High-stiffness puncture-resistant low-friction coefficient composite film and preparation method thereof

A technology with a low coefficient of friction and high stiffness, applied in chemical instruments and methods, synthetic resin layered products, flexible coverings, etc., can solve the problem of poor smoothness of packaging bags, inability to carry out radiation treatment, and limit product applications field and other issues, to achieve the effect of excellent protection effect, humanized and rationalized design, and strong adaptability of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] 1. Preparation of high stiffness and puncture resistant PE film

[0059] Add the composite layer resin, middle layer resin and heat-sealing layer resin into the three barrels of the extruder respectively, and form a melt through the action of the heating device and the extruder screw, and extrude through the die opening of the ring die to form a tubular shape After the tube leaves the die, it is blown into a bubble film under the action of blowing compressed air from the center hole of the die head; the bubble film is pulled up by the traction mechanism, cooled by the air ring Blister clamping and flattening; the double-layer film is formed by clamping with traction rollers, and then the outer surface is coronad by a corona device, trimmed and divided into pieces, and wound into rolls to obtain a high-stiffness and puncture-resistant PE film. The production speed is 20m / min, and the melt pressure of the extruder is less than 45MPa.

[0060] 2. Printing of KPET film

...

Embodiment 1~5

[0079] ① Preparation of high stiffness and puncture resistant PE film

[0080] Add the composite layer resin, middle layer resin and heat-sealing layer resin into the three barrels of the extruder respectively, and the formulations of each layer of resin in each embodiment are shown in Table 3. After the heating device and the extruder screw, it forms a melt, and extrudes through the die opening of the ring die to form a tube; Blow up into a bubble-like film; the bubble-like film is pulled up by the traction mechanism, cooled by the wind ring, and flattened by the herringbone plate; the double-layer film is formed by being clamped by the traction roller, and then the outer surface is corona by the corona device , trimmed into pieces, and wound into rolls to obtain high stiffness and puncture-resistant PE film. The production speed is 20m / min, and the melt pressure of the extruder is less than 45MPa.

[0081] table 3

[0082]

[0083]The thickness of each layer in the hig...

Embodiment 6~12

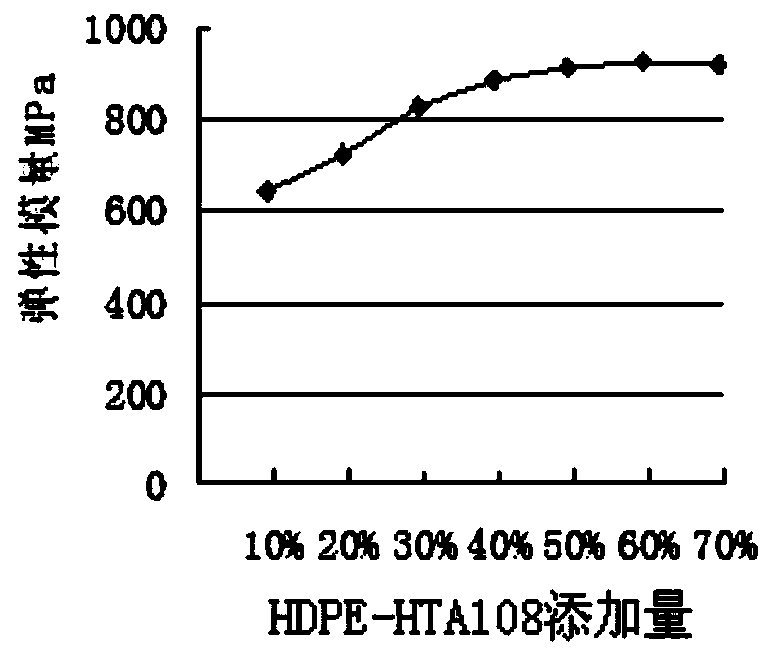

[0102] The preparation of the composite film is the same as in Example 1, except that the amount of HDPE-HTA108 added in the middle layer accounts for 10%, 20%, 30%, 40%, 50%, 60% and 70% of the total weight of the middle layer material. And detect the elastic modulus of 7 kinds of composite membranes prepared respectively, please refer to figure 1 . It can be seen from the figure that when the addition amount of HDPE-HTA108 is between 10% and 50%, the elastic modulus of the film increases significantly. When the addition amount reaches about 60-70%, the elastic modulus does not change significantly. However, when the added amount increases to more than 70%, the film will be prone to embrittlement, which will easily cause problems such as decreased puncture resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com