Novel lithium-ion polymer battery and packaging process thereof

A packaging process and polymer technology, which is applied in the manufacture of battery pack components, non-aqueous electrolyte batteries, and electrolyte battery manufacturing, etc. The effect of strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

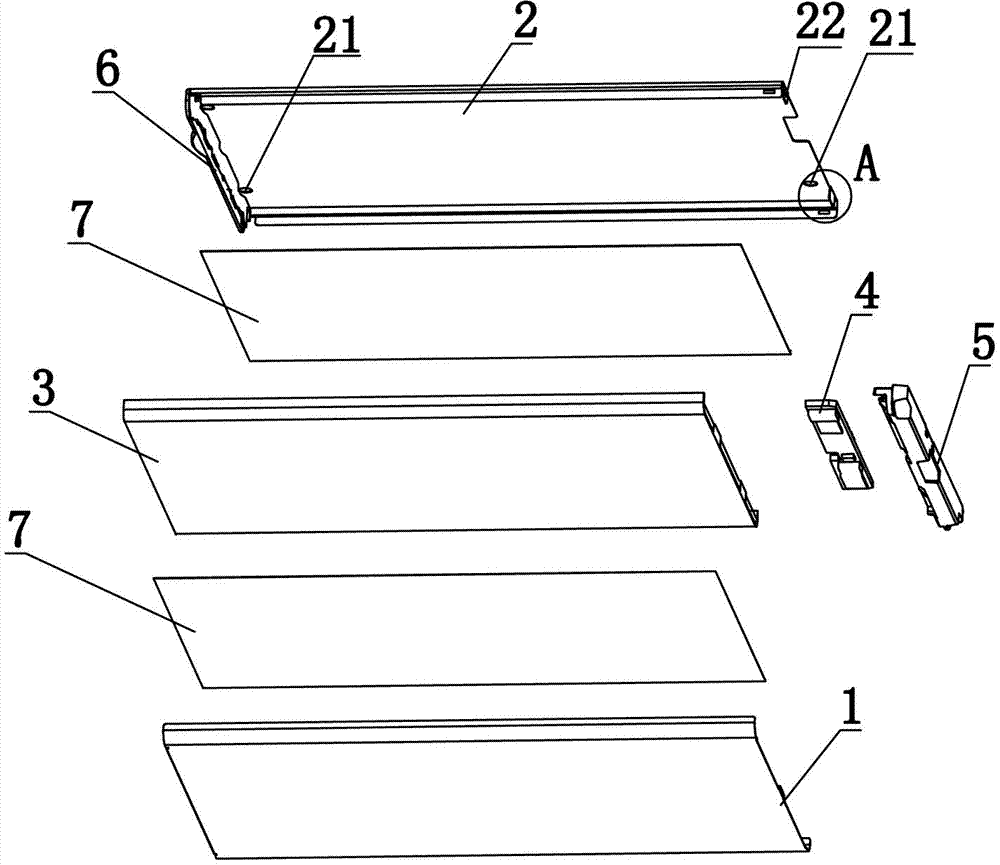

[0024] Such as figure 1 As shown, a novel lithium ion polymer battery comprises a metal lower case 1, a metal upper case 2, and a polymer cell assembly, and the metal upper case 2 is provided with several injection ports 21; the polymer The cell assembly includes a polymer cell 3, a protective plate 4, a front cover 5, and a rear cover 6, and the rear cover 6 is connected to one end of the metal upper case 2; the ear end of the polymer cell 3 is welded with a protective plate 4 The front cover 5 is sleeved on the protective plate 4; the other end of the polymer cell 3 is connected to the rear cover 6; the metal upper case 2 and the metal lower case 1 are pasted by double-sided adhesive 7 Combine the upper and lower sides of the polymer cell assembly; the back cover 6 is located at the tail end of the metal upper case 2 and the metal lower case 1; the front cover 5 is located at the metal upper case 2 and the metal lower case 1 The front end of the synthetic case; the front co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com