Thrust structure of engine cam shaft

A technology for camshafts and engines, applied in the directions of engine components, machines/engines, connecting components, etc., can solve the problems of insufficient structure, increase the size of the blank, increase the difficulty of manufacturing, etc., so as to reduce the overall diameter and reduce the blank. Size, the effect of saving thickness and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

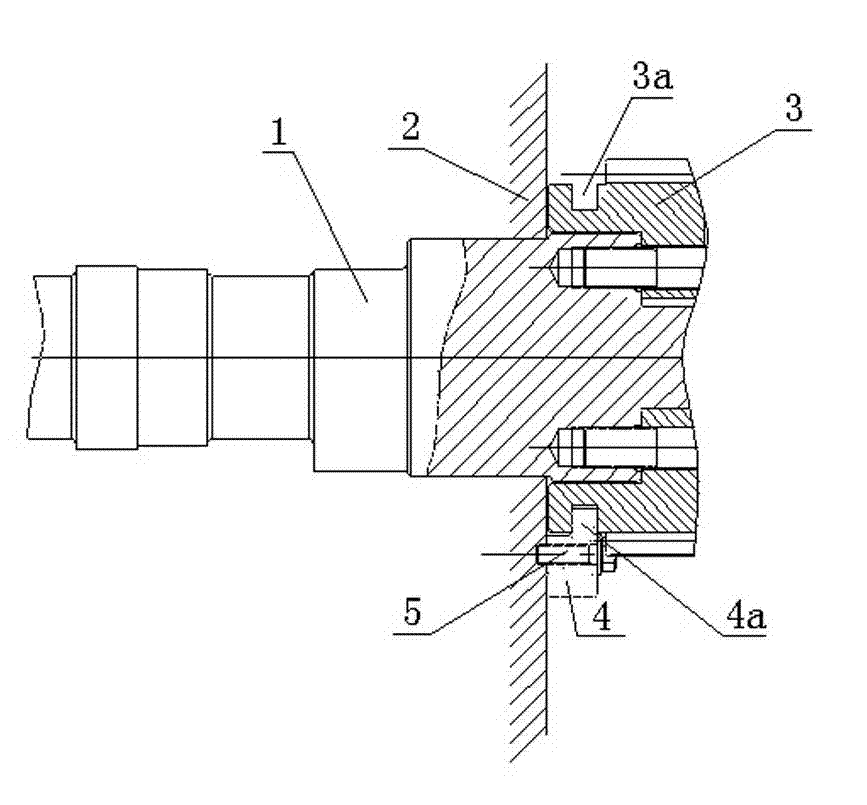

[0012] Such as figure 1 As shown, the camshaft 1 is installed on the engine body 2, the gear 3 is installed on the outer end of the camshaft 1, and the outer circumference of the gear 3 near the end of the engine body 2 is provided with an annular groove 3a; the thrust plate 4 is fixed on the engine body by bolts 5 2, the thrust plate 4 is provided with a positioning lip 4a that is snapped into the annular groove 3a, so that the thrust plate 4 fixed on the engine body 2 limits the relative movement of the camshaft 1 in the axial direction. Movement of the engine block 2.

[0013] Such as figure 1 As shown, the side of the positioning convex edge 4a of the thrust plate 4 corresponding to the annular groove 3a is concave arc-shaped, so as to adapt to the shape of the annular groove 3a. An oil channel is opened in the thrust plate 4, and the oil channel is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com