Exhaust pipe applying rotary arc-shaped heat exchange tube

A technology of heat exchange tubes and exhaust pipes, which is applied in exhaust devices, noise reduction devices, engine components, etc., can solve problems such as poor heat dissipation effect and limited heat dissipation efficiency, and achieve high design life and service life, low cost, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

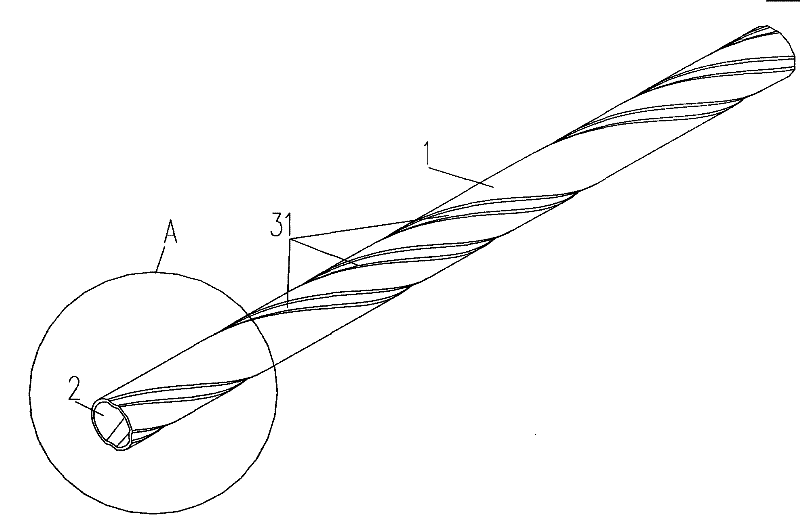

[0027] Such as figure 1 , figure 2 As shown, in the exhaust pipe using the arc-shaped heat exchange tube in this embodiment, the tube body is a arc-shaped heat exchange tube 1 .

[0028] The arc-shaped heat exchange tube 1 in the present invention is a metal welded pipe with a certain length, such as austenitic stainless steel welded pipe, carbon steel welded pipe, titanium and titanium alloy welded pipe, nickel and nickel alloy welded pipe, or austenitic-iron welded pipe. Element body duplex steel welded pipe, etc.

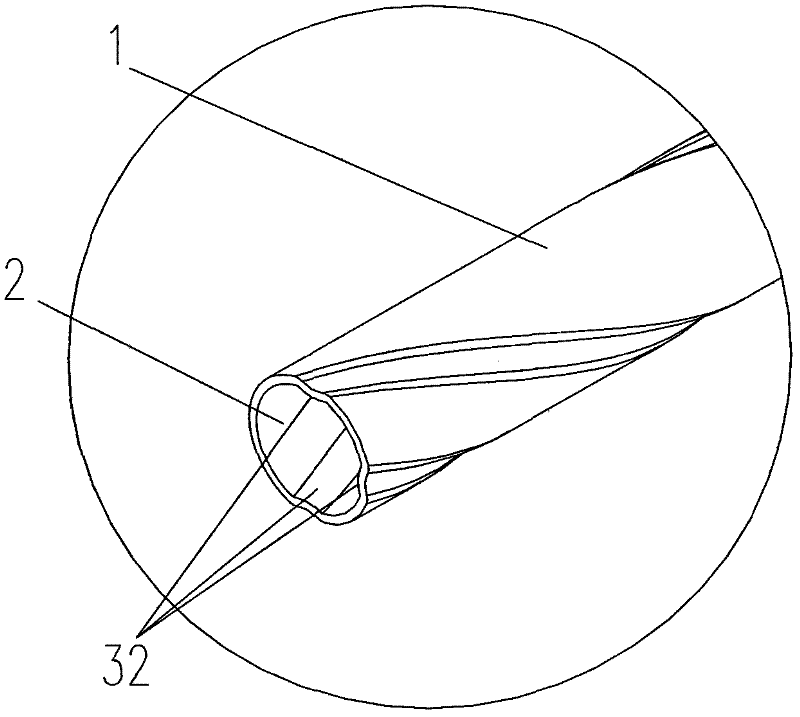

[0029] The pipe body is a special-shaped pipe section, which encloses and forms a gas channel 2 . A plurality of arc-shaped grooves 31 are formed on the pipe wall of the special-shaped pipe section. The plurality of grooves 31 are parallel to each other and form a rotation angle with the axis of the pipe body.

[0030] The rotation angle between the groove 31 and the axis of the tube body has a significant influence on the heat dissipation performance of the...

Embodiment 2

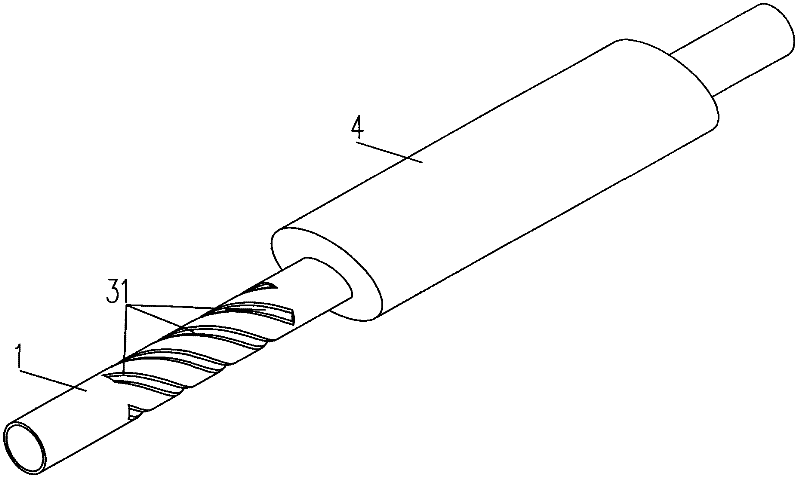

[0038] Such as image 3 As shown, the structure of the exhaust pipe using the arc-shaped heat exchange tube in this embodiment is basically the same as the structure of the above-mentioned embodiment, the difference is that the exhaust pipe using the arc-shaped heat exchange tube also includes a muffler 4.

[0039] Such as image 3 As shown, the tube body of the arc-shaped heat exchange tube 1 encloses a gas passage, and the tube body is an integral structure of a special-shaped tube section and a first straight tube section and a second straight tube section.

[0040] The grooves 31 form corresponding raised lines on the inner wall of the tube body.

[0041] In other embodiments, the arc-shaped heat exchange tube can also be made into an elliptical or flat shape to save thickness space.

[0042] In other embodiments, the arc-shaped heat exchange tubes can also be made into S-shape or U-shape as required.

Embodiment 3

[0044] Such as Figure 4 As shown, the structure of the exhaust pipe using arc-shaped heat exchange tubes in this embodiment is basically the same as that in Example 2, the difference is that the shell of the muffler 4 also uses arc-shaped heat exchange tubes .

[0045] Since more components use arc-shaped heat exchange tubes, the exhaust pipe as a whole has a better heat dissipation effect.

[0046] In this embodiment, components such as an air cleaner can also be added to the exhaust pipe as in the prior art.

[0047] Compared with exhaust pipes of other structures with the same diameter in the prior art, the arc-shaped heat exchange tube used in the present invention has the same cross-sectional area, but the internal disturbance effect of the arc-shaped heat exchange tube is obvious, and its heat dissipation efficiency is greatly improved. improve.

[0048] The arc-shaped heat exchange tube used in the present invention is not easy to scale due to the turbulence effect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com