Intelligent label connector

A technology of smart labels and connectors, applied in the direction of connection, parts of connection devices, contact parts, etc., can solve problems such as unfavorable market competitiveness, complex assembly process, inconvenient maintenance, etc., to ensure stability and communication quality, Guaranteed communication quality and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

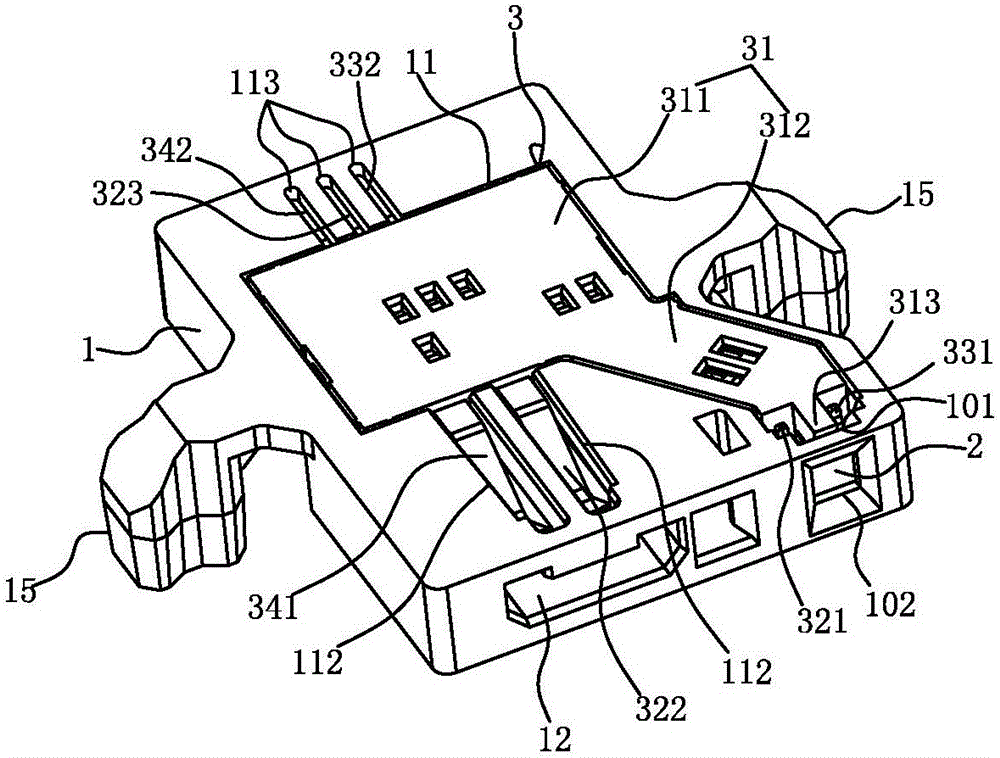

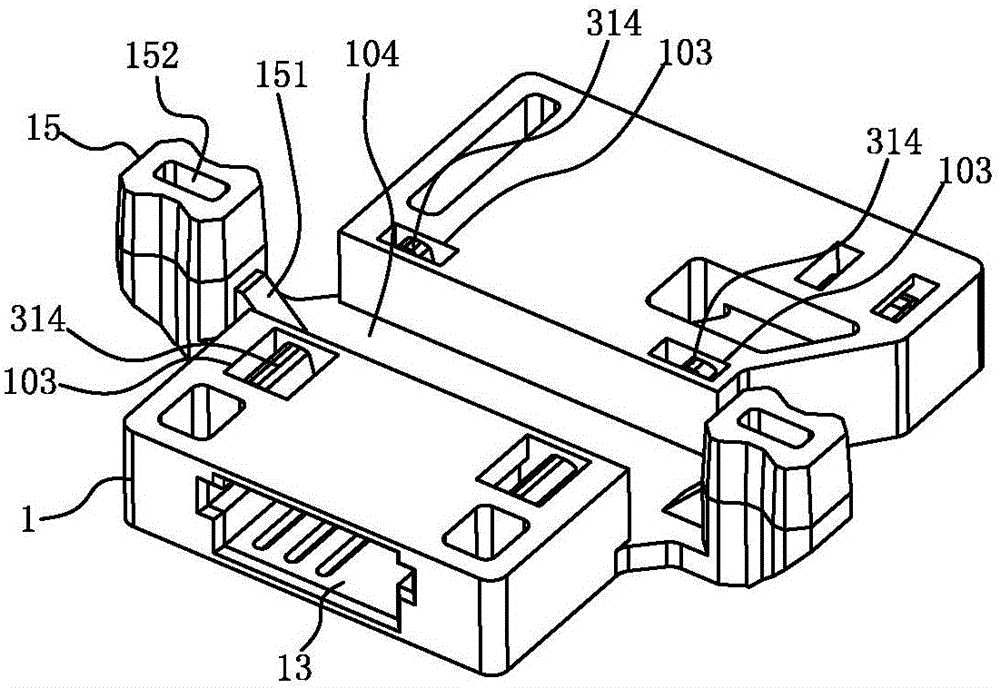

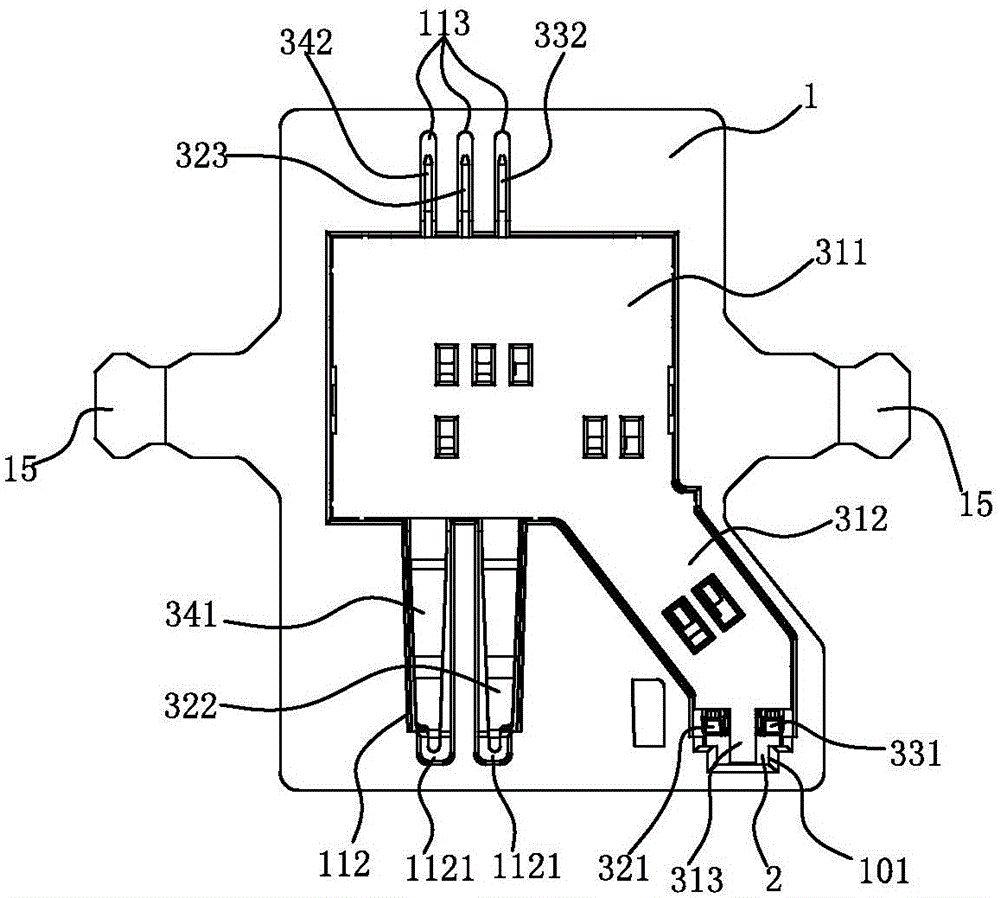

[0063] See Figure 1-3 Shown is a smart label connector, which includes: a flat plastic seat 1 , at least one LED chip 2 installed in the plastic seat 1 and a terminal assembly 3 installed in the plastic seat 1 .

[0064] The plastic seat 1 is provided with an accommodating groove 11 for the assembly of the terminal assembly 3 and first and second insertion ports 12 and 13 communicating with the accommodating groove 11. The connection ports 12 and 13 are respectively used for docking with electronic tags and control lines.

[0065] The LED chip 2 is inserted and installed in the plastic seat 1 along its side; specifically, the plastic seat 1 is provided downward along its upper end to communicate with the accommodating groove 11 and fit the shape of the LED chip 2. The insertion position 101, and the plastic seat 1 is provided with a window 102 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com