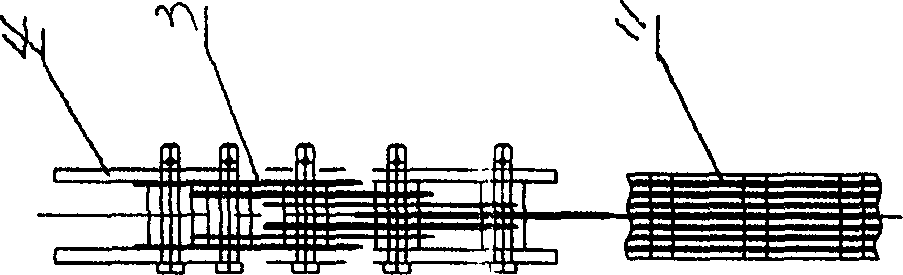

Chinese date sequential slicing mechanism

InactiveCN103264403ASave thickness spaceMake sure not to be damagedMetal working apparatusEngineeringMechanical engineering

The invention relates to a Chinese date sequential slicing mechanism which comprises a machine frame. A material stirring disc is arranged on an inner side of the machine frame, and the material stirring disc is vertically arranged and can rotate. Grooves are evenly formed in the outer circumference of the material stirring disc in the circumferential direction. A knife rest is fixed on the portion, above the material stirring disc, of the machine frame, and a hairbrush mechanism is arranged on the position, below the knife rest, of the machine frame. The Chinese date sequential slicing mechanism is characterized in that a plurality of sets of slicing knives are arranged on the inner side of the knife rest in the rotation direction of the material stirring disc, the number of the slicing knives in the last set of slicing knives is one, the number of the slicing knives in other sets of slicing knives is two, and the other sets of slicing knives are located on two sides of the last set of slicing knives and slowly and outwards expand to be distributed at equal interval. On a projective plane parallel to the disc face of the material stirring disc, each set of slicing knives are partially overlapped with the previous set of slicing knives. Blade grooves are formed in the positions, where the slicing knives correspond to, of the outer circumference of the material stirring disc, and parts of cutting edges of the slicing knives are inserted in the blade grooves corresponding to the slicing knives. By means of the mechanism, slicing processing can be carried out on different parts of a Chinese date in sequence, damage to Chinese date sheets cannot be caused easily, and material discharging difficulties are avoided.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

Interface device and electronic equipment

ActiveCN102842799BSmall footprintSave thickness spaceLine/current collector detailsCouplings bases/casesButt jointPrinted circuit board

The invention discloses an interface device and electronic equipment, relating to the technical field of plugging-in devices and aiming at being better applied to equipment with strict requirement on thickness. The interface device comprises a socket which is arranged on an equipment shell and provided with an opening, wherein the socket is formed by mutual butt joint of a first socket and a second socket, and the second socket and the equipment shell are integrally formed; and the interface device also comprises a pin, wherein the pin is arranged in the opening of the socket, and the pin is electrically connected with a PCB (Printed Circuit Board) in the equipment shell. The interface device disclosed by the invention is mainly suitable for being used in the electronic equipment.

Owner:HONOR DEVICE CO LTD

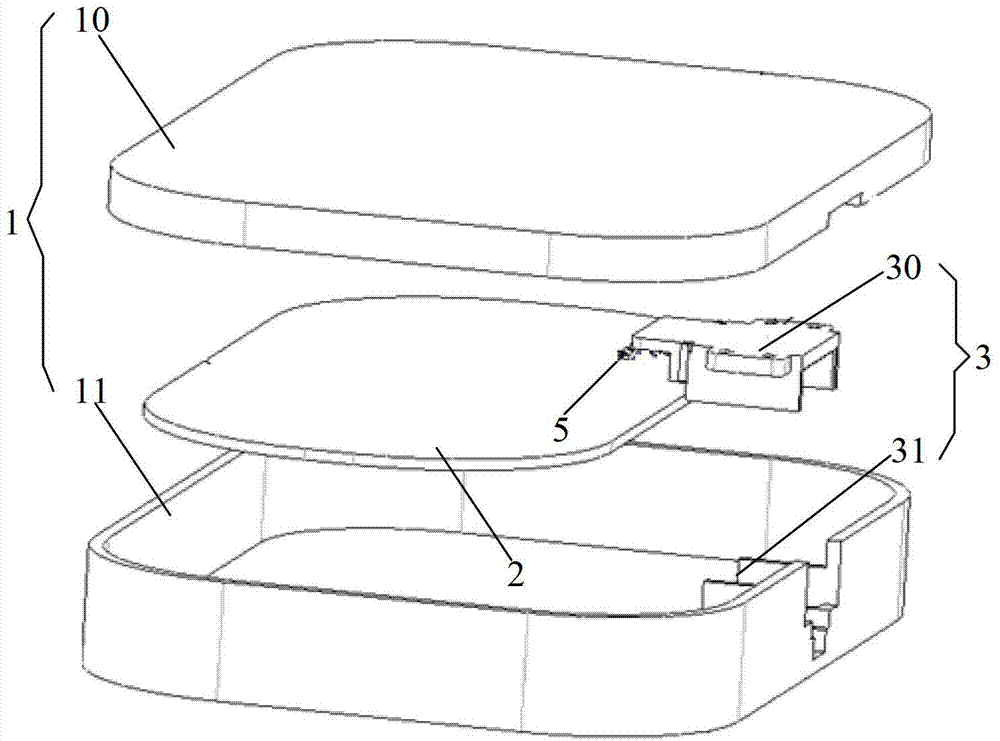

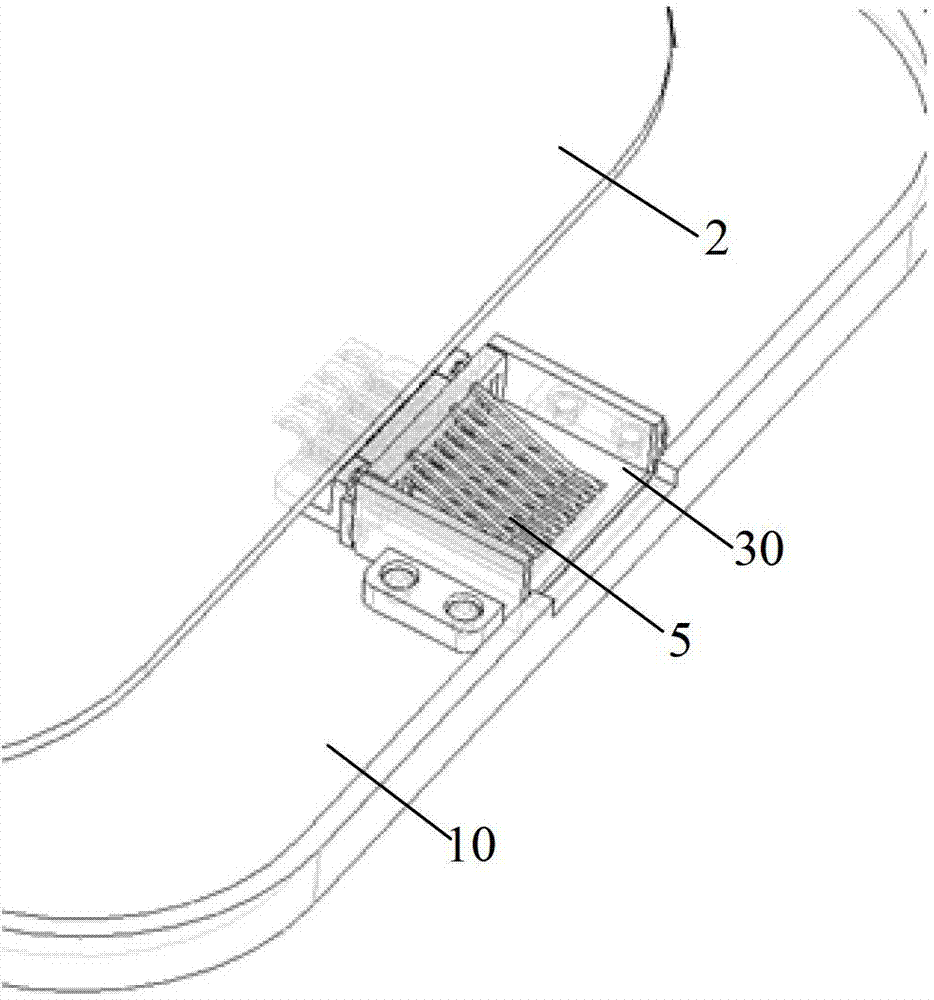

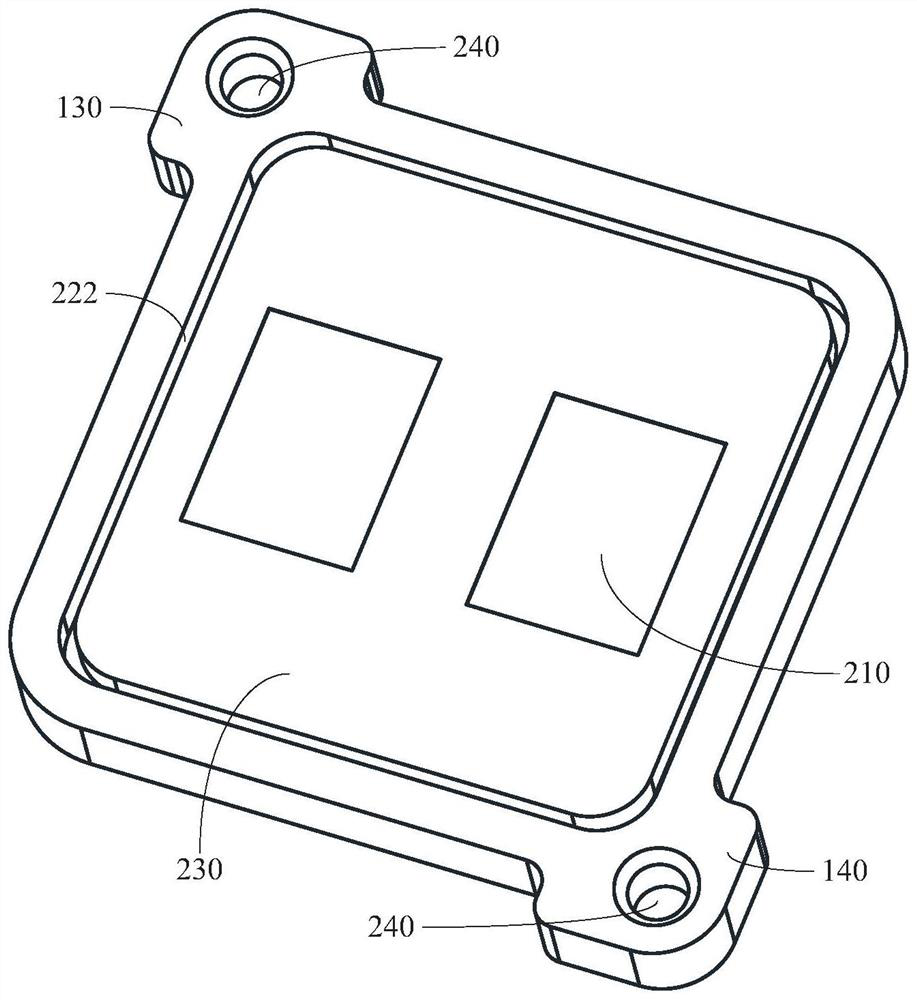

Driving device, camera module and electronic equipment

PendingCN114598758ASave thickness spaceTelevision system detailsColor television detailsCamera moduleControl theory

The invention provides a driving device. The driving device comprises a mounting frame, a sliding frame and a power assembly. The mounting rack is provided with a mounting surface for mounting a first functional part; the sliding frame is arranged on the mounting frame and is used for connecting a second functional part; the power assembly is arranged on the mounting frame, connected with the sliding frame and used for driving the sliding frame to slide relative to the mounting frame; when the sliding frame slides relative to the mounting frame, the second functional part responds to sliding of the sliding frame and slides in the first direction relative to the sliding frame; after the second functional part slides to a preset position in the first direction, the second functional part can also slide in the second direction relative to the mounting frame in response to sliding of the sliding frame and can slide to the position where the second functional part and the first functional part are stacked; the first direction intersects with the sliding direction of the sliding frame, and the second direction is parallel to the sliding direction of the sliding frame. In this way, the thickness space occupied by the first function part and the second function part can be reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

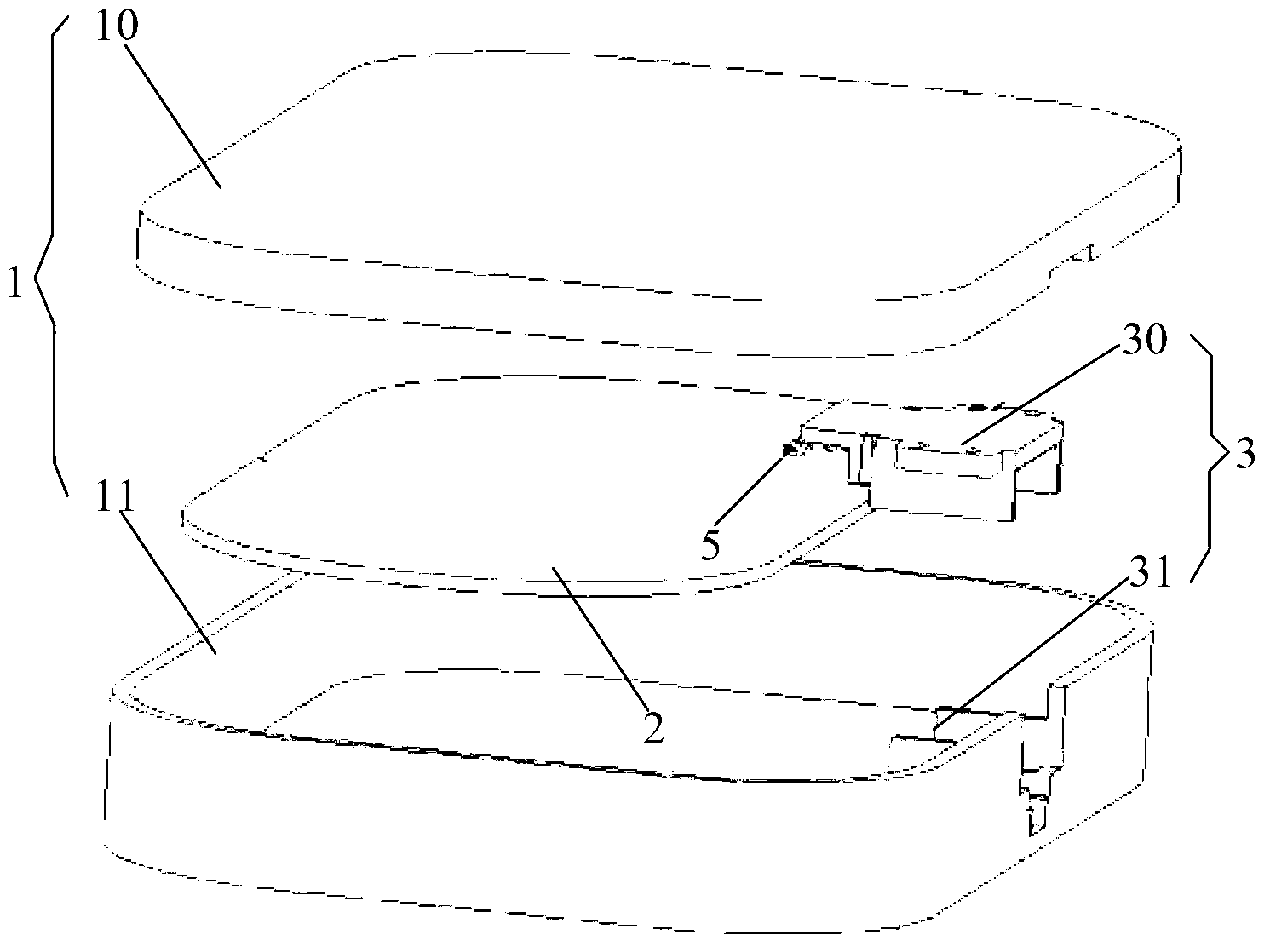

Novel lithium-ion polymer battery and packaging process thereof

ActiveCN102751537BSave thickness spaceSave width spaceFinal product manufactureCell component detailsEngineeringBattery capacity

The invention discloses a novel lithium-ion polymer battery and its packaging process, comprising a metal lower case, a metal upper case, and a polymer cell assembly. The metal upper case is provided with several glue injection ports; The polymer cell assembly described above includes a polymer cell, a protective plate, a front cover, and a rear cover, and the rear cover is connected to one end of the metal upper casing; the tab end of the polymer cell is welded with a protective plate; the front cover covers Set on the protective plate; the other end of the polymer cell is connected to the back cover; the metal upper shell and the metal lower shell are set on the upper and lower composite shells of the polymer cell assembly; the back cover is located at the tail end of the shell The front cover is located at the front end of the shell; the gap between the front cover and the back cover and the polymer battery cell, the metal upper case and the metal lower case is provided with filling glue; the present invention effectively protects the safety performance of the battery and the same space While maximizing the battery capacity, semi-automatic production is realized to improve production efficiency and yield.

Owner:SCUD FUJIAN ELECTRONICS

Intelligent LED (light emitting diode) flashing device

ActiveCN102663969BSimple structureImprove visual effectsAdvertisingIlluminated signsControl signalLight guide

The invention discloses an intelligent LED (light emitting diode) flashing device which comprises a circuit board, wherein LED light sources, an anode, a cathode and a lightproof locating plate are arranged on the circuit board; the anode and the cathode are conducted with the LED light sources, and the lightproof locating plate is used for covering the circuit board, and a light guiding plate assembly corresponding to the position of the LED light sources is arranged on the locating plate; the light guiding plate assembly is covered by an optical filter which is covered by a light transmitting pattern layer; and the intelligent LED flashing device further comprises an emitting device used for emitting signals, the circuit board is connected with a controller used for controlling each path of the LED light sources to light and extinguish, and the controller can receive the signals emitted by the emitting device and convert the emitted signals into control signals so as to control the LED light sources. According to the intelligent LED flashing device, the emitting device emits the signals to the controller, and the controller controls the corresponding LED light sources according to operation instructions of the emitted signals, so that different flashing requirements can be met.

Owner:江门市艺光科技开发有限公司

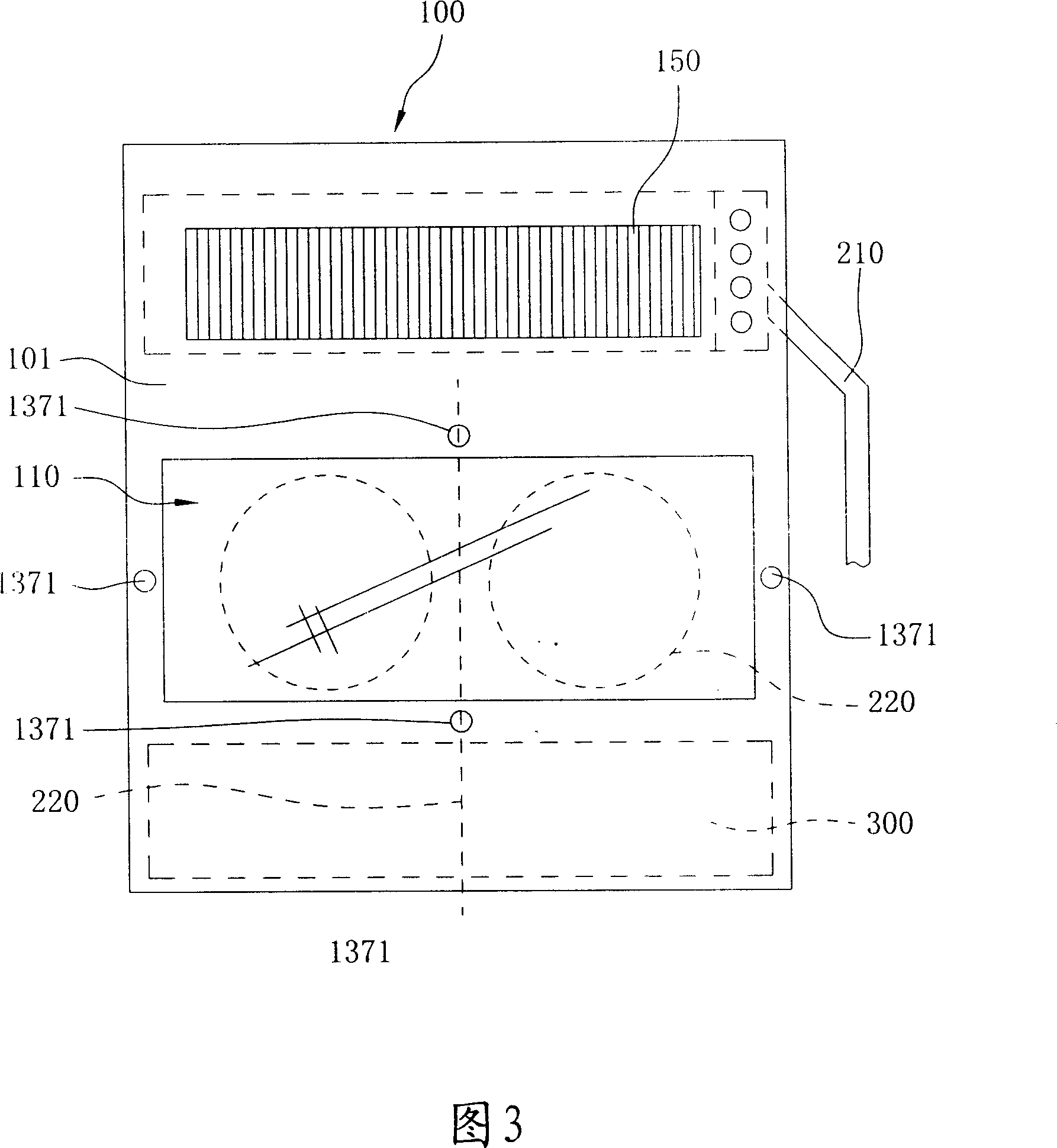

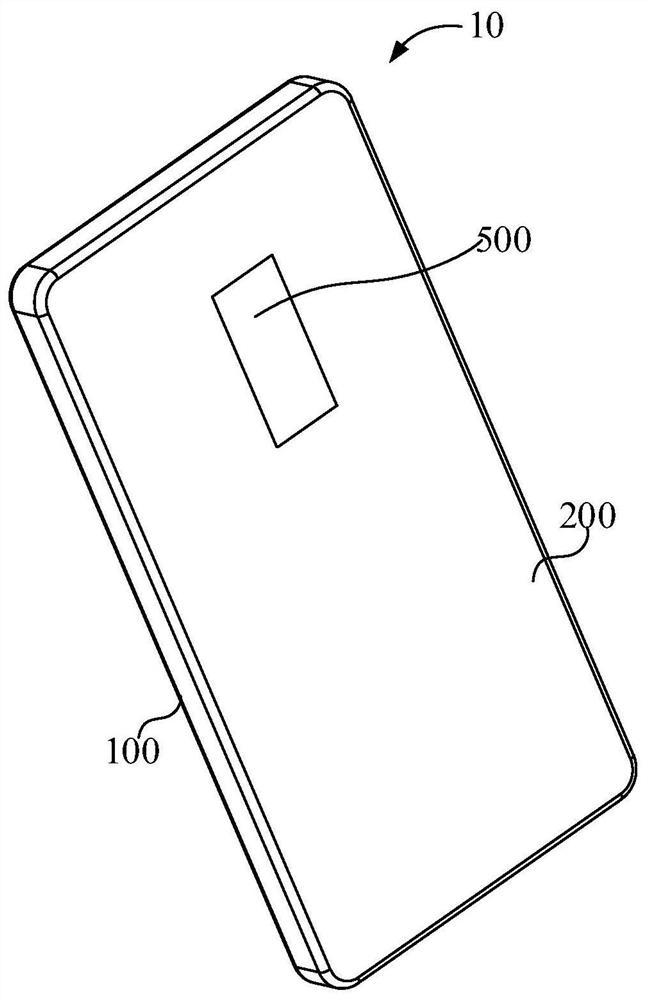

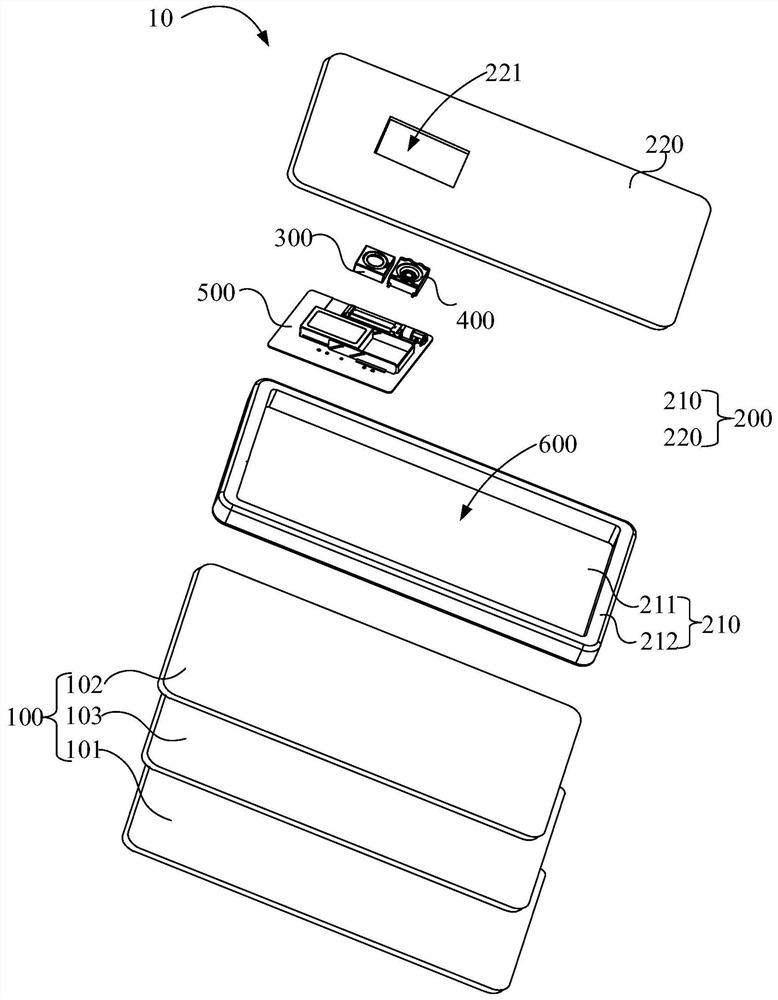

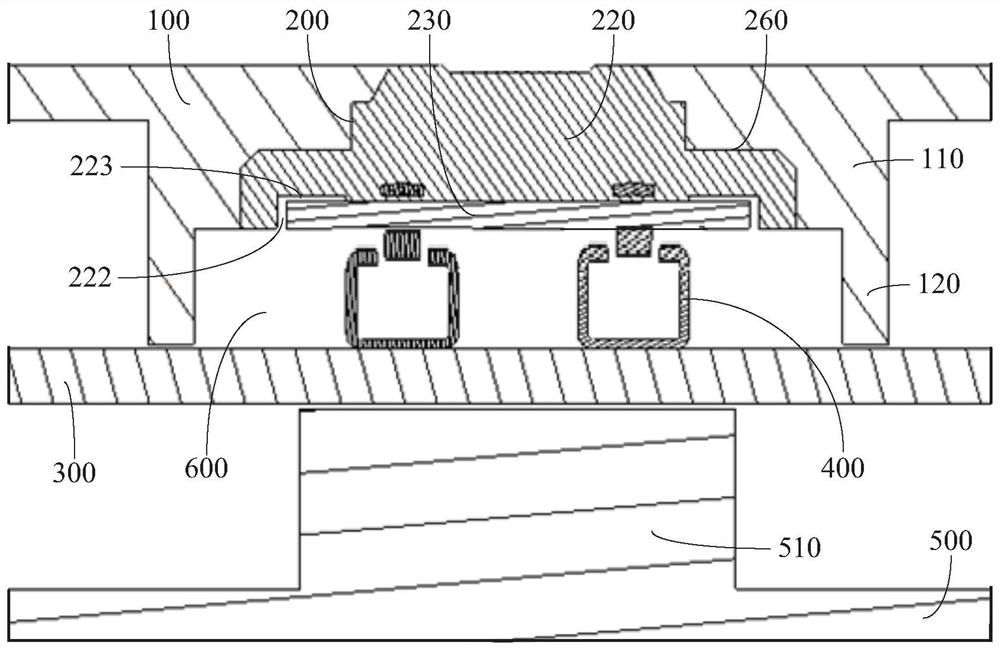

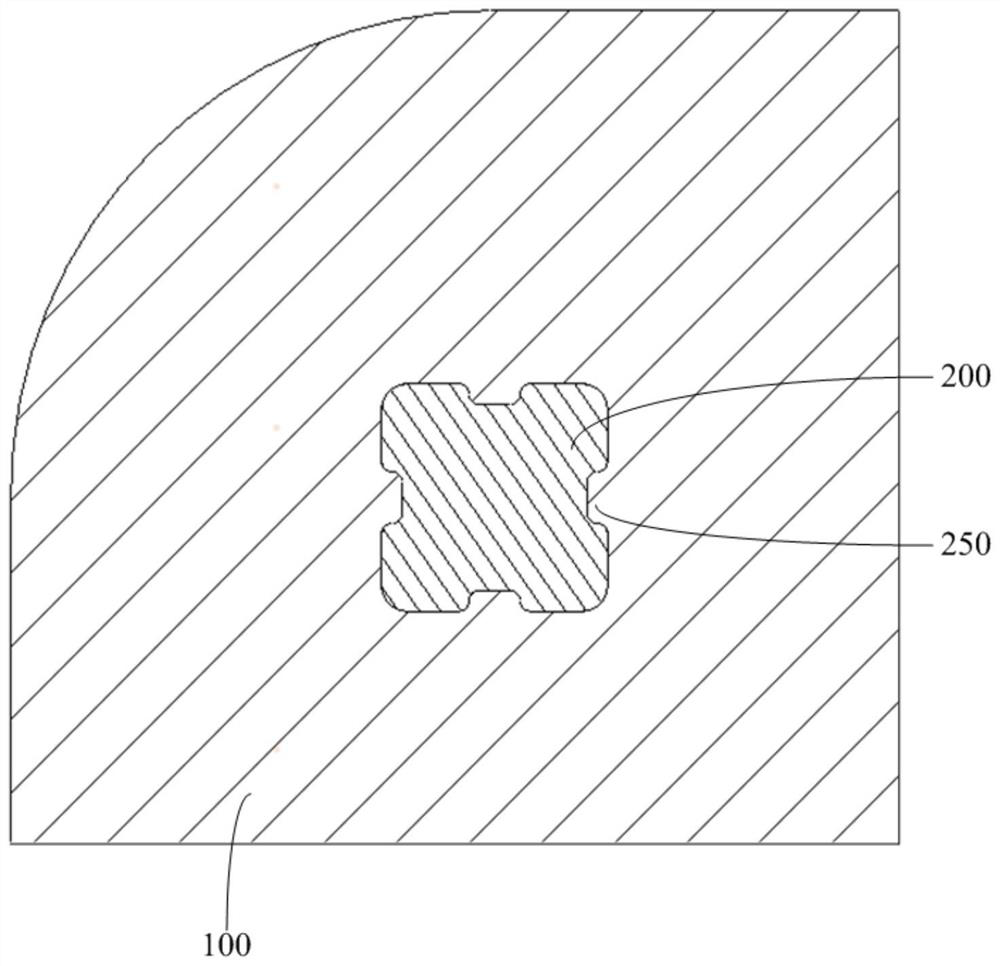

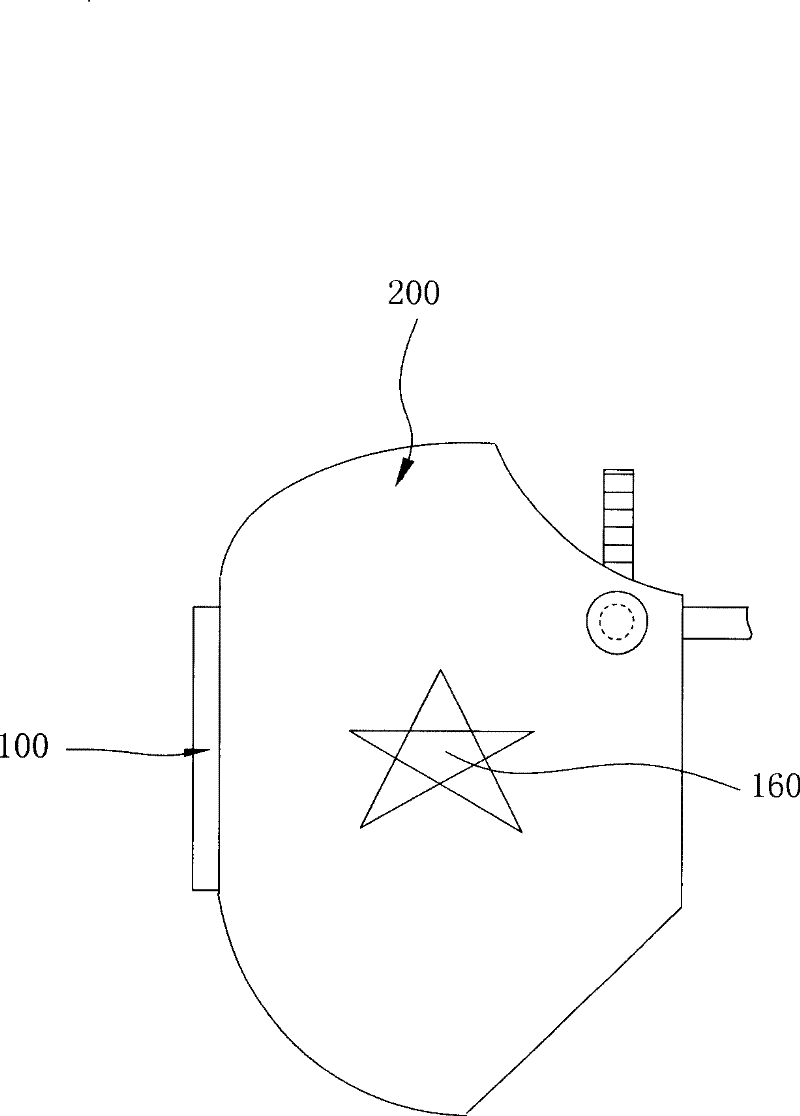

Electronic equipment

ActiveCN113670444AReduce thicknessConducive to the development of light and thinRadiation pyrometryThermometer applicationsElectrical connectionEngineering

The invention discloses electronic equipment. The electronic equipment comprises a first shell (100) which is provided with a through hole, a temperature sensor module (200) which is arranged in the through hole and is provided with a first electric connection part (210) and afirst circuit board (300). The first circuit board (300) is provided with a second electric connection part (400), the second electric connection part (400) is electrically connected with the first electric connection part (210), and the temperature sensor module (200) is connected with the first shell (100) in an injection molding mode. According to the scheme, the problems that the shell structure of the electronic equipment is low in strength and the electronic equipment is thick can be solved.

Owner:VIVO MOBILE COMM CO LTD

Circuit allocation switching unit

ActiveCN102244370BSave thickness spaceReduced Thickness DimensionsBus-bar/wiring layoutsSwitchgear detailsElectricityEmbedded system

The invention discloses a circuit allocation switching unit, comprising a circuit allocation adapter and a low-current unit drawer, wherein the circuit allocation adapter comprises a metal shell; the metal shell is internally provided with an incoming line bus and an outgoing line bus; an outgoing line end of the incoming line bus and an outgoing line end of the outgoing line bus pass through a jack of the drawer on a metal shell panel respectively to form a static bus socket; and the low-current unit drawer is provided with a movable plug which is electrically connected with the static bus socket of the circuit allocation adapter in an insertion mode. Only one movable contact exists between the circuit allocation adapter and the low-current unit drawer when the circuit allocation adapter is connected with the low-current unit drawer in an insertion mode, thus the temperature is low, the inserted connection reliability is high and the manufacturing cost is reduced.

Owner:周金隆

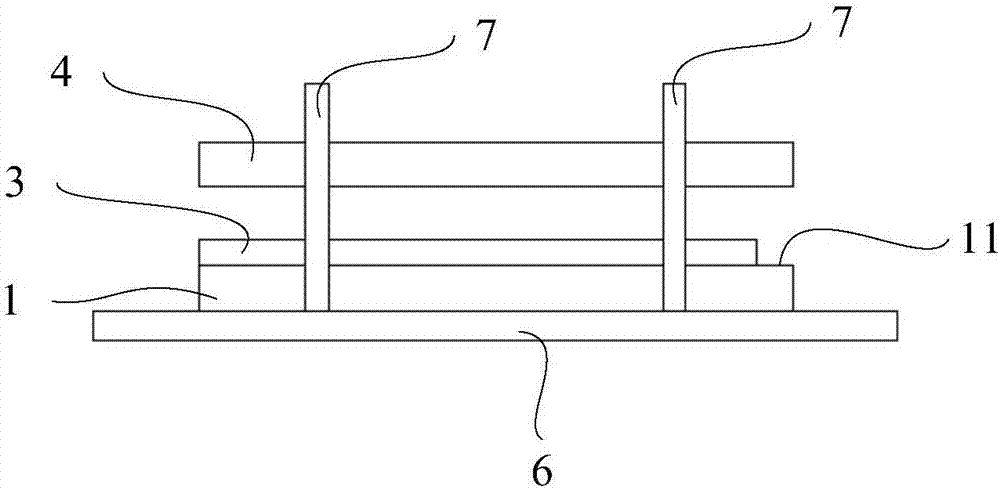

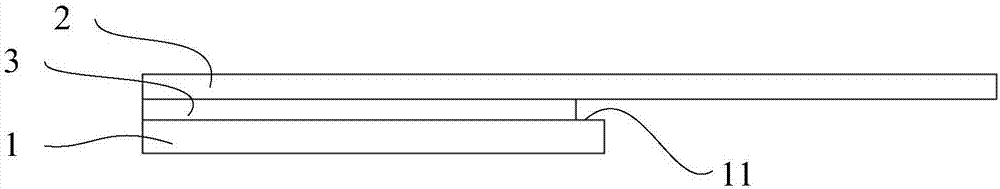

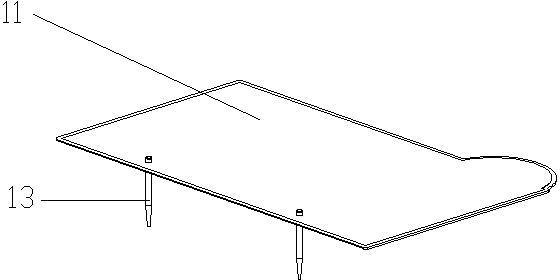

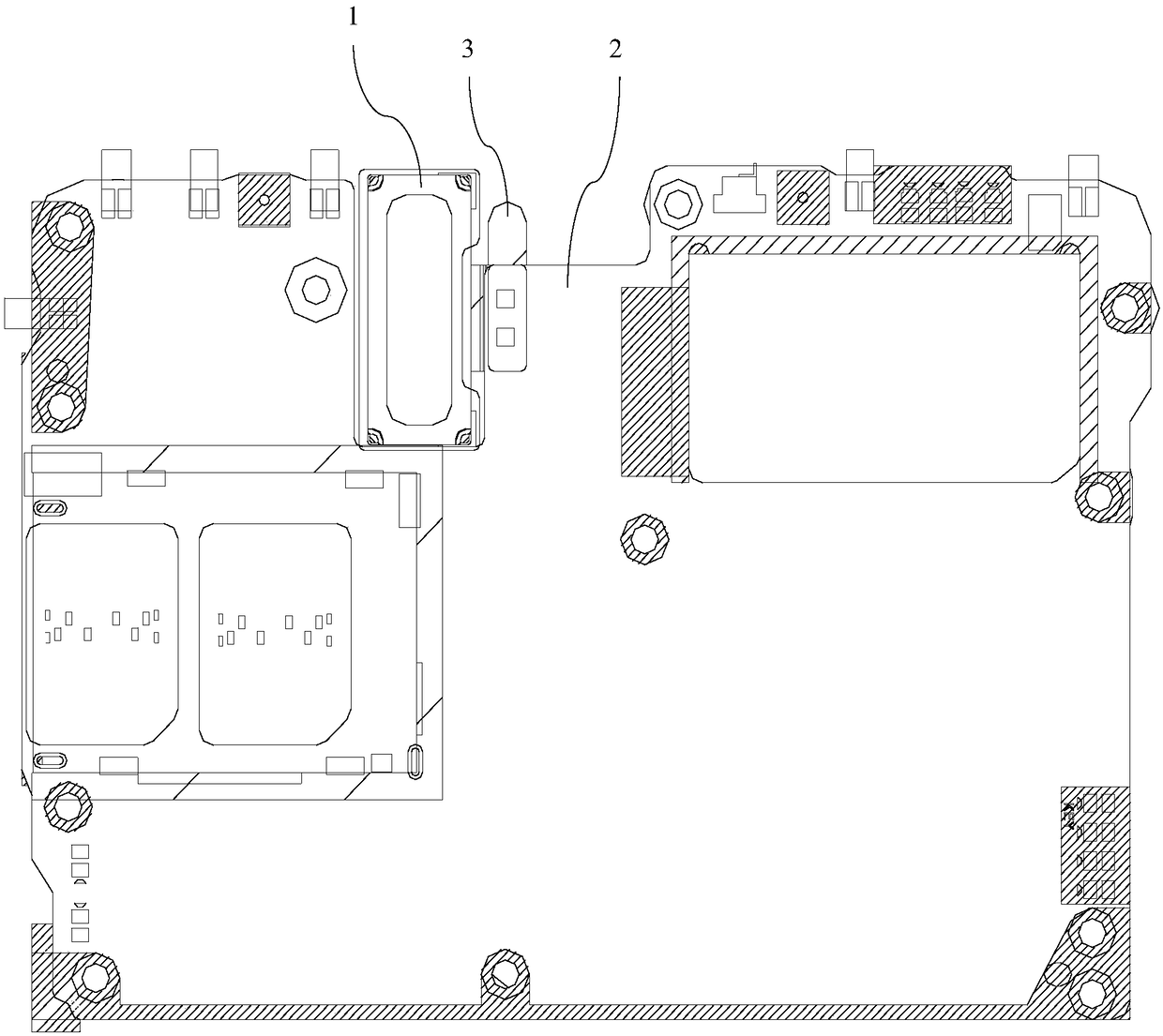

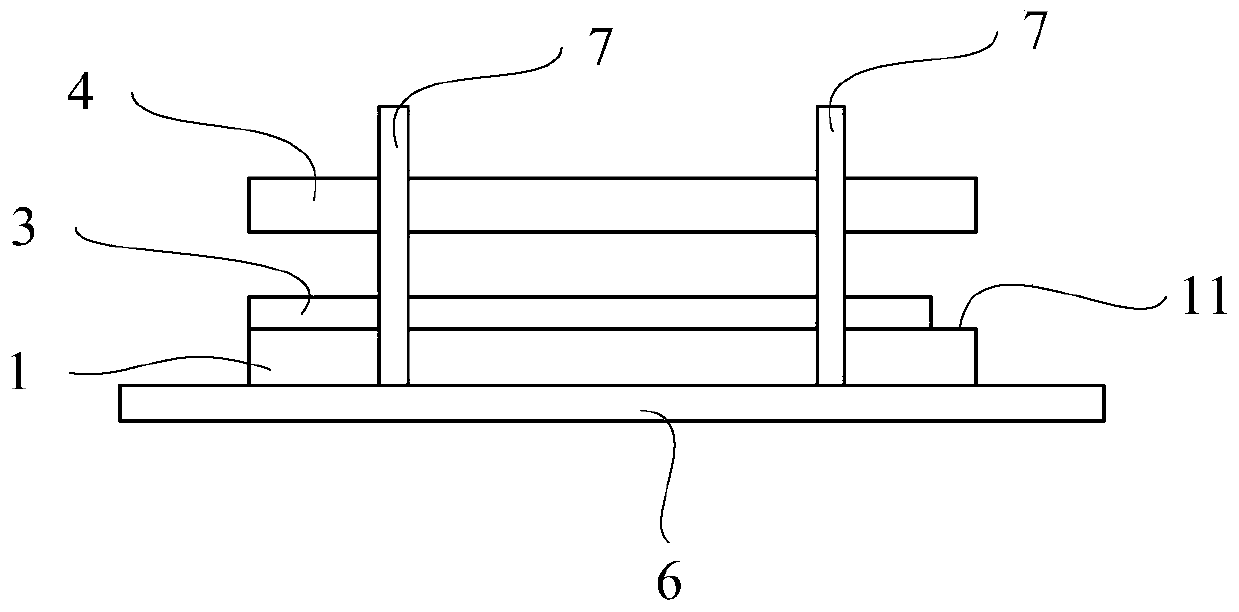

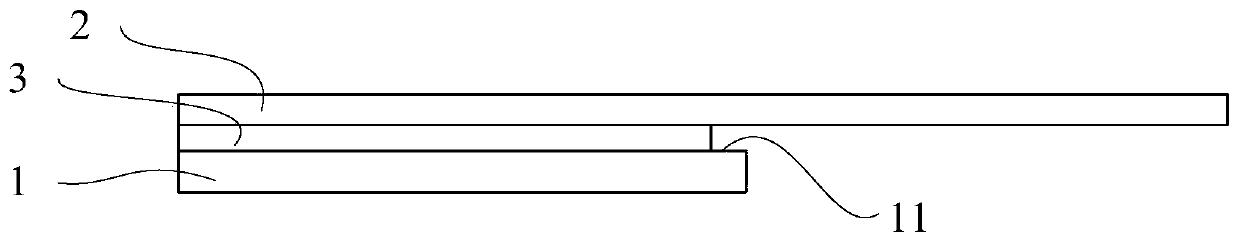

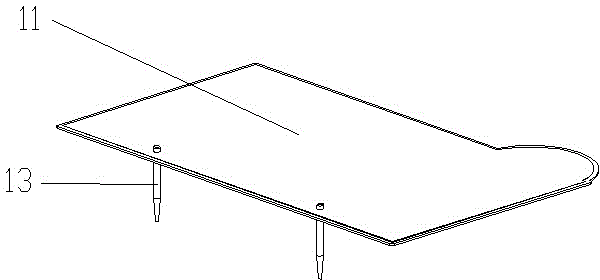

Plate-breaking type receiver assembling component and assembly method thereof and mobile terminal

InactiveCN108390974ASave thickness spaceSave layout spaceTelephone set constructionsElectricityGps receiver

The invention relates to a plate-breaking type receiver assembling component and an assembly method thereof and a mobile terminal. The plate-breaking type receiver assembling component comprises a shell, wherein the shell comprises a front shell and a rear shell which are mutually covered; a receiver and a main control board are arranged in the shell; a containing hole used for containing the receiver is arranged in the main control board; the receiver is arranged in the containing hole; the receiver is separated from the main control board; and the receiver is electrically connected to the main control board through a conduction piece. According to the plate-breaking type receiver assembling component, the receiver is arranged in the containing hole of the main control board, the conduction piece is compressed through the back shell in order to be switched to the main control board, so that the stacking thickness of the whole machine can be effectively reduced, a problem of insufficient space is solved, the thickness space is saved, and the layout space of the main control board is effectively reduced, and thus the whole area of the main control board is smaller, the cost is saved, multiple purposes are achieved, and the thickness of the whole machine is reduced particularly.

Owner:NUBIA TECHNOLOGY CO LTD

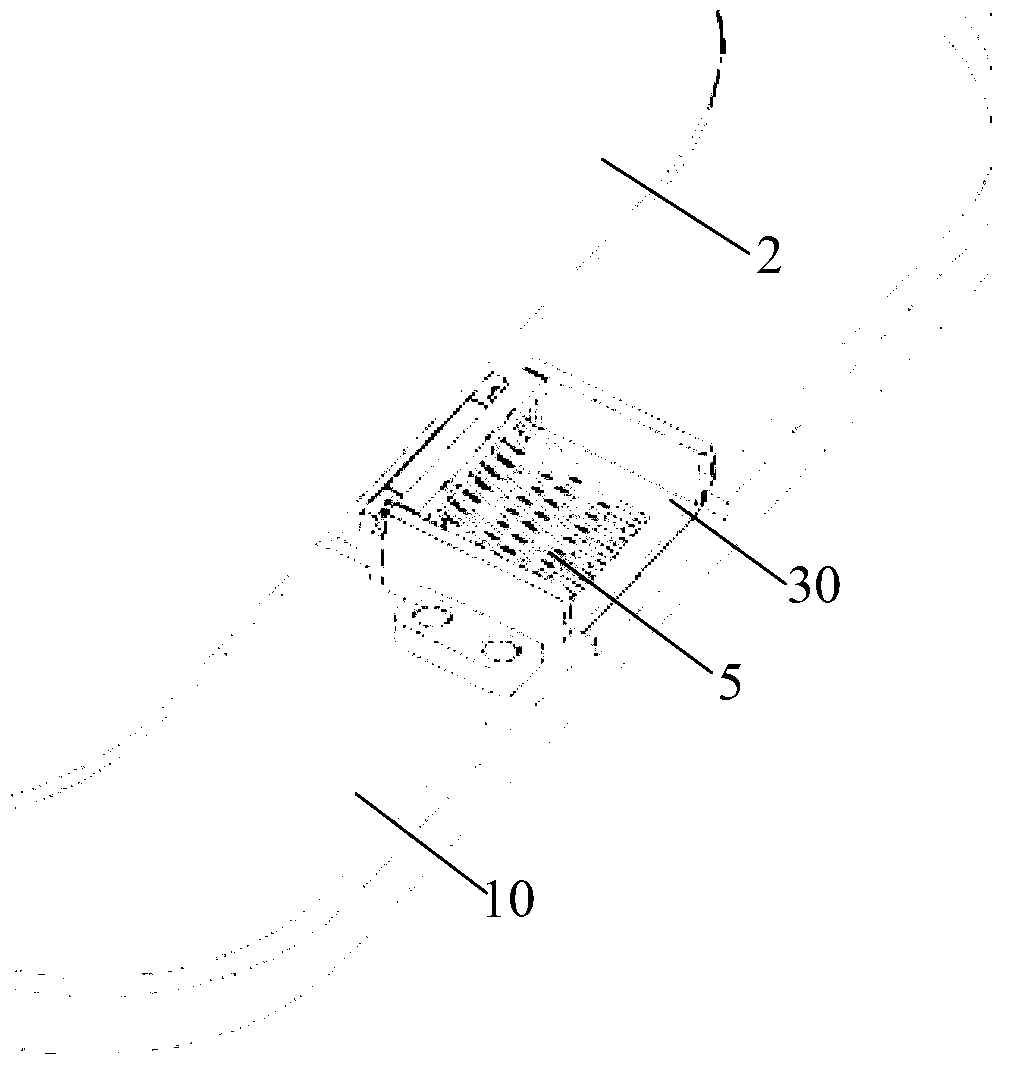

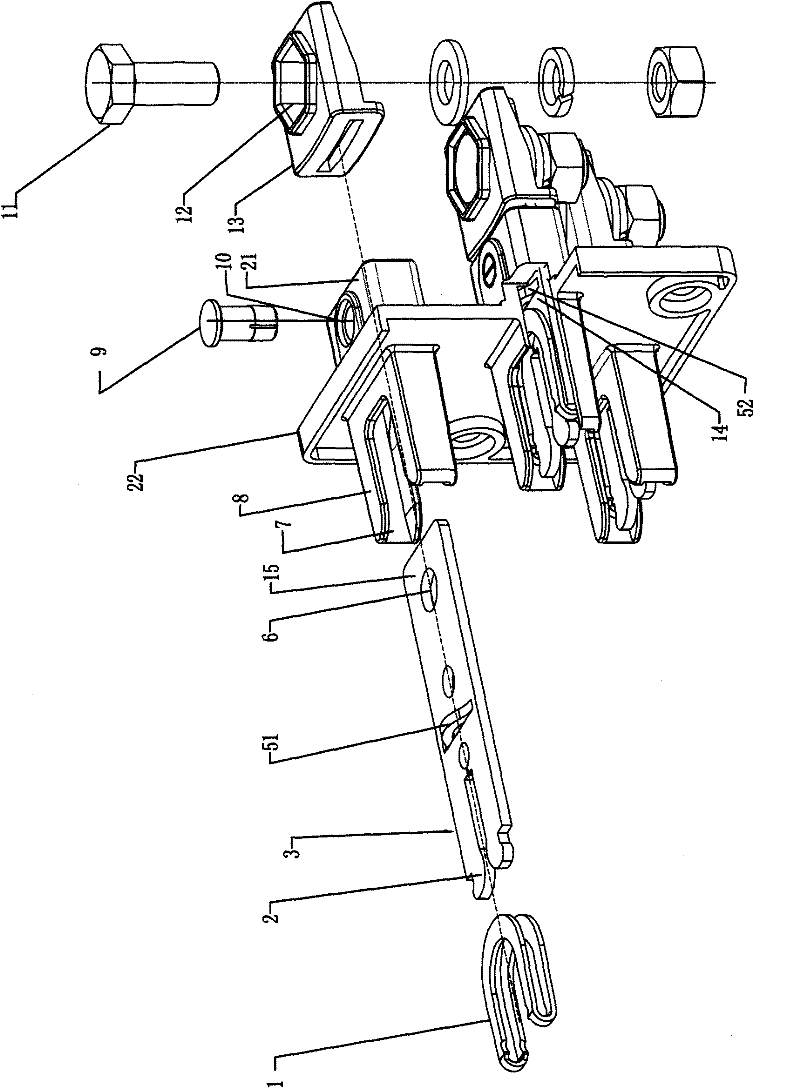

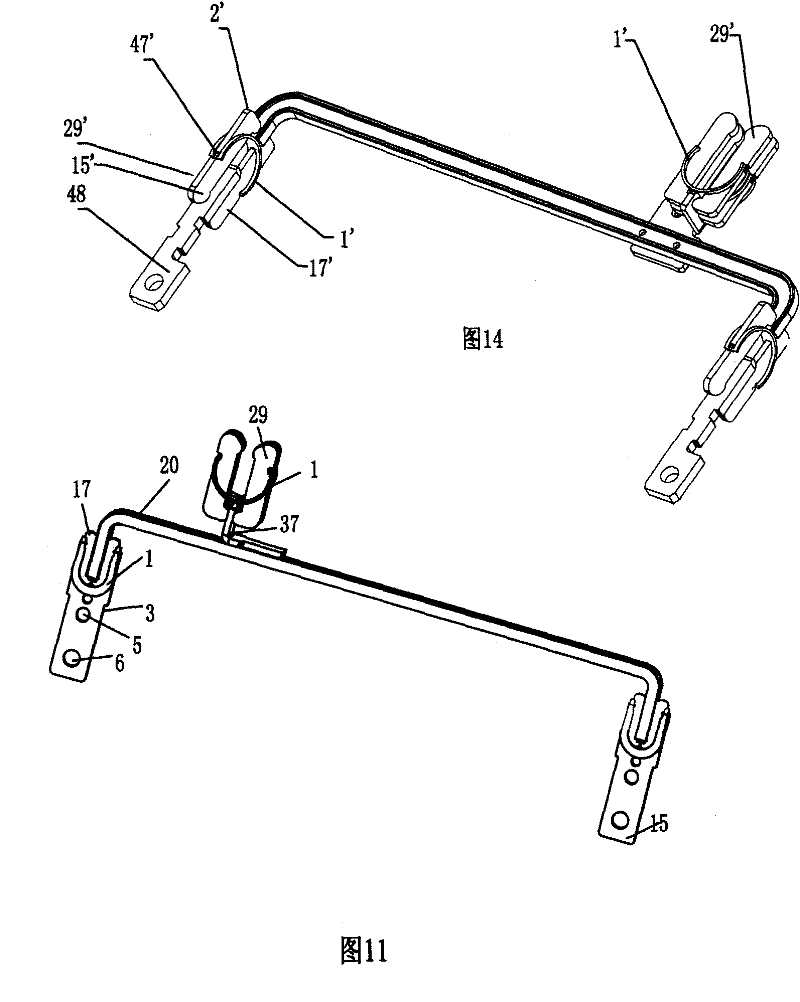

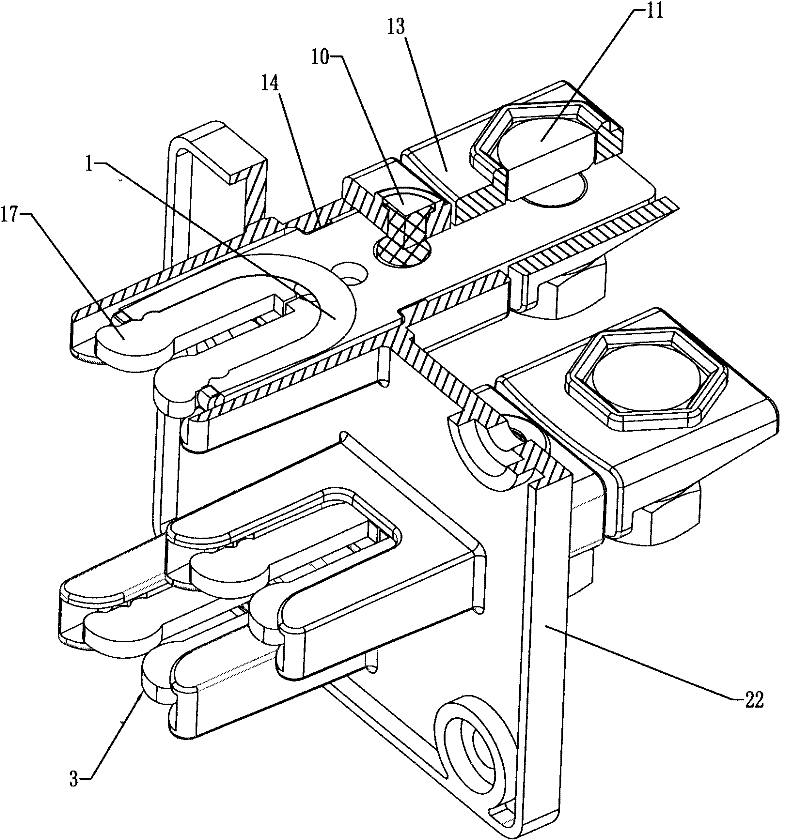

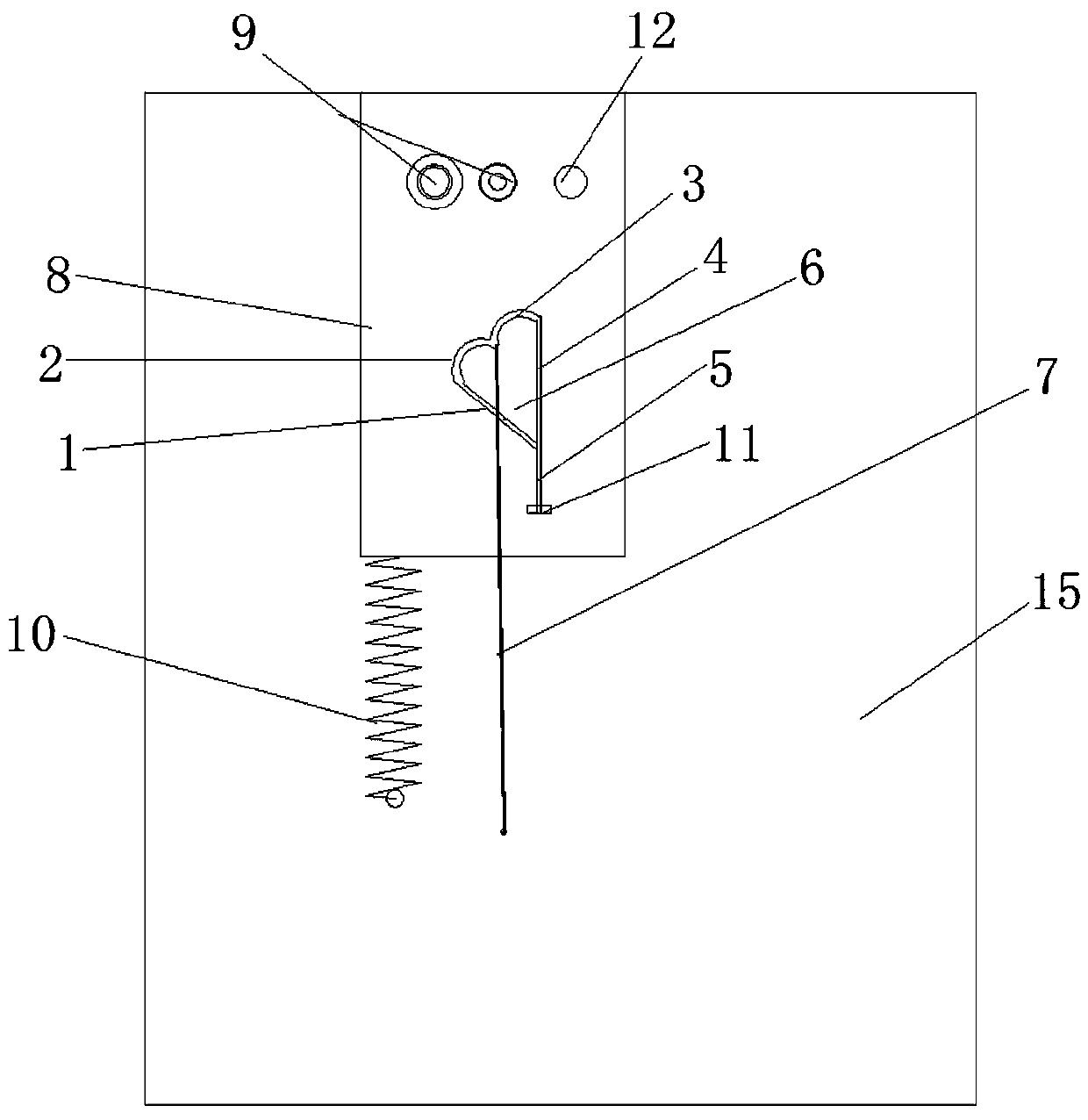

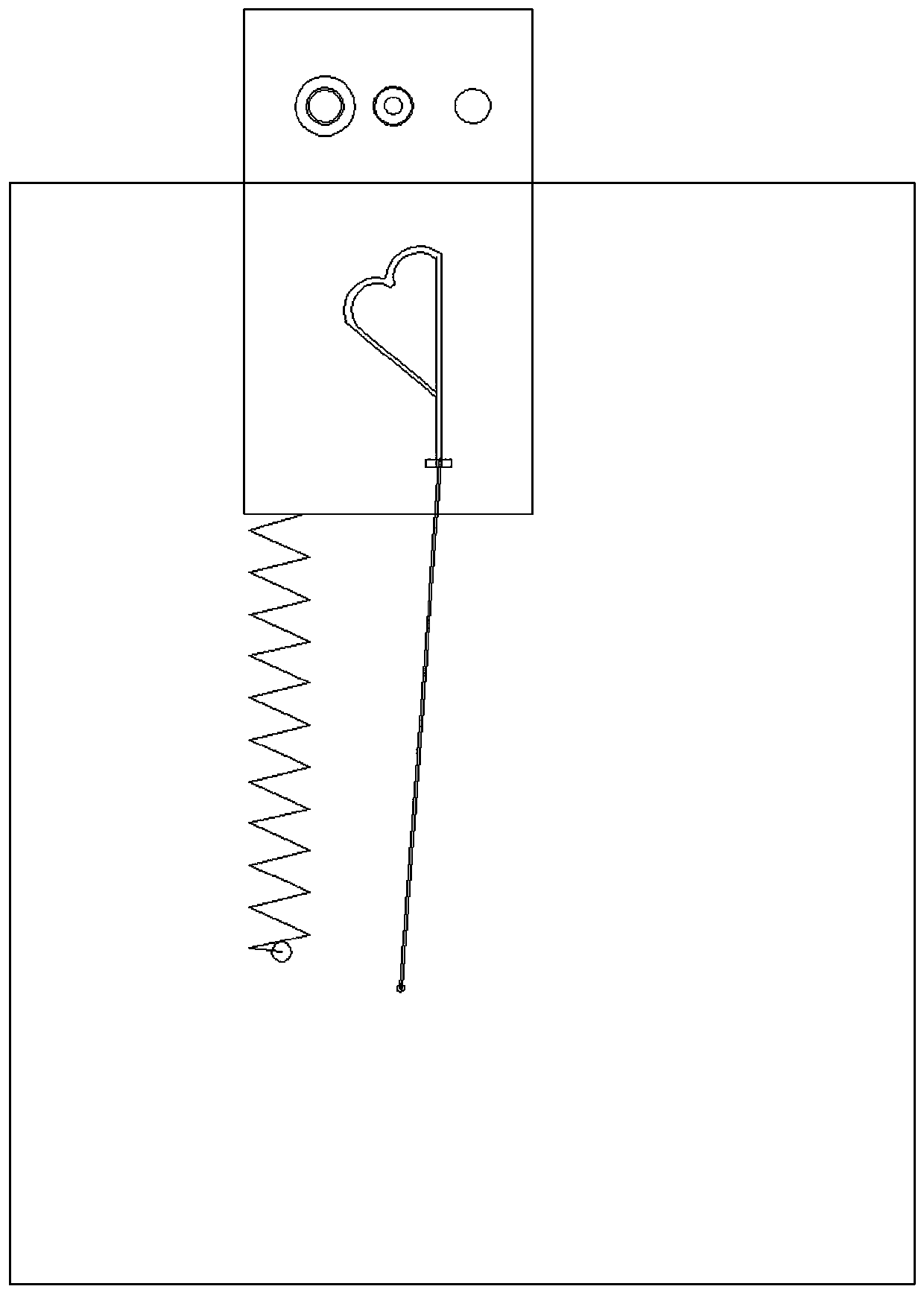

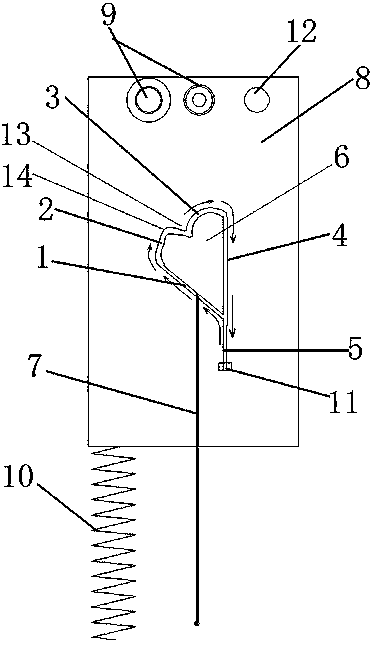

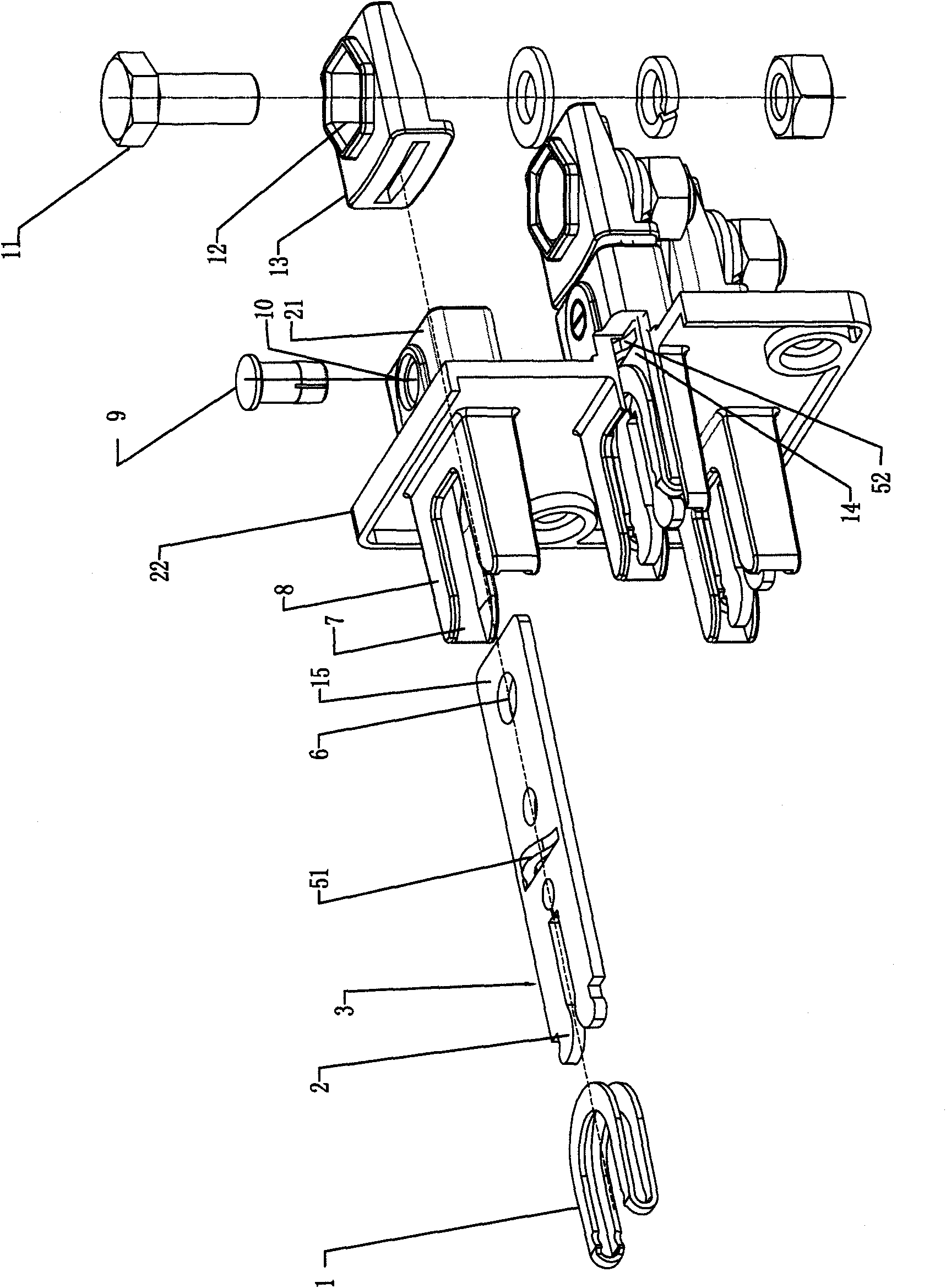

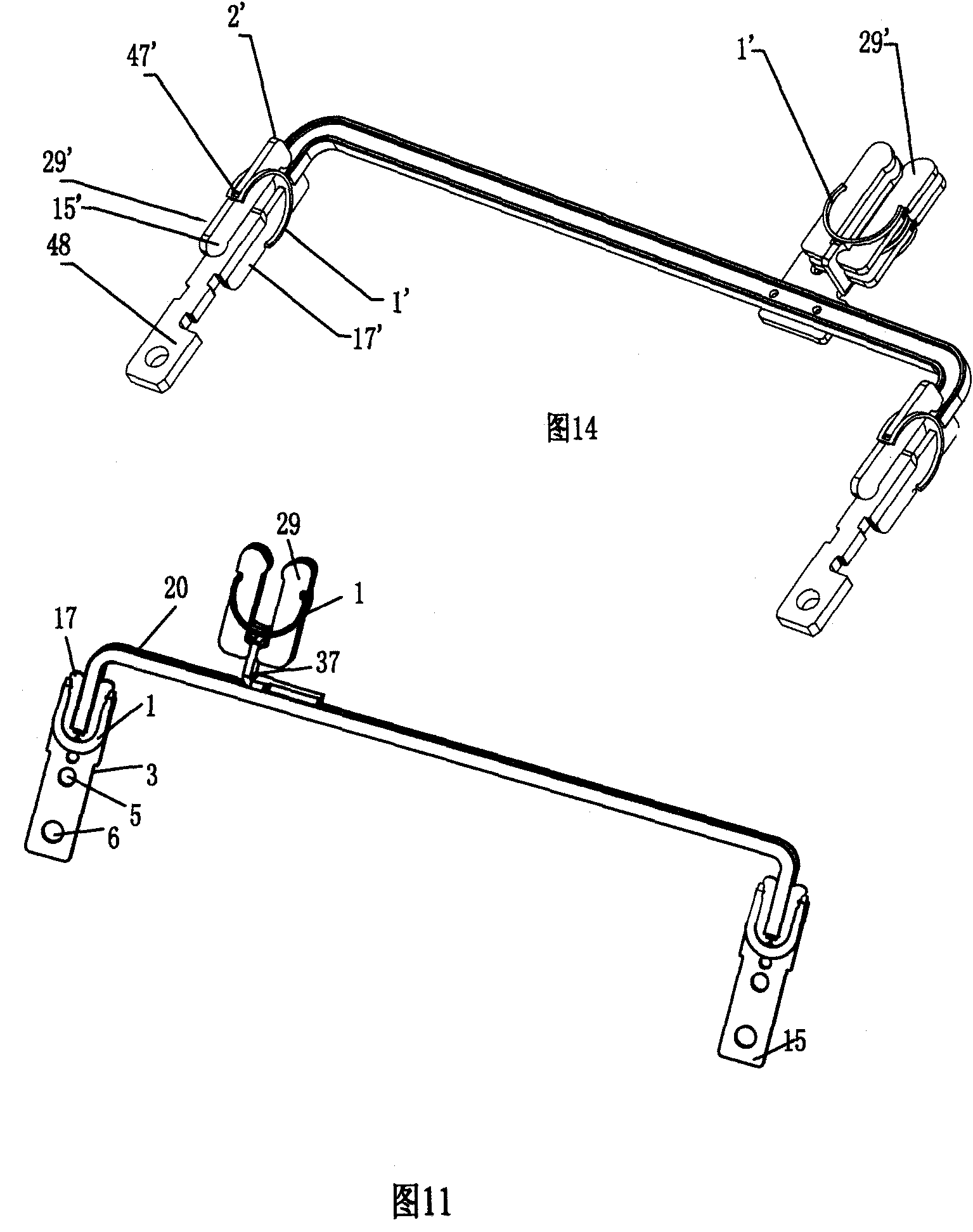

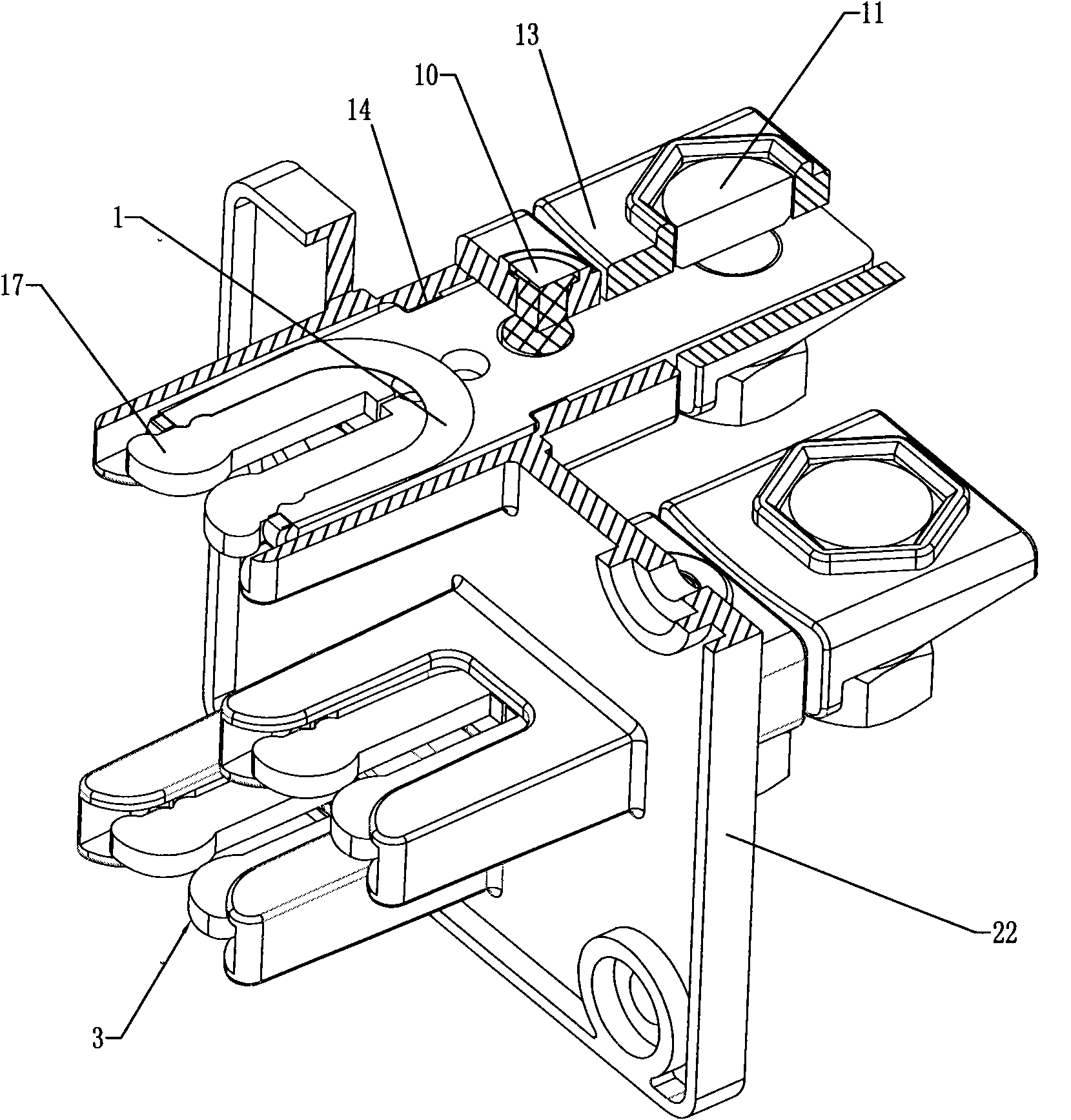

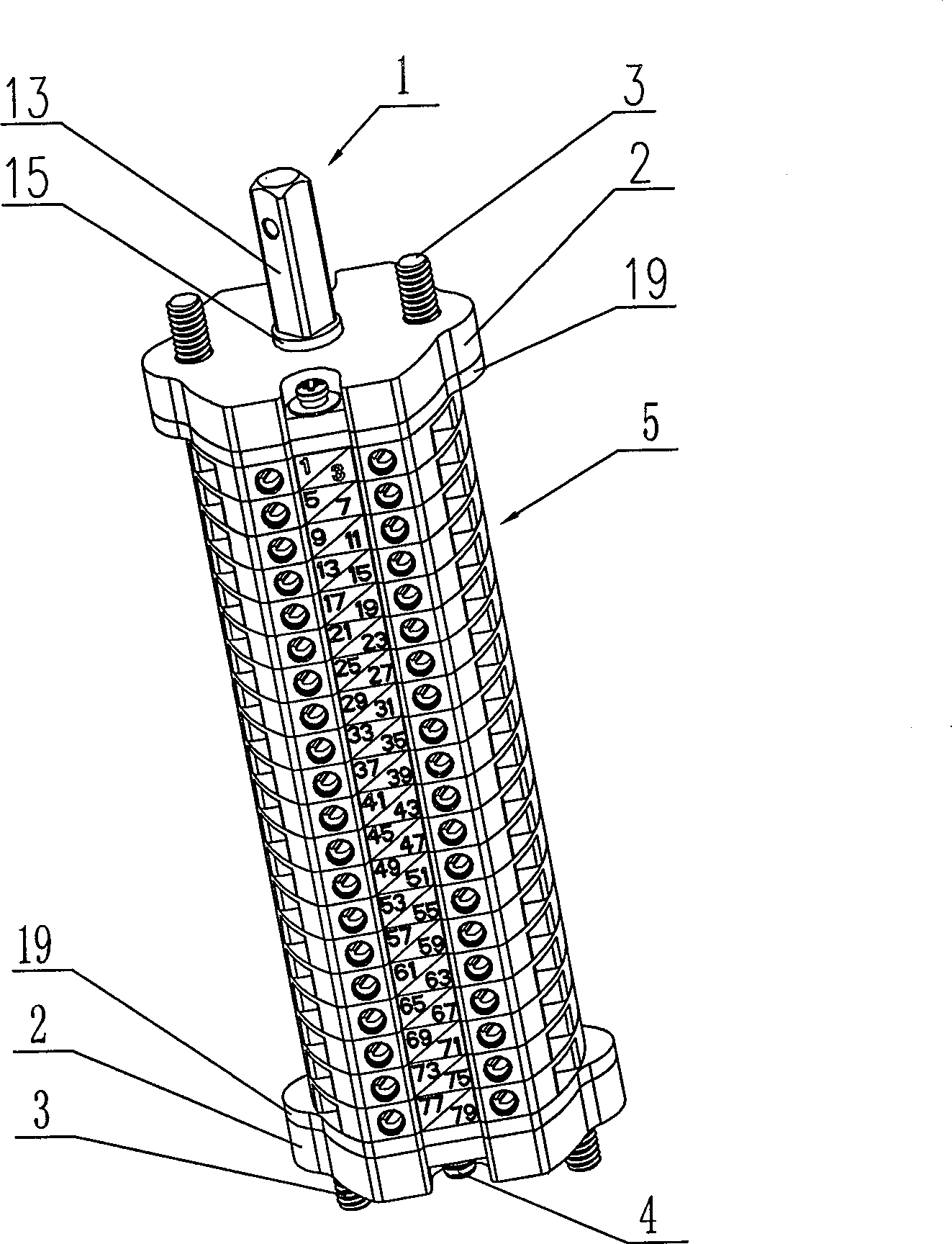

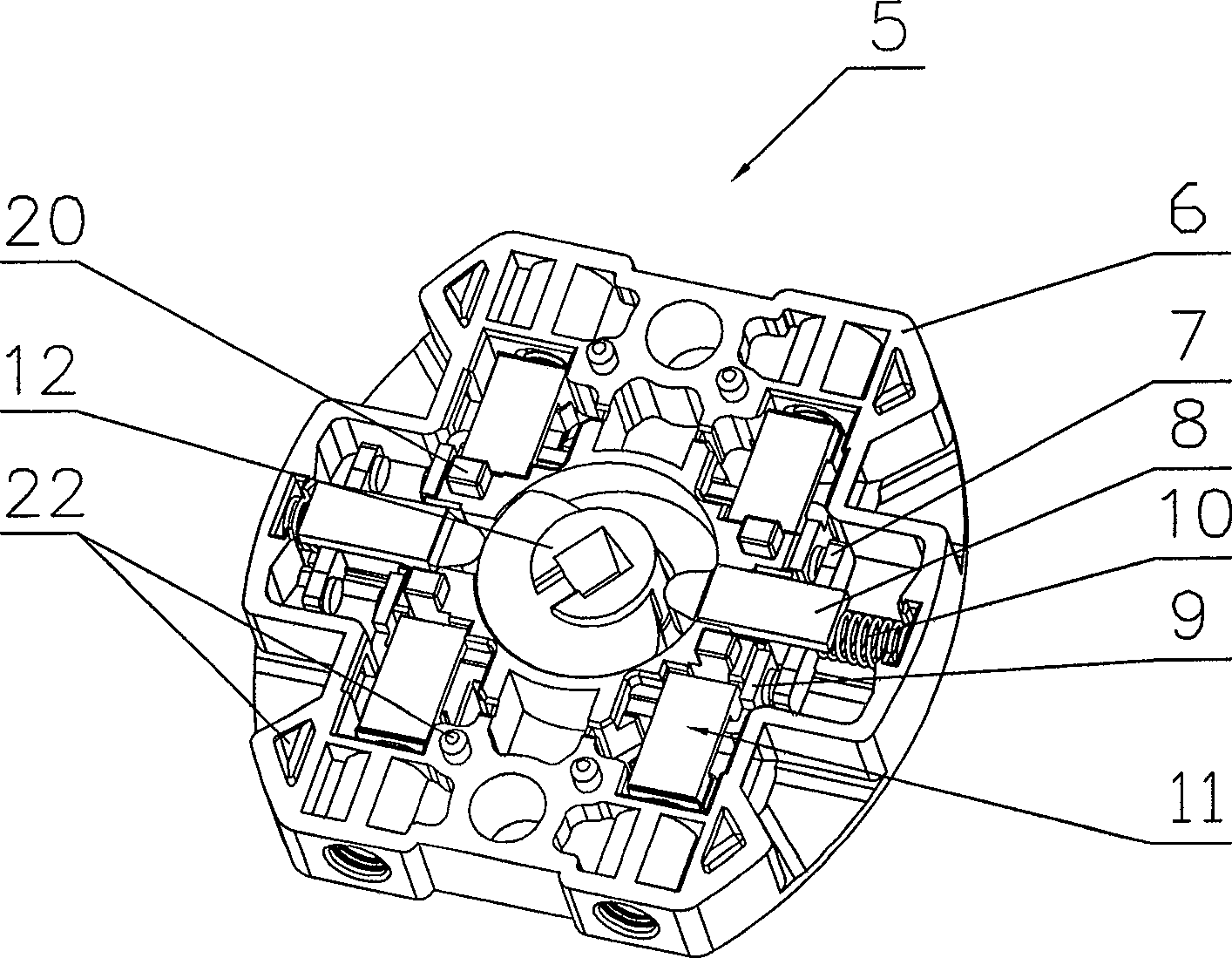

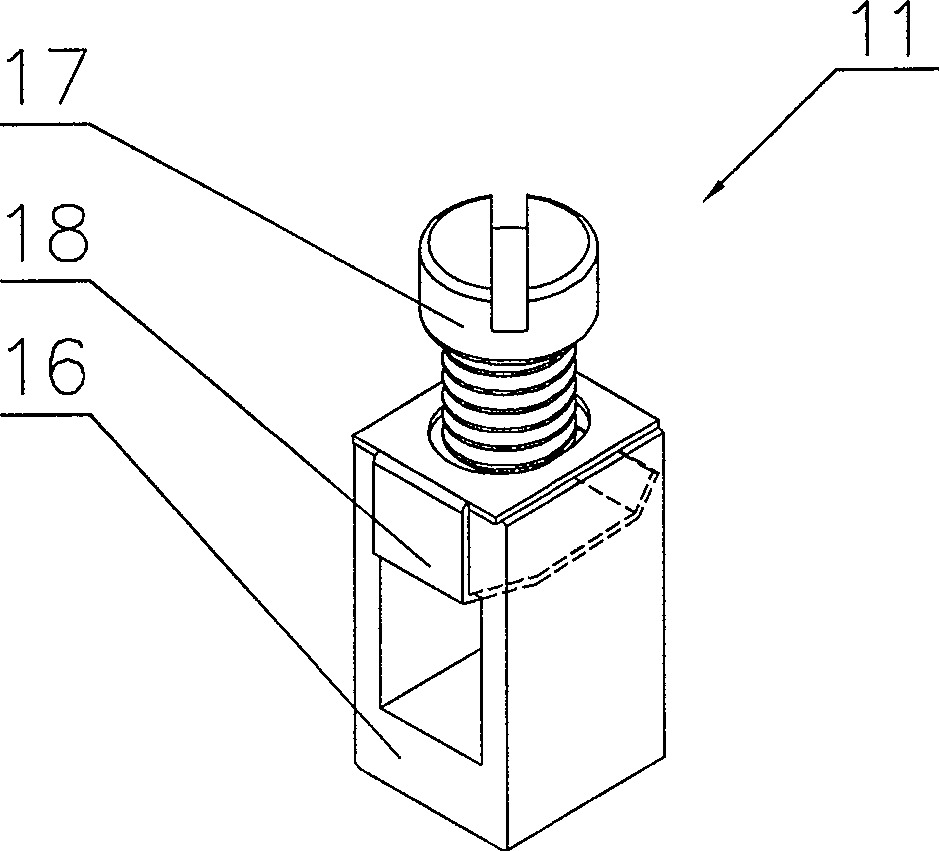

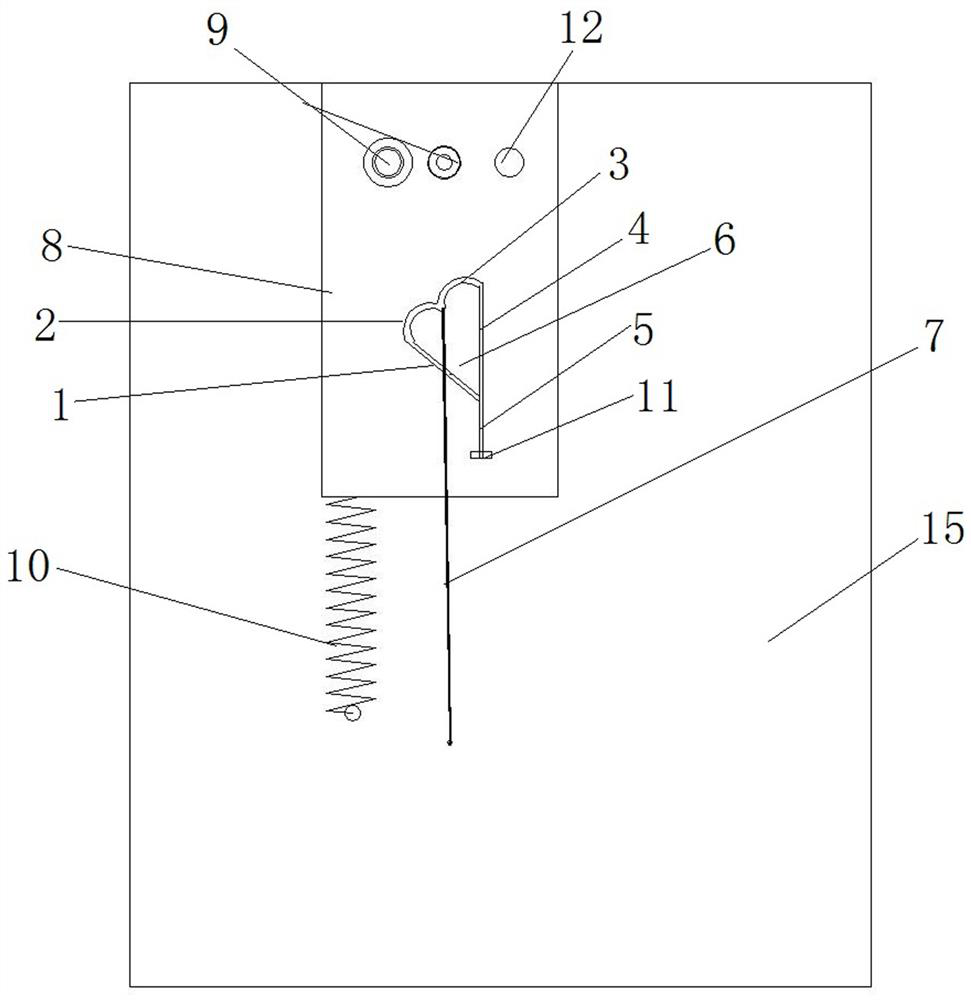

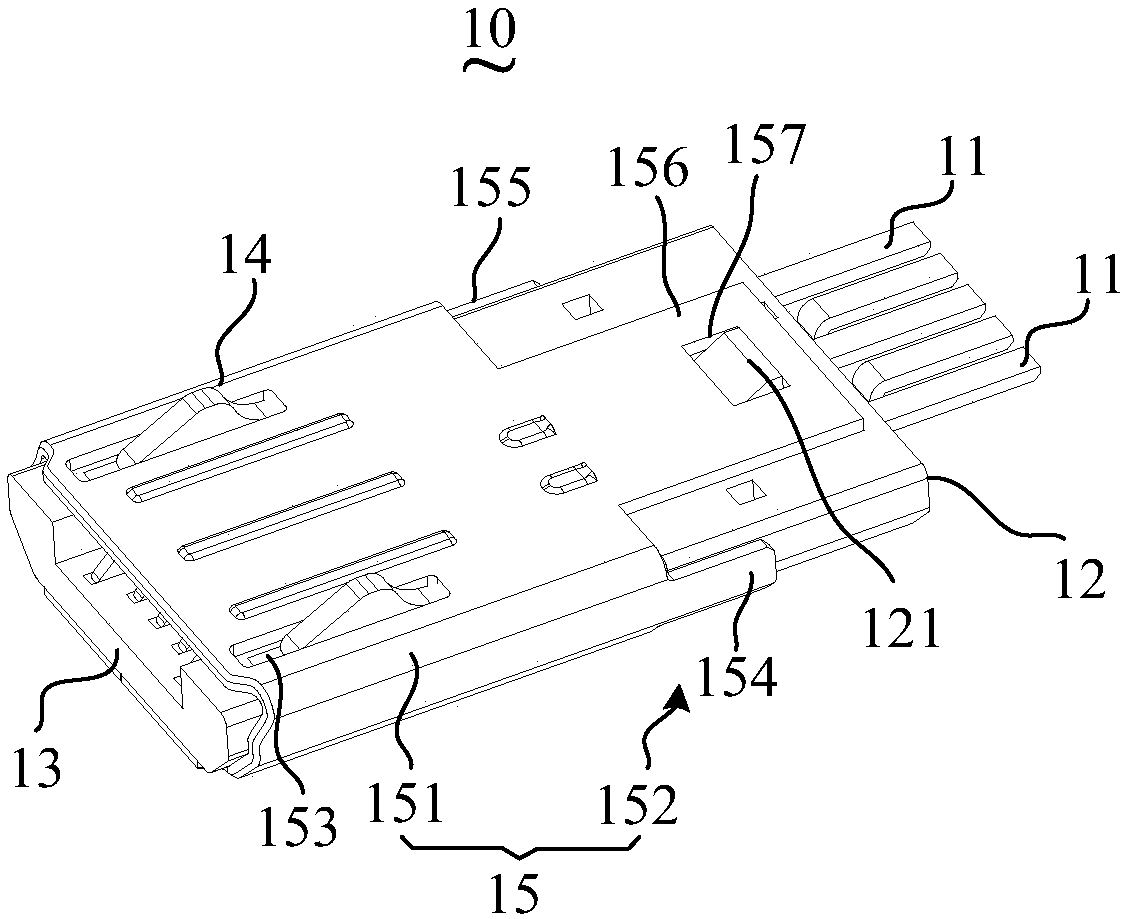

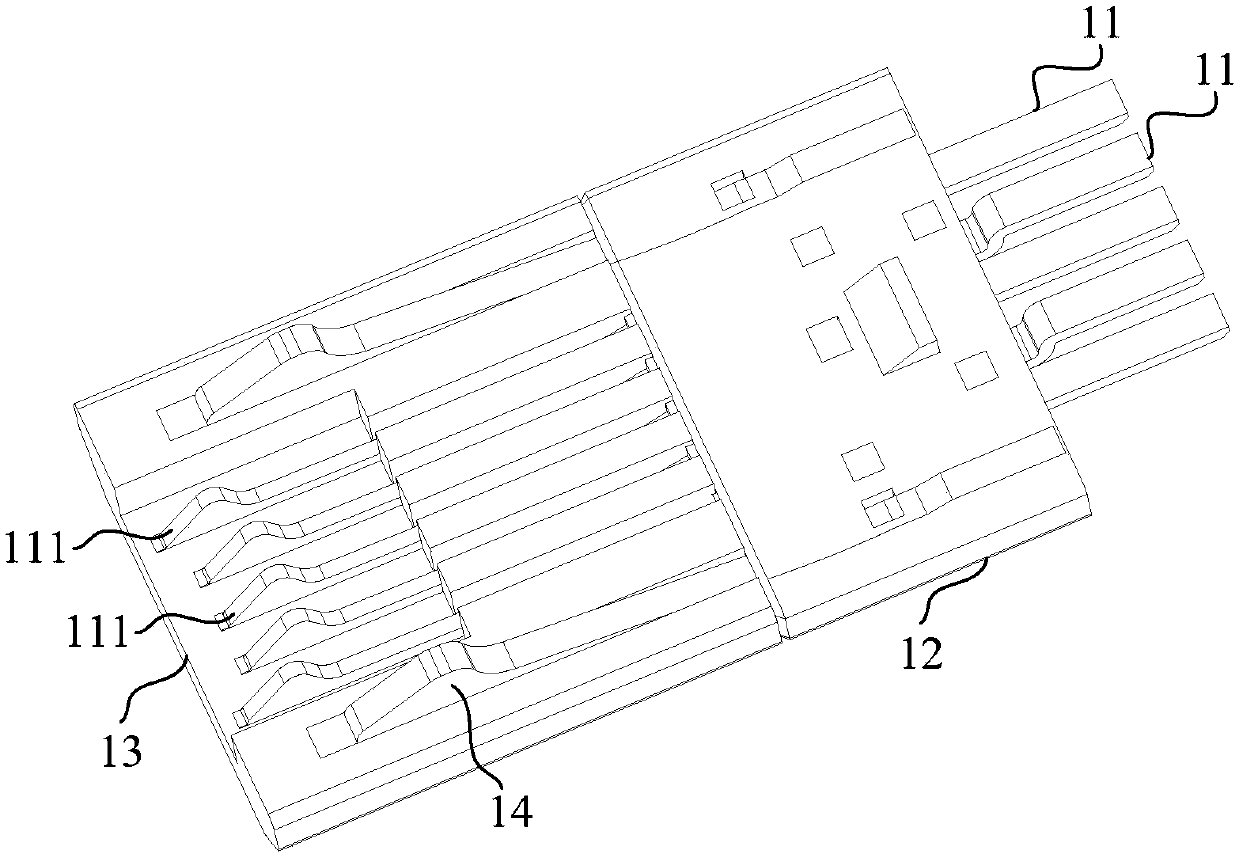

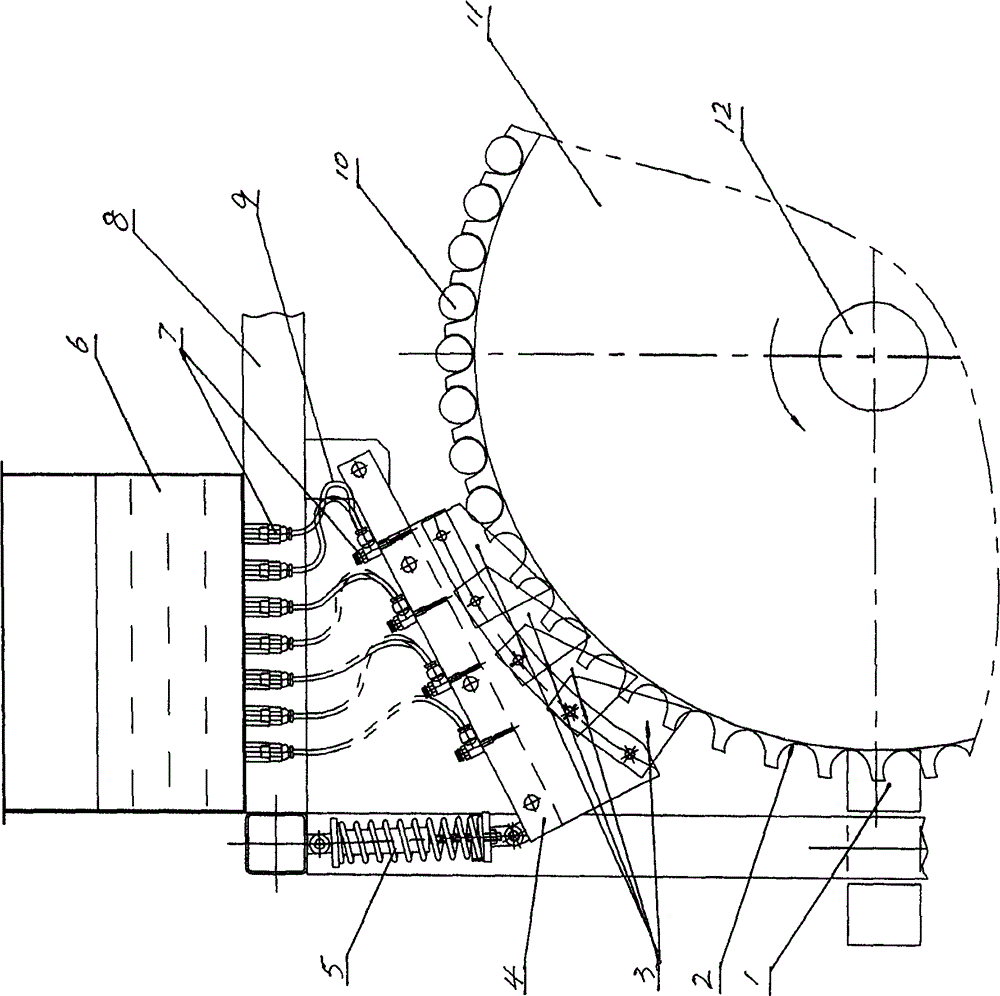

Auxiliary switch

The invention discloses an auxiliary switch, which includes a rotary shaft (1), a cover (2), a connection bolt (3), a pull rod (4), and a multi-layer contact component (5). Each layer of contact component (5) includes a base (6), a moving contact (7), a moving contact base (8), a static contact (9), a spring (10), a wiring device (11), and a cam (12). The rotary shaft (1) is divided into a thick shaft (13) and a thin shaft (14), both of which are of polygon. A limiting base (15) is arranged on the thick shaft (13) at the connection of the thick shaft (13) and the thin shaft (14). The wiring device (11) is composed of a tension frame (16) and a bolt (17). The invention has the advantages of small cubage, small thickness, multiple layers, concise structure, convenient wiring, and automatic operation.

Owner:CHENGDU RELIANCE ELECTRIC

Safety goggles with phonetic output

InactiveCN101088481BReduce distractionsSave thickness spaceGogglesEye-masksDisplay deviceEngineering

The present invention relates to one kind of safety goggles with phonetic output. The safety goggles include one goggles body, light filters, one display device, and one phonetic output device. The phonetic output device connected electrically to the display device includes one main controller, one power source unit, one sound output control unit, one sensing circuit with at least sensor set on the goggles, and one driving circuit connected electrically to the light filters. It has the welding operation state output to the phonetic output device and the plate display, so that the operator canobtain welding operation state indication auditorily and visually.

Owner:杨雅琪

A push-up type mobile phone camera device and its working method

ActiveCN111343313BGuaranteed aestheticsReduce cutting costsTelevision system detailsColor television detailsEngineeringMechanical engineering

The invention relates to a push-and-pop-up mobile phone camera device, which relates to a lifting device for a front camera of a mobile phone. A press pop-up mobile phone camera device has a sliding base, a camera is installed above the sliding base, the camera is connected to the processor signal of the mobile phone, and the side or bottom of the sliding base has an obliquely cut heart-shaped stopper, There are slide rails arranged around the block; the slide rails are respectively smoothly connected by slide rail 1, slide rail 2, slide rail 3, slide rail 4 and slide rail 5, among which slide rail 1 and slide rail 4 are respectively located on the block On both sides below, slide rail 2 and slide rail 3 are respectively located on both sides above the block, slide rail 5 is located below slide rail 1 and slide rail 4, and slide rail 5 and slide rail 4 are connected in a straight line; A sleeve rod is placed inside, and the other end of the sleeve rod is movably connected to the inside of the mobile phone; an elastic piece for pushing the sliding base to slide up and down is arranged inside the mobile phone.

Owner:无锡鸿儒网络科技有限公司

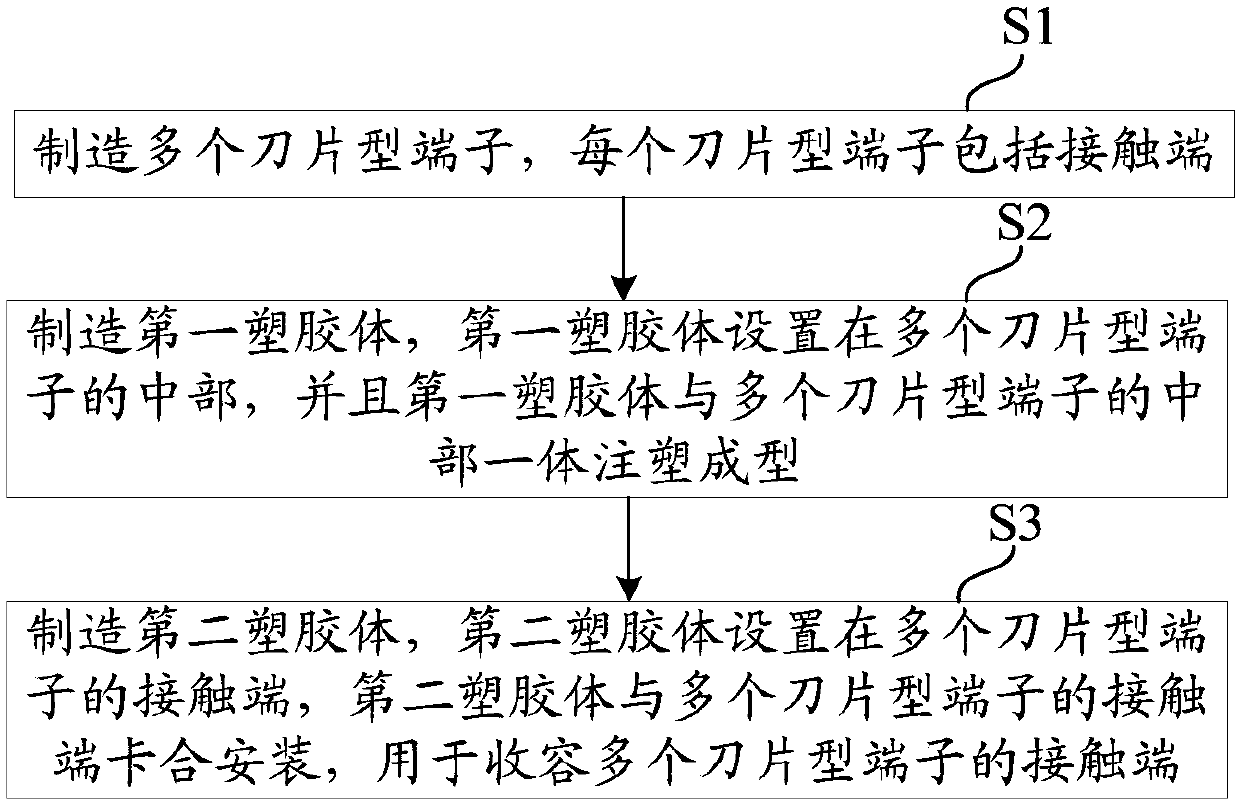

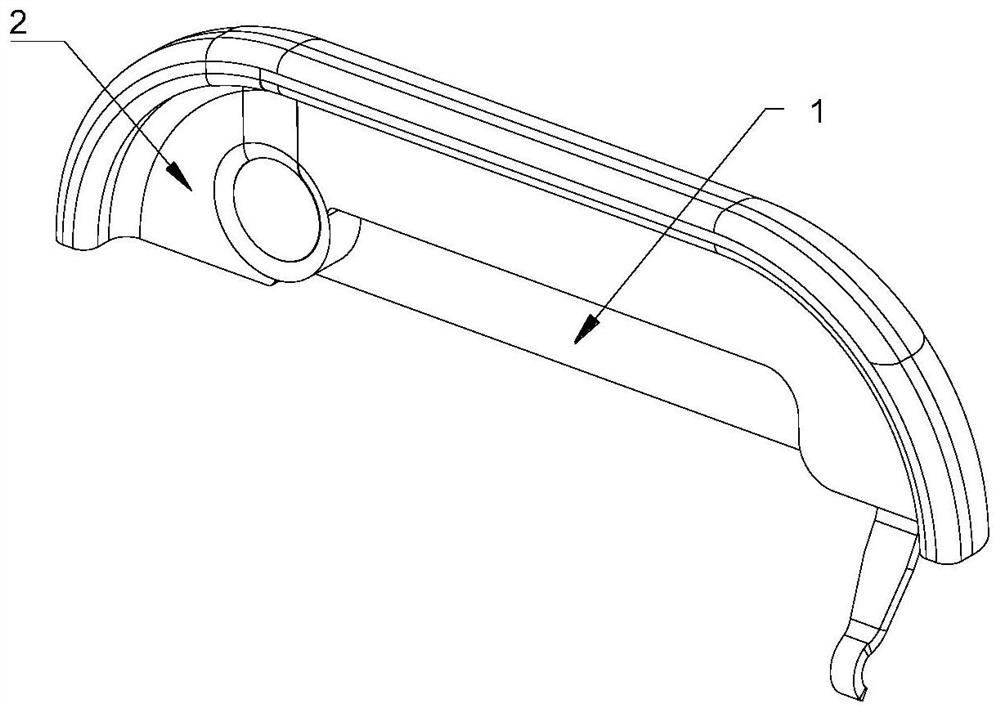

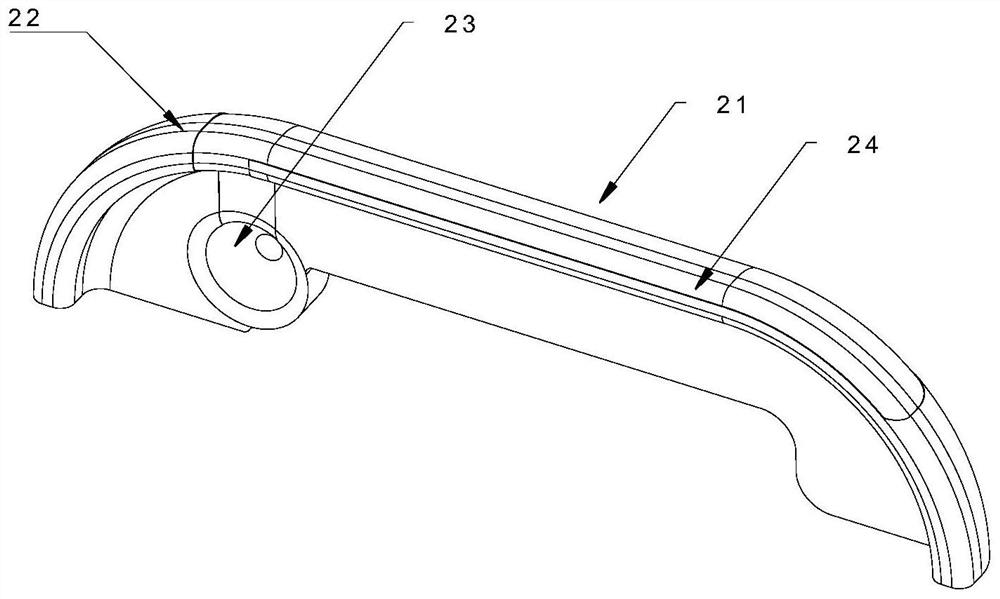

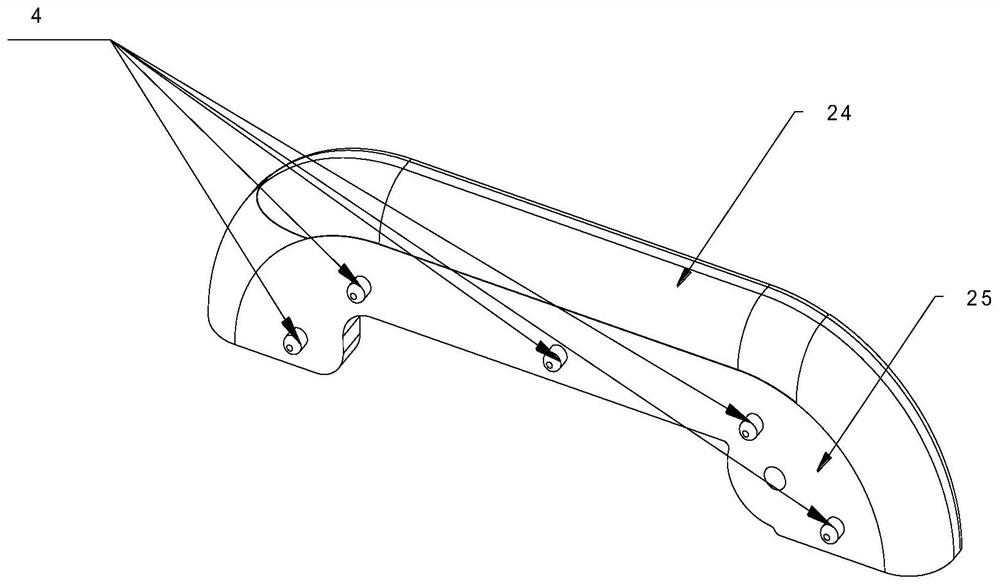

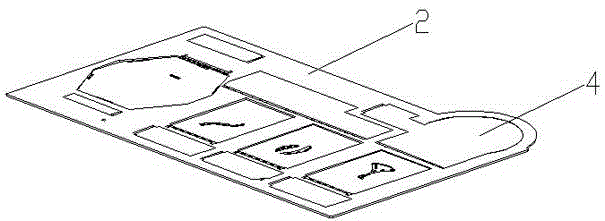

Blade type USB plug and manufacturing method thereof

InactiveCN107681304ASave thickness spaceBig plastic spaceContact member manufacturingContact member assembly/disassemblyInjection mouldingUSB

The invention discloses a blade type USB plug and a manufacturing method thereof. The blade type USB plug comprises a plurality of blade type terminals, a first plastic body and a second plastic body,and is characterized in that each blade type terminal comprises a contact end; the first plastic body is arranged at the middle parts of the plurality of blade type terminals, and the first plasticbody and the middle parts of the plurality of blade type terminals are molded through integrated injection; and the second plastic body is arranged at the contact ends of the plurality of blade type terminals, and the second plastic body is assembled with the plurality of blade type terminals in a buckling manner and used for accommodating the contact ends of the plurality of blade type terminals.Therefore, the blade type USB plug can reduce the thickness of the first plastic body under the condition of ensuring the contact stability, and enables products to be thinner, thereby having betterappearance plasticity.

Owner:SHENZHEN TINNO WIRELESS TECH +1

An electronic device and its antenna

ActiveCN110021810BImprove performanceImprove structural strengthAntenna supports/mountingsRadiating elements structural formsSheet metal stampingMechanical engineering

The invention discloses an electronic device and its antenna, comprising a sheet metal stamping antenna and an LDS antenna, the LDS antenna includes a bracket, the antenna line is chemically plated on the bracket, the bracket is fixedly connected to the sheet metal stamping antenna, and the LDS antenna is connected to the sheet metal stamping antenna The antenna is conductive by soldering. In the electronic equipment and its antenna provided by the present invention, a part of the antenna is made by LDS technology, and the other part is made by sheet metal parts, so it has both the advantages of sheet metal stamping antenna and LDS antenna, and the space of the curved surface can be rationally used by the LDS antenna , so as to improve the performance of the antenna, and can also take advantage of the thickness advantage of the sheet metal stamping antenna to partially save the space in the thickness direction, and increase the overall structural strength and reliability of the antenna. To sum up, the electronic device and its antenna provided by the present invention can meet the space limitation, structural strength and reliability requirements of the electronic product for the antenna.

Owner:荣成歌尔科技有限公司

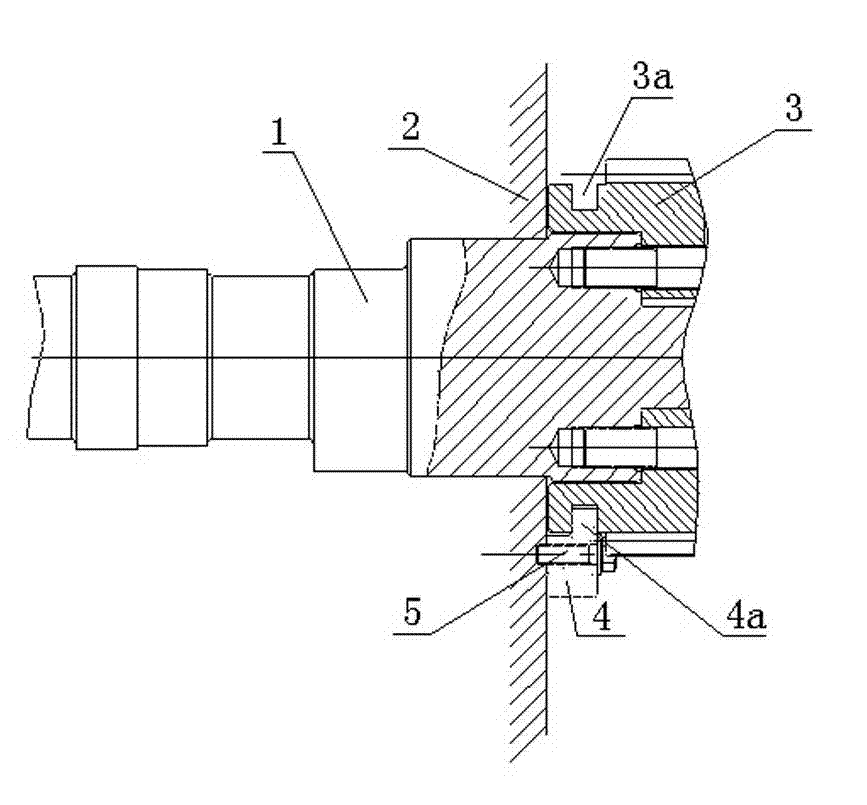

Thrust structure of engine cam shaft

An engine camshaft thrusting structure. A camshaft (1) is arranged on an engine block (2). A gear (3) is arranged on an outer end of the camshaft (1). An annular groove (3a) is provided on the periphery of the gear (3) close to the engine block (2). A thrust plate (4) is fixed on the engine block (2). Arranged on the thrust plate (4) is a positioning nosing (4a) for snapping into the annular ring (3a). The camshaft thrusting structure allows for reduced overall diameter of the camshaft, thus allowing for reduced blank size, and for reduced manufacturing difficulty. While at the same time, because an annular protrusion of the camshaft is obviated, the space for the thickness of the thrust plate is conserved, this allows for reduced distance between an end face of the camshaft and the engine block, thus for reduced size of the entire engine.

Owner:WUXI KIPOR POWER CO LTD

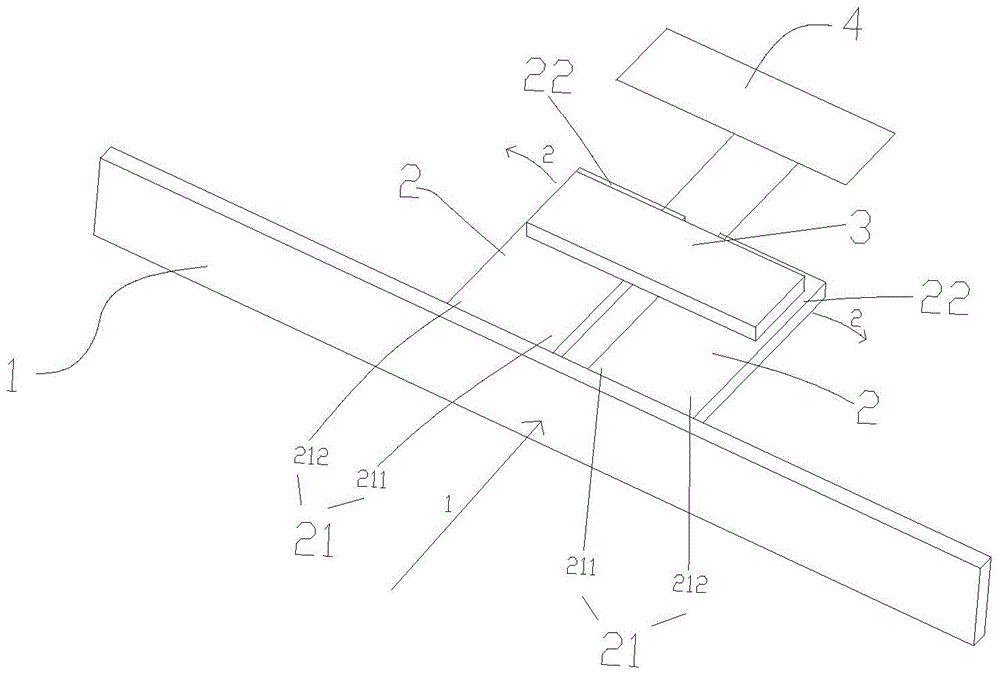

A kind of fpc device mounting method, fpc component and terminal

ActiveCN107454756BGuaranteed smoothSave thickness spacePrinted circuit assemblingSurface mountingEngineering

The invention provides a flexible printed circuit (FPC) device surface-mounting method, an FPC assembly and a terminal. The method comprises the following steps of pasting a first surface of a reinforcement plate and a first surface of an FPC by an adhesive layer; attaching a target device onto a region, corresponding to the adhesive layer, of a second surface of the FPC; and separating the adhesive layer and the reinforcement plate from the FPC, wherein the first surface of the FPC and the second surface of the FPC are two surfaces, opposite to each other, of the FPC. Therefore, the FPC and the reinforcement plate are pasted to ensure that the FPC is smooth during device surface-mounting on the FPC, the FPC carried with the target device is separated from the adhesive layer after surface mounting of the target device is completed, the purpose of removing the reinforcement plate after FPC surface-mounting is achieved, so that the integral thickness of the FPC device region is thinned, and the thickness space occupied by the FPC is favorably saved.

Owner:VIVO MOBILE COMM CO LTD

Circuit board module

ActiveCN102679288BSimple structureEasy processing and assemblyMechanical apparatusPoint-like light sourceLight guideEngineering

The invention discloses a circuit board module which comprises a circuit board provided with an LED (Light Emitting Diode) light source and an anode and a cathode connected with the LED light source. The circuit board is provided with a lightproof positioning plate which covers the circuit board. The positioning plate is provided with a light guide plate assembly corresponding to the LED light source in position. The light guide plate assembly comprises at least a light guide plate such that the LED light source is taken as a background light source for transparency or / and the LED light source is taken as a work exhibition light source for transparency. By the arrangement of the light guide plate assembly, the whole light guide plate assembly forms a uniform light emitting surface when the LED light source emits light. For an independent light emitting area, a single-layer light guide plate assembly can be directly used as the background light source to emit light. For crossed and superposed light emitting areas or the light emitting areas in complex relationships, two or more layers of light guide plates are combined and superposed to form the light source to emit light and change to various suitable light emitting shapes and effects so as to achieve the optimal light emitting effect.

Owner:江门市艺光科技开发有限公司

Chinese date sequential slicing mechanism

InactiveCN103264403BNot easy to cause adhesionMake sure not to damageMetal working apparatusEngineeringKnife blades

The invention relates to a Chinese date sequential slicing mechanism which comprises a machine frame. A material stirring disc is arranged on an inner side of the machine frame, and the material stirring disc is vertically arranged and can rotate. Grooves are evenly formed in the outer circumference of the material stirring disc in the circumferential direction. A knife rest is fixed on the portion, above the material stirring disc, of the machine frame, and a hairbrush mechanism is arranged on the position, below the knife rest, of the machine frame. The Chinese date sequential slicing mechanism is characterized in that a plurality of sets of slicing knives are arranged on the inner side of the knife rest in the rotation direction of the material stirring disc, the number of the slicing knives in the last set of slicing knives is one, the number of the slicing knives in other sets of slicing knives is two, and the other sets of slicing knives are located on two sides of the last set of slicing knives and slowly and outwards expand to be distributed at equal interval. On a projective plane parallel to the disc face of the material stirring disc, each set of slicing knives are partially overlapped with the previous set of slicing knives. Blade grooves are formed in the positions, where the slicing knives correspond to, of the outer circumference of the material stirring disc, and parts of cutting edges of the slicing knives are inserted in the blade grooves corresponding to the slicing knives. By means of the mechanism, slicing processing can be carried out on different parts of a Chinese date in sequence, damage to Chinese date sheets cannot be caused easily, and material discharging difficulties are avoided.

Owner:JIANGSU KAIYI INTELLIGENT SCI & TECH

LED flickering device

ActiveCN102663970BSimple structureImprove visual effectsAdvertisingIlluminated signsLight guideTransmitted light

The invention discloses an LED flickering device which comprises a circuit board. LED light sources, anodes and cathodes are arranged on the circuit board, each anode and the corresponding cathode are conducted with the corresponding LED light source, a positioning plate which covers on the circuit board and is light-proof is disposed on the circuit board, a light guide plate component corresponding to positions of the LED light sources is arranged on the positioning plate and consists of at least one light guide plate, the LED light sources are used as background light source to transmit light or the LED light sources are used as working display light sources to transmit light by the aid of the light guide plates, an optical filter covers on the light guide plate component, and a light-transmitting pattern layer covers on the optical filter. When the LED light source are luminous, the integral light guide plate component forms a uniform luminous surface; the light guide plate component with a single layer can be directly used as the background light source to emit light for an independent luminous area; two or more layers of light guide plates can be combined and stacked to form a light source to emit light when the LED flickering device is used in a luminous area with cross superposition or other complicated relations, various suitable luminous shapes and effects are realized after change, and an optimal luminous effect is achieved.

Owner:广东大仲马广告有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com