Blade type USB plug and manufacturing method thereof

A manufacturing method and blade technology, which is applied in the field of data transmission, can solve the problems of the plasticity space of the outer mold becomes smaller, the appearance design cannot be achieved, and the overall thickness of the USB plug becomes thicker, so as to achieve the effect of saving thickness space and large plastic space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

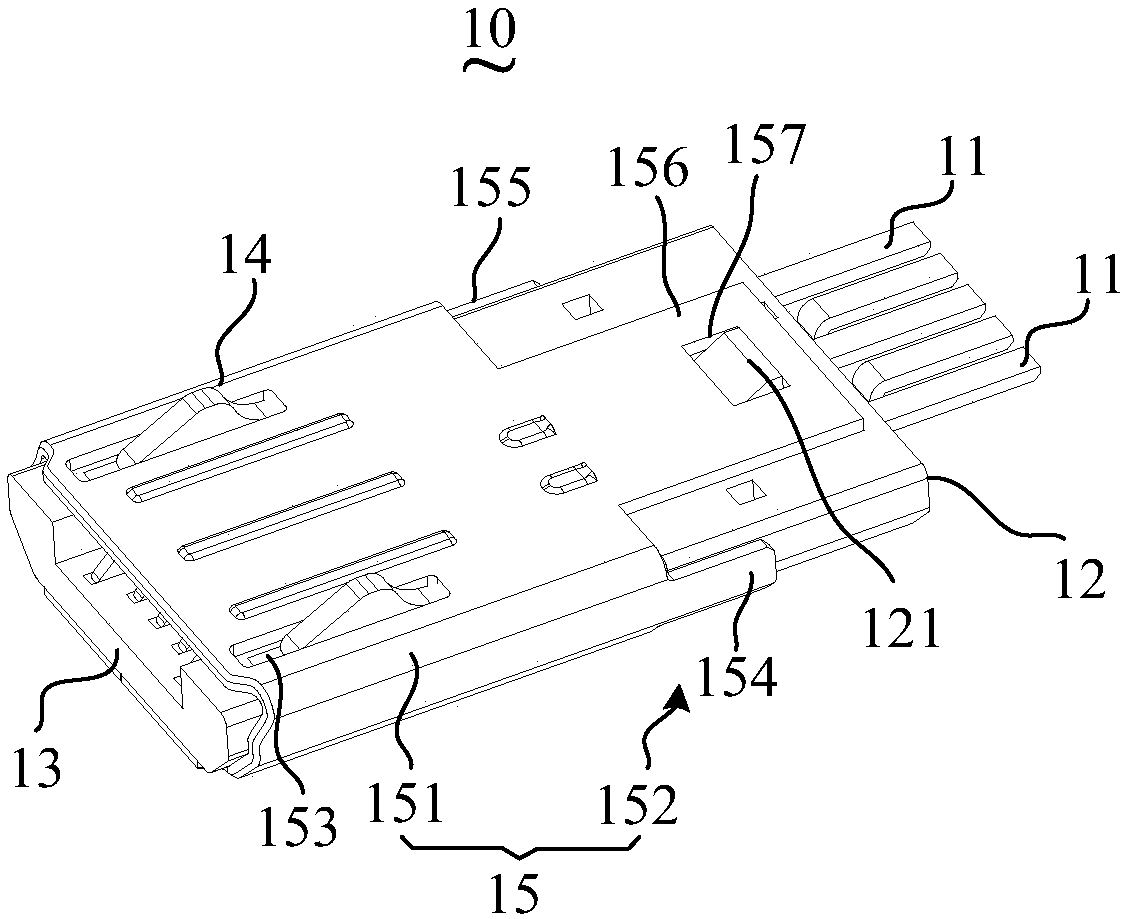

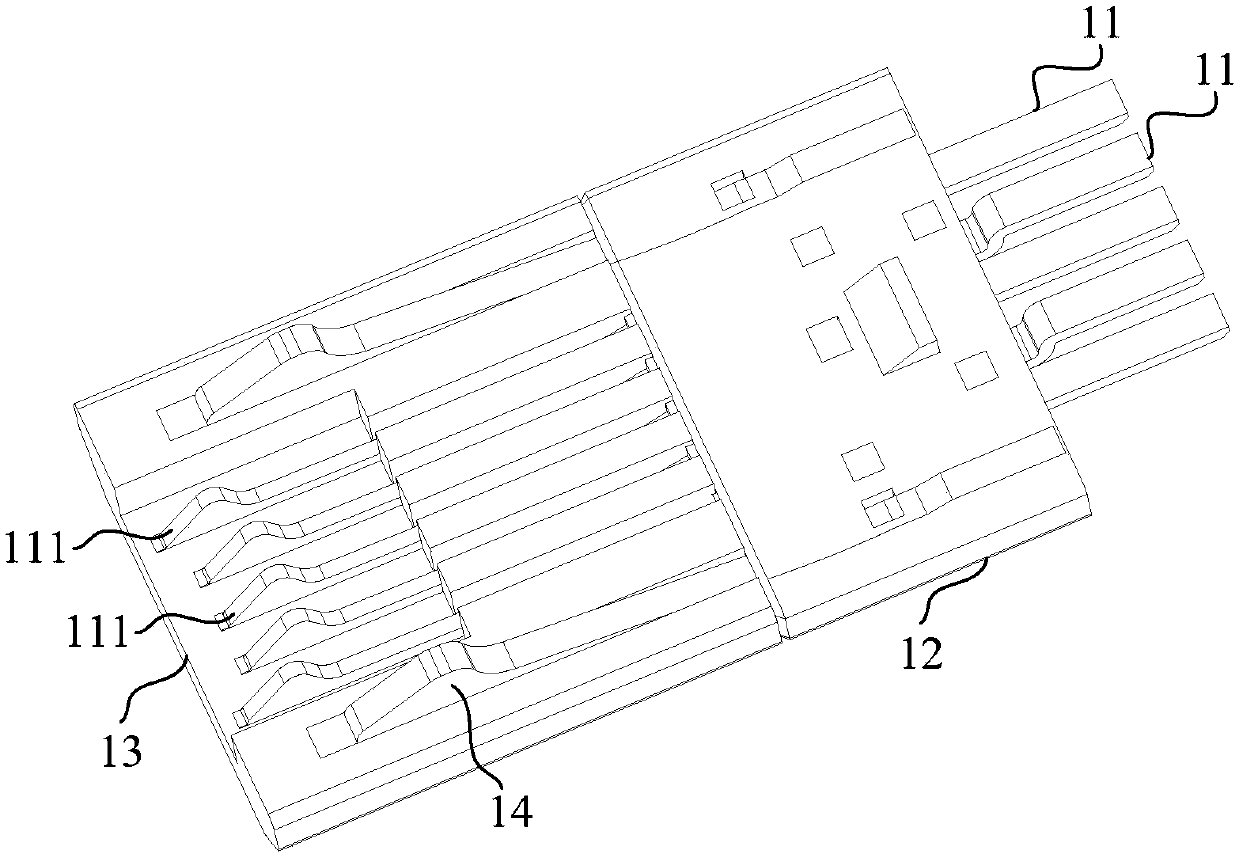

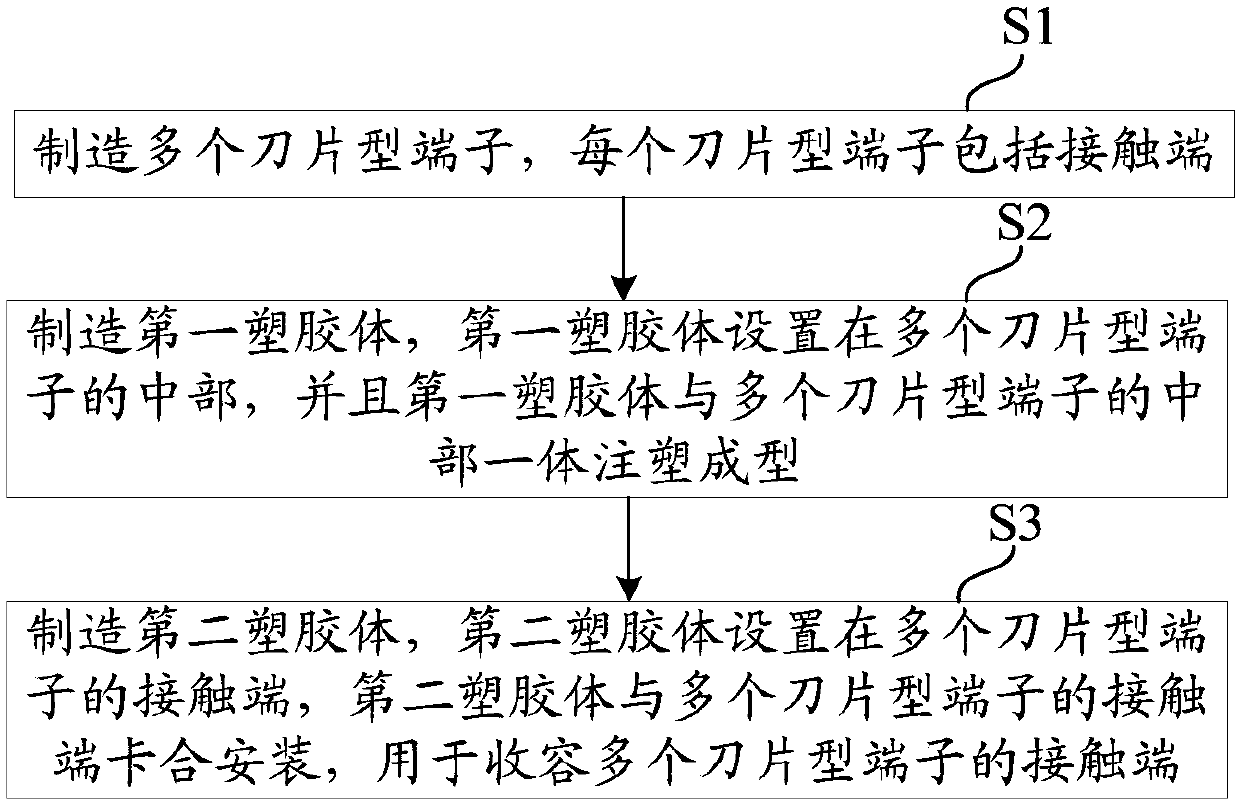

[0034] Please refer to figure 1 Such as 2, figure 1 Is a schematic structural diagram of a blade-type USB plug provided by an embodiment of the present invention, figure 2 Yes figure 1 The USB plug shown is a structural schematic diagram when the shell is omitted. Such as figure 1 with figure 2 As shown, the blade type USB plug 10 of this embodiment includes a plurality of blade type terminals 11, a first plastic body 12 and a second plastic body 13.

[0035] Among them, each blade type terminal 11 includes a contact end 111. The contact end 111 is an arched structure, and the contact end of the arched structure can disperse the pressure downwardly and outwardly when subjected to a positive pressure, so the contact end of the arched structure can withstand greater pressure, so that the contact of the terminal 11 is stable. In this embodiment, the blade-type USB plug 10 includes five blade-type terminals 11, which are sequentially used to connect the positive terminal of the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com