Backlight product interference grain processing process

A processing technology and interference fringe technology, applied in optics, nonlinear optics, diffusing elements, etc., can solve problems such as inability to meet development needs and small profit margins, improve market competitiveness and practical value, save costs, The effect of saving thickness space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

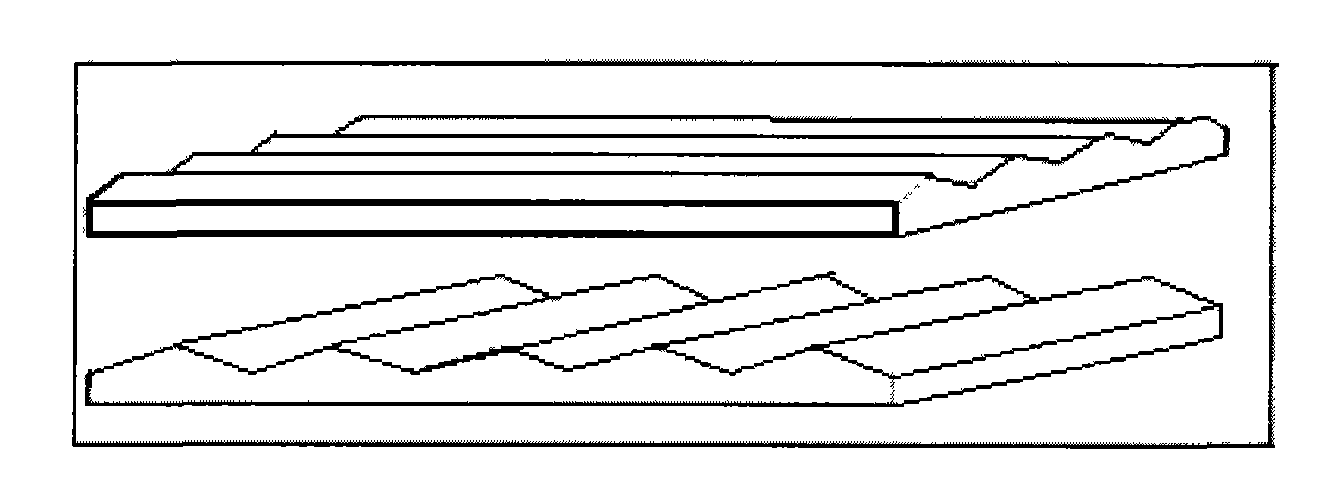

Embodiment 1

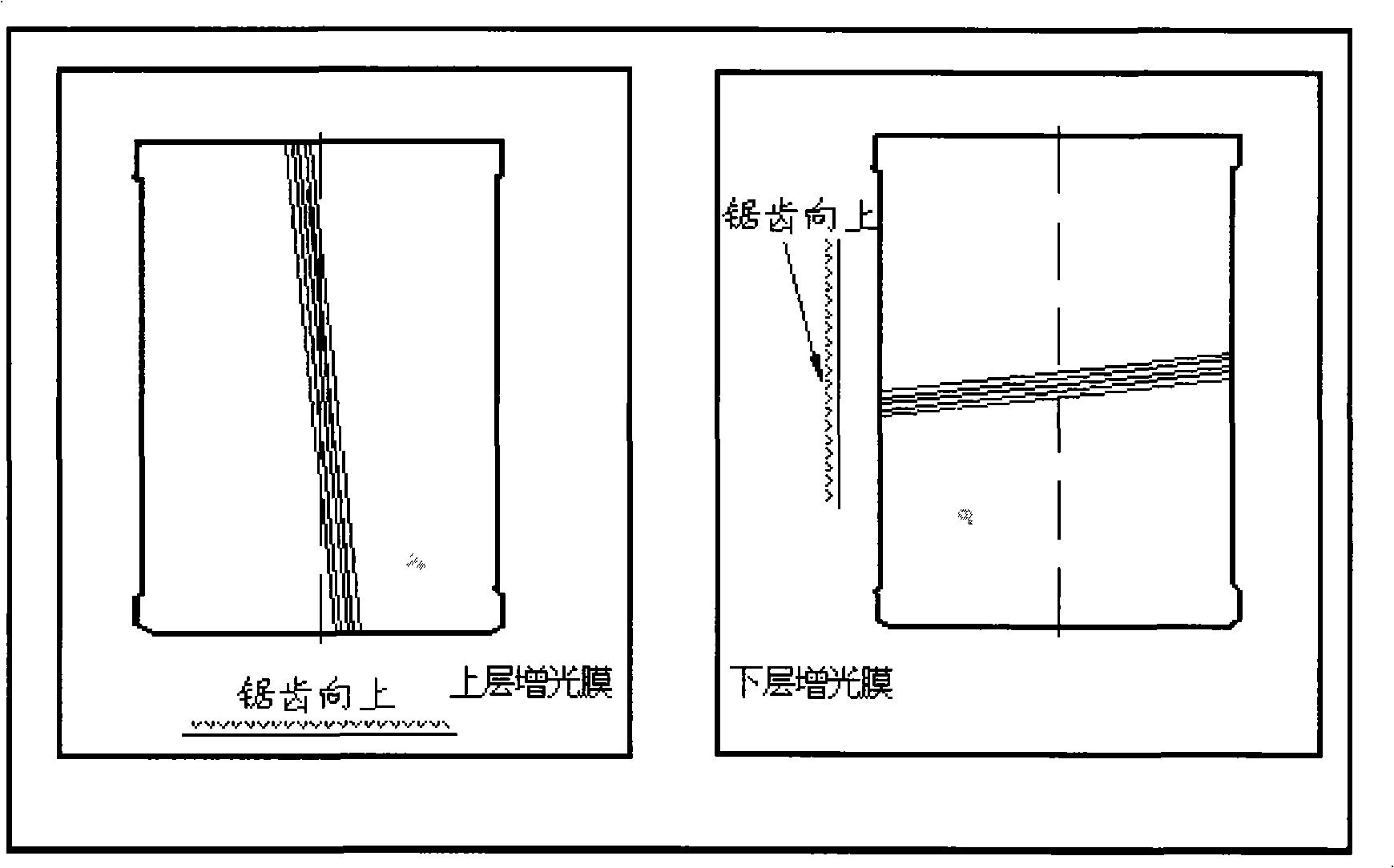

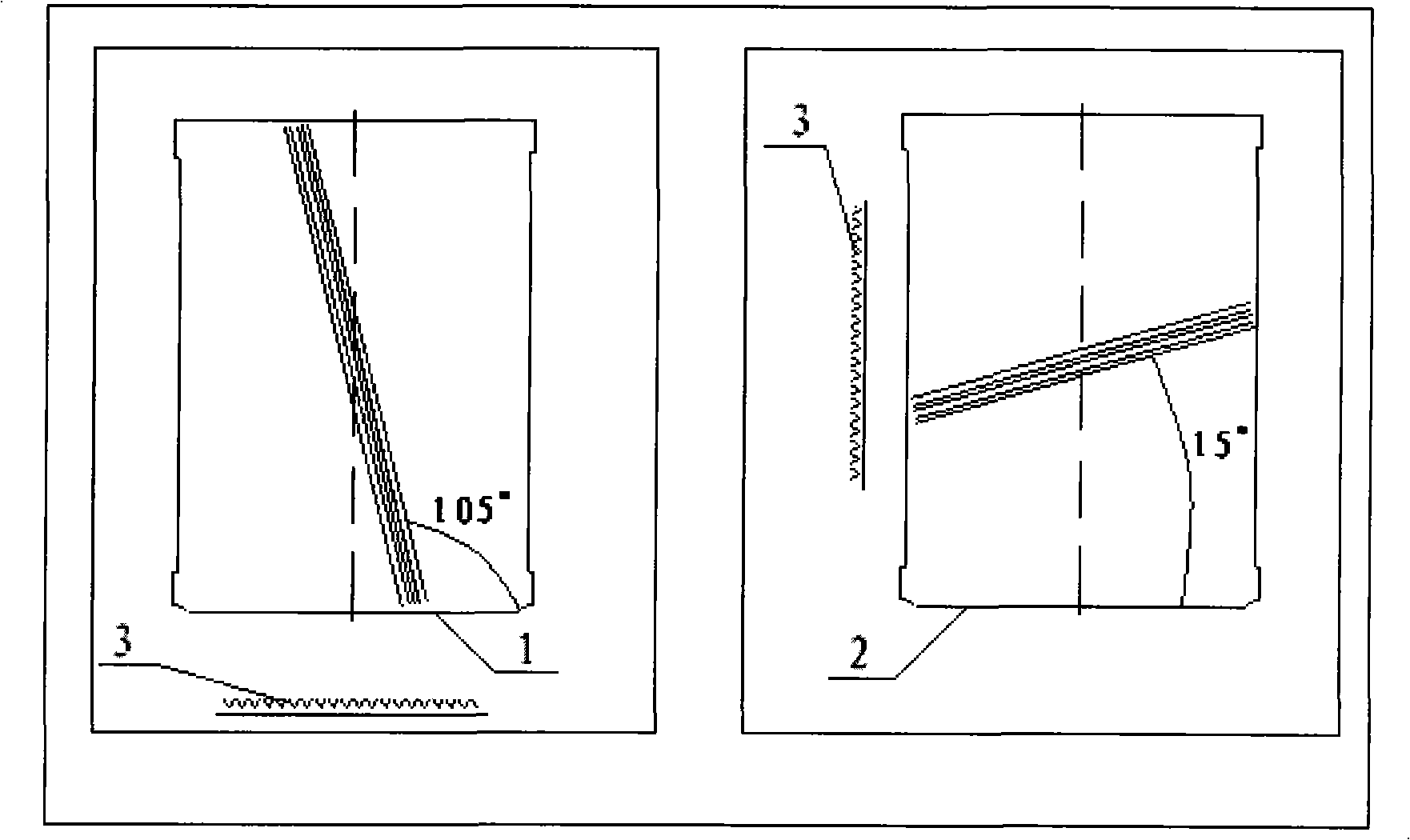

[0020] As shown in Figure 3, the interference fringe treatment process of backlight products, according to the angle of the LCD combined with the backlight, the brightness enhancement film is changed from the conventional 6-degree angle to 15 degrees. The brightness enhancement film is a two-layer assembly structure. The film 1 and the lower layer of the brightness enhancement film 2 are composed of the thickness of the two layers of the brightness enhancement film are 0.065 mm, and the angle at which the upper layer of the brightness enhancement film 1 and the lower layer of the brightness enhancement film 2 intersect after assembly is exactly 90 degrees, and the serrated surface 3 of the brightness enhancement film is along the The direction of the light is upward, so that it matches the angle of the LCD polarizer to eliminate the interference fringe generated after passing through the LCD. Finally, the LCD is combined to detect the elimination of the interference fringe to ve...

Embodiment 2

[0022] As shown in Figure 4, according to the LCD angle combined with the backlight, the brightness enhancement film is set from the conventional 94 degrees to 30 degrees. The thickness of each layer of enhancement film is 0.065 mm. After assembly, the upper layer of enhancement film 1 and the lower layer of enhancement film 2 form a cross angle of 90 degrees. Matching, eliminate the interference fringe generated after passing through the LCD, and then combine the LCD to detect the elimination of the interference fringe and verify the effectiveness.

Embodiment 3

[0024] As shown in Figure 5, the angle of the brightness enhancement film is set to 45 degrees. The brightness enhancement film consists of an upper layer of brightness enhancement film 1 and a lower layer of brightness enhancement film 2 to form a two-layer assembly structure. The thickness of the two layers of brightness enhancement films are both 0.065 mm. The intersecting angle of the light-enhancing film on the first layer is just 90 degrees, and the sawtooth surface 3 is upward along the light emitting direction to match the angle of the LCD polarizer. Finally, the elimination of interference fringes is detected by combining the LCD.

[0025] The product processed according to the interference pattern treatment process of the backlight product of the present invention can eliminate the interference pattern generated after passing through the LCD under the premise that the brightness, uniformity and thickness are not affected, so that the display effect of the liquid crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com