A freeze-dried shellfish processing device and method

A processing device and vacuum freeze-drying technology, applied in the field of shellfish processing devices and freeze-dried shellfish processing devices, can solve problems such as heating and affecting the quality of dried scallops, improve drying efficiency, reduce stacking thickness, and ensure drying effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

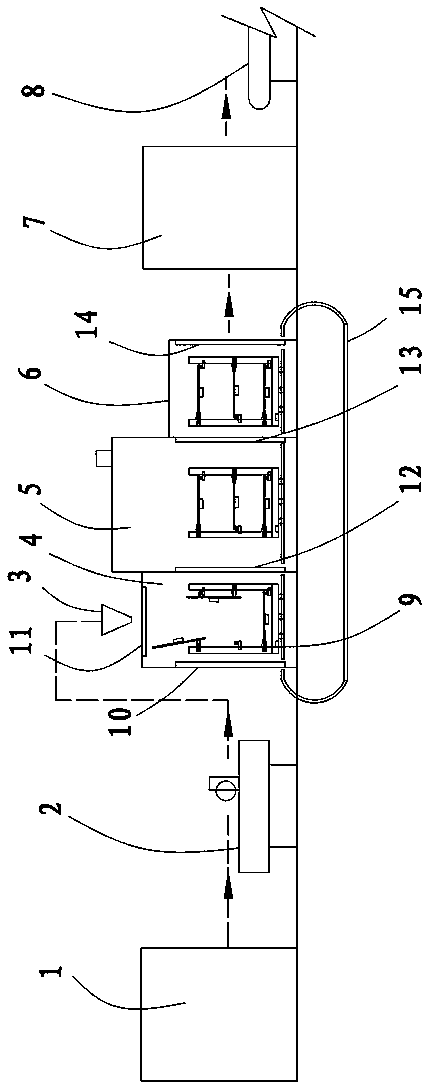

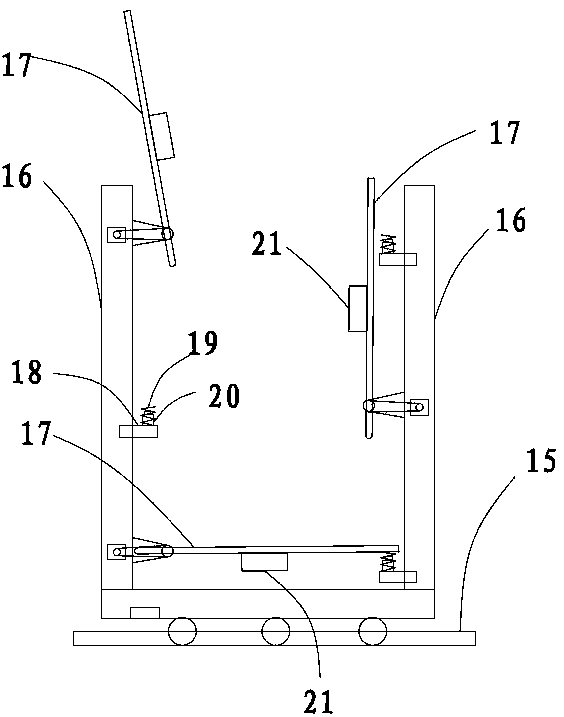

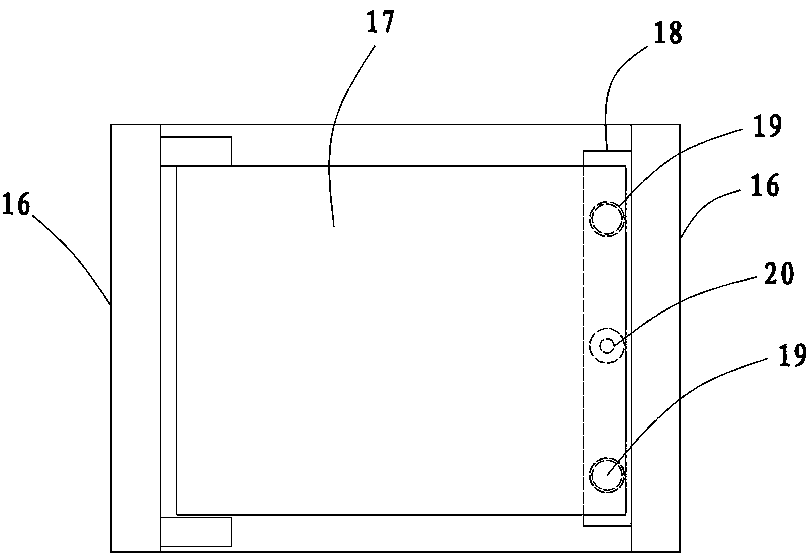

[0021] Embodiment: a kind of freeze-dried shellfish processing device, such as figure 1 shown. After the shellfish of the device is separated from the meat shell, the cleaned shellfish passes through the freezing chamber 1, the slicer 2, the vacuum freeze-drying chamber 5, the return chamber 7, and the packaging machine 8 in sequence.

[0022] Freeze-drying shellfish processing method, after the shellfish is rested and spit out sand, the shell is separated, the shellfish is separated and cleaned, put into the freezer, and frozen at -4 ~ 0°C, and the frozen shellfish is sliced. After the shellfish is sliced, put them into the stock rack in layers, and then send them to the vacuum freeze-drying room for freeze-drying in a vacuum environment of -45~-35°C. for packaging. After the shellfish are washed and separated from the meat shell, they are sent to the freezer and frozen in the freezer at a temperature of -4 to 0°C. In this state, the shellfish is slightly covered with ice s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com